Method for preparing wood/MOF functional composite material

A technology of functional composite materials and wood, which is applied in the field of preparation of wood/MOF functional composite materials, can solve the problems of difficult processing, difficult recycling of single MOF materials, poor operability, etc., and achieve excellent economic benefits, important economic and environmental benefits, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

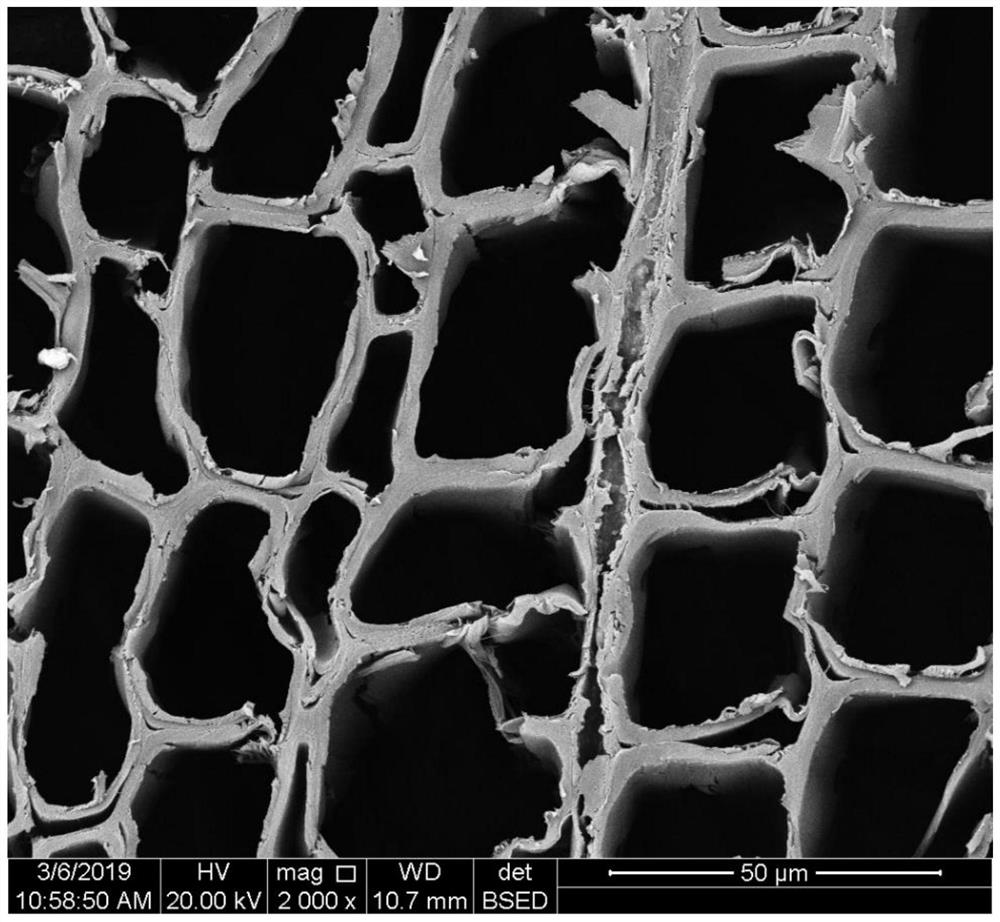

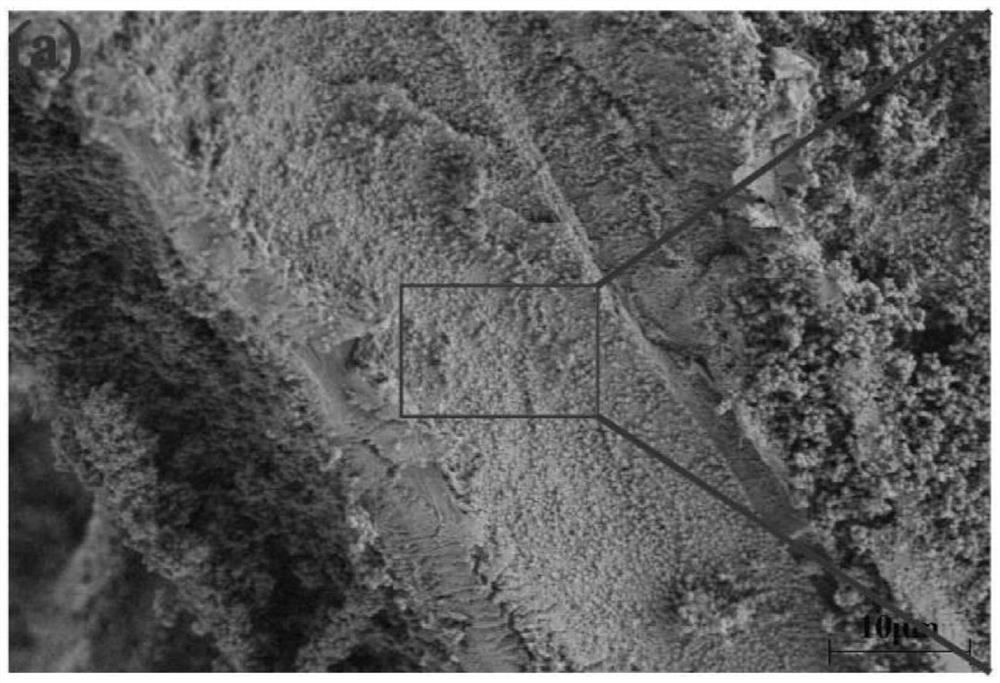

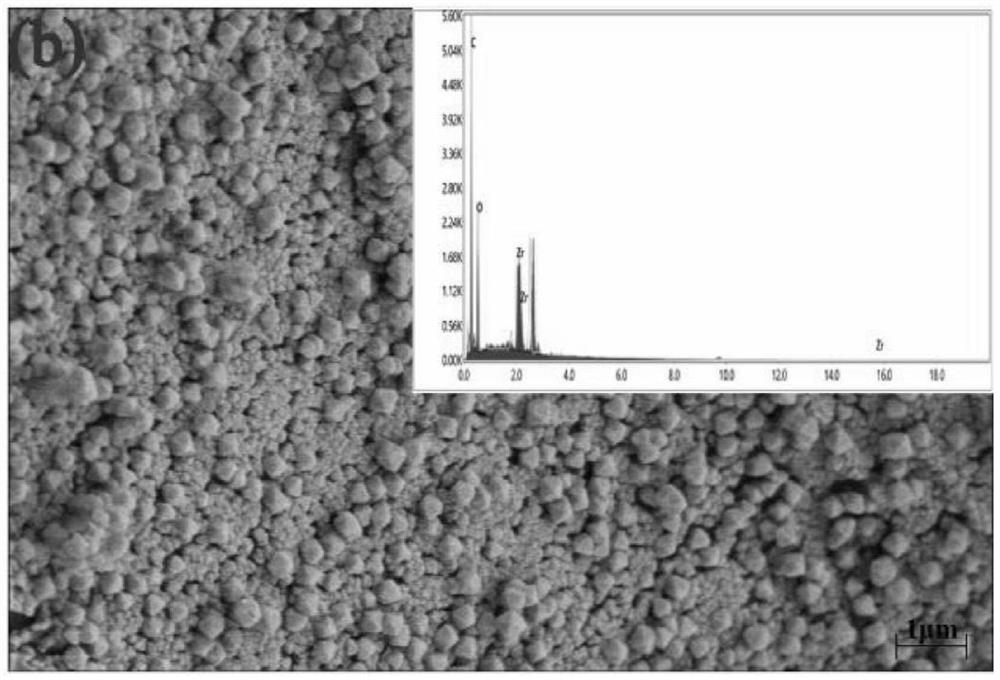

[0027] Example 2: Put balsa wood in a drying oven at 90°C for 24 hours and then cool to room temperature. Add 0.2491g of terephthalic acid and 0.3495g of zirconium chloride to 30mL of N,N-dimethylformamide, and then add 2.68 mL of glacial acetic acid, stirred for 10 minutes to obtain the precursor solution of MOF material, transferred the dried wood and precursor solution into a polytetrafluoroethylene hydrothermal reaction kettle, kept it in an oven at 120°C for 24 hours, and used methanol and N,N - The dimethylformamide solution was washed repeatedly, and then dried in a vacuum oven at 80° C. to obtain a balsa wood / MOF functional composite material.

Embodiment 3

