Production method of silicon-manganese-vanadium composite alloy

A composite alloy and production method technology, applied in the direction of improvement of process efficiency, furnace type, furnace, etc., can solve problems such as long and complex processes, and achieve the effects of low production cost, reduced cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

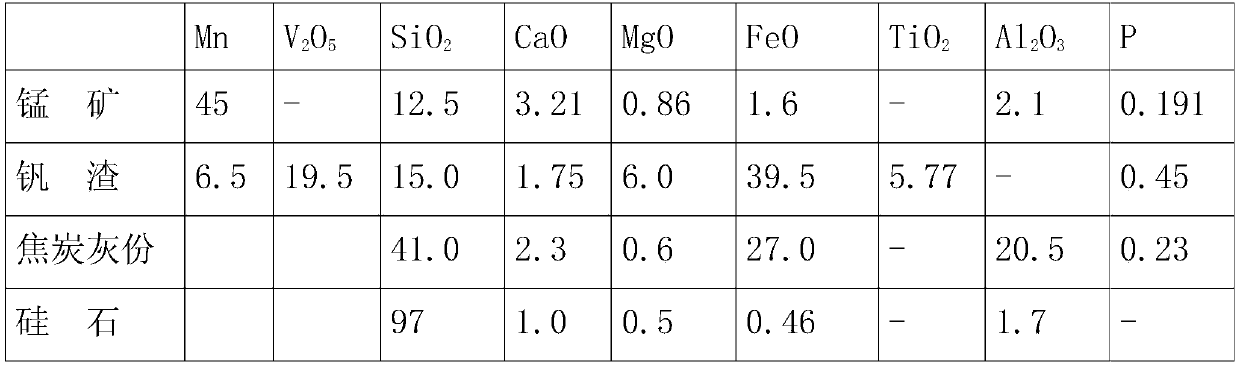

[0033] The percentage of the mixed charge is selected as shown in Table 1:

[0034] MnV 2 O 5

[0035] Table 1

[0036] First, add 2000kg of bottom coke to the empty furnace of 1800KVA electric furnace; according to the batch ratio of 400 parts of vanadium slag, 600 parts of manganese ore, 236 parts of coke with particle size of 10mm~25mm, 47 parts of silica and 90 parts of limestone, stir well and add to the furnace. Inside; adjust the secondary output voltage of the electric furnace transformer (with a power of 1800kVA) to the lowest level of 73V; after power-on, the primary current is slowly increased from 10A to 120A, and the furnace will be released after 6 hours; the slag and iron after the furnace are separated to obtain the slag and silicon-manganese-vanadium composite alloy .

[0037] The specific composition of the obtained composite alloy is shown in Table 2 below,

[0038] Product ingredients FeV TiPC SiMnCr total Silicomanganese vanadium25.54.54640.70.40172.5144...

Embodiment 2

[0046] The percentage of mixed charge is selected as shown in Table 4 below:

[0047]

[0048] Table 4

[0049] First, add 2000kg of bottom coke into the empty furnace of 1800KVA electric furnace; according to the batch ratio of 150 parts of vanadium slag, 500 parts of manganese ore, 170 parts of coke with a particle size of 10mm~25mm, 110 parts of silica and 90 parts of limestone, stir well and add. Into the furnace; adjust the secondary output voltage of the electric furnace transformer (with a power of 1800kVA) to the lowest level of 73V; after power-on, the primary current is slowly increased from 10A to 120A, and the furnace is released after 6 hours; the slag and iron after the furnace are separated to obtain slag and silicomanganese vanadium Composite alloy.

[0050] The specific content of the composite alloy is shown in Table 5 below,

[0051] Product ingredients FeV TiPC SiMnCr total Silicomanganese vanadium25.54.00.70.40172.51553.53.0100.67

[0052] table 5

[0053] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com