Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197results about How to "Improve stacking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

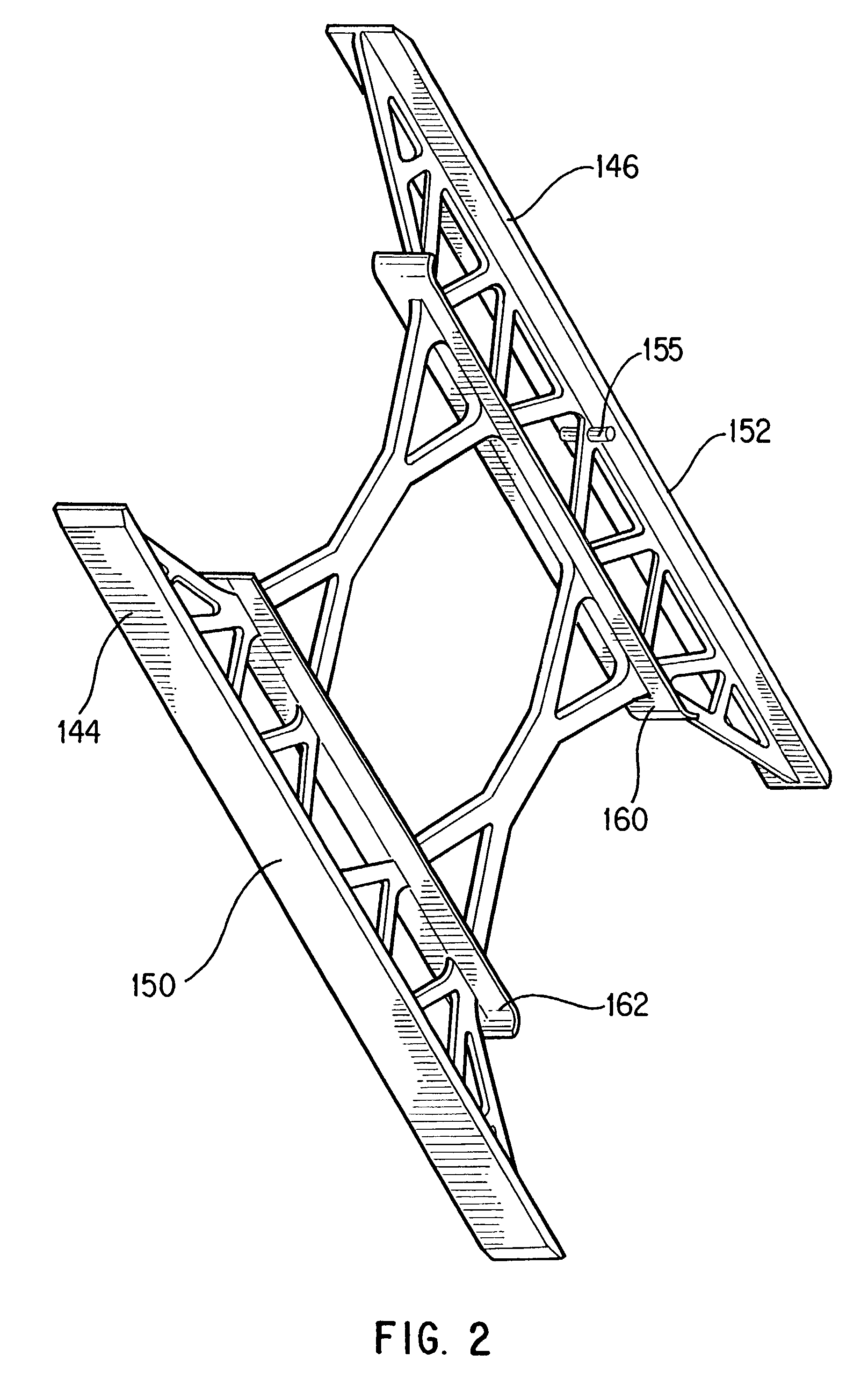

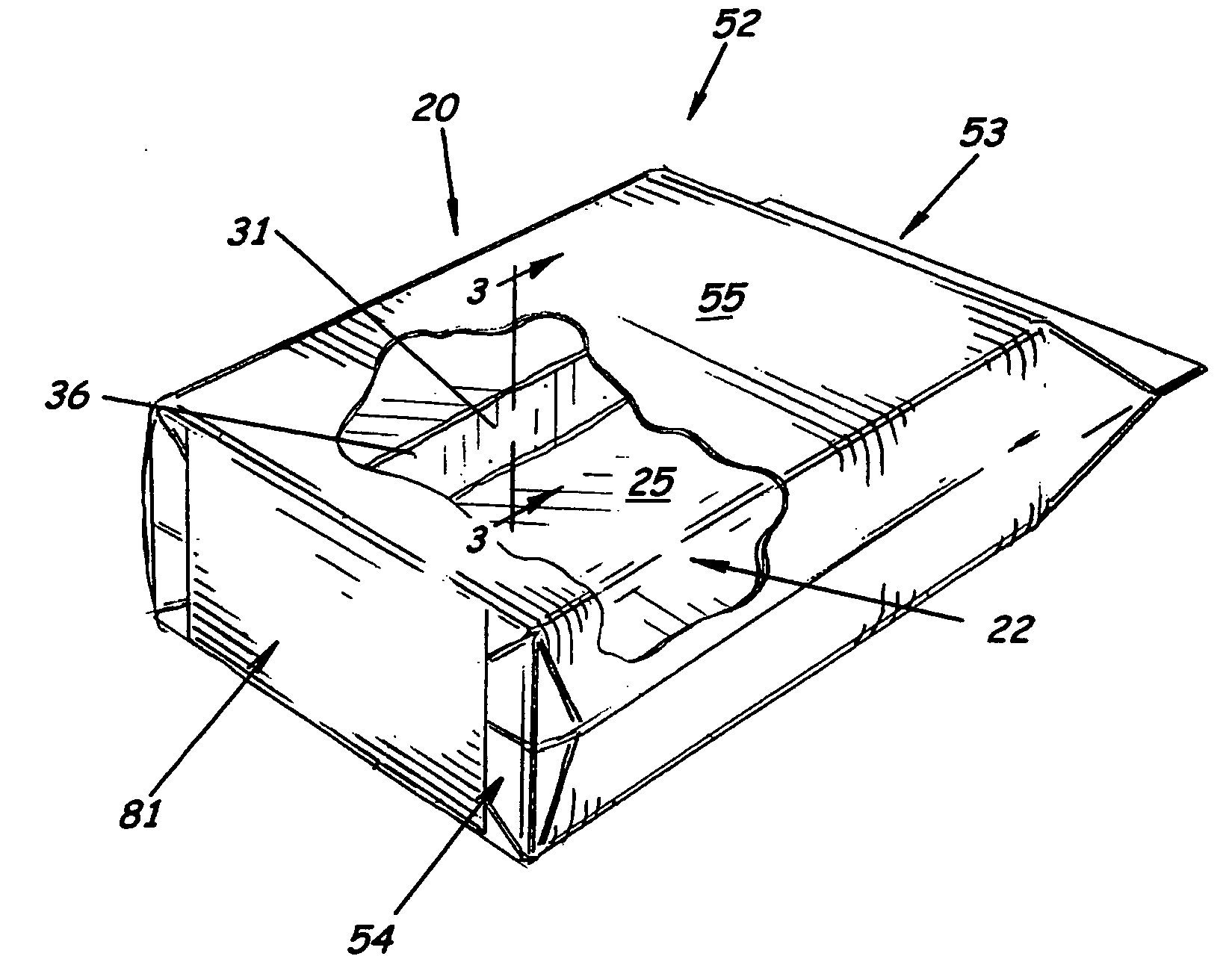

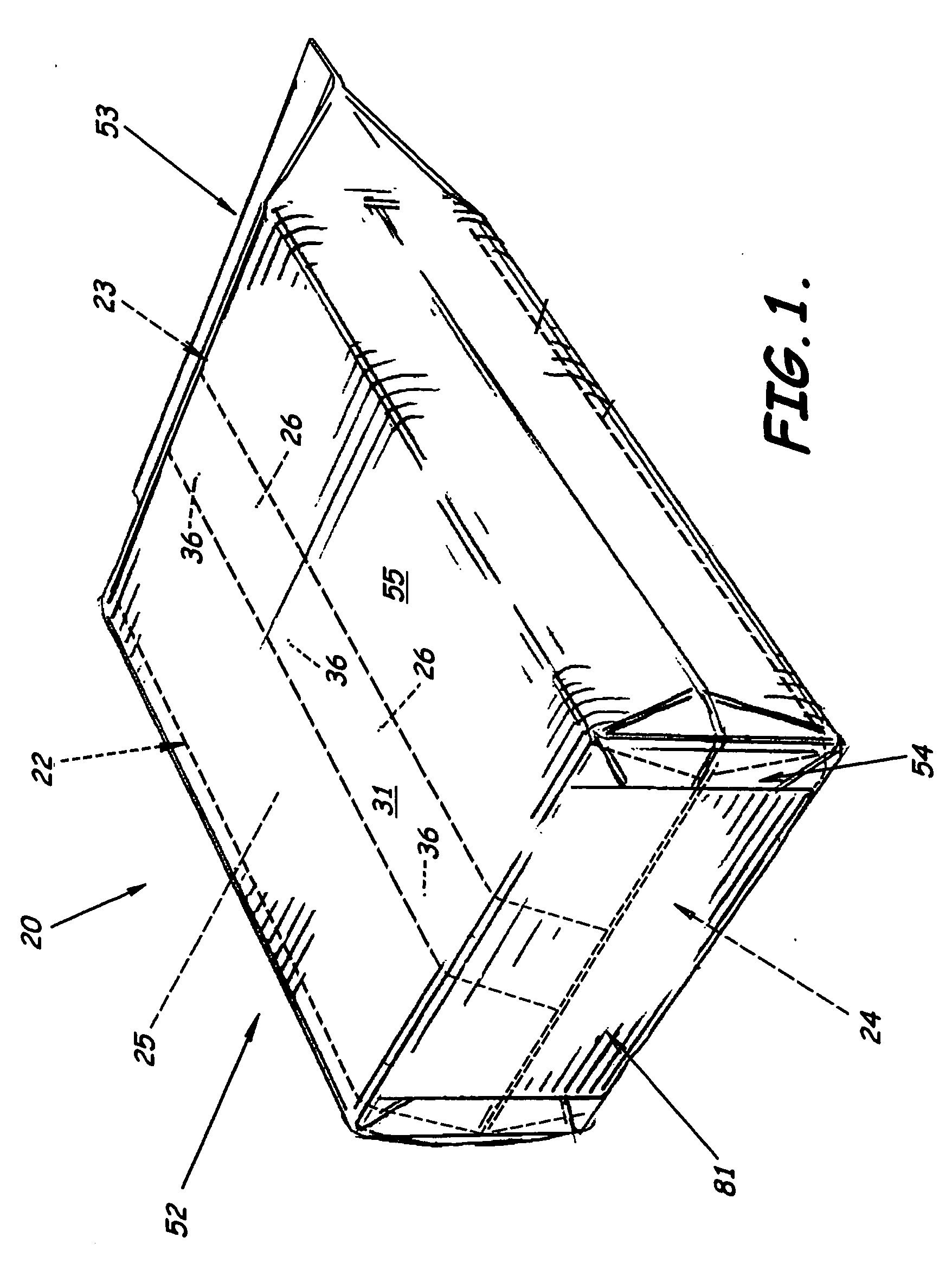

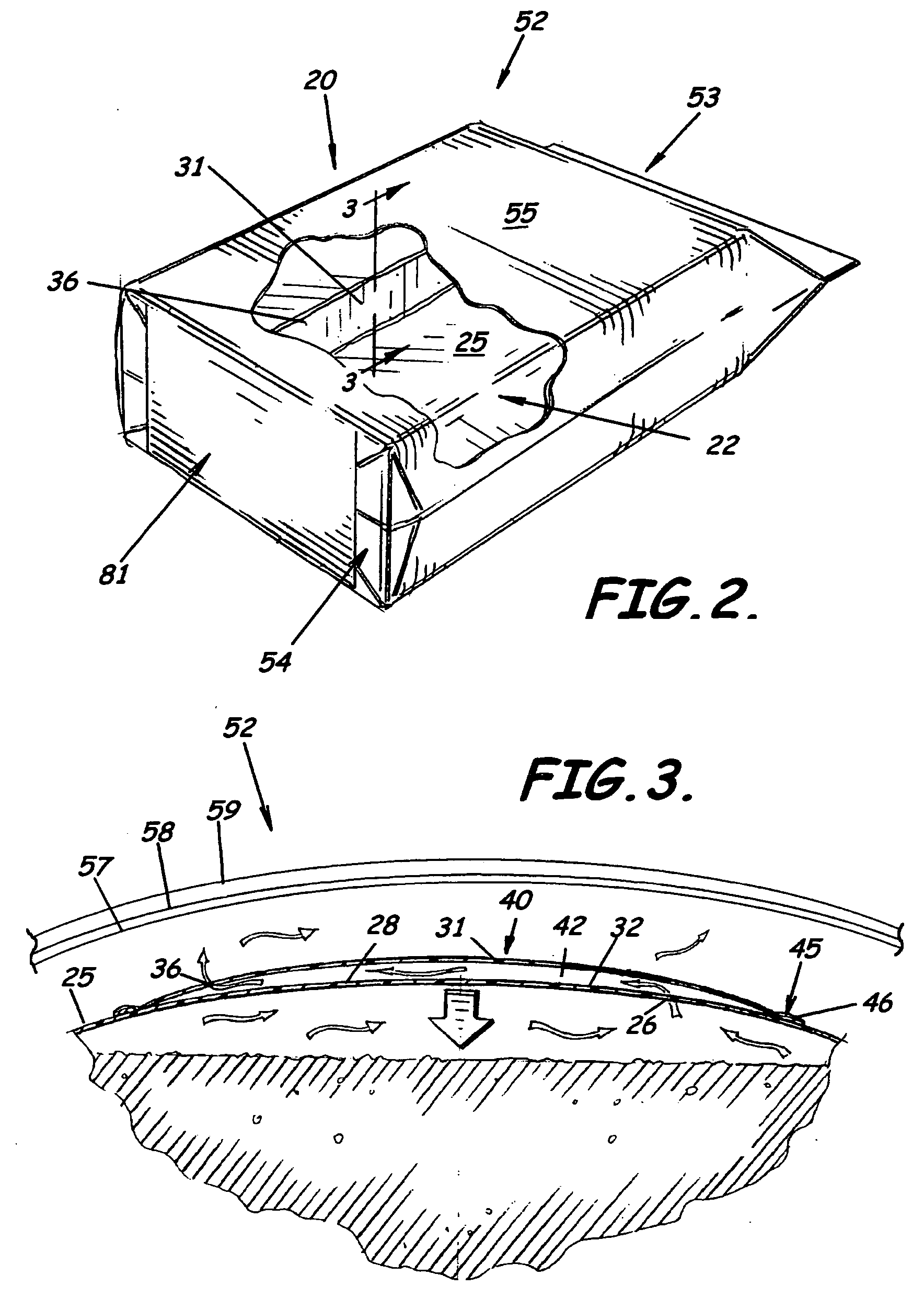

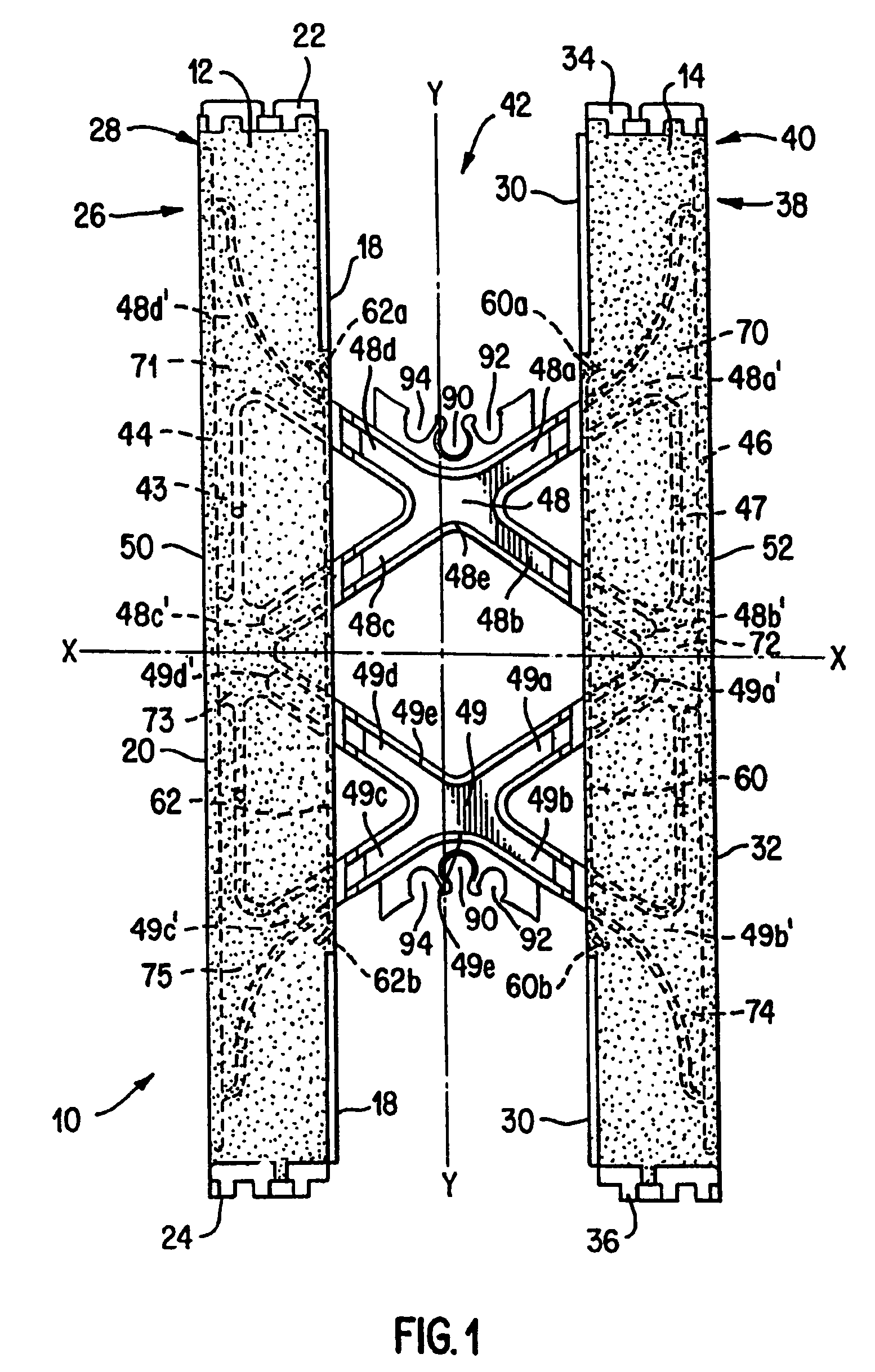

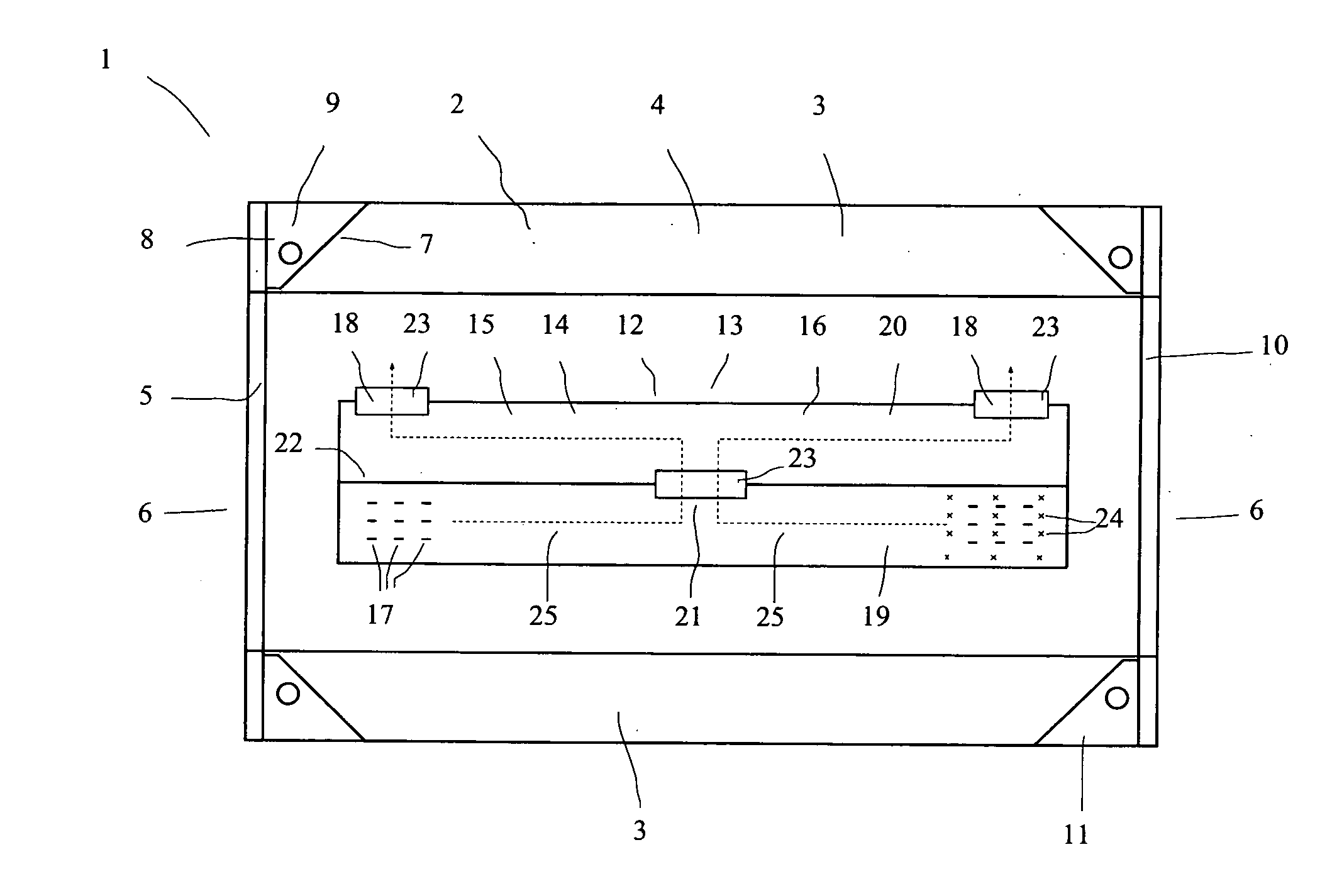

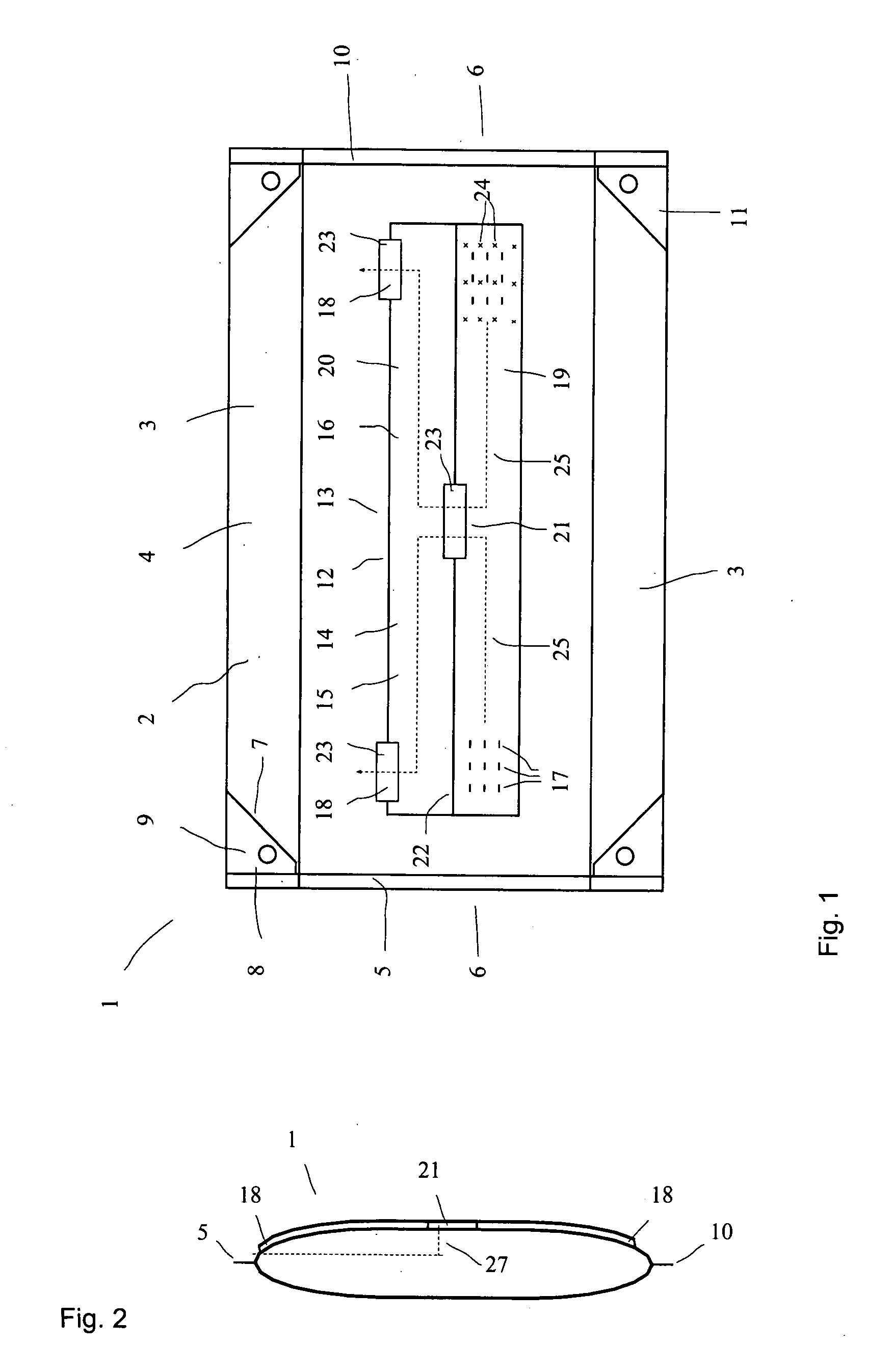

Bridging member for concrete form walls

A building component having first and second high density foam panels and improved bridging members for connecting the panels that extend between and may be molded into the panels. The bridging members include a pair of elongated end plates oriented in a top to bottom direction of the panels, a pair of substantially identical web members joining the end plates and being substantially symmetrically disposed above and below a central horizontal axis of the bridging member, and a pair of strip members oriented in the top to bottom direction of the panels intersecting the web members. The web members have a unique configuration that maximizes load bearing capacity with a minimum amount of material. The strip members may abut against and be substantially flush with respective inner surfaces of the foam panels to assist in positioning and forming the panels during molding. Seating areas for positioning horizontally and / or vertically disposed rebar in predetermined positions are also provided.

