Track laying machine and track laying method

A technology of track laying machine and laying method, which is applied in the direction of track, track laying, track maintenance, etc., which can solve the problems of many safety hazards, high construction cost, non-detachable and other problems of track row running, so as to reduce the investment of personnel and turnover materials, Improved construction safety and stable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

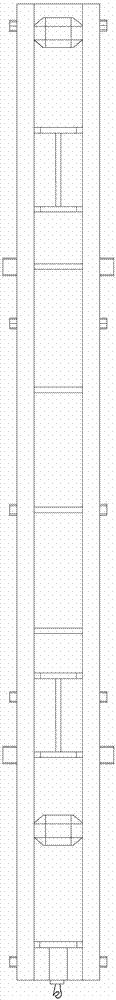

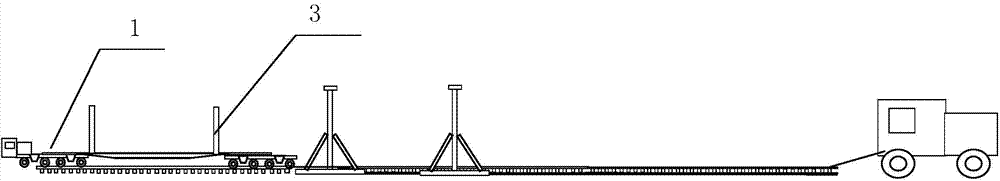

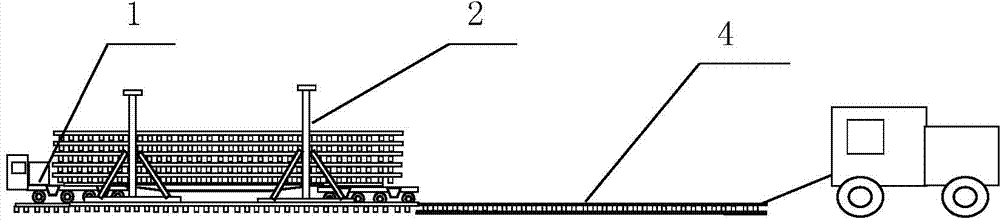

[0042] Such as Figure 1-12 As shown, the rail-laying machine includes an inverted gantry, a rail-laying gantry 2, a rail-laying transport vehicle, a tractor, a track-laying flatbed vehicle 1 with its own power, a rail-laying gantry bracket 3 and a group of movable steel Tool rail row 4.

[0043] The design length of the tool rail row 4 is 25m. Two 40cm wide channel steels are used for the base part. A 35cm high steel pier is welded at an interval of 1m above the channel steel, and a 50kg / m steel rail is welded above the steel pier. Holes are drilled at both ends of the rail for easy connection. Install transverse gauge rods on the steel piers and rails at intervals of 1m to maintain the gauge of the rail row. The movable tool rail row 4 can be split into two 12.5-meter rail rows during transportation.

[0044] The function of the self-powered track-laying flatbed truck 1 is to transfer the rail row by inverting the gantry, hoist and feed the 25-meter rail row to the track-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com