[0028] Example 3: Put poplar wood in a drying oven for 105°C heat treatment for 12 hours, then cool to room temperature, add 0.2491g of terephthalic acid and 0.466g of zirconium chloride to 30mL of N,N-dimethylformamide, then add 2.68mL of ice Acetic acid, stirred for 10 minutes to obtain the precursor solution of MOF material, transferred the dried wood and precursor solution into a polytetrafluoroethylene hydrothermal reaction kettle, kept it in an oven at 120°C for 36 hours, and used methanol and N,N-di The methylformamide solution was washed repeatedly, and then dried in a vacuum oven at 100°C to obtain a poplar / MOF functional composite.

Embodiment 4

[0029] Example 4: Put the pine wood in a drying oven at 85°C for 24 hours and then cool it to room temperature. Add 0.2491g terephthalic acid and 0.5826g zirconium chloride to 30mL N,N-dimethylformamide, then add 2.68mL Glacial acetic acid, stirred for 10 minutes to obtain the precursor solution of MOF material, transferred the dried wood and precursor solution into a polytetrafluoroethylene hydrothermal reaction kettle, kept it in an oven at 120°C for 48 hours, and used methanol and N,N- The dimethylformamide solution was washed repeatedly, and then dried in a vacuum oven at 103°C to obtain a pine wood / MOF functional composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com