Owner:AIRLITE PLASTICS

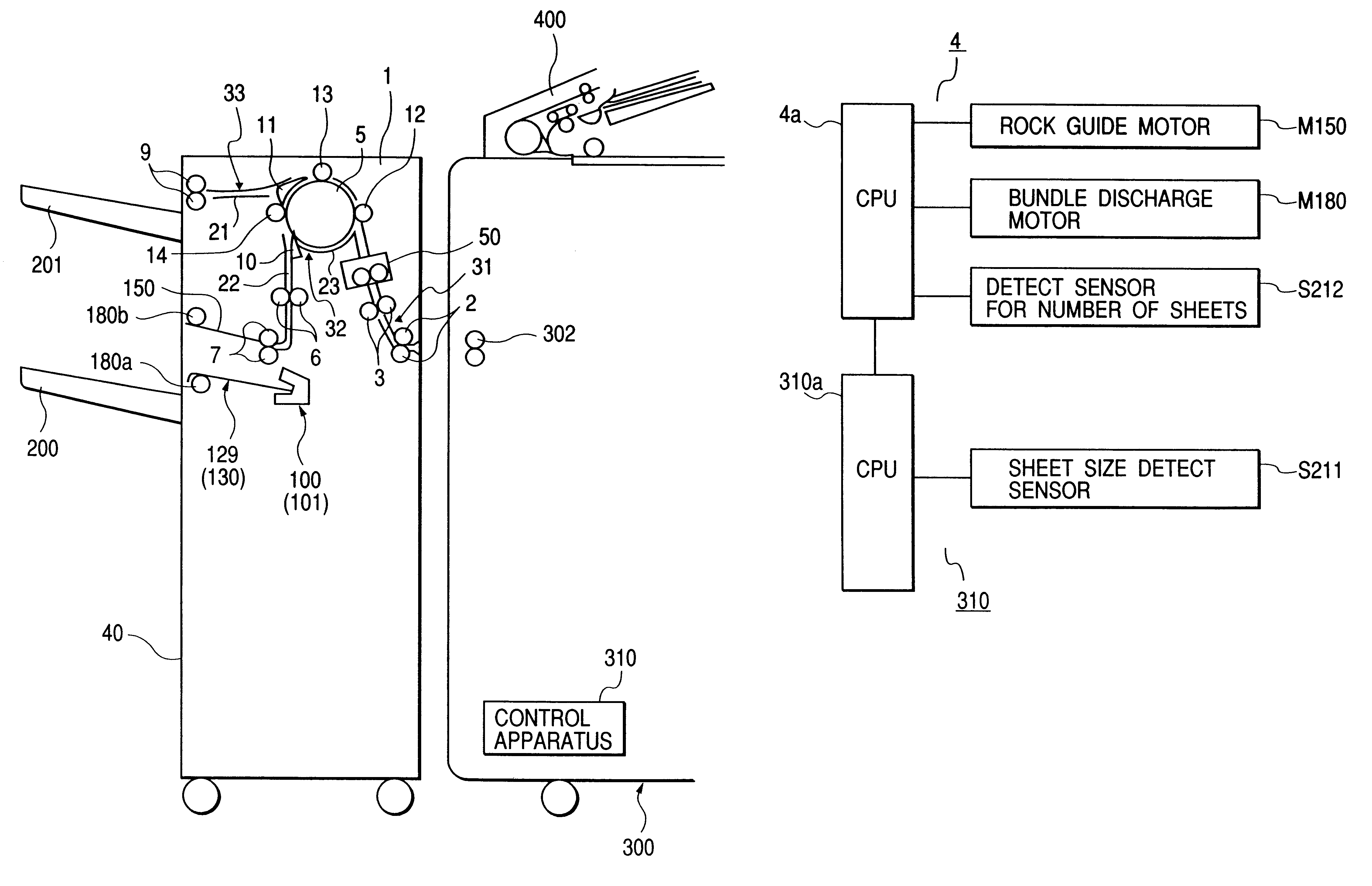

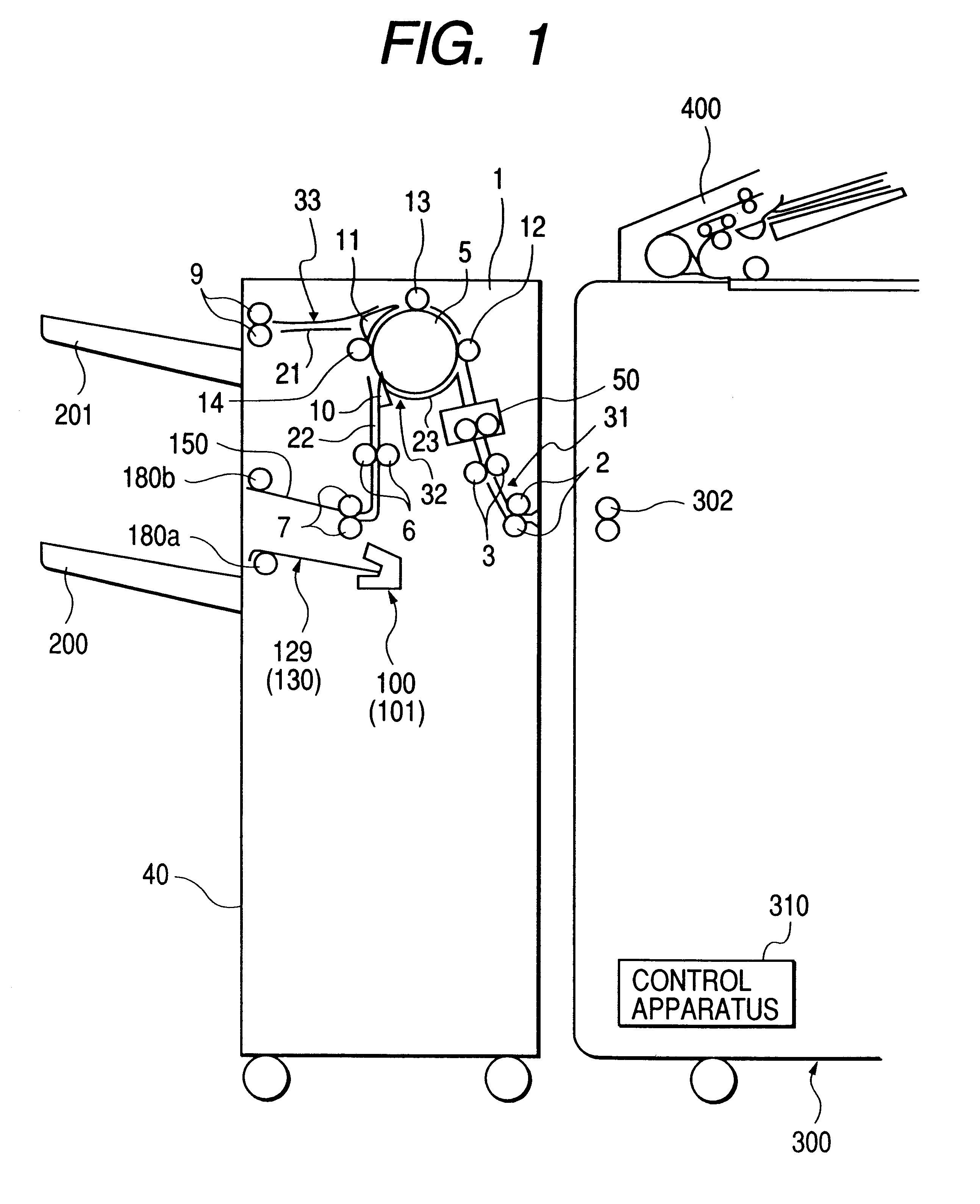

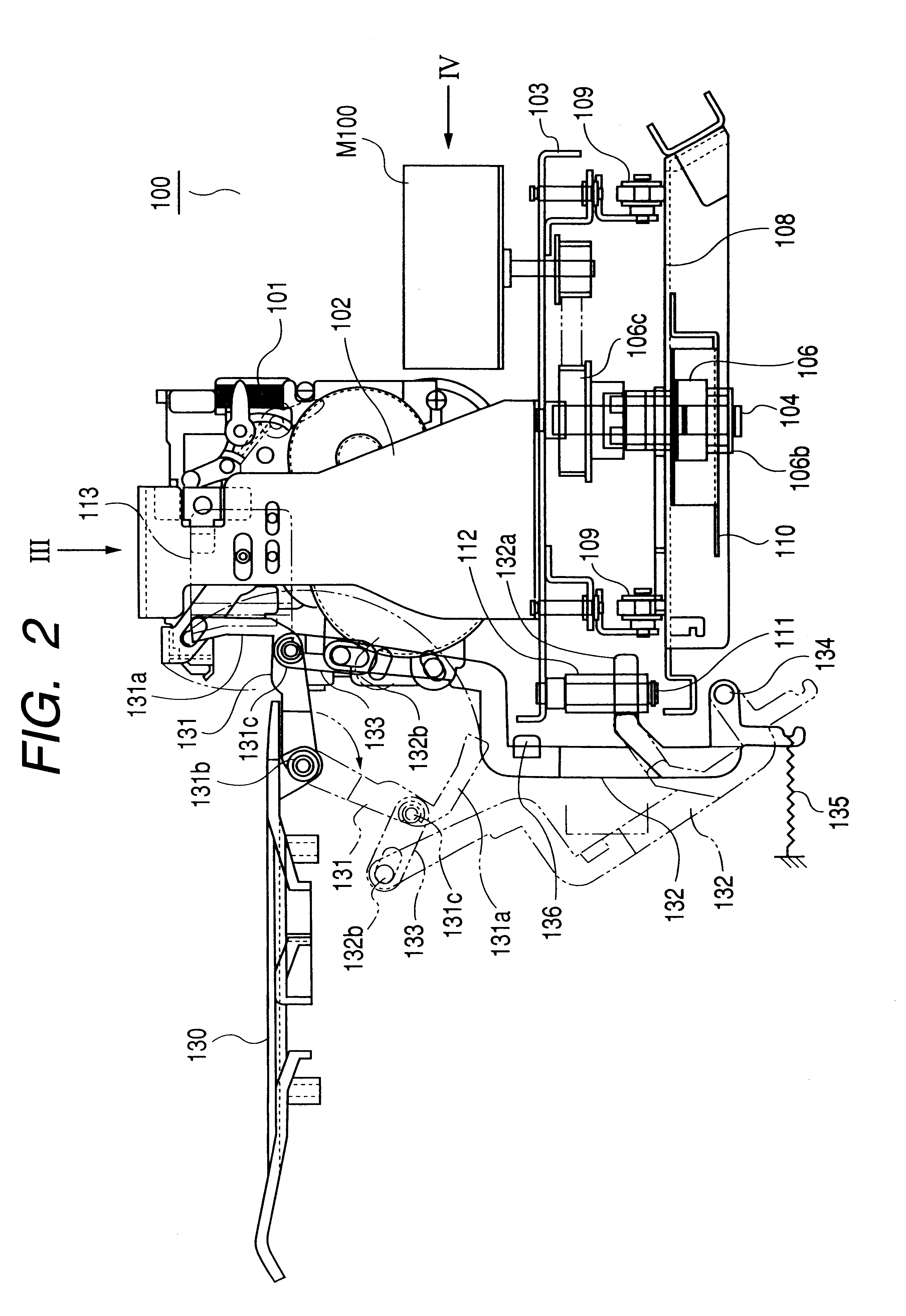

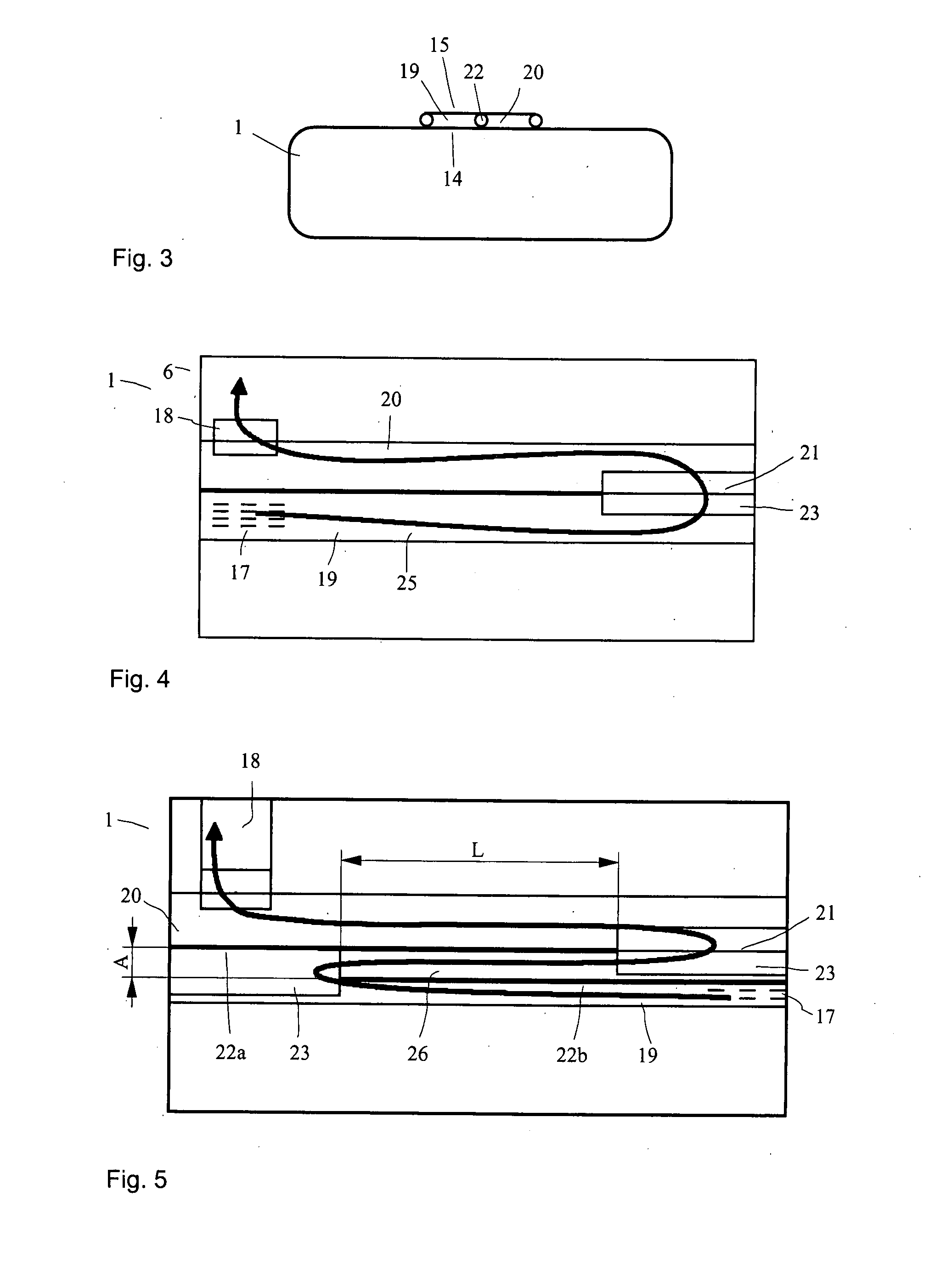

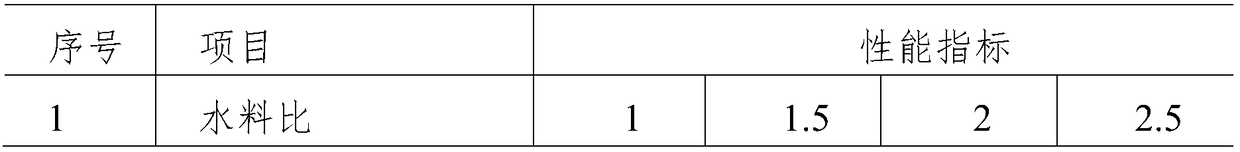

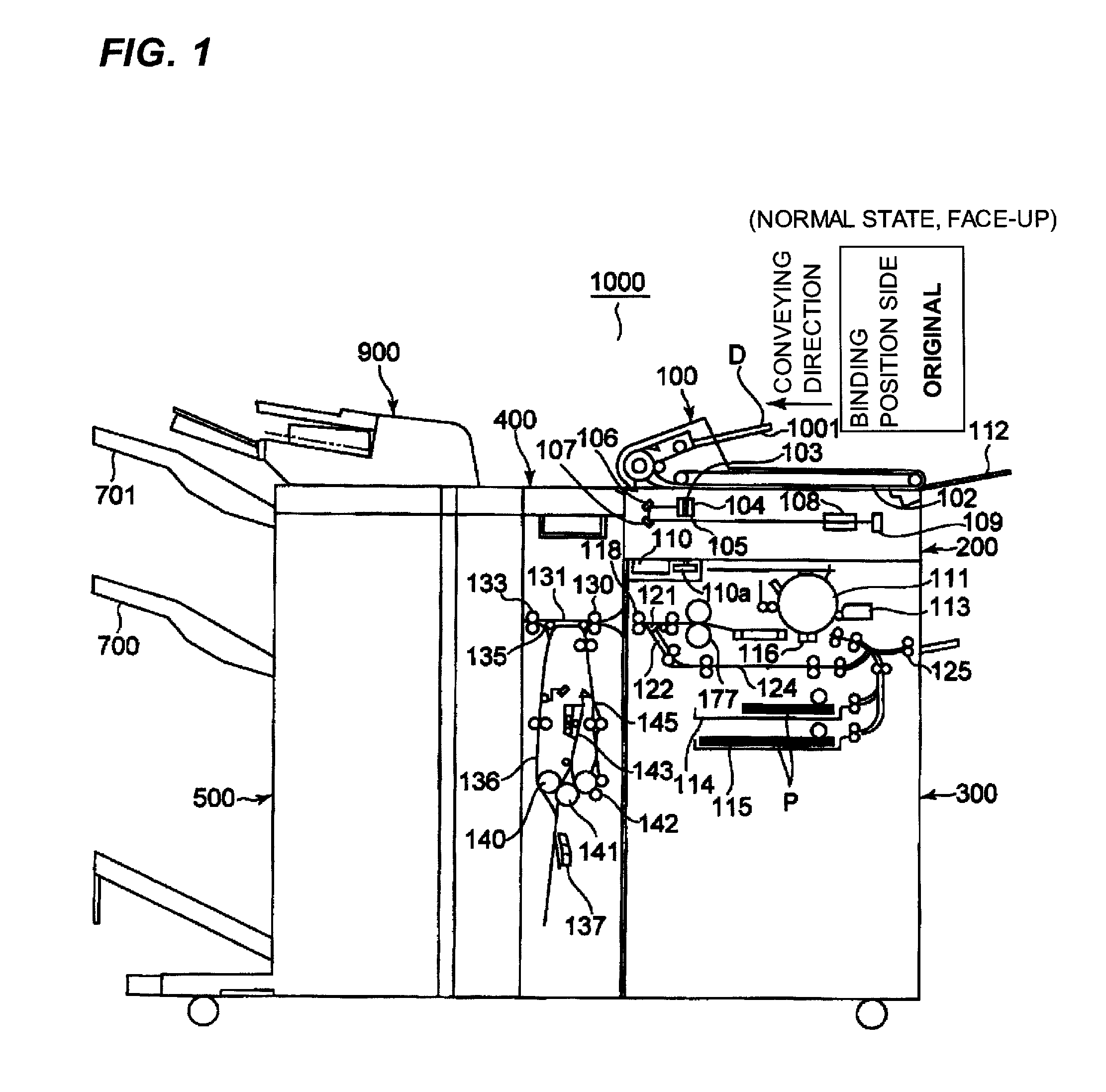

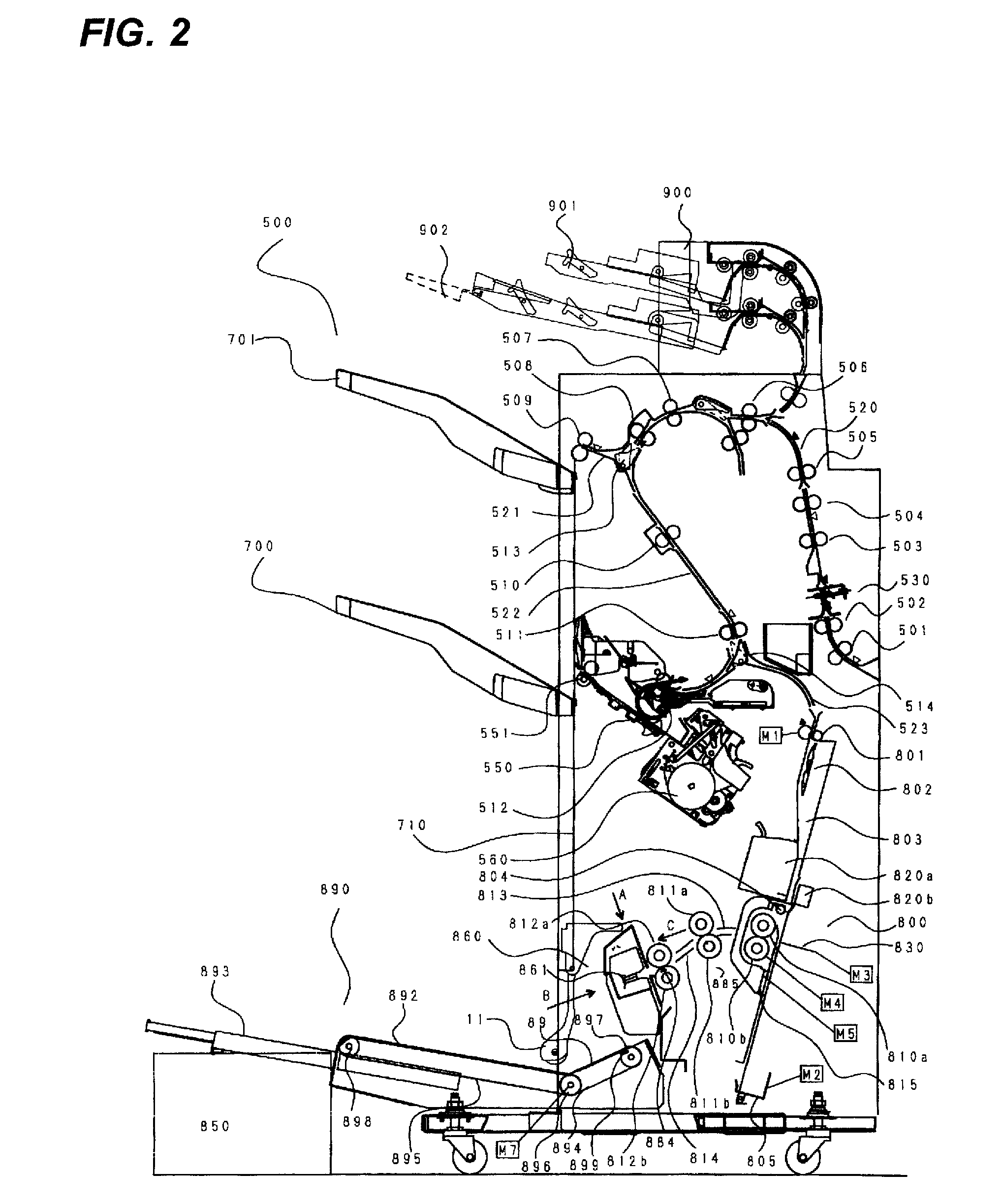

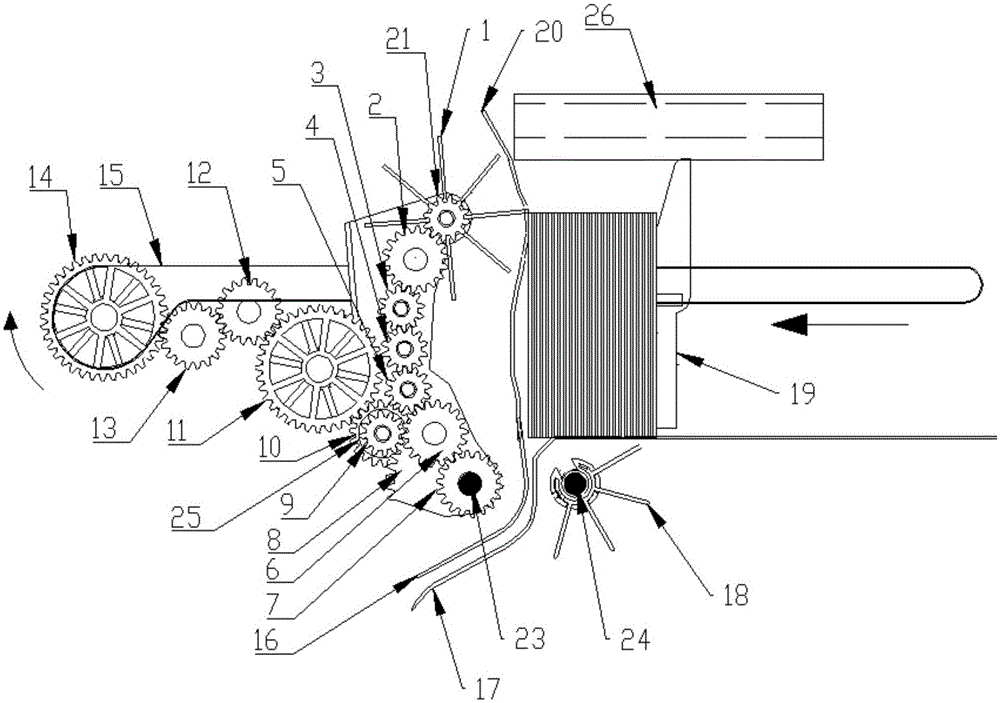

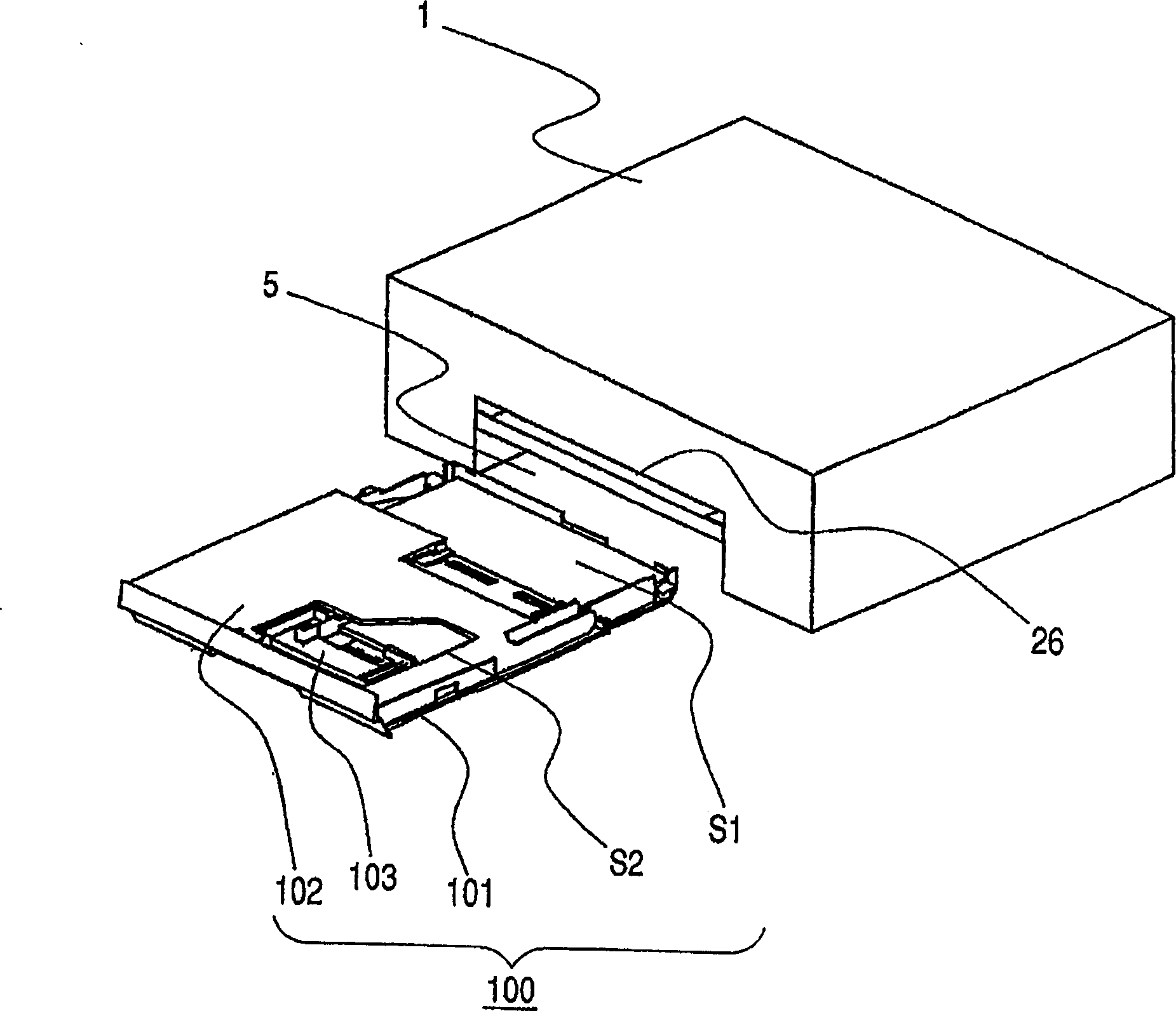

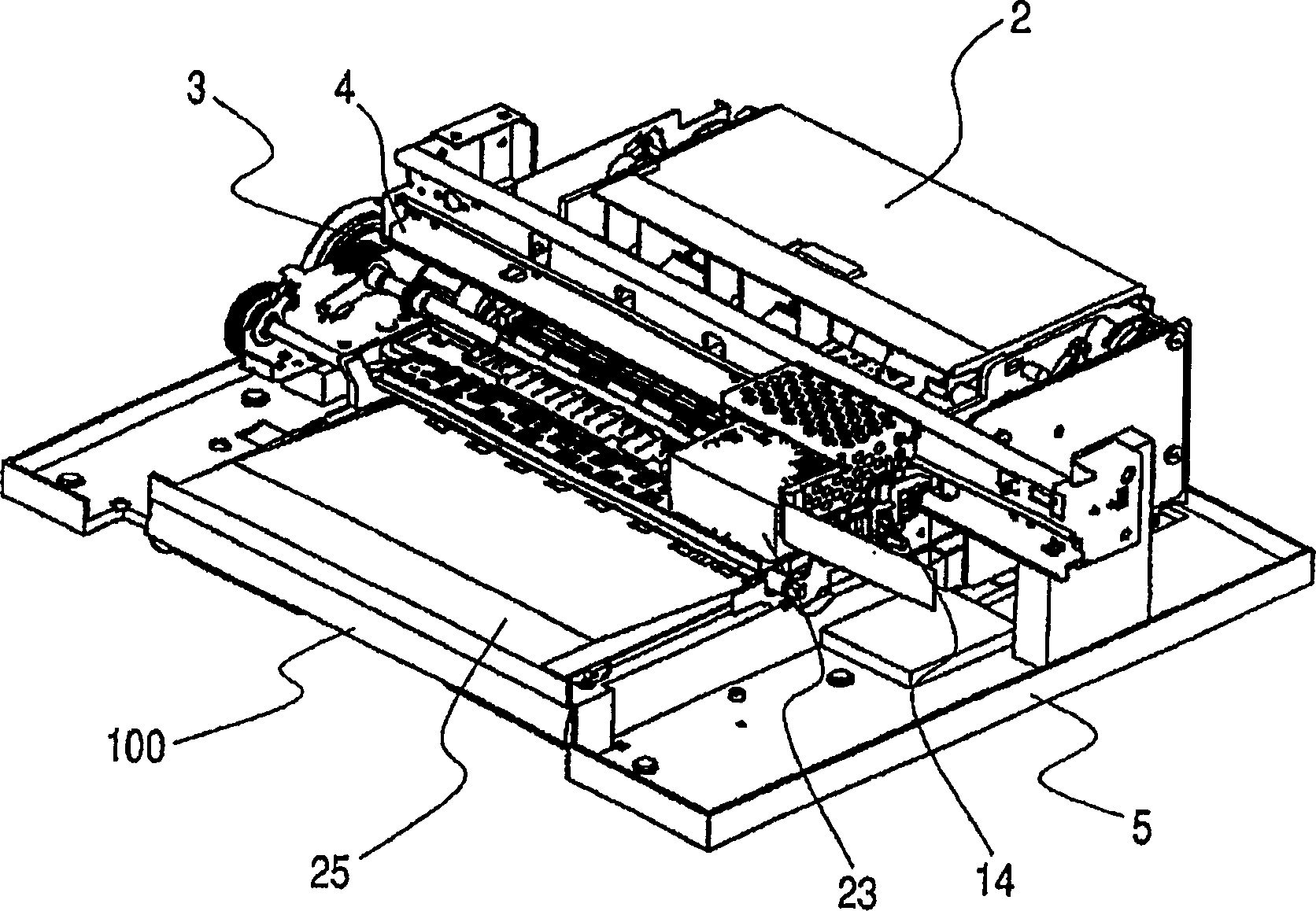

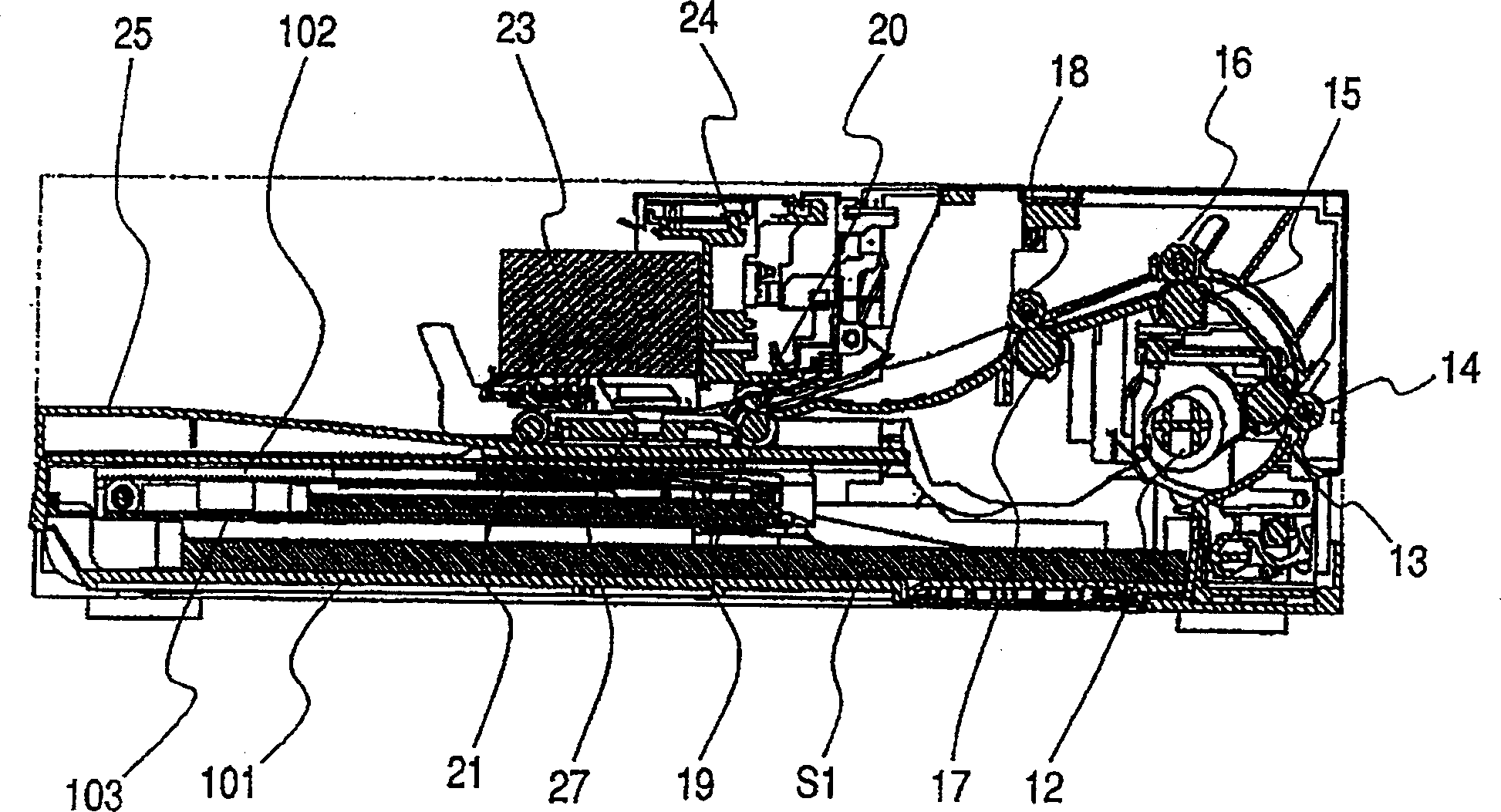

Sheet process apparatus

InactiveUS6264189B1Improve stacking effectElectrographic process apparatusPile receiversEngineeringSheet material

The present invention provides a sheet process apparatus comprising a sheet discharge means for discharging a sheet, a first stacking means for stacking the sheet discharged by the sheet discharge means, a bundle discharge means for discharging a sheet bundle rested on the first stacking means, and a second sheet stacking means for stacking the sheet bundle discharged by the bundle discharge means. Wherein the number of sheets in the sheet bundle to be discharged onto the second stacking means is selected to become smaller, when a sheet size in a sheet conveying direction is great, than when a sheet size in the sheet conveying direction is small.

Owner:CANON KK

Method of forming a vented bag

Owner:EXOPACK TECH

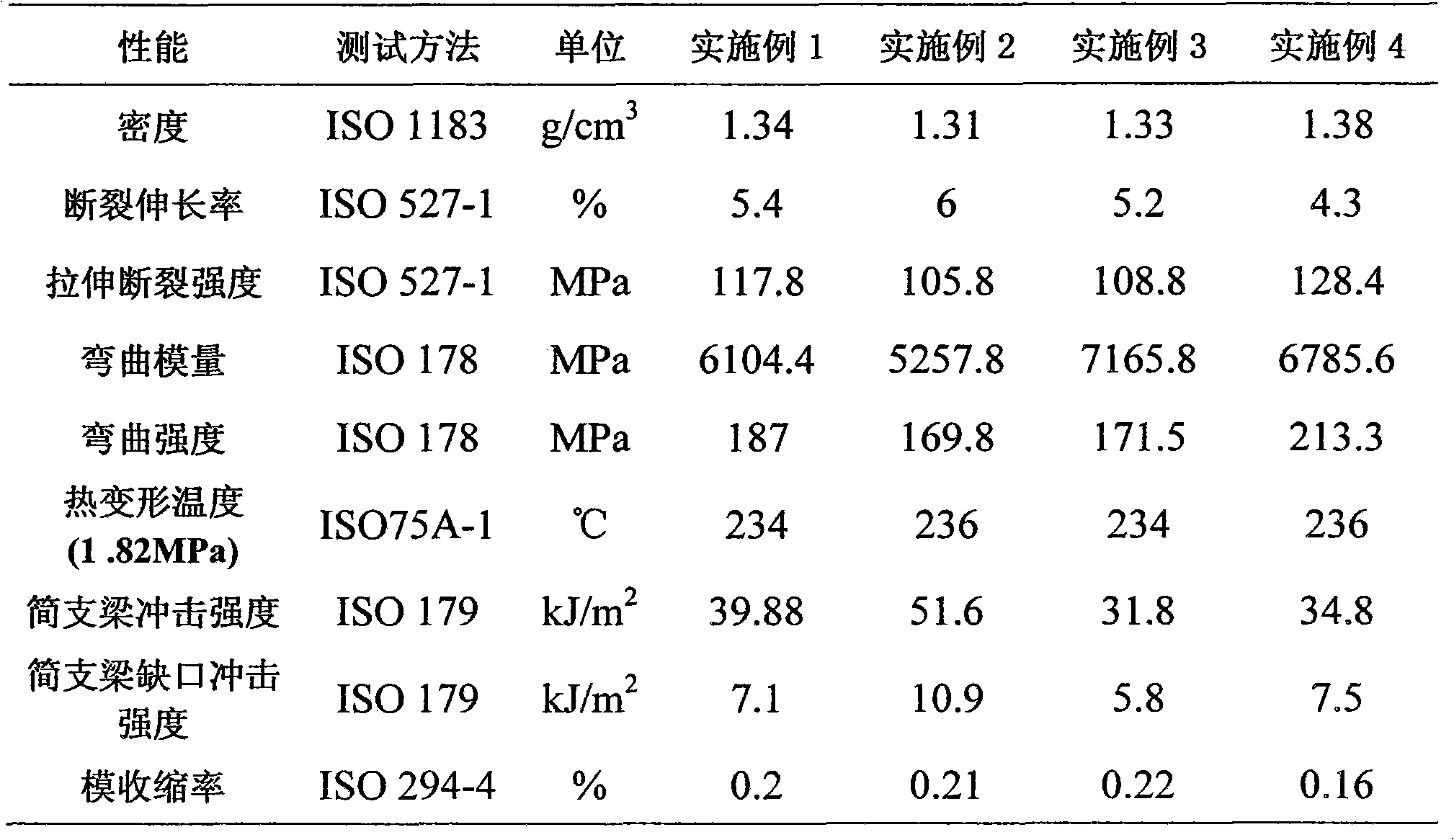

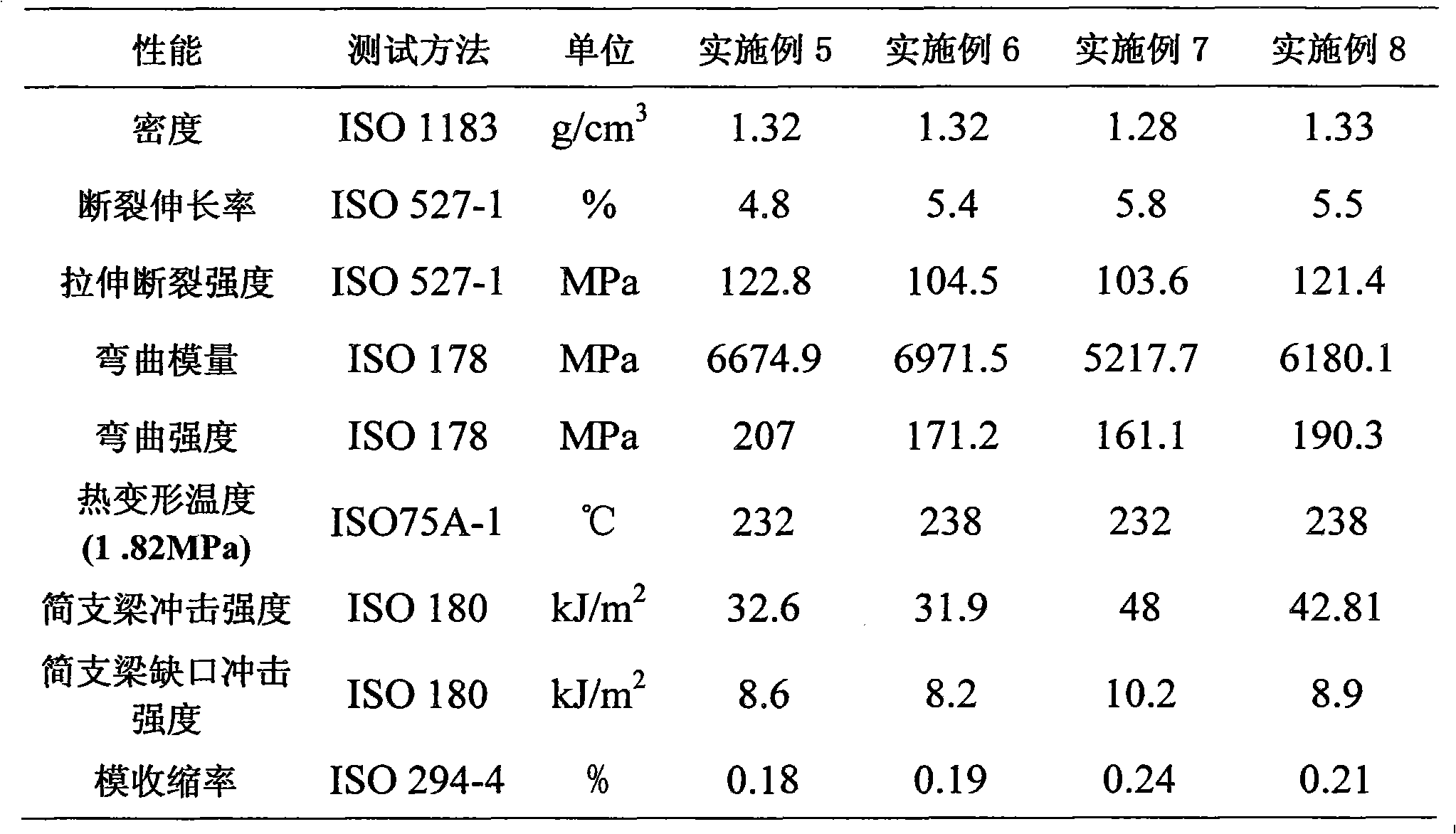

Warpage resistance nylon 6 composite material for vehicle air conditioning air door and preparation method thereof

InactiveCN101580636AHigh impact strengthImprove liquidityAir-flow control membersGlass fiberFlexural modulus

The invention discloses a warpage resistance nylon 6 composite material for a vehicle air conditioning air door and a preparation method thereof. The composite material is composed of nylon 6 chips, fiberglass, glass microballoons, compatilizer, antioxidizer, a coupling agent and a lubricating agent. The preparation method includes the following steps: (1) after being uniformly mixed, the nylon 6 chips, the compatilizer, the antioxidizer, the coupling agent and the lubricating agent are added into a double screw extruder on the first segment of a barrel, the glass microballoons are added by a side feeding machine on the fourth segment of the barrel, and the fiberglass is added by the side feeding machine on the sixth segment of the barrel; and (2) after being extruded outside, the prepared particles are dried and cooled, and finally the warpage resistance nylon 6 composite material for the vehicle air conditioning air door can be obtained. The warpage resistance nylon 6 composite material prepared by the invention has the advantages of extremely high flexural modulus, high fluidity and favorable dimension stability, solves the problem of warpage of a large finished piece caused by material shrinkage, and guarantees the assembly of the finished piece.

