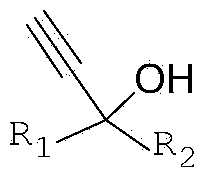

Method for preparing propargyl alcohol by using micro-structural reactor

A microstructure reactor, propargyl alcohol technology, applied in the direction of organic Grignard reaction, chemical instruments and methods, organic chemical methods, etc., can solve the problem of unreported propargyl alcohol, and achieve high selectivity and mild reaction conditions. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as figure 1 Shown: Ethylmagnesium bromide is injected into micromixer B1 (cross-toed micromixer, HPIMM, IMM, Germany, length×width×height=25×21×37μm) from high-pressure syringe pump A1 and metered into acetylene by F Gas reaction, the gas flow rate ratio of ethylmagnesium bromide to acetylene is 1:300, Grignard exchange reaction occurs in thermostat D1 (0°C), enters microchannel reactor C1 (inner diameter: 1mm) and continues to react for 10s, the product ethynyl Magnesium bromide is pumped into micro-mixer B2 (V2, IMM, Germany) by plunger pump A4 and mixed with tetrahydrofuran mixture (0.1mol / L) of benzaldehyde pumped by high-pressure syringe pump A2 in thermostat D2 (25°C) , the molar ratio of Grignard reagent to benzaldehyde is 1:1, and then enter the microchannel reactor C2 (inner diameter: 1mm) to continue the reaction for 20s, and the obtained product enters the micromixer B3 (T-type tee, inner diameter: 1mm) React with ammonium chloride solution pumped by sy...

Embodiment 2

[0028] Such as figure 1 Shown: Ethylmagnesium bromide is injected into micro-mixer B1 (Caterpillar, IMM, Germany, length×width=300×300μm) from high-pressure syringe pump A1 to react with acetylene gas metered by F, and the ratio of ethylmagnesium bromide to acetylene gas The flow rate ratio is 1:100, the Grignard exchange reaction occurs in the incubator D1 (0°C), and enters the microchannel reactor C1 (inner diameter: 0.5mm) to continue the reaction for 5s, and the product ethynylmagnesium bromide is pumped into the microchannel reactor by the plunger pump A4. Mixer B2 (cross-toed micro-mixer, HPIMM, IMM, Germany, length × width × height = 25 × 21 × 37 μm) and the tetrahydrofuran mixture (1mol / L) of benzaldehyde pumped by high-pressure syringe pump A2 were kept at constant temperature Mix in box D2 (25°C), the molar ratio of Grignard reagent to benzaldehyde is 1:1.2, and then enter the microchannel reactor C2 (inner diameter: 1mm) to continue the reaction for 6s, and the obta...

Embodiment 3

[0030]As shown in the figure: Ethylmagnesium bromide is injected into falling film microstructure reactor B1 (length×width: 300×100μm) from high-pressure injection pump A1 to react with acetylene gas metered by F, and the flow rate of ethylmagnesium bromide is higher than that of acetylene gas Ratio 1:50, Grignard exchange reaction occurs in thermostat D1 (0°C), enters microchannel reactor C1 (inner diameter: 3mm) and continues to react for 2 minutes, and the product ethynylmagnesium bromide is pumped into the micromixer by plunger pump A4 B2 (T-type tee, inner diameter: 1mm) is mixed with the tetrahydrofuran mixture (3mol / L) of benzaldehyde pumped by the high-pressure syringe pump A2 in the incubator D2 (25°C), and the moles of Grignard reagent and benzaldehyde The ratio is 1:0.8, and then enter the microchannel reactor C2 (inner diameter: 1mm) to continue the reaction for 2 minutes, and the obtained product enters the micro-mixer B3 (T-type tee, inner diameter: 6mm) and is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com