One-step copper smelting process and its device

A copper smelting and crafting technology, applied in the field of non-ferrous metallurgy, to achieve the effect of high oxygen utilization rate, good heat and mass transfer conditions, and less heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

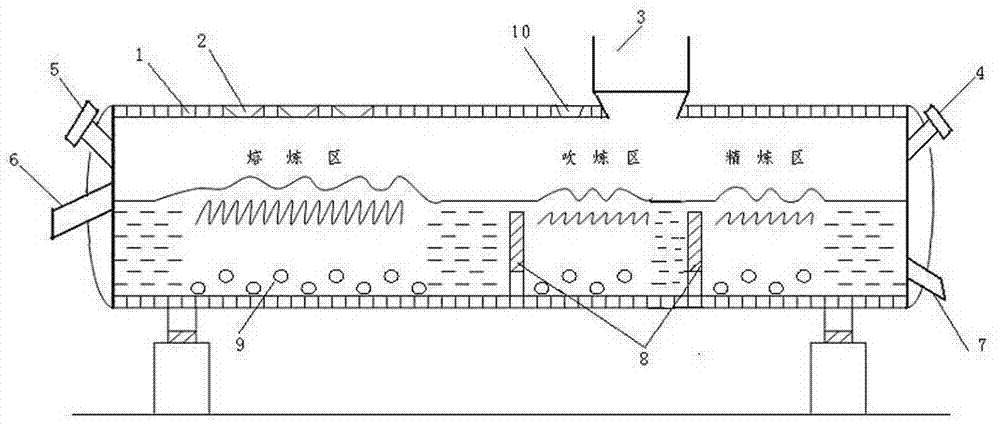

[0026] Attached below figure 1 Embodiments of the device structure of the present invention will be described in detail.

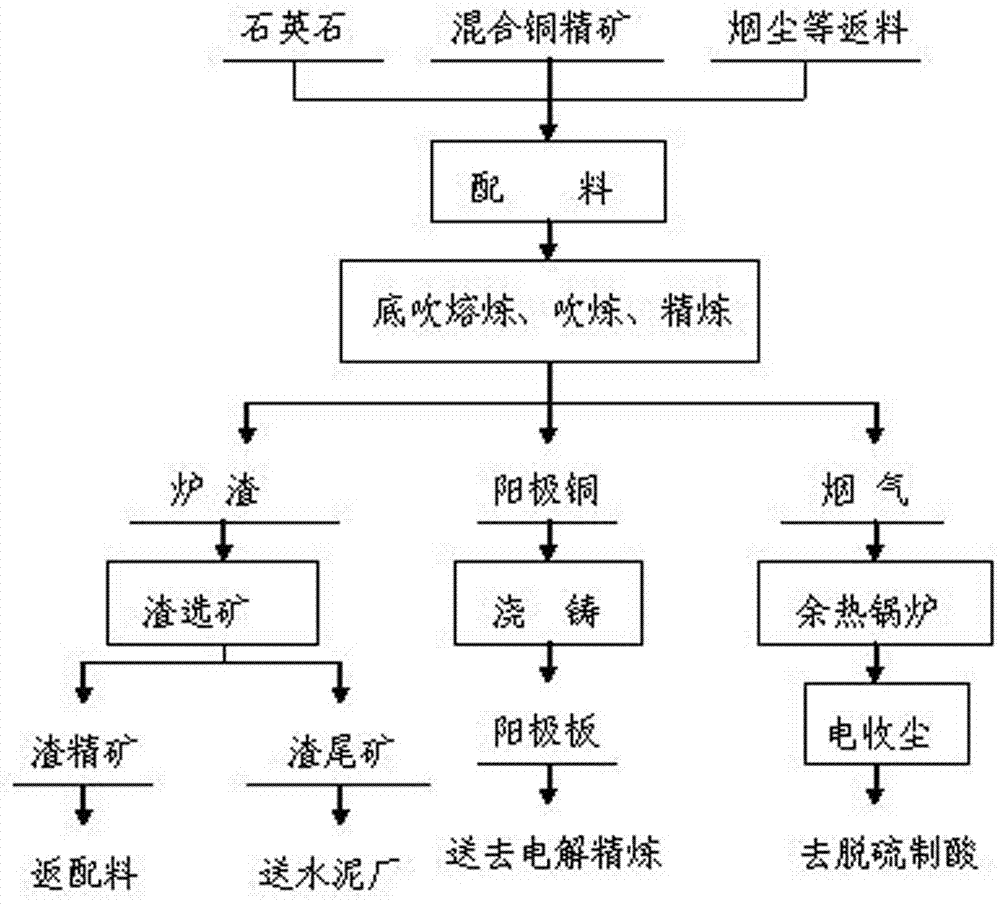

[0027] A one-step copper smelting device and its process, the device includes a furnace body 1, a feed port 2, a flue port 3, burners 4 and 5, a slag discharge port 6, a copper discharge port 7, a spray gun 9, a flux port 10, the furnace body 1 It consists of three parts: smelting area, blowing area and refining area, which are separated by retaining wall 8; Two supporting rollers are supported on the foundation, one end of which is equipped with a motor and gear transmission, and the furnace body 1 can be set to rotate along the axis; two rows of staggered arrangements are installed at the bottom of each area, separated by a certain distance, and facing each other at a certain angle. Spray guns 9 that spray oxygen-enriched air or natural gas crosswise into the furnace; feed port 2 is set above the smelting zone, flue port 3 and flux port 10 are set above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com