Owner:合诚技术股份有限公司

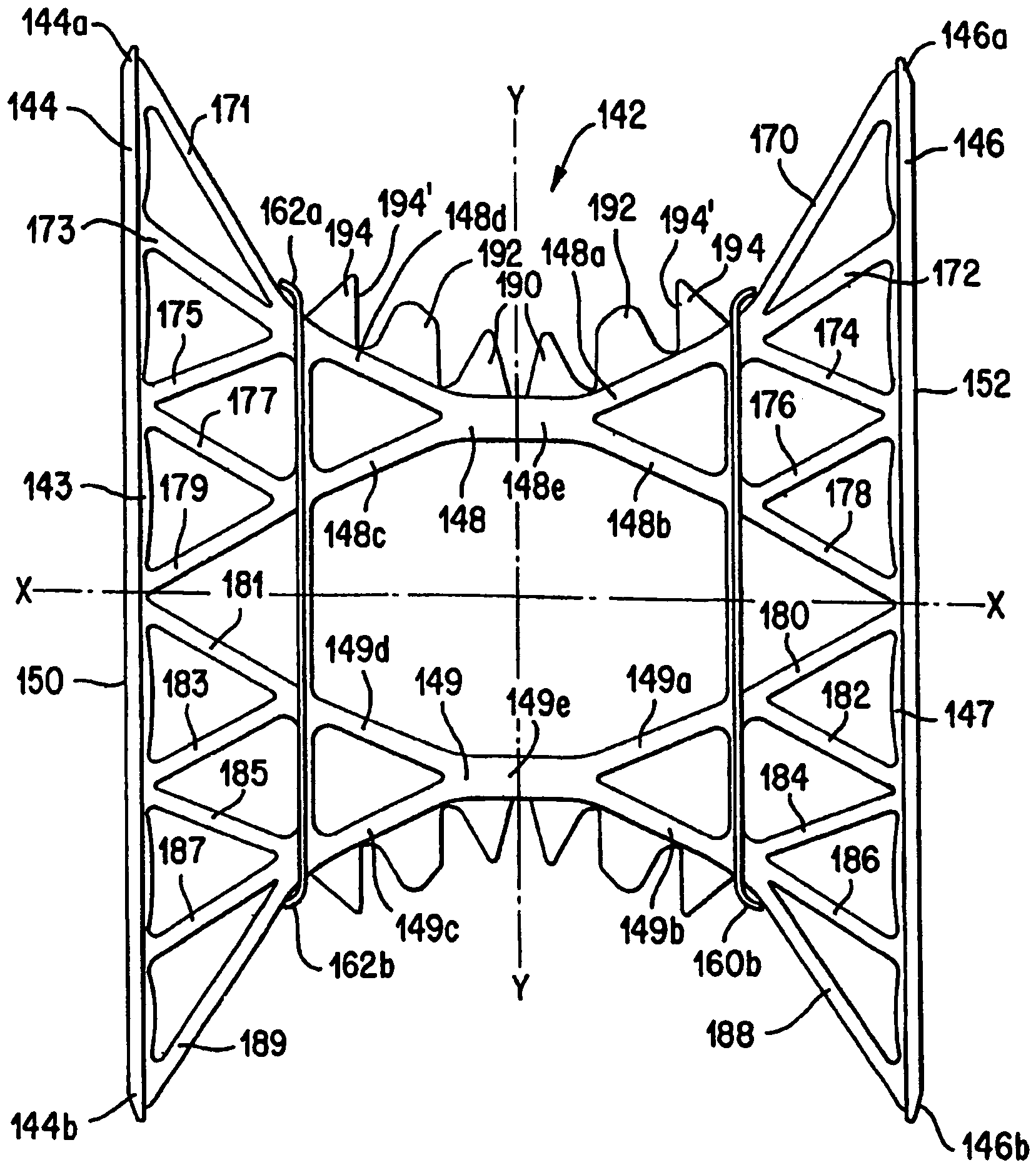

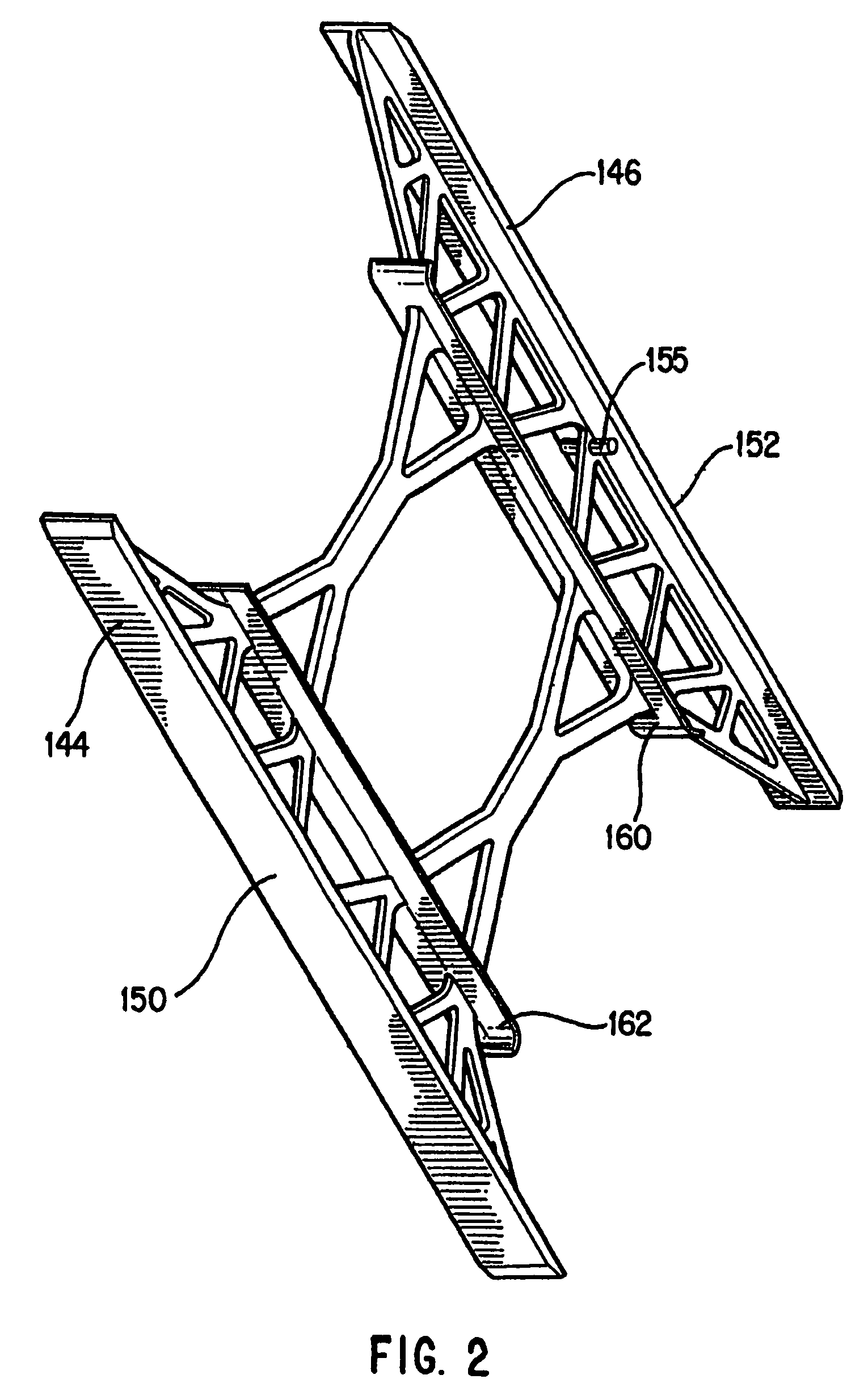

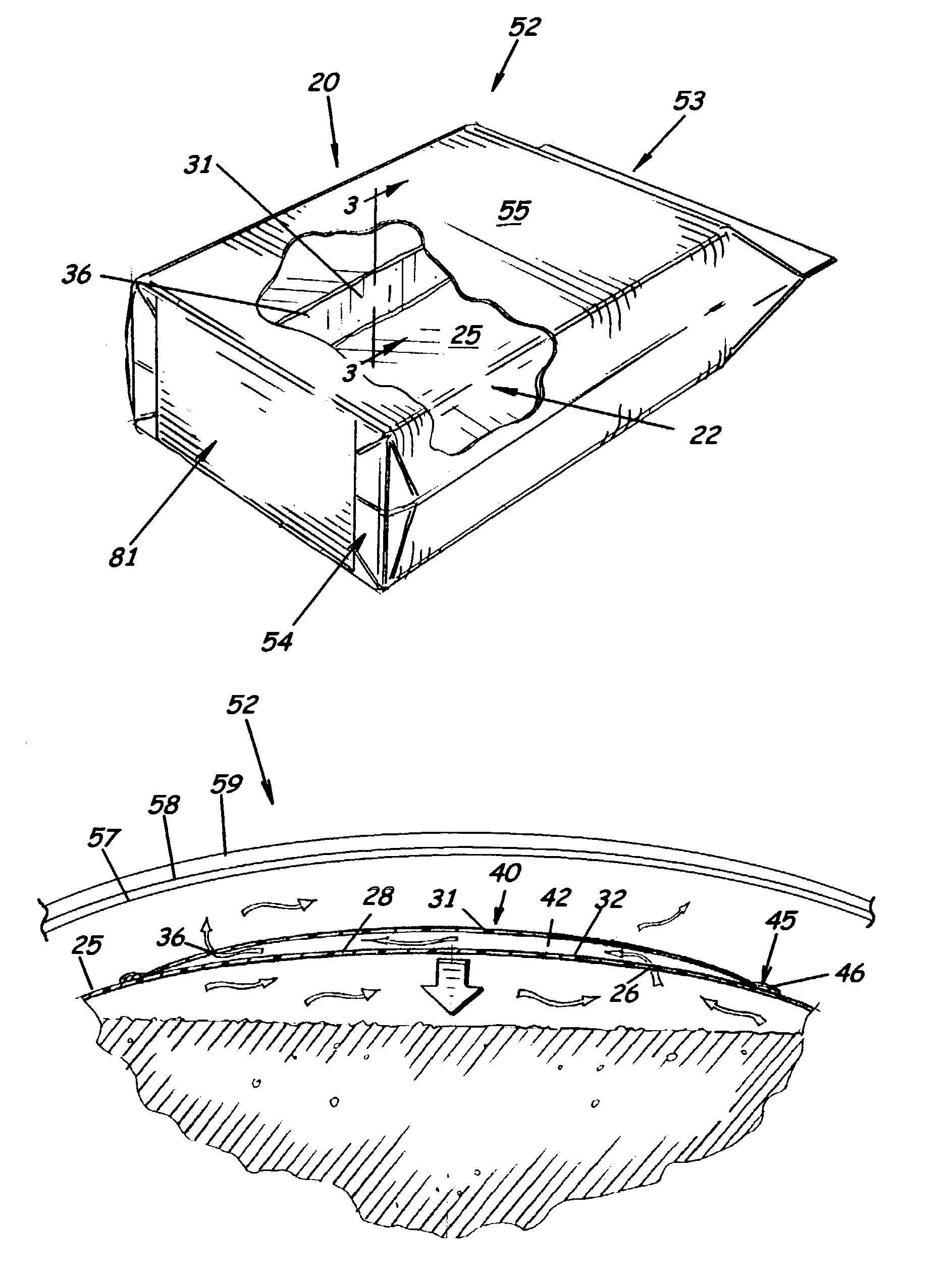

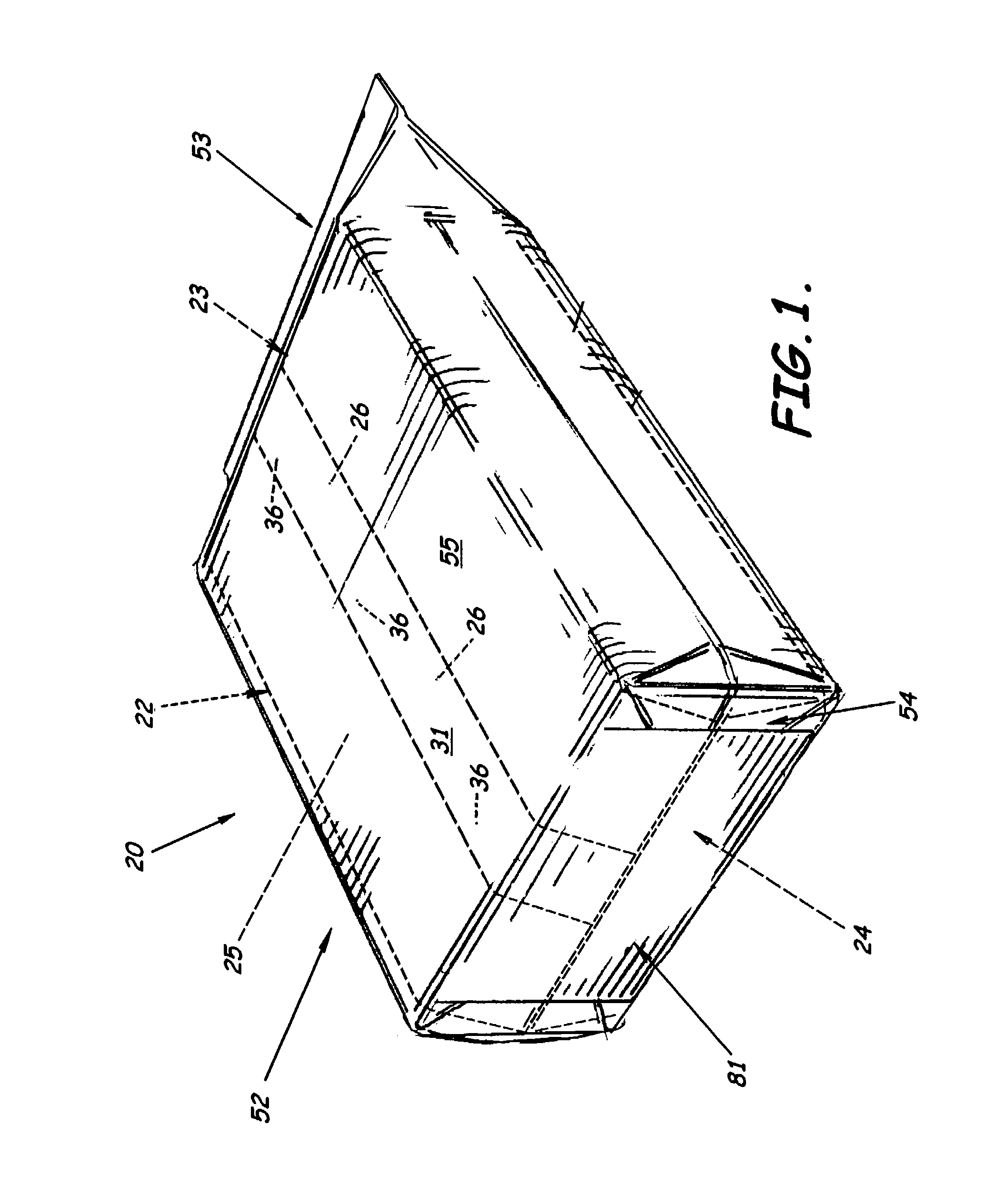

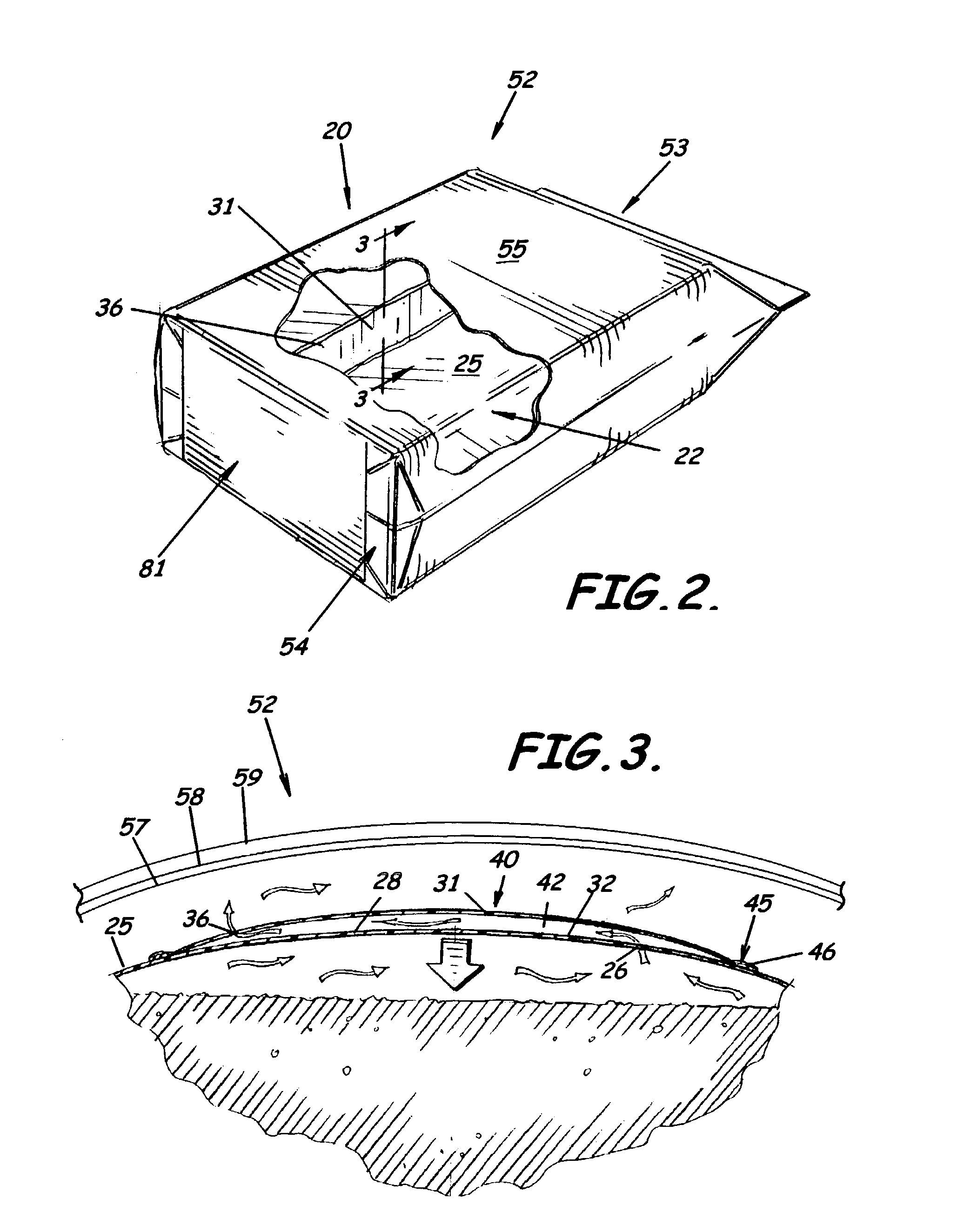

Bridging member for concrete form walls

InactiveUS7284351B2Enhanced strengthening and reinforcing gridReduce materialStrutsWallsHigh densityHorizontal axis

A building component having first and second high density foam panels and improved bridging members for connecting the panels that extend between and may be molded into the panels. The bridging members include a pair of elongated end plates oriented in a top to bottom direction of the panels, a pair of substantially identical web members joining the end plates and being substantially symmetrically disposed above and below a central horizontal axis of the bridging member, and a pair of strip members oriented in the top to bottom direction of the panels intersecting the web members. The web members have a unique configuration that maximizes load bearing capacity with a minimum amount of material. The strip members may abut against and be substantially flush with respective inner surfaces of the foam panels to assist in positioning and forming the panels during molding. Seating areas for positioning horizontally and / or vertically disposed rebar in predetermined positions are also provided.

Owner:AIRLITE PLASTICS

Preparation of polymer composite gelling agent for grouting and application method thereof

The invention belongs to the technical field of a gelling agent for geologic hazard control as well as filling control of goaf and waste laneway or collapse craters after exploitation of other mines, and provides a formula and a method of a novel polymer composite gelling agent for grouting. The gelling agent comprises the following components in percentage by weight: 10-25% of bentonite, 5-20% of cellulose, 5-20% of vegetable gum, 10-15% of calcium hydroxide, 10-25% of inorganic hygroscopic agent, 0.5-1.5% of inorganic dispersant, 0.5-2% of inorganic flocculent, 6-18% of organic flocculent, and 5-15% of alkali metal carbonate. The gelling agent is used for processing and crushing, mixing with water, and injecting to slurry for gelling. According to the invention, the characteristics of high-hydroscopicity mineral matters and hydroscopic synthetic resin are sufficiently absorbed and utilized, and various ion groups are introduced and adjusted to obtain specific performance, so that the gelling agent has strong water solubility, can form hydrophile and water-insoluble gel in the slurry, and has excellent adhesion force to solids and dissolved matters in the slurry, good gelling property, strong water control function, high and adjustable jelling speed, low cost and no pollution.

Owner:JICHANG XIANDAO ENG MATERIAL

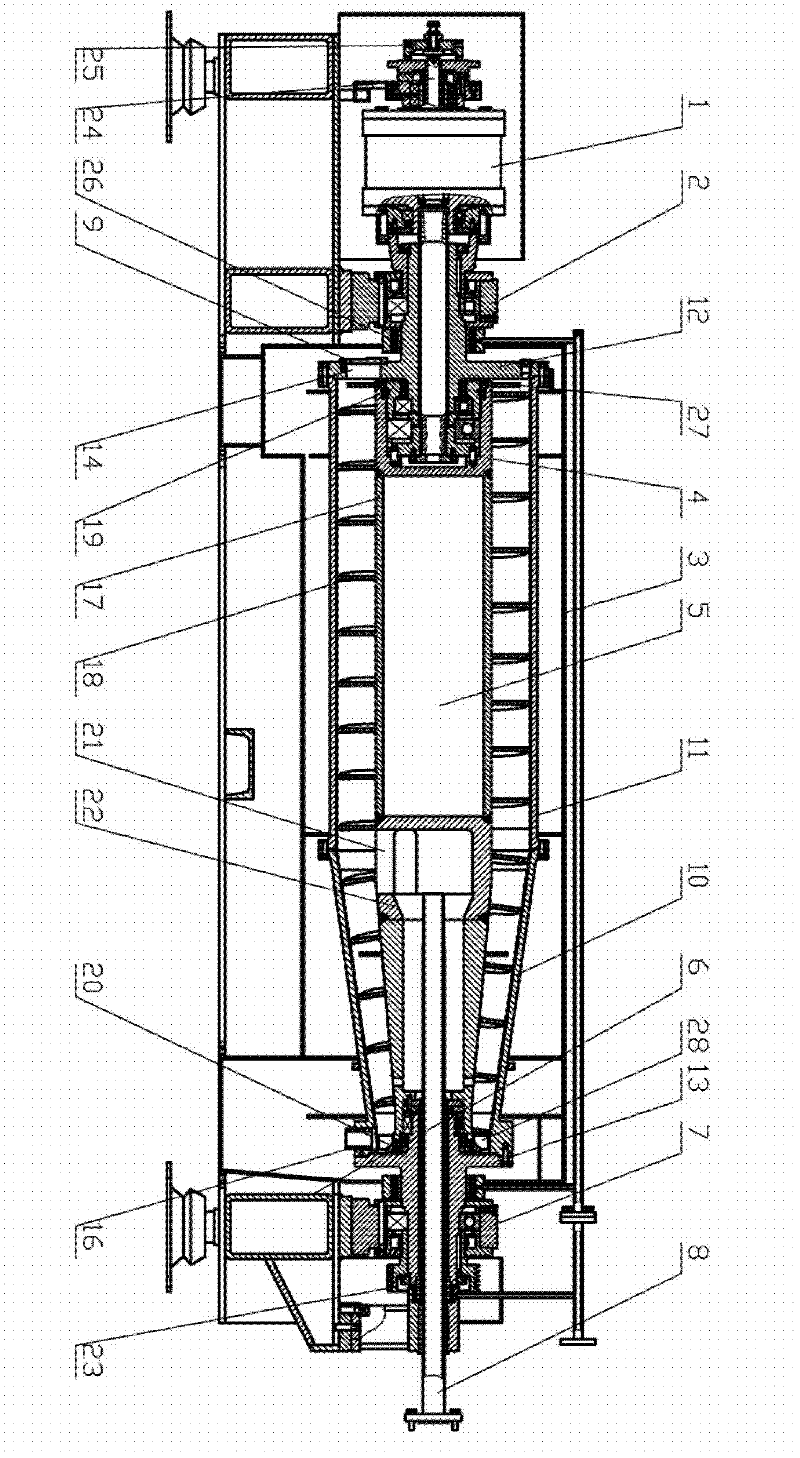

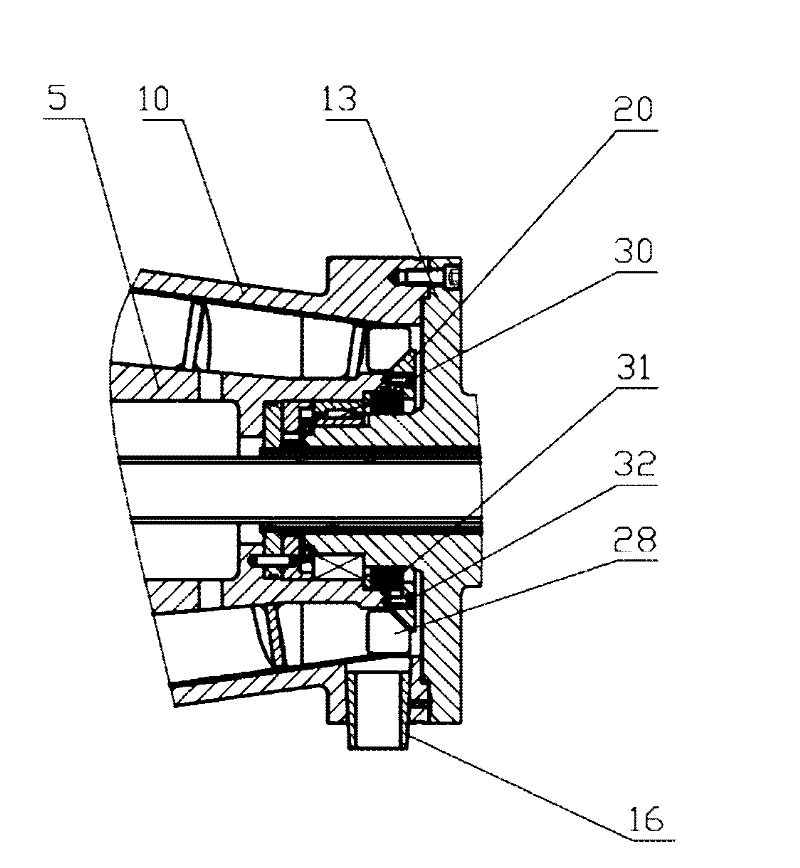

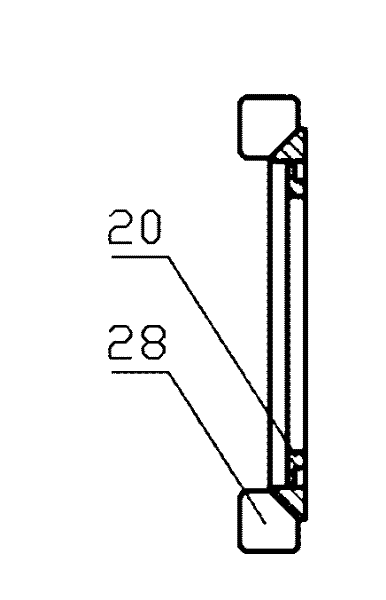

Horizontal decanter solid-bowl centrifuge

The invention relates to a rotary solid bowl centrifuge with a helical conveyor, in particular to a horizontal decanter solid-bowl centrifuge. A flange plate is provided with a scraper, and is connected to the auger conveyor through a screw; a liquid limit ring is arranged on the end part of a helical large-end cylinder, has a sheet ring shape, and has the outer diameter smaller than the inner diameter of a cylindrical bowl; the middle of the liquid limit ring is provided with a through hole sleeved on the helical large-end cylinder and the liquid limit ring is fixedly arranged on the helical large-end cylinder; and an adjusting plate is fixedly arranged on a large-end cover of the bowl, and is fixedly connected with a blocking plate. The horizontal decanter solid-bowl centrifuge has the characteristics of compact structure, convenience for installation, simple operation and maintenance, good use effect and the like; the scraper can effectively scrape solid-phase particle accumulation, has a good effect, and protects the safety of a seal ring and a bearing; the liquid limit ring contributes to settling fine solid-phase particles to greatly improve the separating performance of the machine; and the adjusting plate with the blocking plate effectively prevents flowing liquid from splashing to a labyrinth seal ring, and the liquid is prevented from being leaked to protect environment. The technology is applied to the horizontal decanter solid-bowl centrifuge.

Owner:XIANGTAN CENTRIFUGE

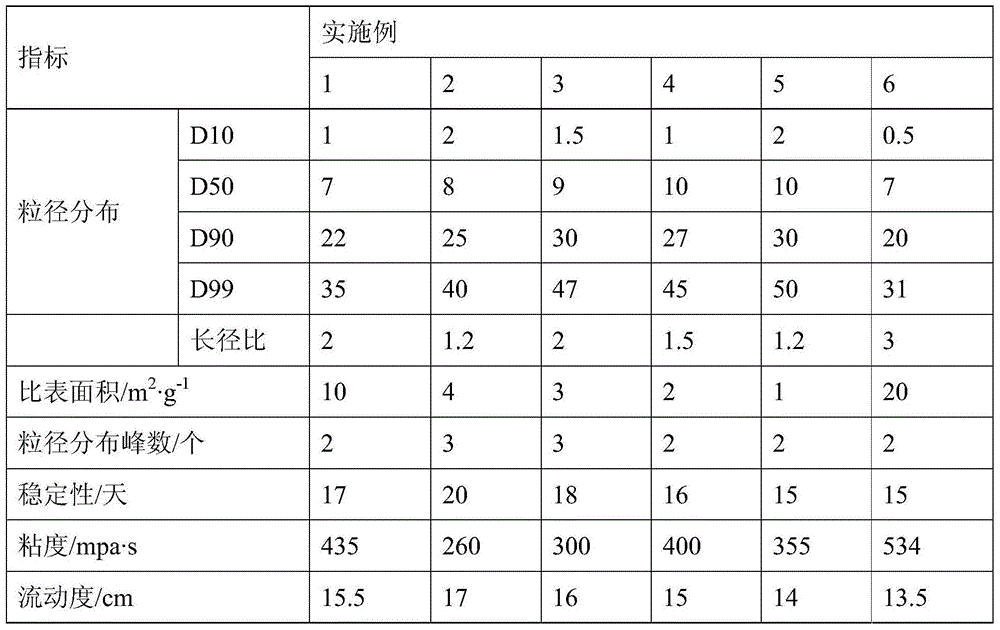

Filler composition and application thereof

ActiveCN104558689AImprove liquidityImprove stabilitySynthetic resin layered productsMetal layered productsThermal dilatationPolymer science

The invention relates to a filler composition and application thereof. The filler composition comprises an angular siliceous micro powder filler, and can be used for preparing a copper clad laminate substrate and bonding sheet resin composition. The filler composition is formed by an angular silicon dioxide with the specific particle size distribution or the mixture of at least two angular silicon dioxides with different particle sizes and the specific particle size distribution, the flowability of the composition and the sedimentary stability in a solution or resin system can be improved, the coefficient of thermal expansion is reduced remarkably, the bonding interface between resin and an inorganic filler, the interlayer adhesiveness between laminates and the adhesive force between a resin layer and a copper foil are improved, and the production cost is reduced greatly.

Owner:GUANGDONG SHENGYI SCI TECH

Multiwall vented bag, vented bag forming apparatus, and associated methods

Owner:HOOD PACKAGING

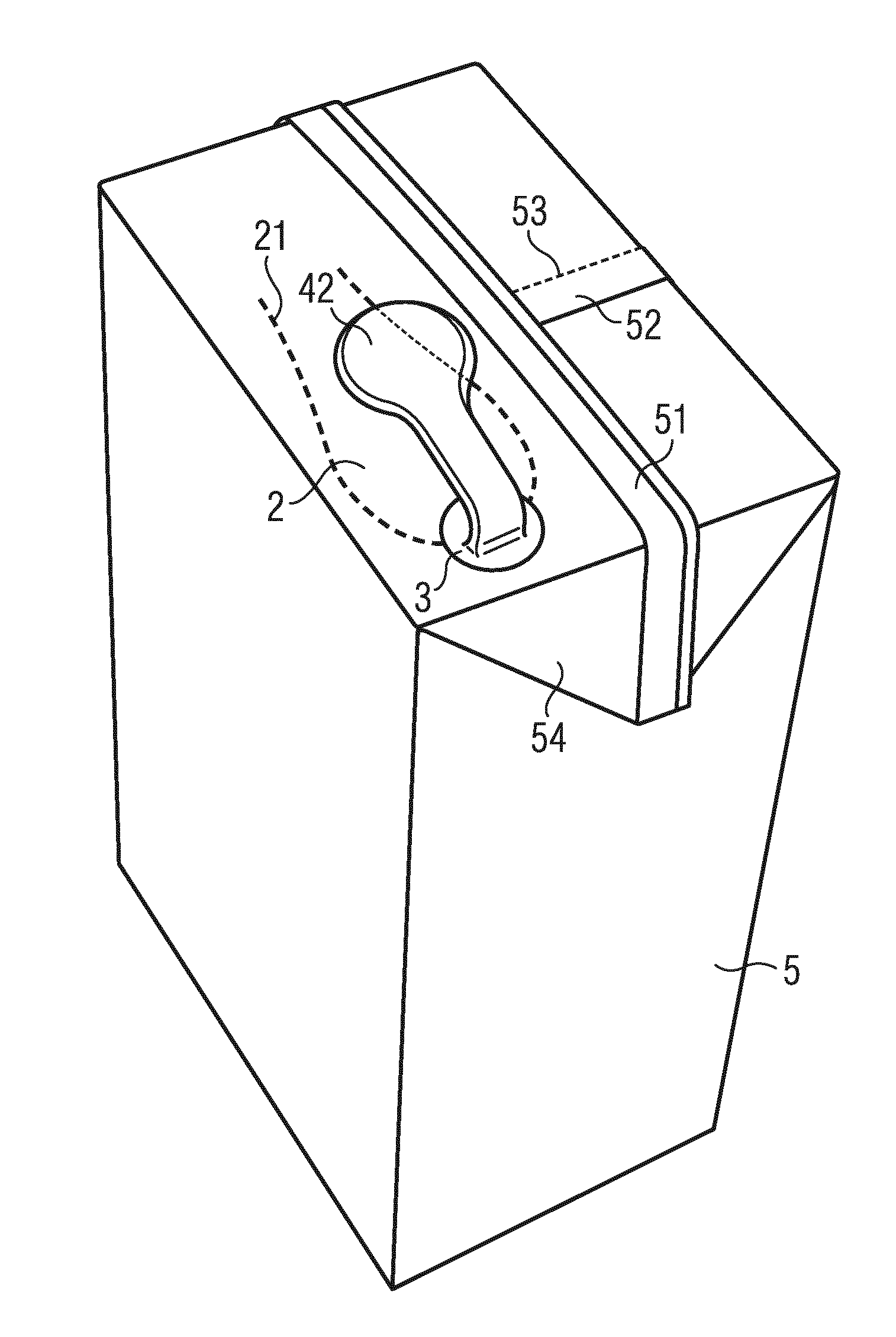

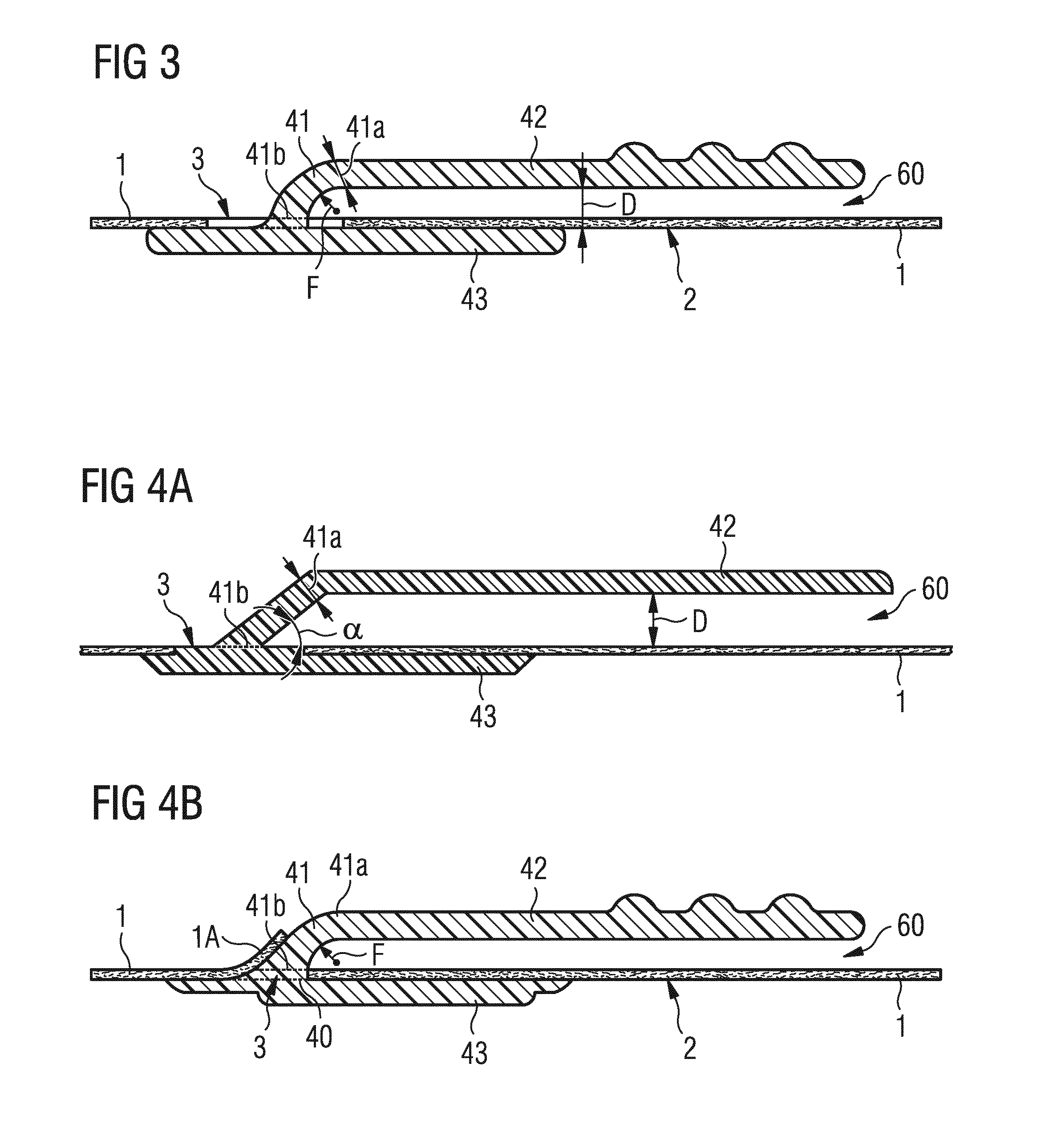

Package material blank, package with such device and method for manufacturing an opening device

InactiveUS20160325878A1Good opening characteristicEasy to catchSynthetic resin layered productsBoxesEngineeringR package

A package material blank comprises a plastic opening device, having a first portion on a first side and a second portion on a second side of the package material blank. The portions are connected with each other via a material bridge penetrating the blank. A grip portion is attached to a distal end of the first portion and displaced form the blank to facilitate easy grabbing for a consumer.

