Material for hard alloy slitting tool and preparation method of material

A cemented carbide and cutting tool technology, applied in the field of cemented carbide cutting tool materials and their preparation, can solve problems such as insufficient fatigue resistance and toughness of cemented carbide, high production cost, and increase of cemented carbide cost. , to achieve good uniformity and fluidity, fast drying, improve fatigue resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

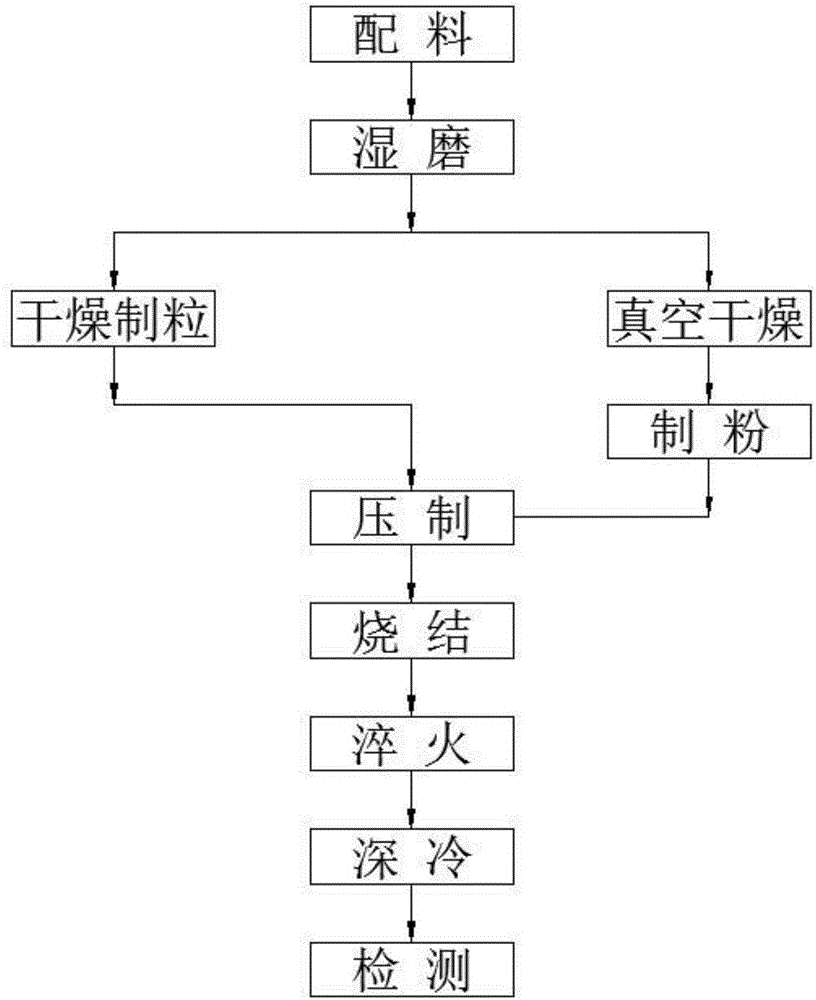

[0036] Such as figure 1 Shown, a kind of cemented carbide cutting tool material and preparation method thereof, comprises the following steps:

[0037] Step 1, batching: Fe, Co, Ni, Tic and WC are added to the wet mill for mixing; the new material is prepared from the following raw materials by weight percentage: Fe: 18%, Co: 8.0%, Ni: 4.0% , Tic: 8.0%, the balance is WC;

[0038] Step 2, wet grinding: add the raw materials prepared in step 1, wet grinding medium and molding agent together into the wet mill and mix evenly, and the wet grinding time is 24h-28h;

[0039] Step 3, drying and granulating: dry and granulate the wet-milled mixture in a spray drying tower;

[0040] Step 4, pressing: the dry and granulated mixture is pressed into shape by a press, and the pressure value is: 0.3MPa~1.0MPa;

[0041] Step 5, sintering: put the pressed blank into a graphite boat and put it in a vacuum sintering furnace, and sinter at a high temperature of 1360°C to 1420°C to make a new ...

Embodiment 2

[0048] Such as figure 1 Shown, a kind of cemented carbide cutting tool material and preparation method thereof, comprises the following steps:

[0049]Step 1, batching: Fe, Co, Ni, Tic and WC are added to the wet mill for mixing; the new material is prepared from the following raw materials by weight percentage: Fe: 20%, Co: 5.0%, Ni: 0.5% , Tic: 5.0%, the balance is WC;

[0050] Step 2, wet grinding: add the raw materials prepared in step 1, wet grinding medium and molding agent together into the wet mill and mix evenly, and the wet grinding time is 24h-28h;

[0051] Step 3: Vacuum dryer and powder making, dry the wet-milled mixture in a vacuum dryer, the vacuum degree is ≥0.95MPa, and the drying time is 8h-12h; the mixture is dried in a vacuum dryer and then powdered. Flour is sieved with 40 mesh to 80 mesh sieve;

[0052] Step 4, pressing: the dry and granulated mixture is pressed into shape by a press, and the pressure value is: 0.3MPa~1.0MPa;

[0053] Step 5, sinterin...

Embodiment 3

[0060] Embodiment 3 is basically the same as Embodiment 1 or 2. The difference is that the new material in step 1 is prepared from the following raw materials by weight percentage: Fe: 30%, Co: 5.0%, Ni: 0.5%, Tic: 10% , with a margin of WC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com