Owner:TETRA LAVAL HLDG & FINANCE SA

Package

InactiveUS20070267414A1Improve water tightnessImprove stacking effectClosuresBagsEngineeringWater tightness

A package for feed material comprising a package body consisting of sheet plastic and a de-aerating means having a de-aerating area, where an inner sheet layer and an outer sheet layer are provided to form a de-aeration channel to connect an inner de-aeration opening in connection with the interior of the package body with at least one outer de-aeration opening in connection with the environment of the package body. The de-aeration channel comprises two separate chambers interconnected through an overflow opening wherein the inner de-aeration opening is provided at the first chamber and the outer de-aeration opening, at the second chamber so as to increase water tightness.

Owner:HAVER & BOECKER

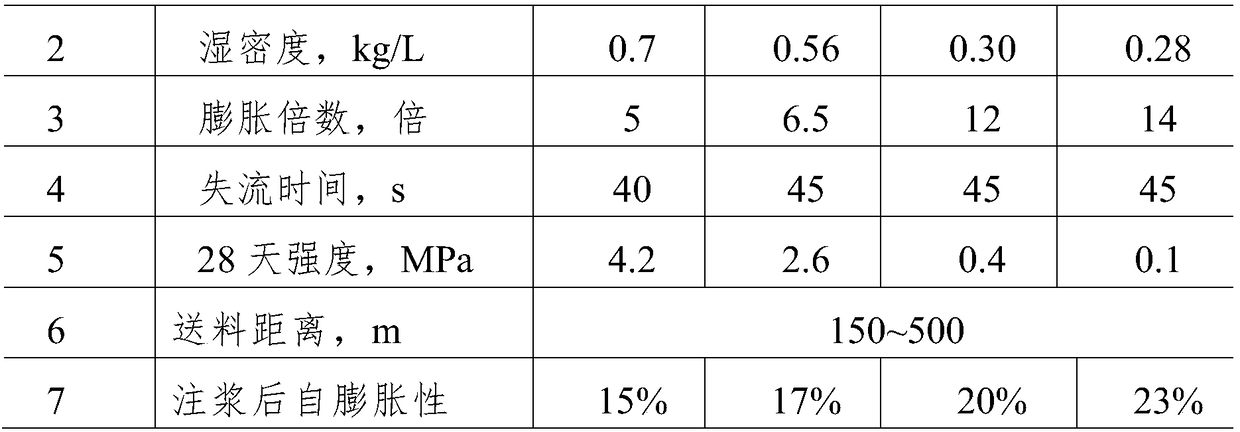

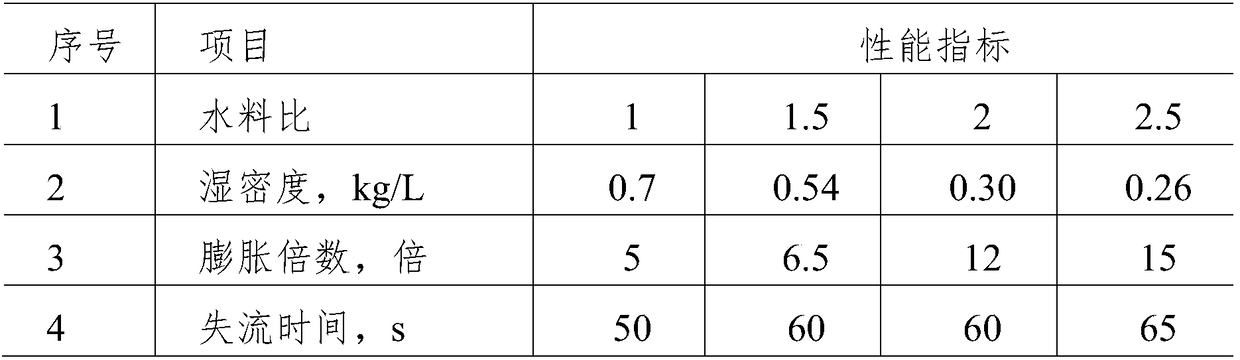

Self-expanding inorganic foam foaming filling material for mines

ActiveCN109020371ASelf-expandingPrevent leakage/accumulationDust removalFire preventionFoaming agentSlurry

The invention relates to a self-expanding inorganic foam foaming filling material for mines. The foaming filling material comprises, by weight, 82-96 parts of a hydraulic cementing material, 1-5 partsof an air entraining agent, 1-5 parts of a reactive chemical foaming agent, 0.5-2 parts of an early strengthening agent, 1-5 parts of a thickener, 0.5-1 part of a foam stabilizer and 1-5 parts of a coagulation accelerator. The foaming filling material can be conveyed for a long distance by screw grouting after being mixed with water having an amount 2-3 times the amount of the foaming filling material, so large-water-material ratio and long-distance conveying is achieved; and the above obtained slurry is continuously foamed and expanded in the conveying process, has a large expansion ratio after being discharged from a tube orifice, and also has the characteristics of certain self-expansion, permanent consolidation, and realization of no shrinkage or collapse and stable volume of a foamedbody before being completely solidified. The product has excellent construction performance, has a good fluidity in a conveying pipeline, makes the foamed body have a small specific gravity and a high strength, is suitable for filling and sealing treatment of the top-coal caving region and corners over and below of underground coal mines, is especially suitable for filling of irregular caving spaces, and realizes the dense topping effect by means of the self-expansion of the material.

Owner:BEIJING RUINUOANKE NEW ENERGY TECH

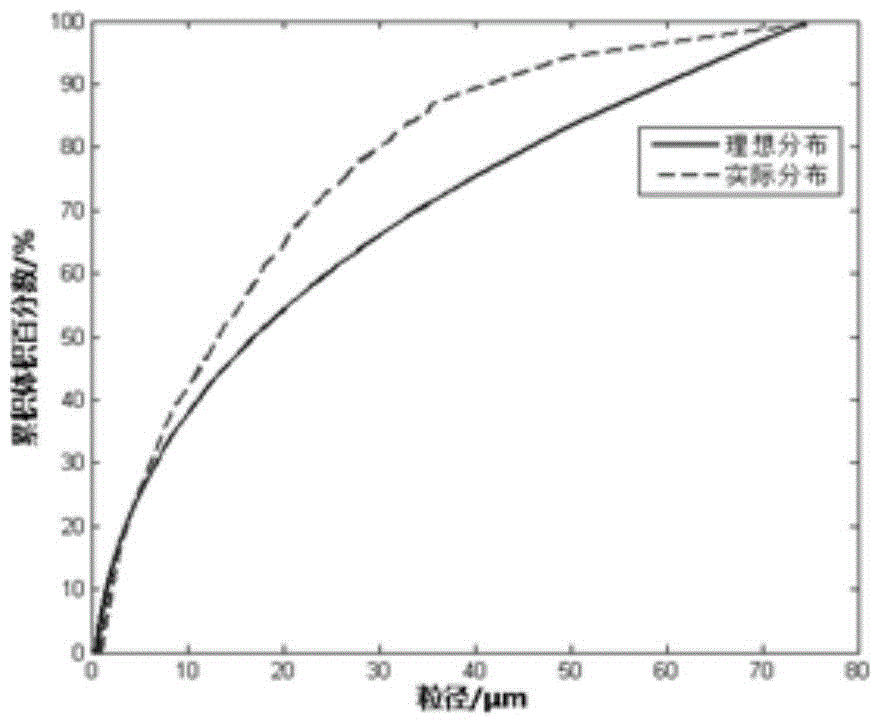

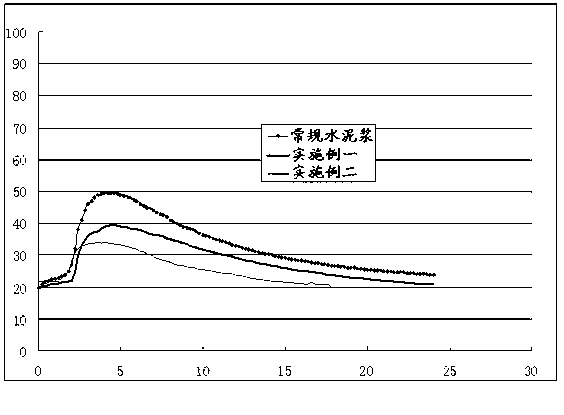

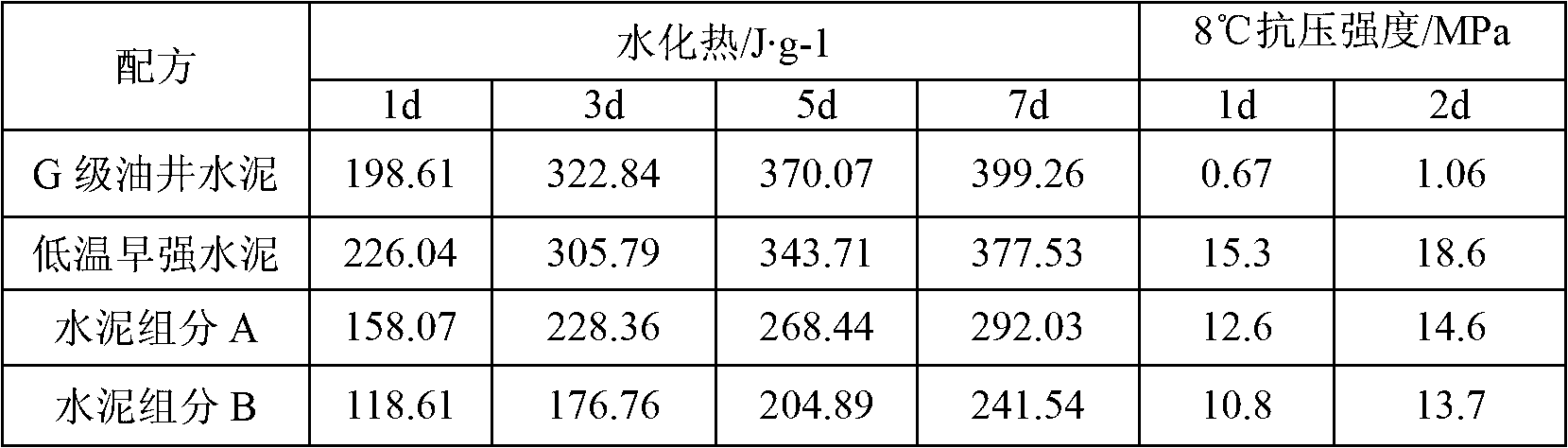

Low-hydration-heat early-strength cement for well cementation

InactiveCN102796500ARapid development of strengthImprove stacking effectDrilling compositionPermafrostHorizon

The invention relates to low-hydration-heat early-strength cement for well cementation, which is used in permafrost horizon or deepwater hydrate-bearing strata in oil drilling engineering. The cement disclosed herein comprises the following ingredients: 30-70wt% of low-temperature early-strength cement, 20-50wt% of pozzolanic material, and 10-40wt% of fine spherical particles. According to the invention, the hydration heat of the cement disclosed herein is 1 / 2 of that of ordinary cement, the low temperature strength develops fast; and the cement disclosed herein can be prepared into low-hydration-heat cement mortar, and has good effect and wide application.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

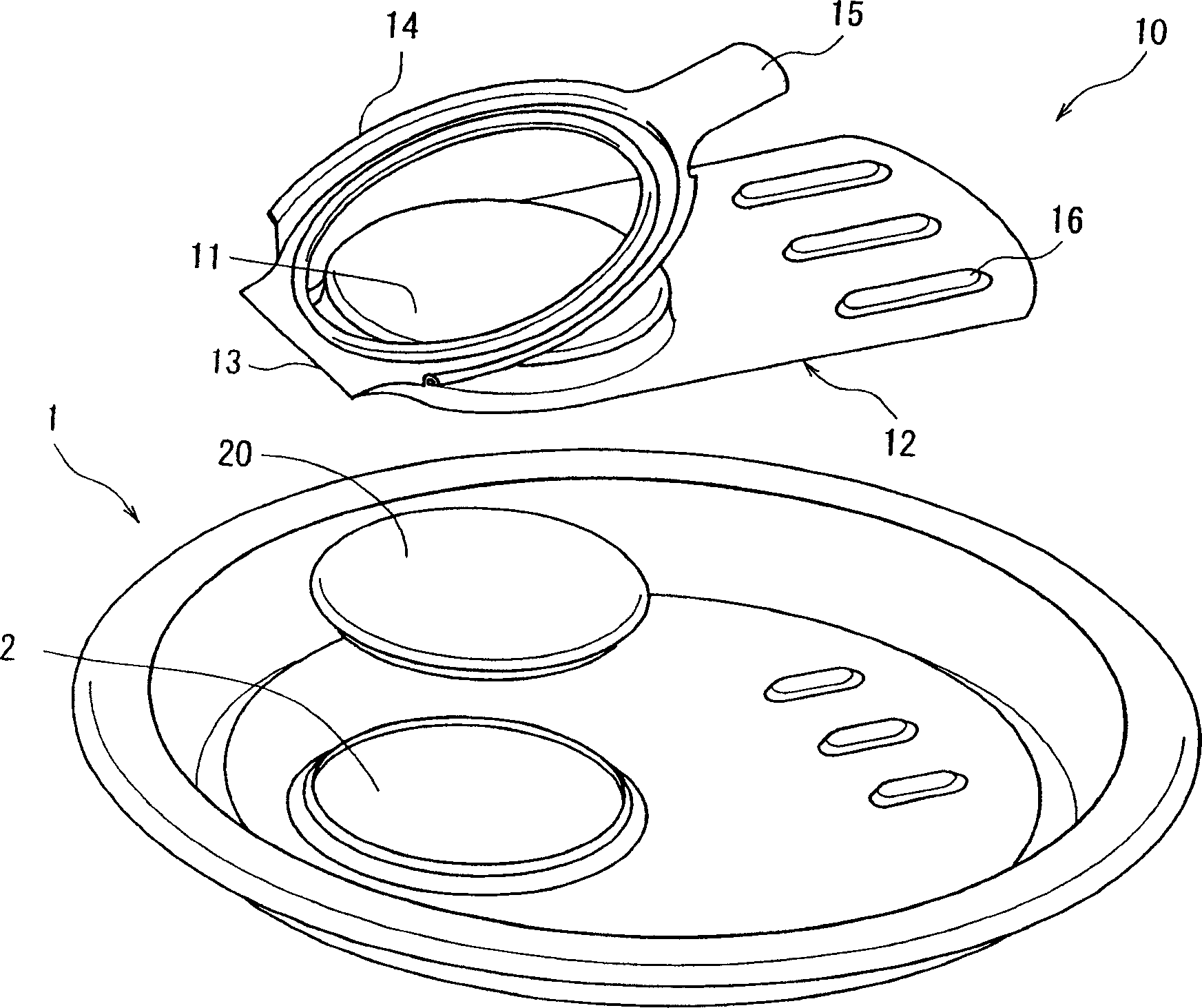

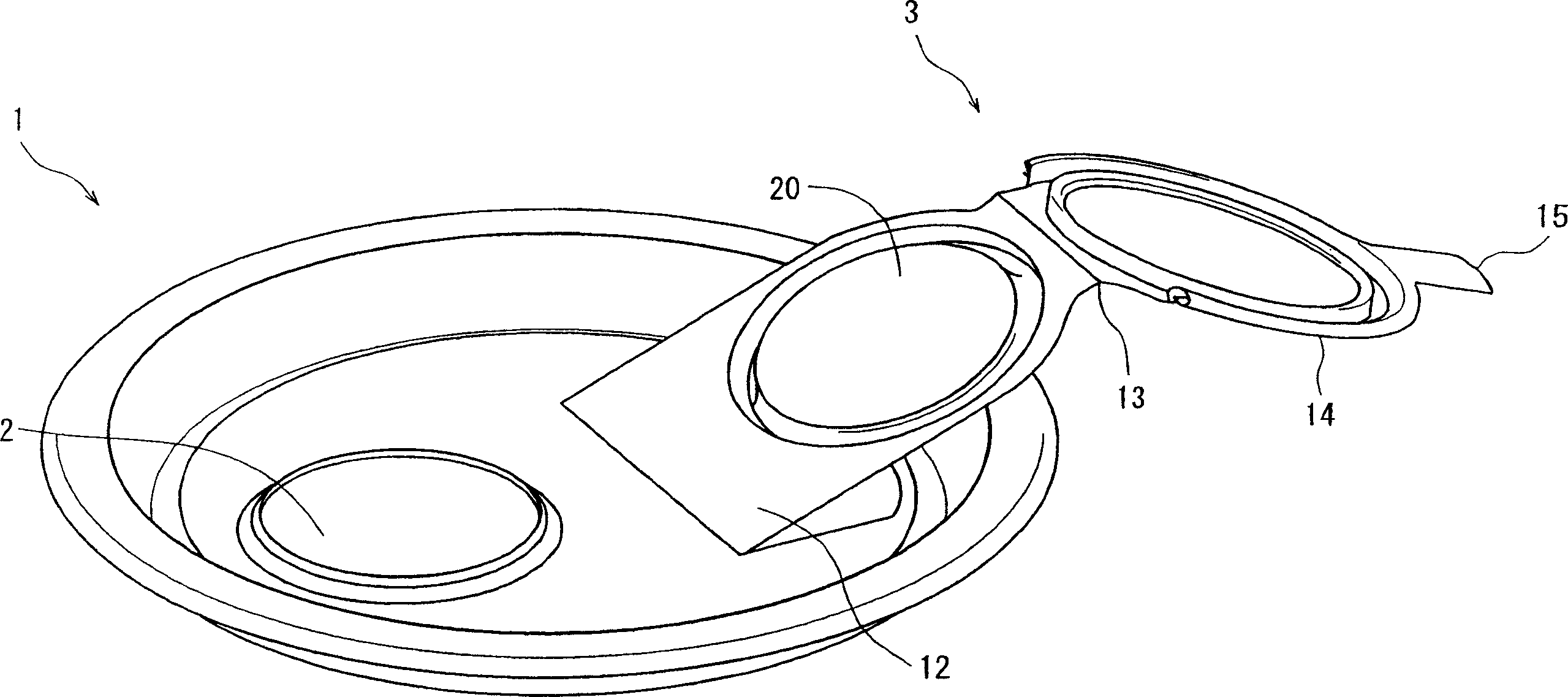

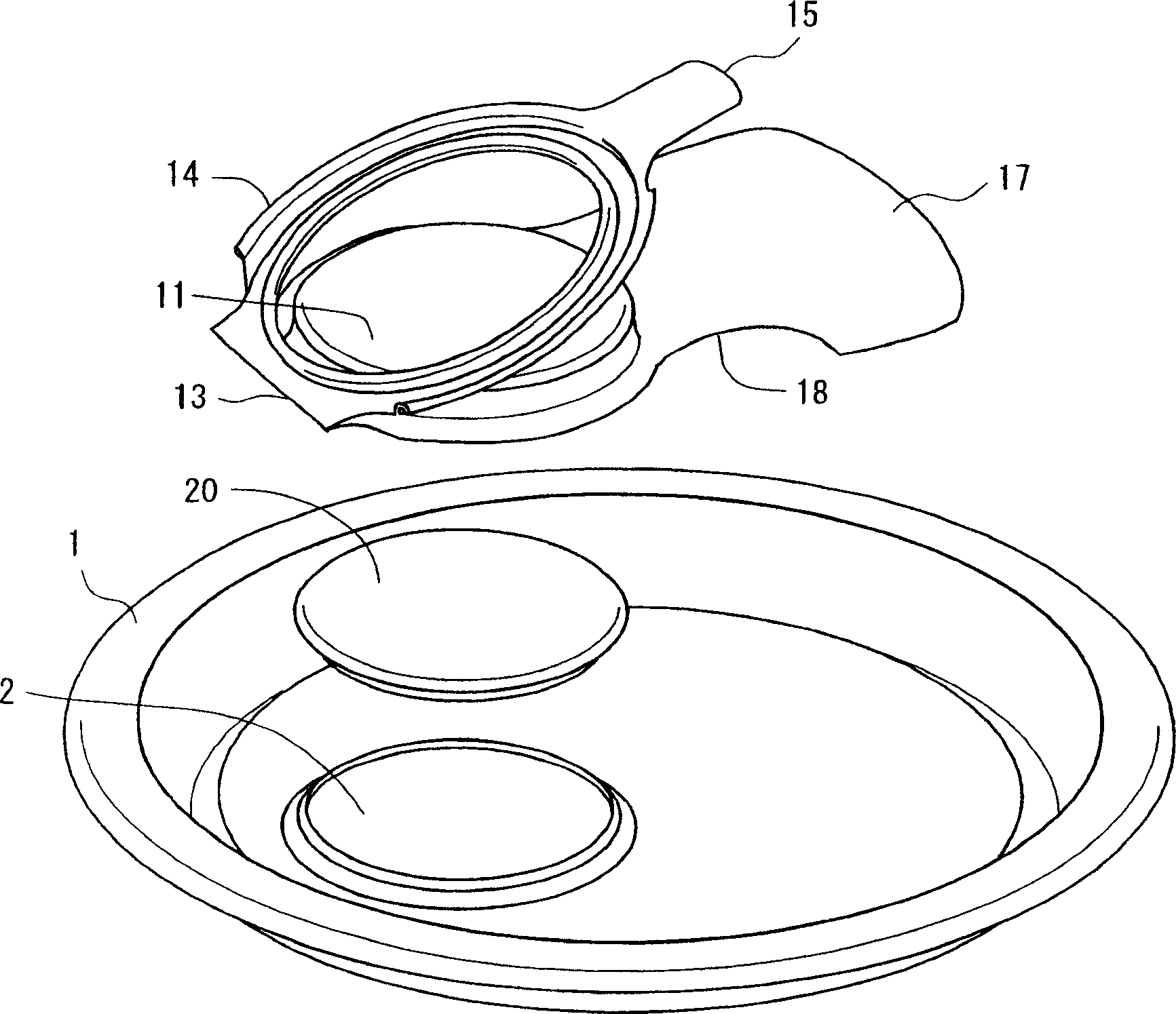

Easily openable container lid with resealability and method of producing the same

InactiveCN1764576AEasy to openImproves resealabilityClosuresClosure using stoppersAdhesiveEngineering

The present invention relates to an easy-open container cap comprising: a cap member having a preformed opening; With a pull tab, the pull tab for unsealing includes a flexible pull tab member and a plug member that is formed to be bonded to the pull tab member and can be fitted with the opening of the aforementioned cover member, and the aforementioned flexible pull tab The member is releasably attached and fixed to the opening peripheral portion of the cover member. Therefore, there is an advantage that good effects can be obtained, that is, having resealability, that is, the temporary reseal that temporarily closes the opening once unsealed can be repeatedly performed, and has good resealability when the sealability and unsealability are good. Indication function, easy opening, etc.

Owner:TOYO SEIKAN KAISHA LTD

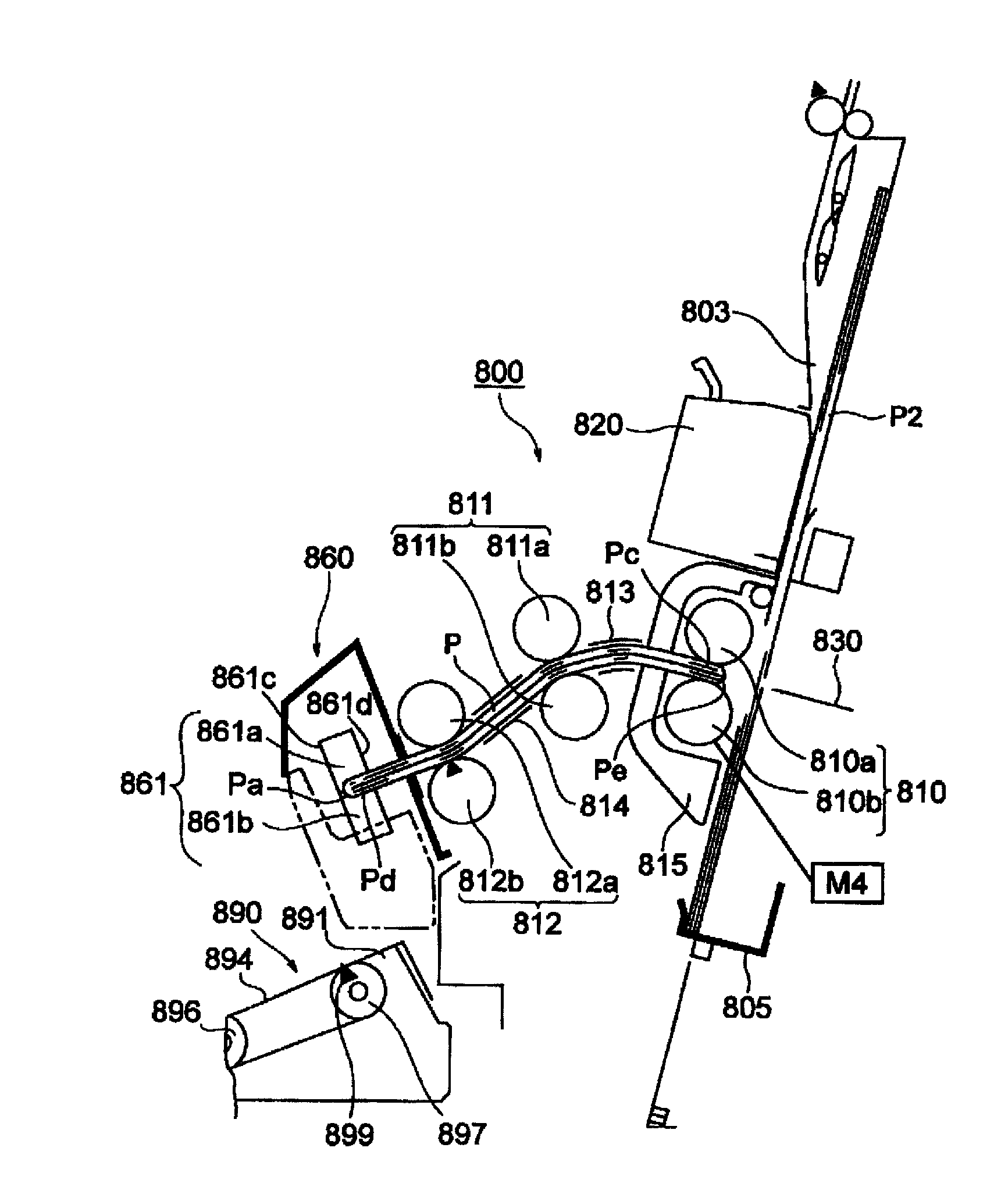

Sheet processing apparatus and image forming device having the same

ActiveUS7802779B2Improve stacking effectPreventing numberMechanical working/deformationFolding thin materialsIntermittent motionEngineering

Owner:CANON KK

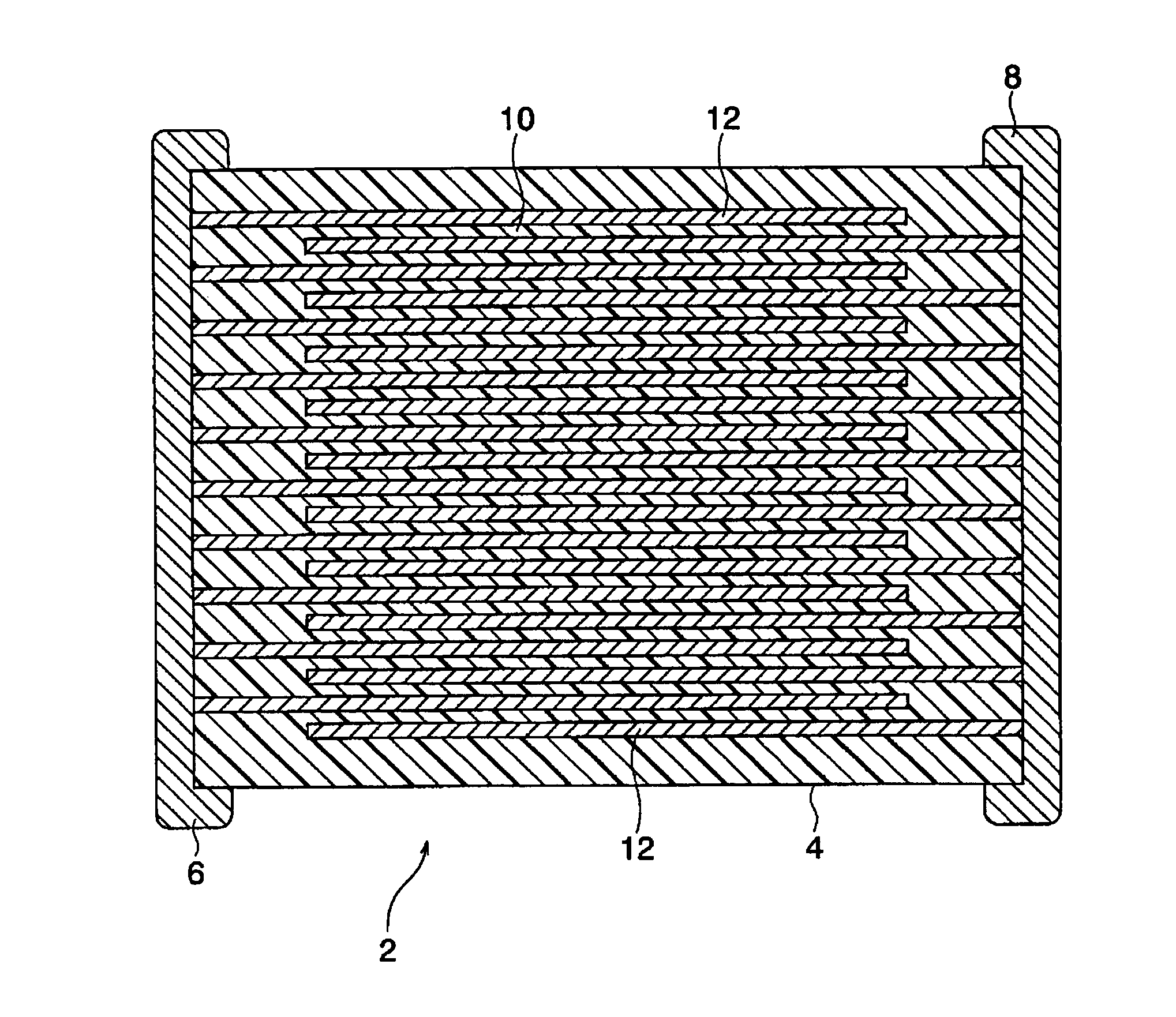

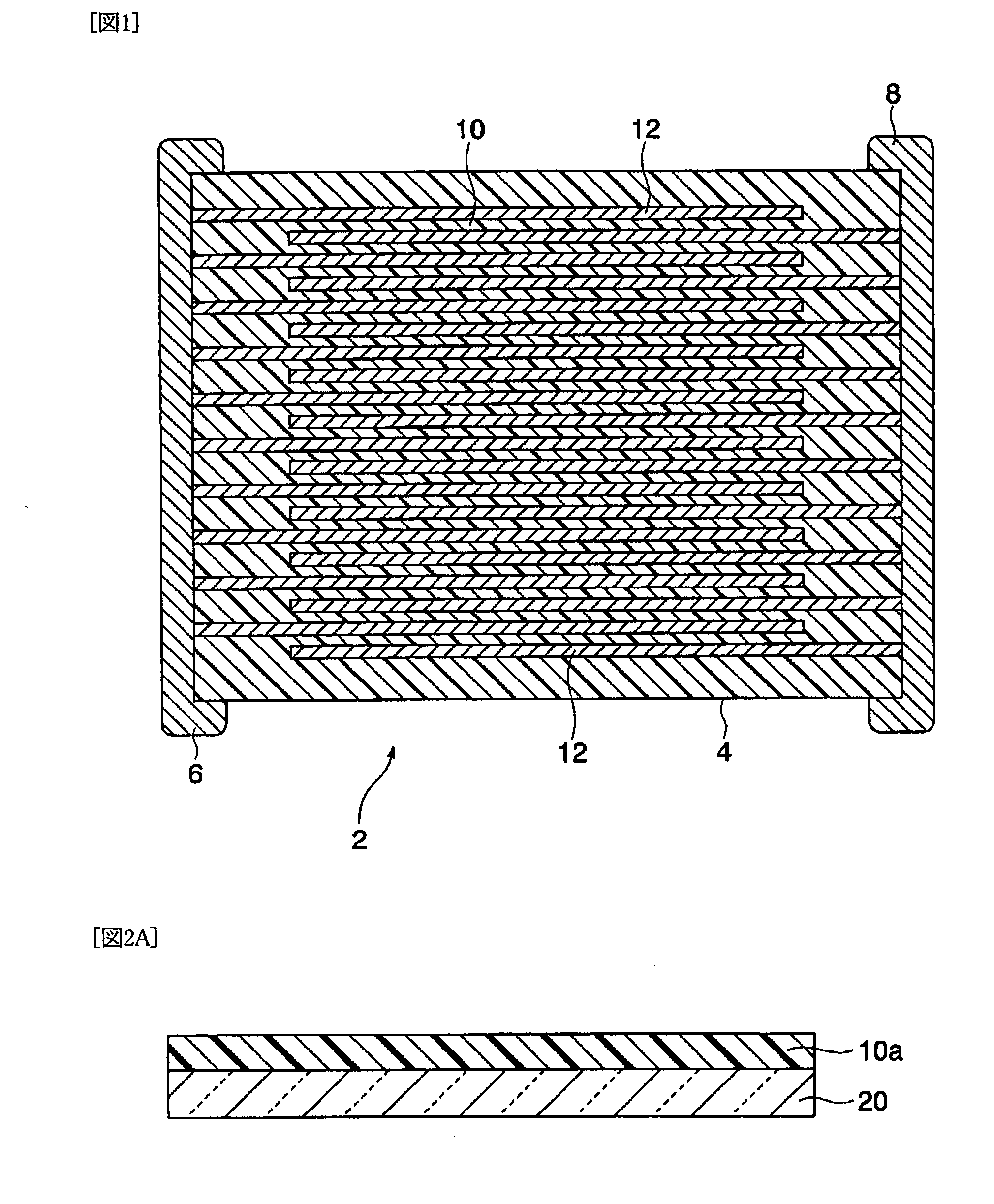

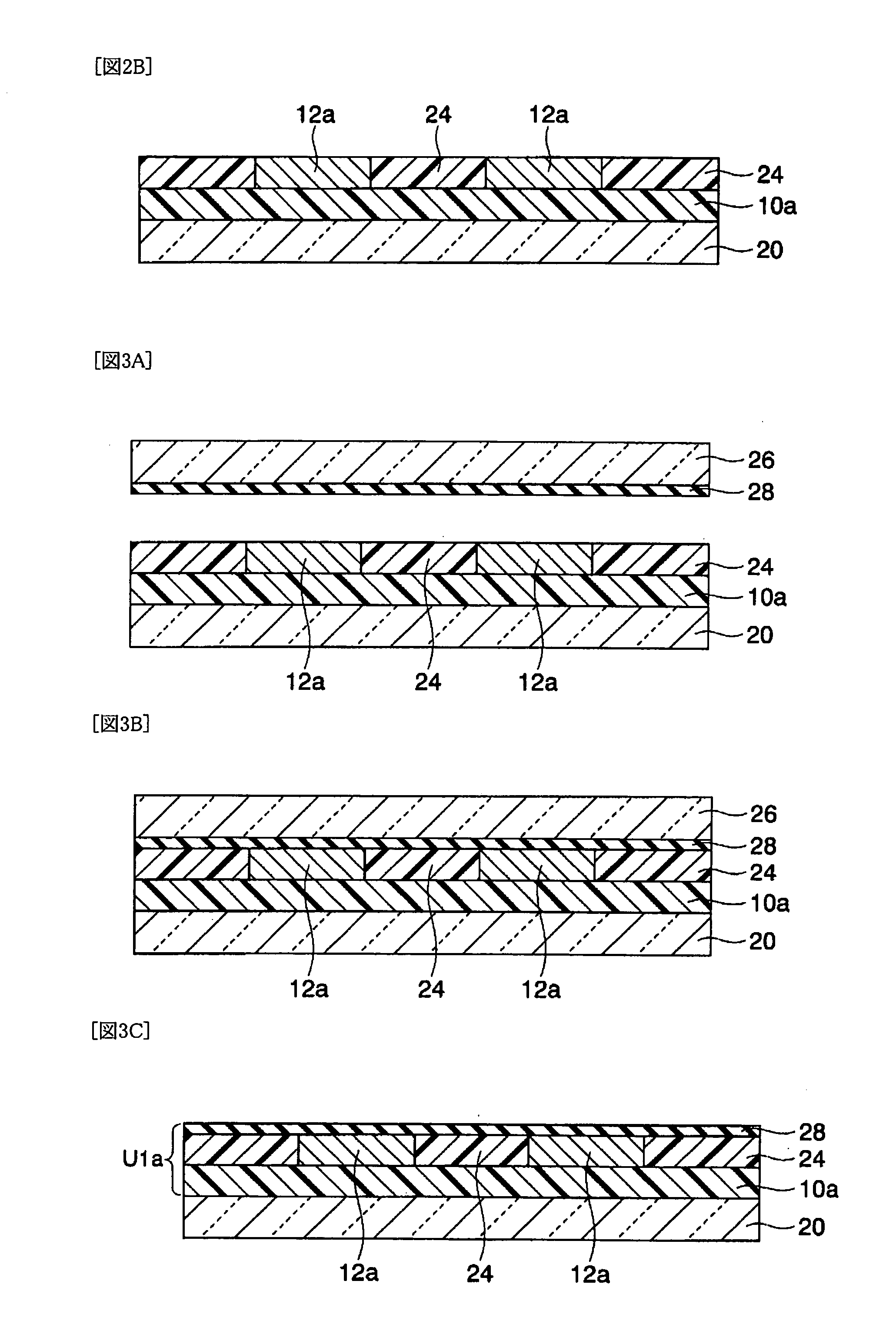

Production Method of Multilayer Electronic Device

InactiveUS20080053593A1Improve stacking effectReduce defective rateStacked capacitorsOptoelectronicsElectrode

A production method of a multilayer electronic device, comprising the steps of forming a green sheet 10a; forming an electrode layer 12a on a surface of the green sheet 10a; stacking the green sheets 10a, each having the electrode layer 12a thereon, to form a green chip; and firing the green chip: wherein before stacking the green sheet 10a having the electrode layer 12a formed thereon, an adhesive layer 28 is formed on a surface on the electrode layer side of the green sheet 10a having the electrode layer 12a formed thereon; and the green sheet 10a having the electrode layer 12a formed thereon is stacked via the adhesive layer 28.

Owner:TDK CORPARATION

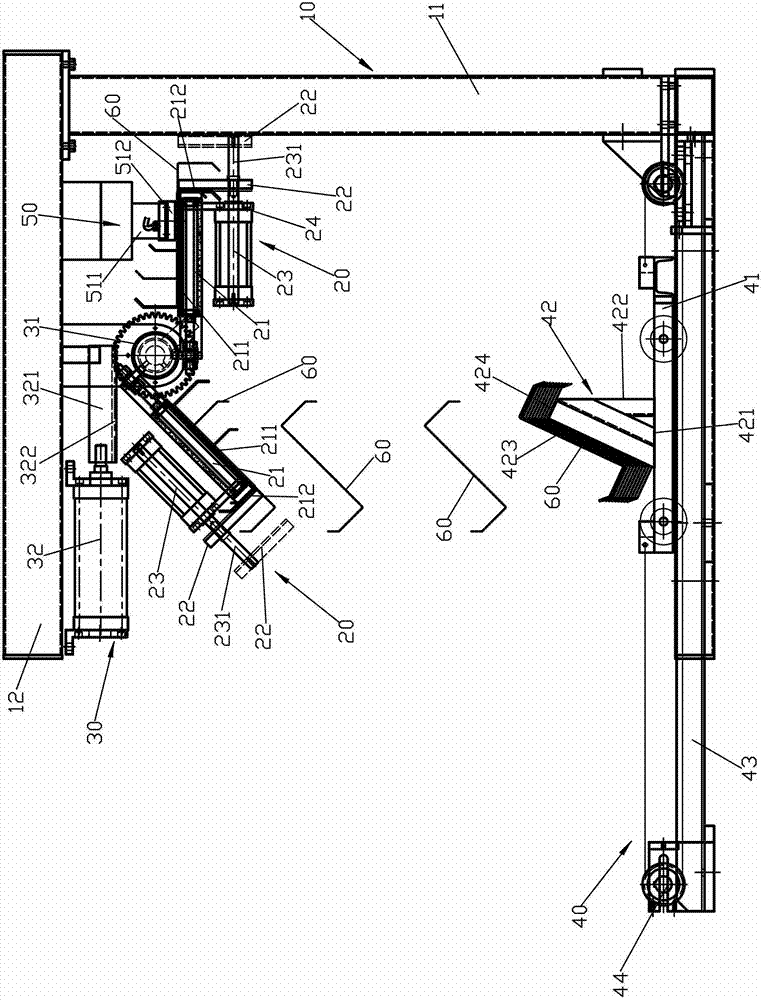

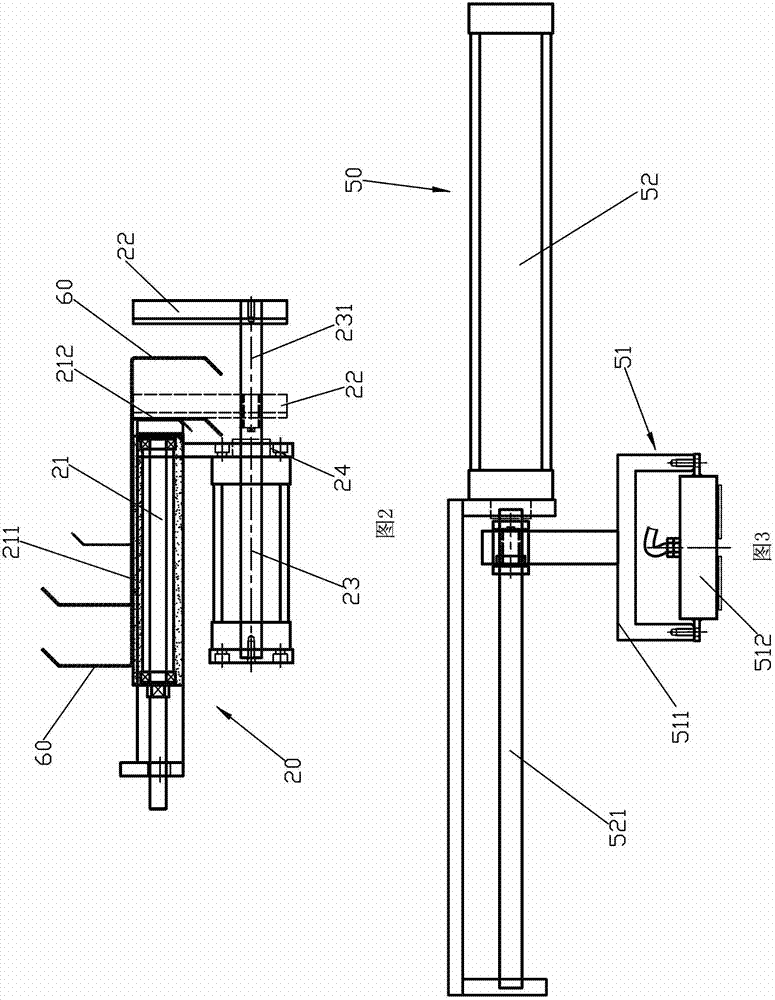

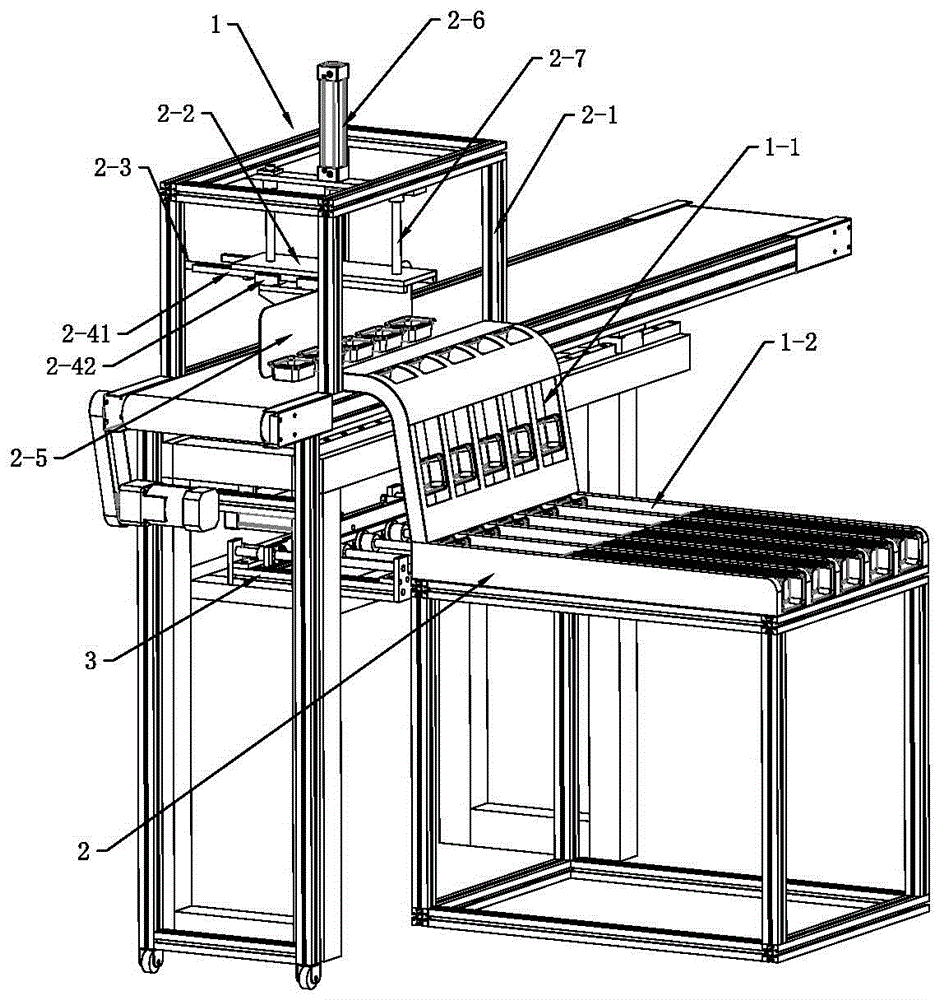

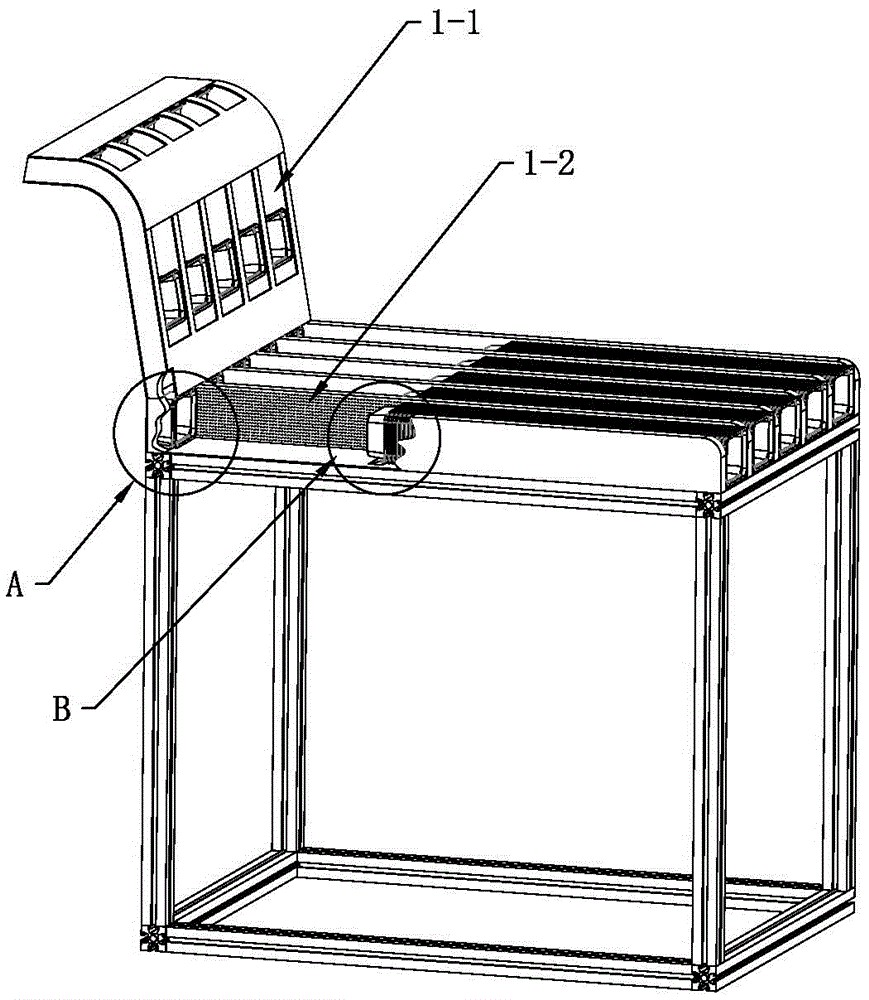

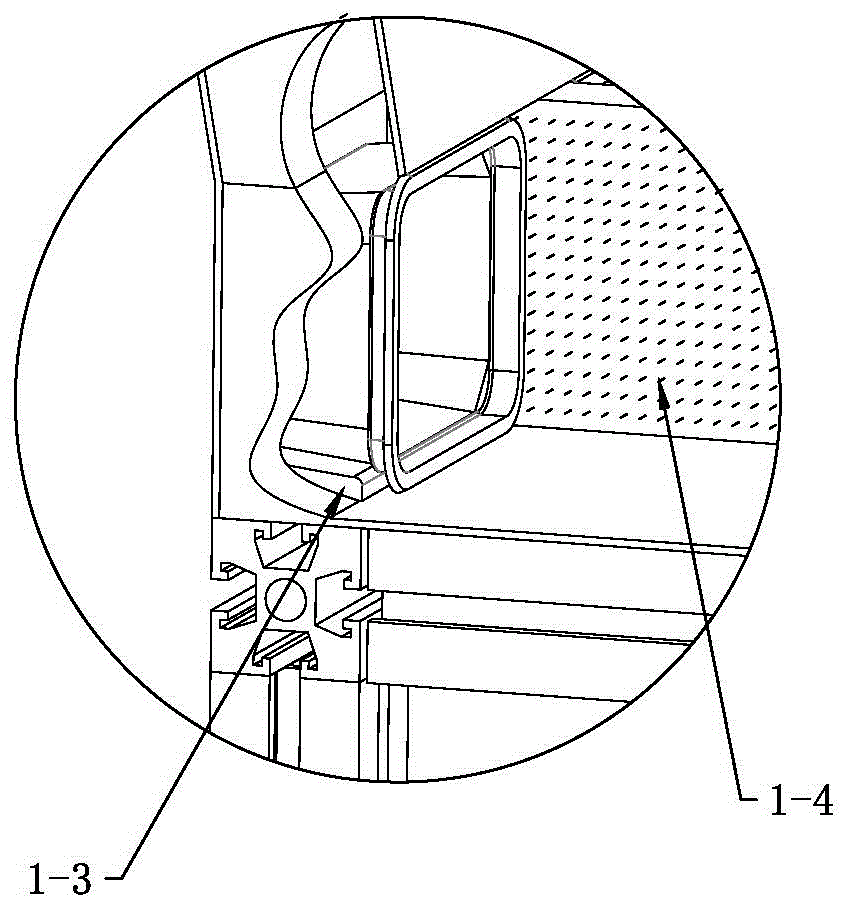

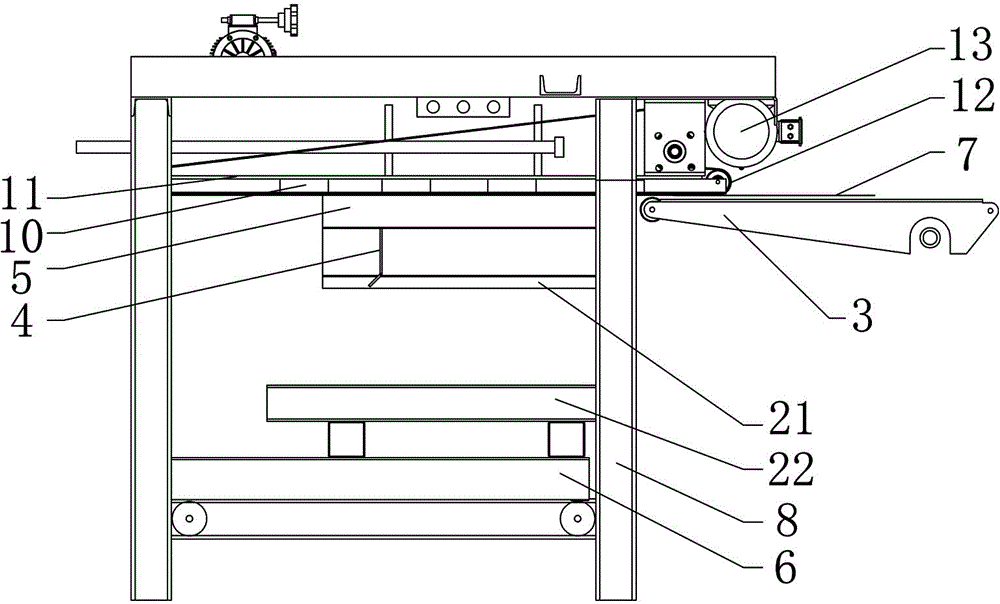

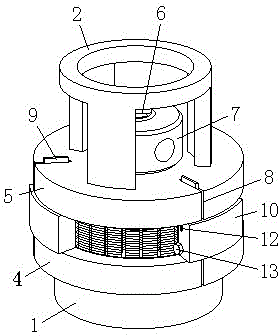

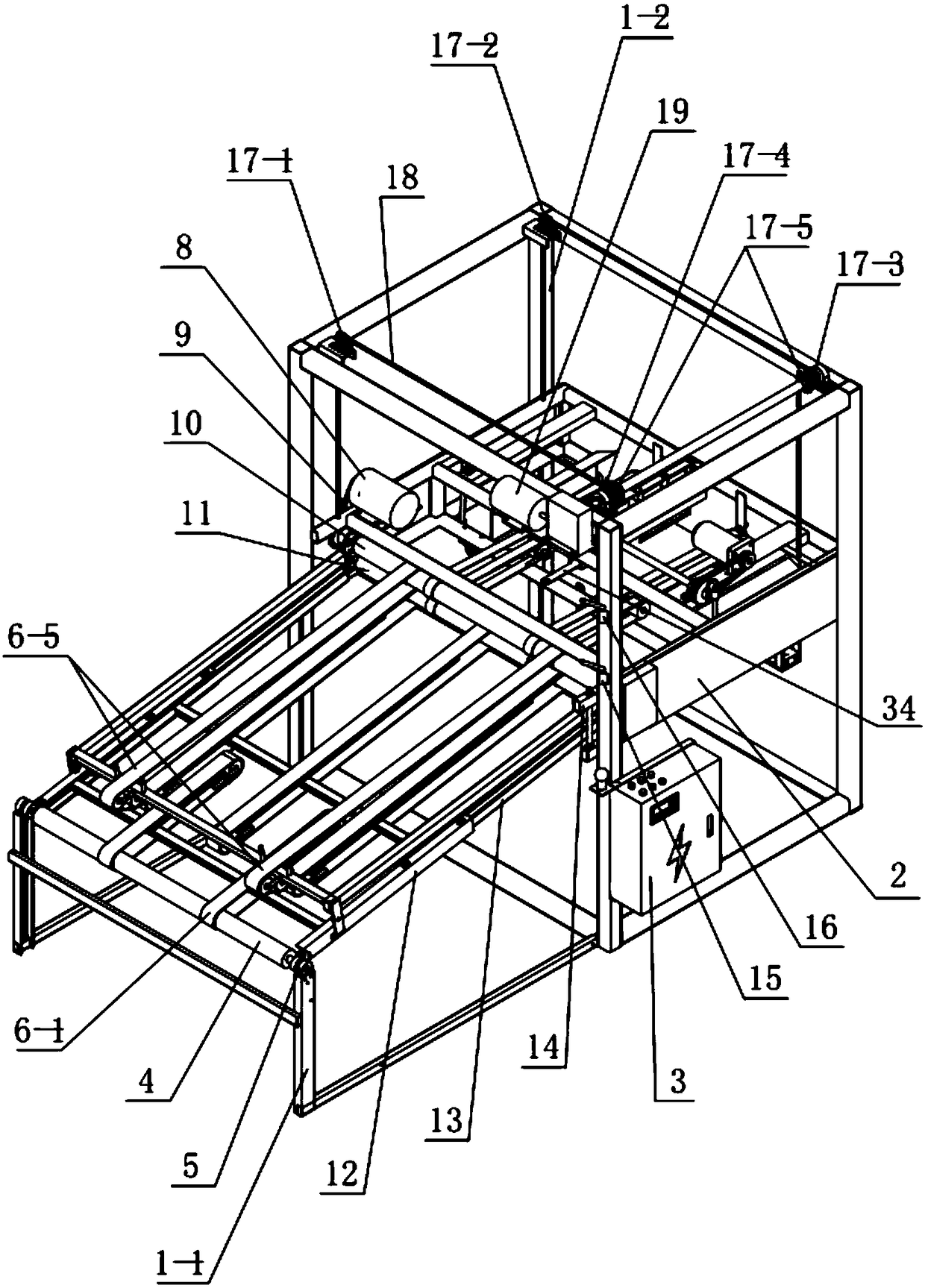

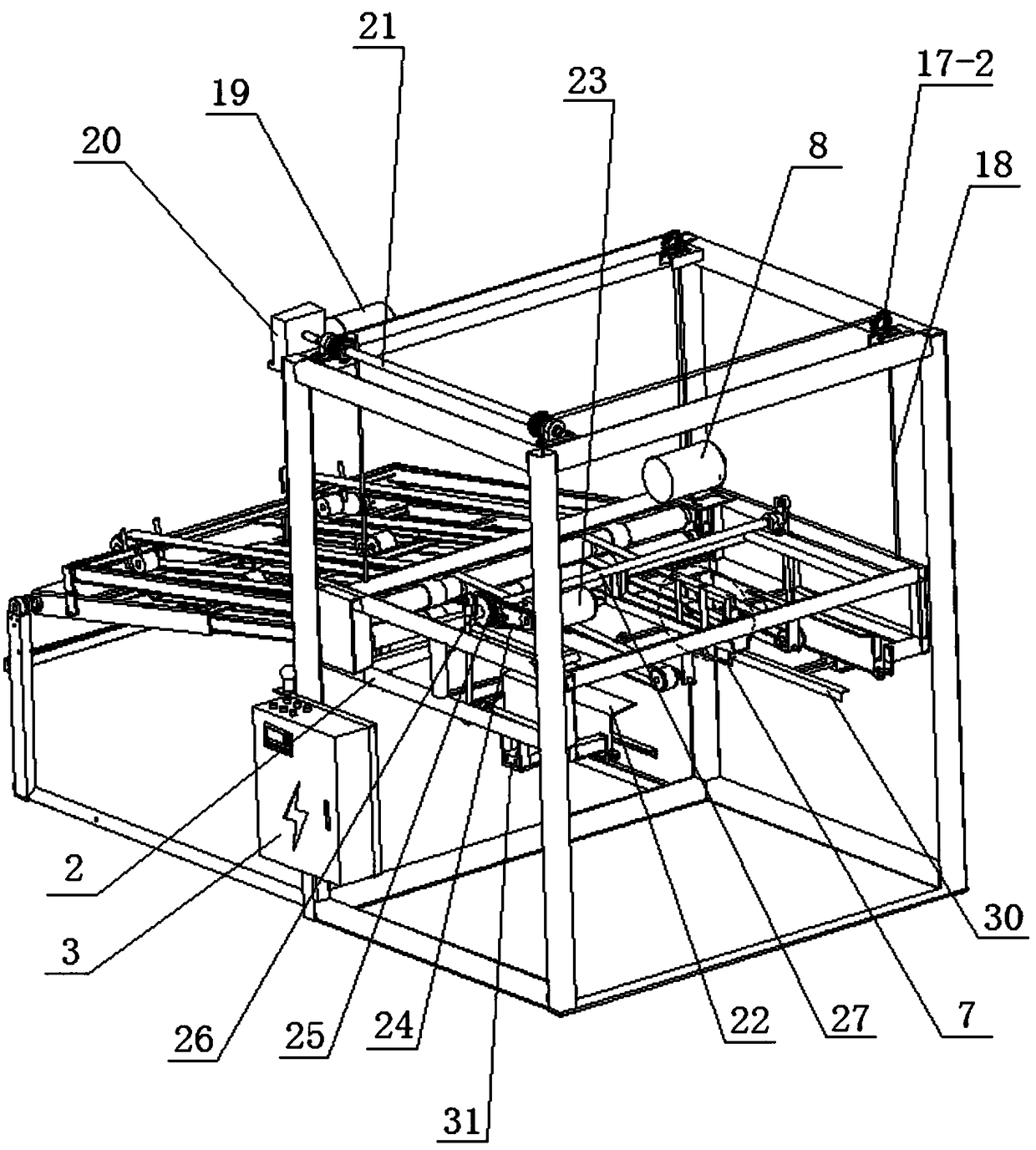

Z-steel stacking equipment

ActiveCN102862824AIncrease productivityEasy to produceStacking articlesEngineeringMechanical engineering

The invention discloses Z-steel stacking equipment, comprising a machine frame 10, a clamping device 20, a rotary device 30 and a stacking platform device 40. The clamping device 20 comprises a workbench 21, a clamping base 22 and a clamping power device 23, wherein the clamping power device 23 is connected with the clamping base 22 in a transmission manner to drive the clamping base 22 to move between a releasing position and a clamping position in a manner relative to the workbench 21. The rotary device 30 comprises a rotary base 31 and a rotary power device 32, the workbench 21 is fixedly connected with the rotary base 31, the rotary power device 32 is connected with the rotary base 31 in a transmission manner to drive the rotary base 31 and the workbench 21 to rotate between a feeding position and a discharge position in a manner relative to the machine frame 10. The stacking platform device 40 comprises a stacking platform 41, and the clamping device 20 arranged at the discharge position is positioned above the stacking platform 41. The Z-steel stacking equipment has the following advantages: automatic stacking is realized, and the production efficiency is high; the production flow is simplified, and the packaging in the next stage is facilitated; the stacking effect is good, and the artificial finishing is not needed; and the equipment structure is simple, and the cost is low.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

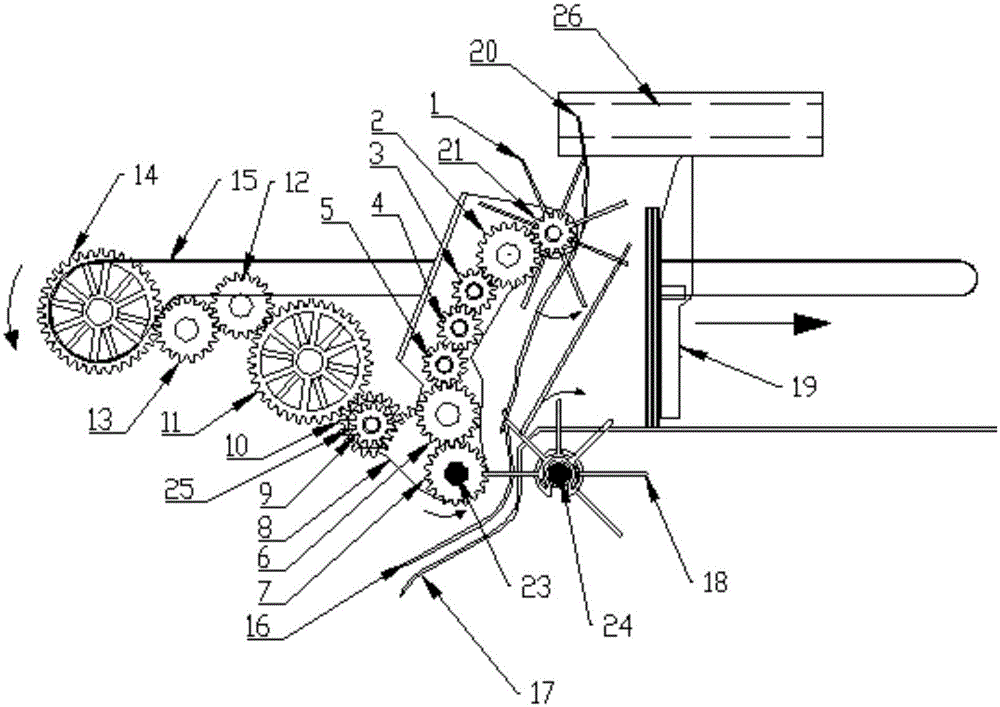

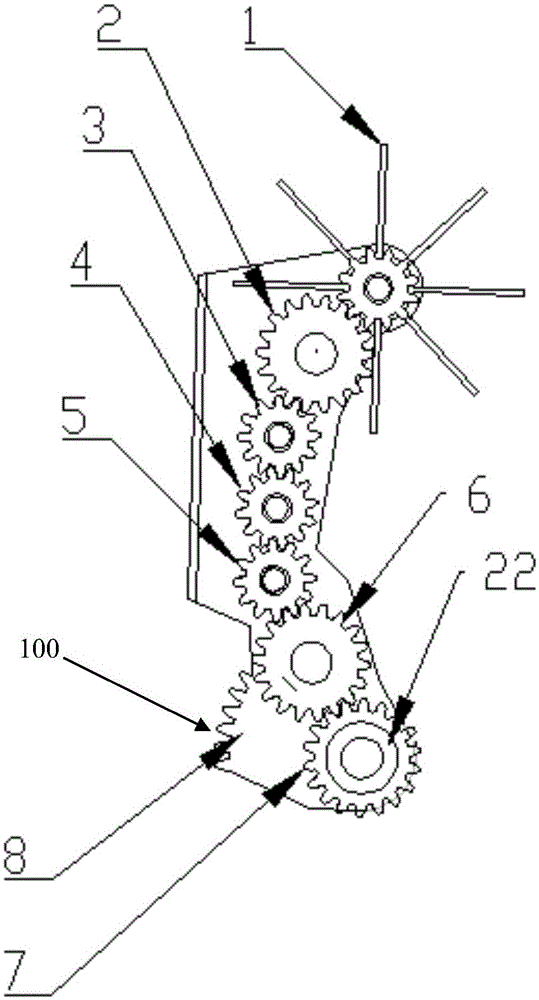

Bill stacking device of finance equipment terminal

The invention discloses a bill stacking device of a finance equipment terminal. The bill stacking device comprises a bill friction assembly, a separating assembly, a bill pressing plate and a bill pressing plate driving mechanism. The bill stacking device is characterized in that the bill stacking device further comprises an auxiliary bill stacking assembly; and the auxiliary bill stacking assembly comprises a driving support arranged in a swinging manner, a front limiting block and a rear limiting block which are arranged corresponding to the driving support and used for limiting the swinging amplitude, a swing linkage mechanism in transmission connection with the driving support and the bill pressing plate driving mechanism, and an auxiliary bill friction blade which is rotationally arranged on the driving support and is in transmission connection with the bill friction assembly through a friction driving mechanism. According to the invention, one dual-station auxiliary bill friction blade is arranged, the auxiliary bill friction blade and a bill toggle blade are utilized to simultaneously to toggle a bill so as to force the bill to move towards the bill pressing plate, and the upper part and the lower part of the bill are stressed at the same time, so that the fill is stressed uniformly, and the stacking effect is substantially improved.

Owner:CASHWAY FINTECH CO LTD

Sheet feeding device and image forming apparatus

InactiveCN1865104AReduce workloadReduce volumePile receiversArticle separationImage formationMechanical engineering

A paper conveying device includes a cassette-type paper storage unit that can be attached to or detached from an image forming apparatus main body in a state where paper is stored. Among them, the paper storage part has a main storage part and a sub storage part composed of a plurality of papers of different types and sizes at the same time. Paper can be conveyed from the sub storage unit in a state where the paper storage unit is attached to the main body of the image forming apparatus. In inkjet printers, etc., in order to reduce the burden on the user when replacing paper, especially for paper that is prone to curling such as postcards, the necessary space is ensured even if the drop to the loading surface of the paper discharge tray is not considered as a curled portion. Stack up space. Therefore, it is easy to adopt such a device as a low-cost model for general consumers, which suppresses the increase in size and manufacturing cost of the device.

Owner:CANON KK

Material pushing and stacking device

InactiveCN106429466APlay the role of slowing down and stoppingEasy and smooth nestingStacking articlesStack effectAutomation

The invention discloses a material pushing and stacking device. The material pushing and stacking device comprises a stacking device, a pushing mechanism and a push rod device. A stacking channel of the stacking device comprises a slide channel and a stacking and pushing channel. The pushing mechanism pushes cup materials into a feeding inlet of the slide channel. The cup materials can creep down along the slide channel under the gravity action of the cup materials and then fall into the stacking and pushing channel from a material falling opening of the slide channel. A push rod of the push rod device pushes the cup materials to advance, and the cup materials are stopped and clamped onto a rim lug. On one hand, the rim lug plays the effect of decelerating and stopping the cup materials; and on the other hand, the bottom of each cup material can be cushioned up so that the next cup material can be stacked smoothly. Compared with the prior art, the material pushing and stacking device has the following main beneficial effects that the degree of automation is high, and human resource cost is reduced; the stacking effect is good, the cup materials are stacked, and meanwhile the entire stacked cup materials can be pushed; and the cup materials can be pushed and stacked at the same time, and thus efficiency is greatly improved.

Owner:GUANGDONG LONGXING PACKAGING IND

Magnetic belt type automatic plate stacker

The invention discloses a magnetic belt type automatic plate stacker, which comprises a frame and an electromagnetic belt assembly arranged on the top of the frame, wherein the electromagnetic belt assembly comprises an electromagnet-mounting frame, a conveyer belt and a motor, a plurality of electromagnets are regularly mounted on the electromagnet-mounting frame, the upper end surfaces of the electromagnets are mounting surfaces, the lower end surfaces of the electromagnets are attracting surfaces and are in direct contact with the conveyer belt, the conveyer belt conveys steel plates under the drive of the motor and the effect of the attracting force of the electromagnets upon the conveyer belt, and an automatic stacking assembly is arranged under the electromagnetic belt assembly. The magnetic belt type automatic plate stacker disclosed by the invention is used for small steel plates after a steel coil is cut into pieces, the range of the sizes of steel plates capable of being stacked by the equipment is wide, moreover, the magnetic belt type automatic plate stacker is easy and convenient to operate, the stacking quality is good, and plate surfaces do not have any damage.

Owner:珠海拾比佰彩图板股份有限公司

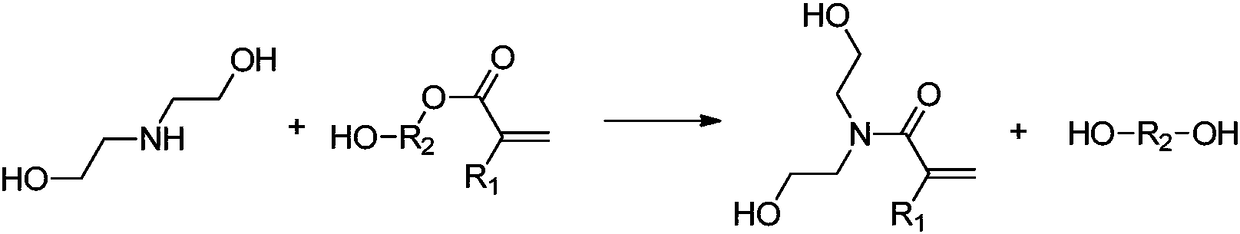

Cement grinding aid and preparation method thereof

The invention relates to the technical field of cement additives, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid comprises an amide compound and a polyol compound. The preparation method includes: mixing and stirring diethanol amine and acrylate derivatives to perform ester aminolysis reaction so as to obtain the cement grinding aid. The cement grinding aid is capable of satisfying the standard requirements of the cement grinding aids, excellent in grinding aiding effect and quality stability, capable of increasing compressive strength and capable of being used along with an existing cement grinding aid to improve the quality stability of the existing cement grinding aid and increase the grinding aiding effect.

Owner:北京金隅节能科技有限公司 +1

Coating equipment

ActiveCN107983578AAvoid wrinklesEfficient removalLiquid surface applicatorsSpraying apparatusEngineeringSteel ball

The invention belongs to the technology for coating surfaces of objects through liquid or other fluid, and particularly relates to coating equipment. The coating equipment comprises a rack, a smoothening part, a bonding part, a cleaning part and a transmission mechanism, the rack is sequentially provided with a feeding unit, a bonding unit, a drying unit and a discharging unit, the smoothening part comprises a steel ball, a compressed spring and a cam for intermittently hitting the steel ball, the bonding part comprises an upper roller used for grinding base cloth and a lower roller used for supporting transfer paper, the cleaning part comprises a rotary barrel rotationally connected with the rack, the rotary barrel is rotationally provided with a cleaning piece used for cleaning the surface of the upper roller in a connected manner, and the transmission mechanism comprises a motor, a upper roller gear, a lower roller gear, a rotary barrel gear, a driving bevel gear and a driven bevelgear. According to the scheme, folding of the base cloth in the coating process can be effectively prevented.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

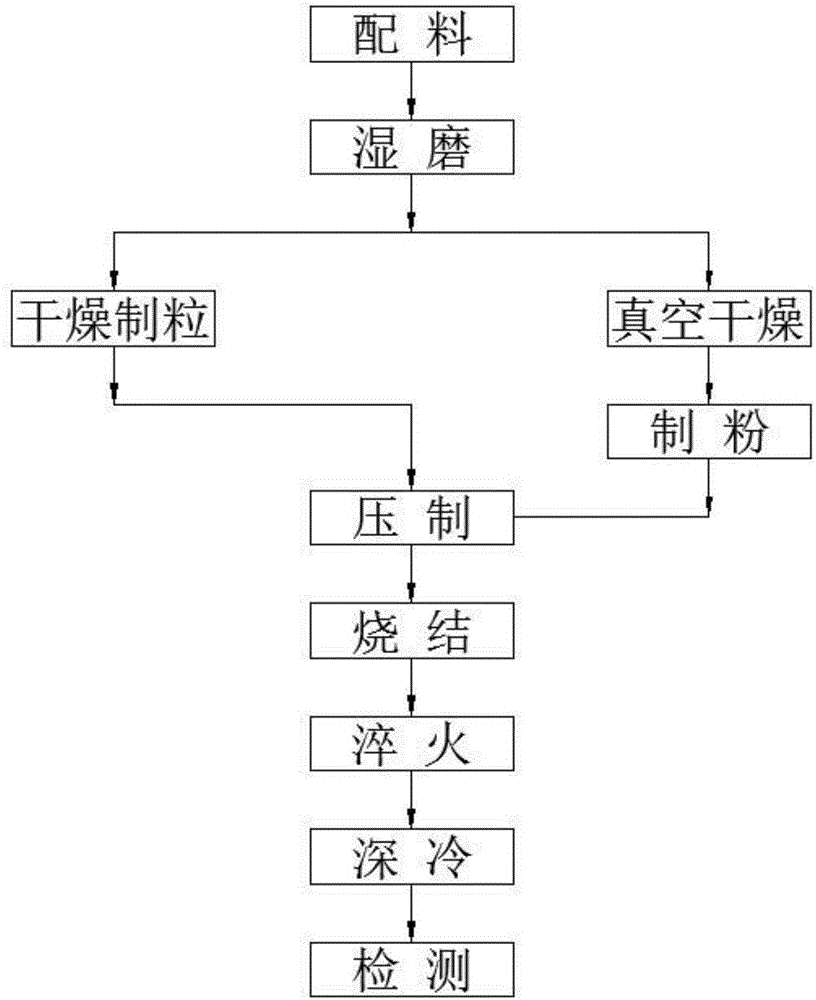

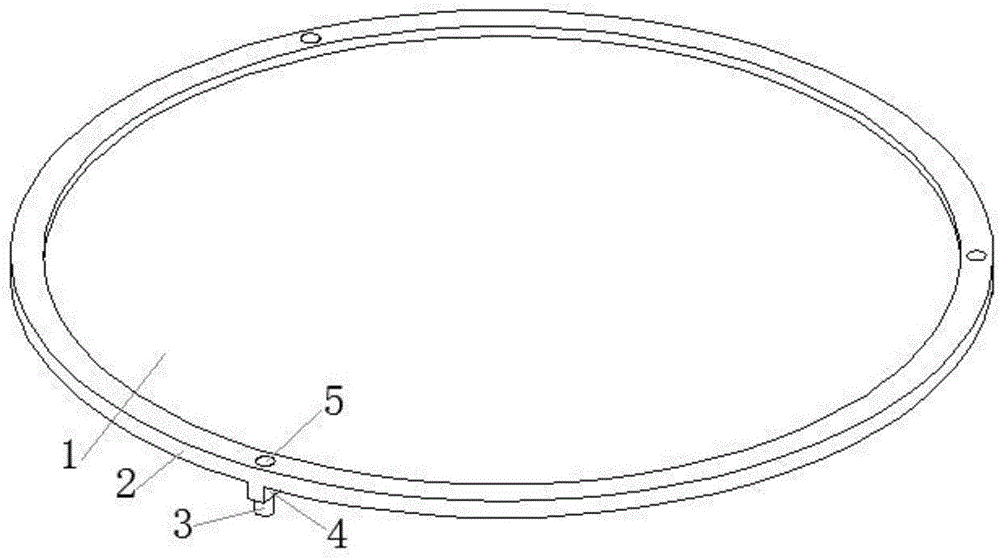

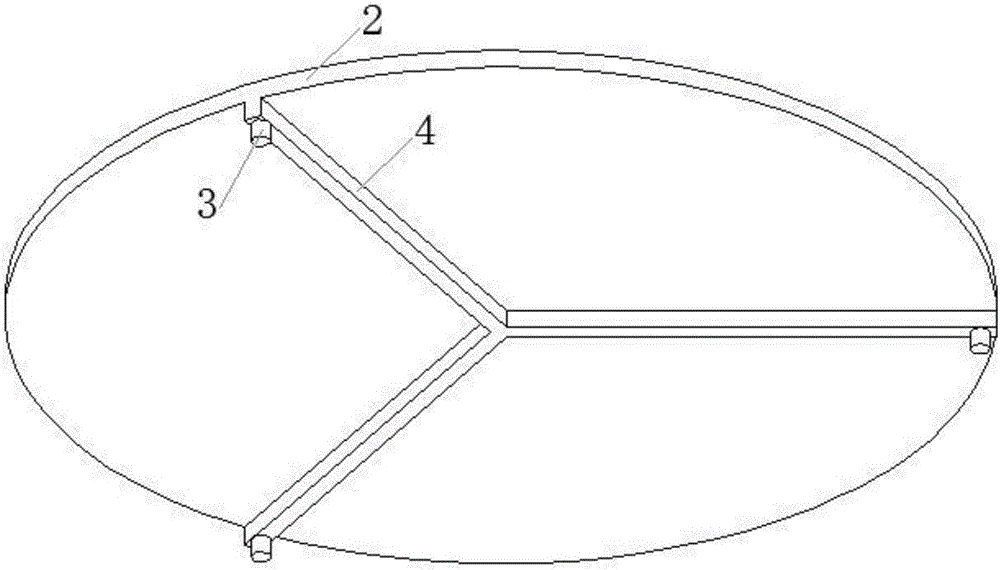

Material for hard alloy slitting tool and preparation method of material

ActiveCN106399794AHigh hardnessExtended service lifeTurbinesOther manufacturing equipments/toolsGraphiteHardness

The invention discloses a material for a hard alloy slitting tool and a preparation of the material. The preparation method comprises the procedures of ingredient proportioning, wet grinding, dry granulation or vacuum dry milling, pressing, sintering, quenching, cryogenic treatment and detection, specifically, Fe-Ni-Co of ingredients is in a binding phase, 5.0%-10% of Tic is added into the ingredients, and the ingredients are subjected to quenching and cryogenic treatment, so that the anti-fatigue performance and toughness of the hard alloy are improved, hardness of the hard alloy is improved, the service life of the tool is prolonged, and production cost can be effectively reduced while the requirement for using performance is met. The invention further discloses a special pressing graphite boat which can effectively reduce strain deformation and improve the stacking effect.

Owner:技锋精密刀具(马鞍山)有限公司

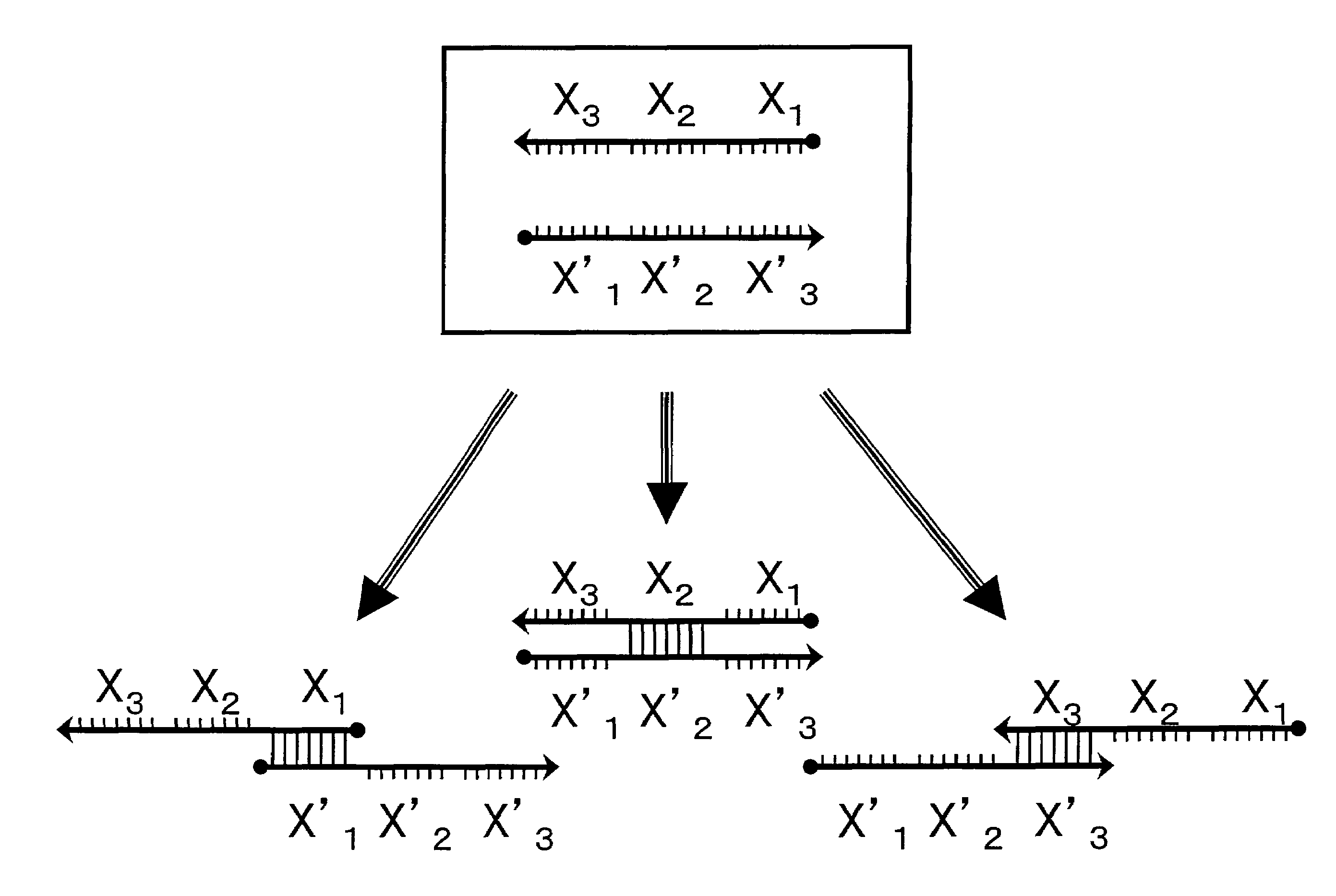

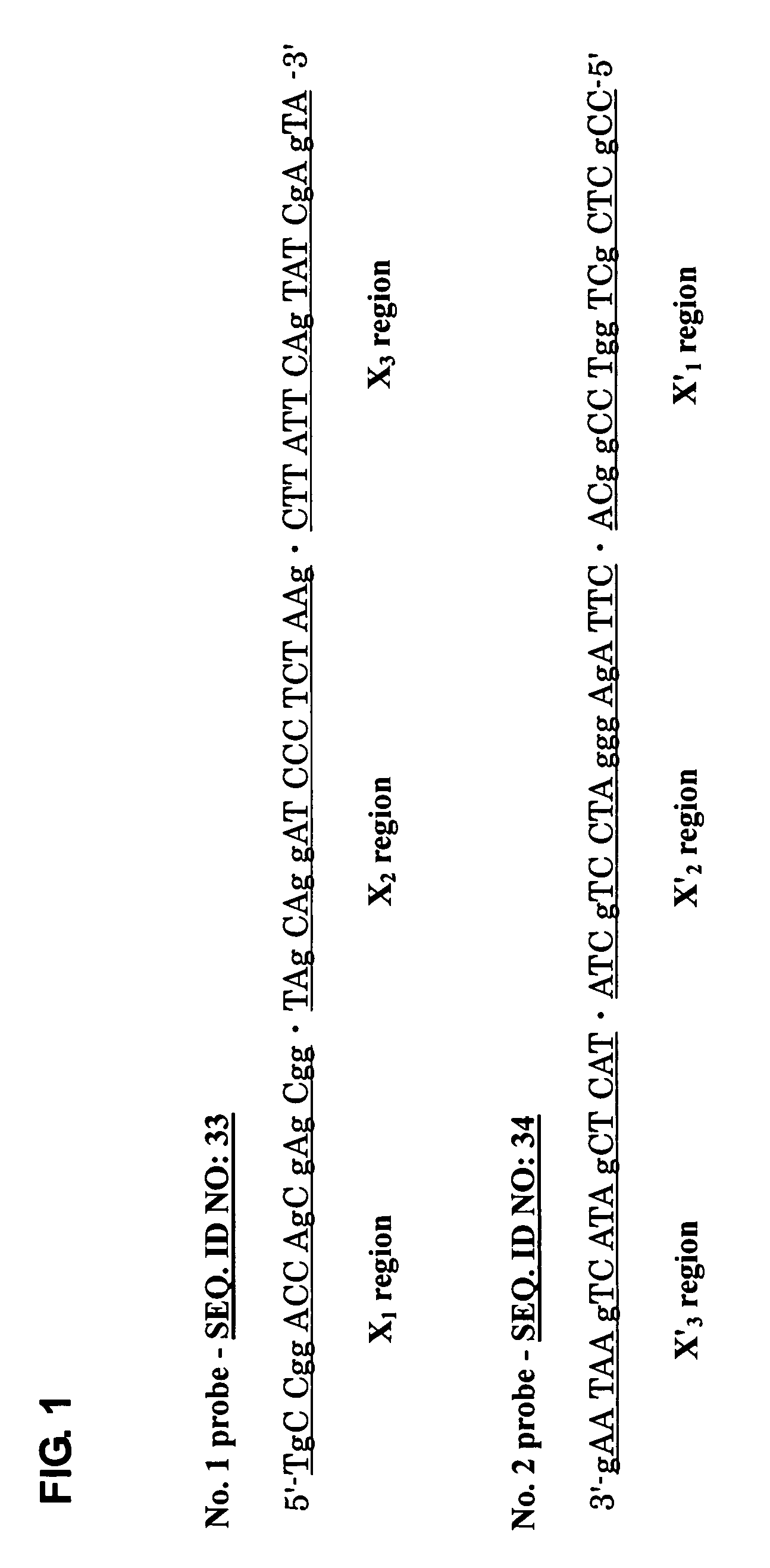

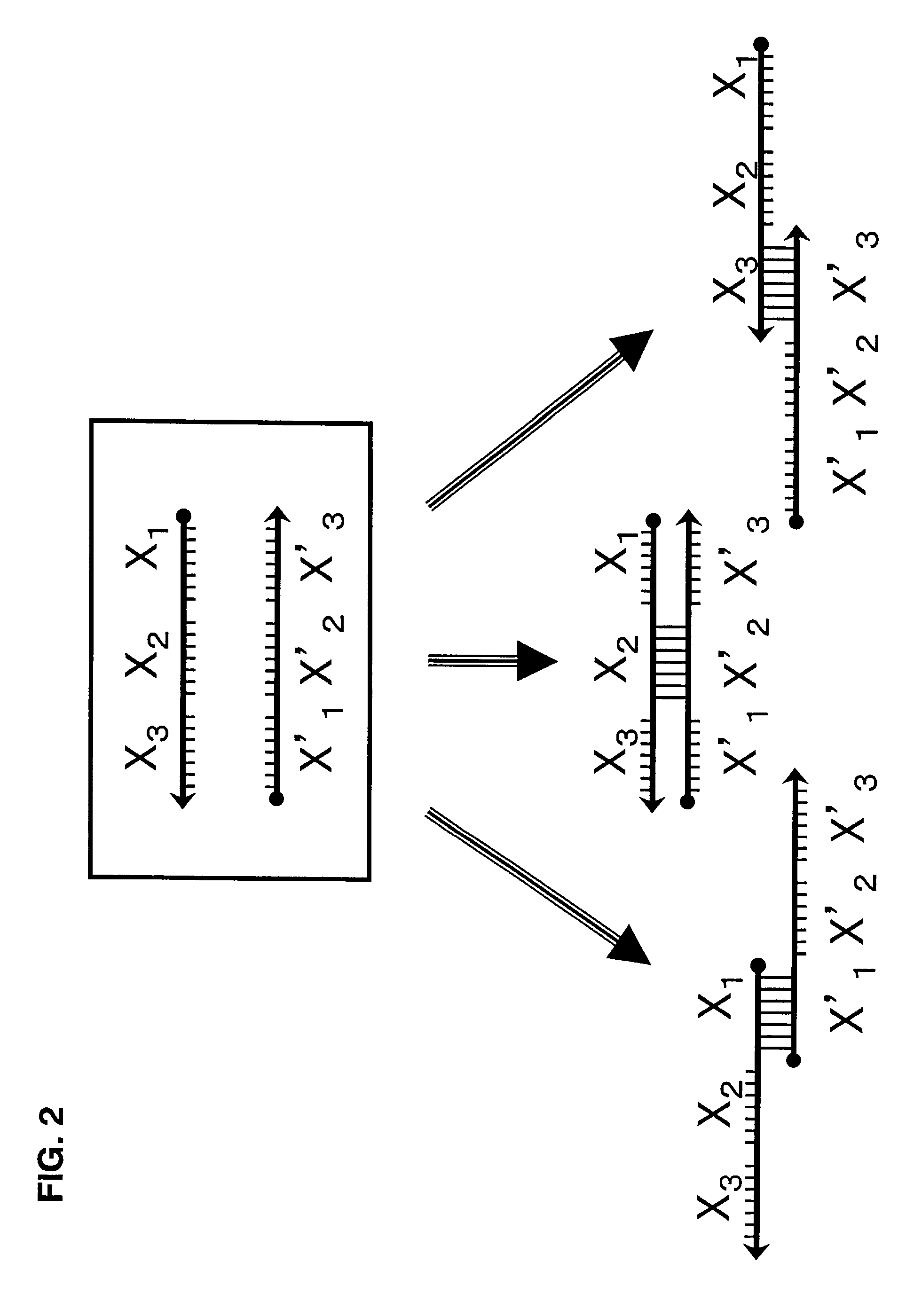

Probe for constructing probe-polymer method of constructing probe-polymer and utilization thereof

InactiveUS7060814B2Well formedImprove stacking effectSugar derivativesMicrobiological testing/measurementCytosineDouble strand

The present invention provides a method for measuring a target gene under isothermal conditions without using enzyme. A pair of probes each having n (n≧3) base sequence regions complementary to each other are hybridized alternately to form a double-stranded probe-polymer. A base pair at branched sites of each complementary base sequence region is designed to be a G (guanine)-C (cytosine) bond, whereby a stable double-stranded probe-polymer is formed. One of complementary portions in one probe is constituted to have a base sequence complementary to a part of a target gene, whereby a target gene-probe-polymer complex is formed and the target gene is measured.

Owner:EIDIA

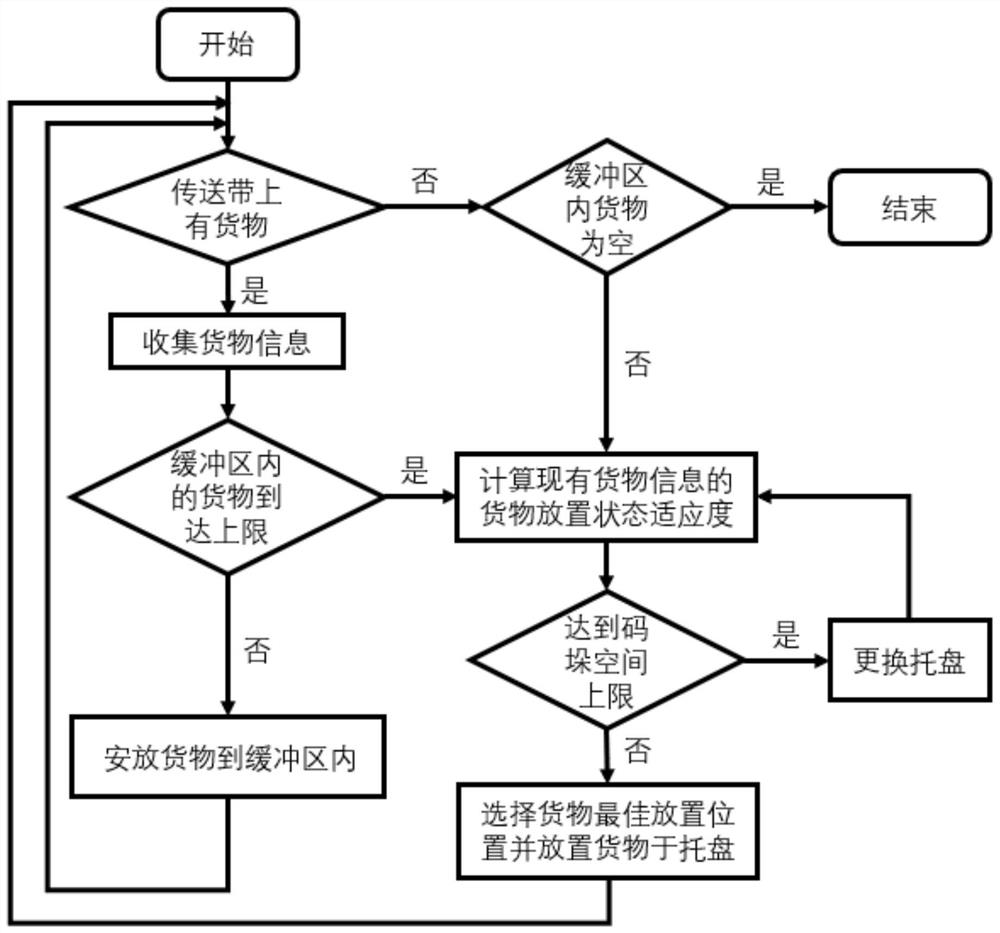

Online mixed stacking method based on buffer area

ActiveCN113222257AReduce production efficiencyImprove space utilizationForecastingStacking articlesStructural engineeringConveyor belt

The invention relates to an online mixed stacking method based on a buffer area. The method comprises the following steps that A, goods on a conveyor belt are sequentially placed in the buffer area, the size information of the goods is collected, and the placing posture of the goods is generated; B, according to the space condition occupied by the placement postures of the cargoes, waste spaces generated by different placement postures of a single cargo and different placement sequences of a plurality of cargoes under different stacking modes when the cargoes are stacked to the tray are calculated, and the waste spaces are gaps between the cargoes and gaps between the cargoes and the tray; C, a stacking method with the least waste space is selected, the cargoes are selected one by one from the buffer area according to the stacking method, and the cargoes are placed into the trays; and D, if the tray space reaches the upper limit, the tray is replaced; and if not, the steps A, B and C are repeated. The stacking time is shortened, and the utilization rate of the stacking space is increased.

Owner:GUANGDONG UNIV OF TECH

Compound sand-suspending agent for slurry filling and preparation method and usage thereof

The invention belongs to the field of coal field fire control engineering and the filling of gobs, abandoned roadways and collapse pits after geological disasters and the mining of coal mines and thelike, and particularly relates to a compound sand-suspending agent for slurry filling and a preparation method and usage thereof. The compound sand-suspending agent is prepared from the following components: 45 to 70 percent of bentonite (sodium-based), 25 to 40 percent of vegetable gum, 2 to 8 percent of cellulose, 0.3 to 3 percent of sodium polyacrylate, 0.3 to 3 percent of polyacrylamide, 0.05to 2 percent of sodium dodecylbenzene sulfonate, 0.5 to 2 percent of hydrous magnesium silicate, 0.2 to 1 percent of calcium hydroxide, 0.5 to 2 percent of calcium sulphate and 0.5 to 5 percent of sodium bicarbonate, and all the percentages are percentages by weight. The invention further discloses the preparation method and usage of the compound sand-suspending agent for slurry filling. The invention mainly achieves the objective that after sand-fly ash slurry filling material is mixed with water and a small amount of sand-suspending agent, long-distance pipeline or borehole transport is realized, the sand slurry is prevented from depositing to block a pipeline in the process of transport, and thereby the sand slurry smoothly arrives at a space to be filled and realizes fracture sealing,temperature decreasing and fire extinguishment, safety and high efficiency and fire zone reburning prevention.

Owner:新疆维吾尔自治区煤田灭火工程局 +1

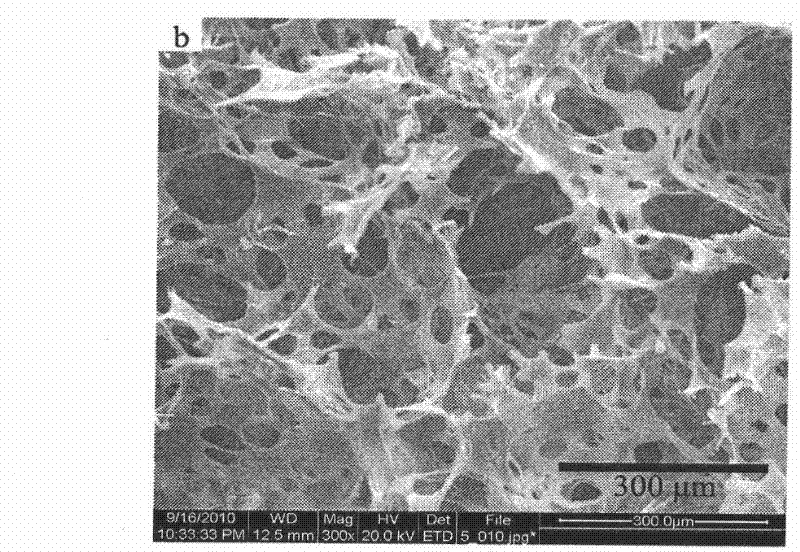

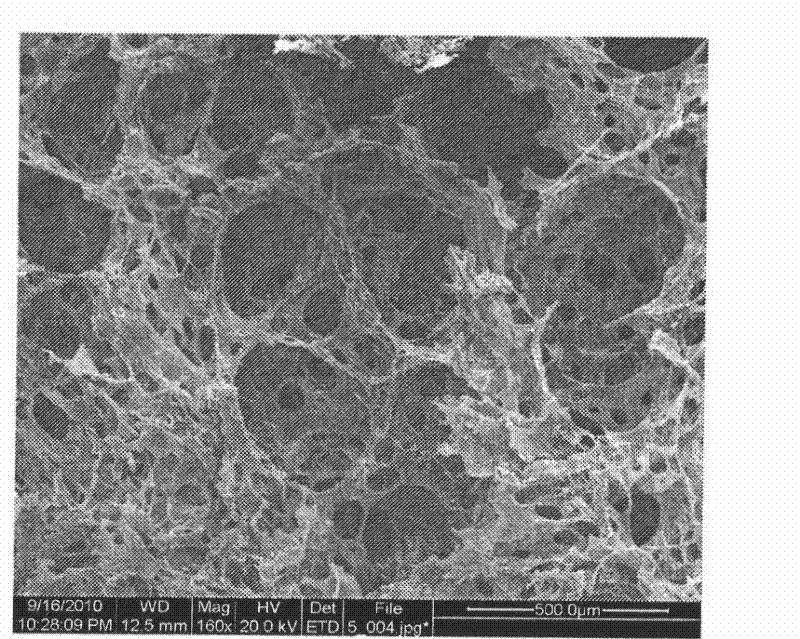

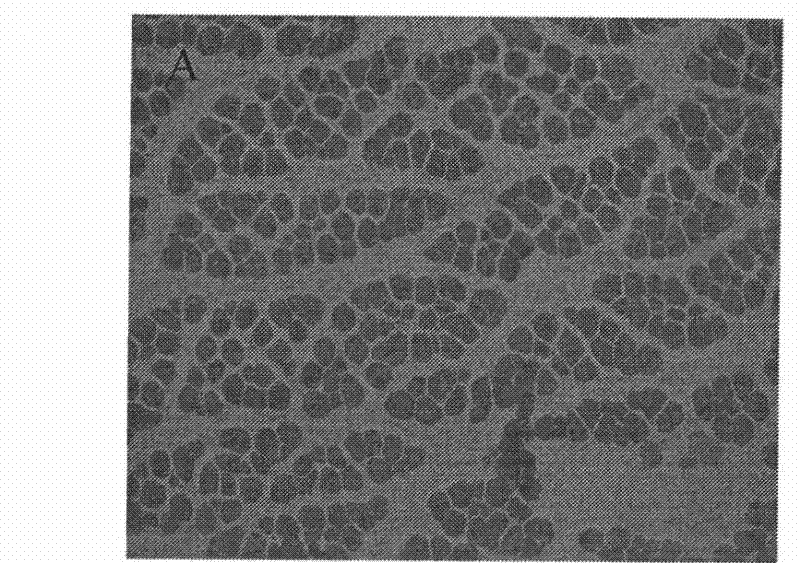

Preparation method of chitosan/hydroxyapatite three-dimensional porous scaffold material

The invention discloses a preparation method of a chitosan / hydroxyapatite three-dimensional porous composite bracket material. Chitosan / hydroxyapatite three-dimensional porous composite brackets of different pore diameters are prepared by taking high-purity SiO2 microspheres with uniform particle sizes and porous surfaces as pore-foaming agents and adjusting the pore space of a porous bracket material in a way of changing the sizes of the SiO2 microspheres based on a solvent pouring-particle leaching technology in combination with an extruding method. Compared with the conventional method forarranging the pore-foaming agents in a close packing way with a bonding agent, the invention has the advantages that: the method is easy and convenient to operate; the pore-foaming agent close packing effect is good; and the prepared porous bracket is free from the residual bonding agent, has high permeability, uniform particle size and higher pore space and compression strength than a pure chitosan porous bracket. As proved by a test result, the bracket has high in-vitro and in-vivo biological compatibility.

Owner:SHAANXI NORMAL UNIV

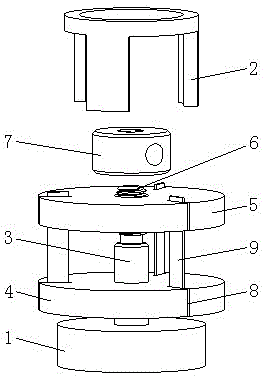

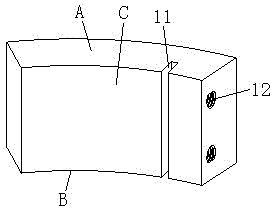

Method for guaranteeing stack mounting precision of straight-slot iron cores of motor and stack mounting die employed in method

InactiveCN104659979AIncrease stiffnessImprove stack qualityManufacturing stator/rotor bodiesElectric machineryProcessing accuracy

The invention discloses a method for guaranteeing the stack mounting precision of straight-slot iron cores of a motor and a stack mounting die employed in the method. According to the method, at least three key boards are adopted for performing positioning during stack mounting of the iron cores, so that the concentricity of the iron cores are improved; limiting blocks are clamped on the key boards between an upper pressure plate and a lower pressure plate, bending deformation of the key boards is limited through clamping grooves of the limiting blocks, and the verticality between the key boards and positioning surfaces of the upper pressure plate and the lower pressure plate is guaranteed through the processing precision of two end surfaces of each of the clamping grooves and the limiting blocks. The method is high in stack mounting efficiency; stacked layers of iron core stamping sheets are regular in a stack mounting process and unlikely to deform, so that the motor quality can be remarkably improved.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Automatic palletizing machine

PendingCN109095191AAccurate OverlayAccurately undertakeConveyorsStacking articlesDrive shaftEngineering

The invention discloses an automatic palletizing machine. The automatic palletizing machine is provided with a board receiving mechanism mainly composed of a board receiving device, a downward pressing device and temporary board receiving devices symmetrically arranged on two sides of the output end of a conveying mechanism. When the machine is in work, a transmission shaft is driven to rotate bya third driving device, so that a crank connection rod component connected with a rotation shaft drives clamping boards to do reciprocating actions of opening or closing, and thus a board can be accurately clamped, meanwhile the arranged downwards pressing device presses downwards, the board is effectively pressed down and palletized, and the board is prevented from blocking the machine. Therefore, the board receiving mechanism adopted by the invention can accurately carry and effectively level the boards, automatically and orderly palletize the boards, and also can solve the technical problems that the boards cannot be palletized due to the fact that the surfaces of the boards are uneven, and the boards deviates during a conveying process; and palletizing of the boards adopts a way of receiving the boards from the bottom up, so that the machine has the advantages of being good in palletizing effect, prevented from being blocked, not easy to wear and high in security performance.

Owner:广西腾森自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com