Warpage resistance nylon 6 composite material for vehicle air conditioning air door and preparation method thereof

A composite material, automotive air conditioning technology, applied in the direction of airflow control components, etc., can solve the problems of unstable product quality, easy warping of products, adverse effects of assembly, etc., to improve fluidity and dimensional stability, improve tensile strength, The effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

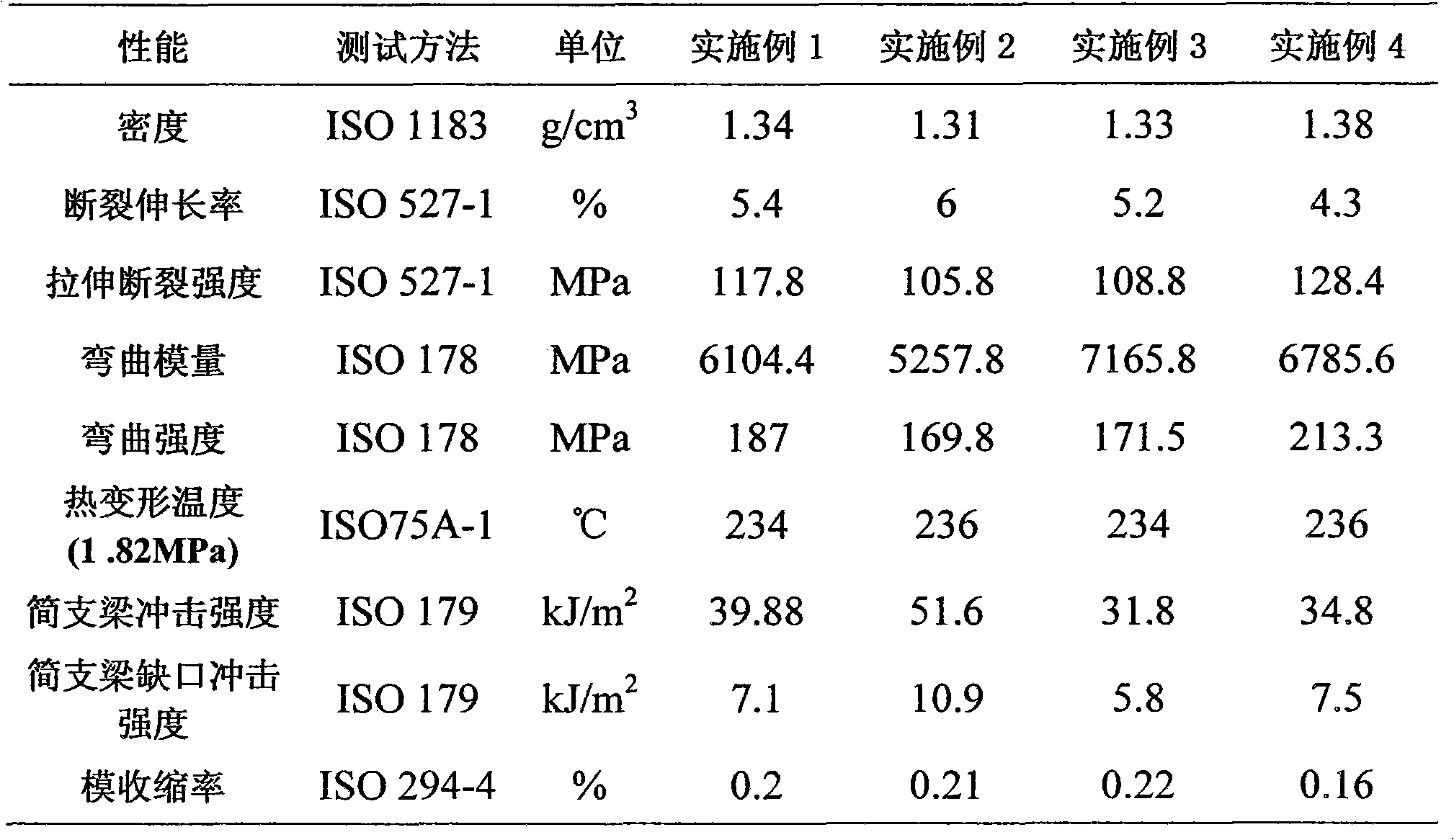

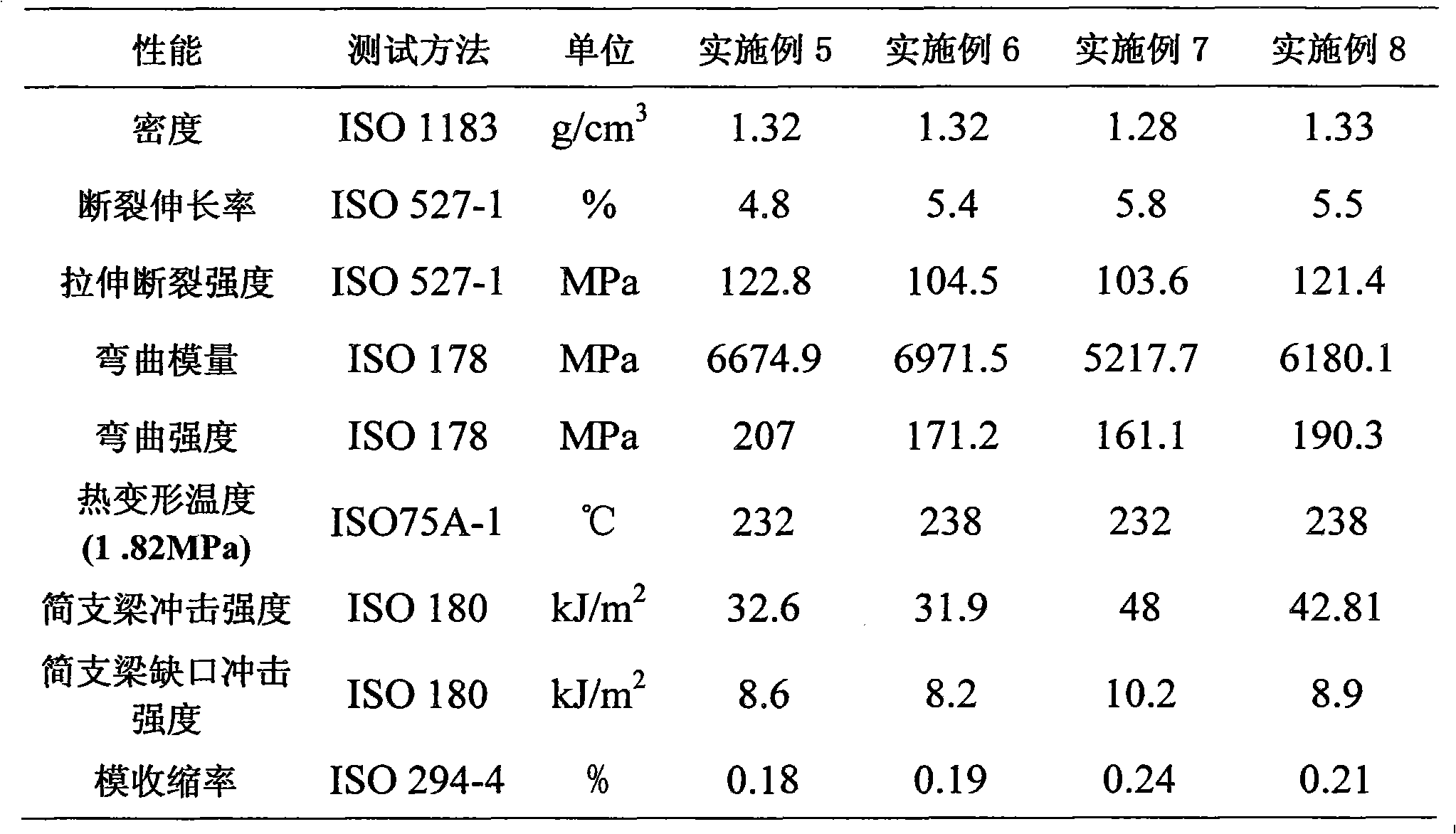

Examples

Embodiment 1

[0033] Nylon 6 chips (relative viscosity 2.7Pa·S) 61.5 parts by weight

[0034] Glass fiber (ECS301CL, purchased from Chongqing International Composite Materials Co., Ltd.) 24 parts by weight

[0035] Glass microspheres (3000CP, purchased from U.S. Porter Company) 8 parts by weight

[0036] 5 parts by weight of compatibilizer (polypropylene grafted maleic anhydride)

[0037] Antioxidant (antioxidant 1098: antioxidant 168=1: 2) 0.5 parts by weight

[0038] Coupling agent (γ-glycidyl etheroxypropyl trimethyloxysilane) 0.4 parts by weight

[0039] 0.6 parts by weight of lubricant (silicone powder)

[0040] Stir the nylon 6 slices, compatibilizer, antioxidant, coupling agent and lubricant in the above ratio in a high-speed mixer at a speed of 1000r / min for 1 minute, and the above-mentioned materials that have been mixed are weighed from the first section of the screw by weight loss. The barrel is added to the twin-screw extruder, and the glass beads are added to the twin-screw...

Embodiment 2

[0042] Nylon 6 chips (relative viscosity 2.5Pa·S) 64.9 parts by weight

[0043]Glass fiber (560, purchased from Zhejiang Jushi Group) 20 parts by weight

[0044] Glass microspheres (050-20-215, purchased from France Fitick Company) 10 parts by weight

[0045] Compatibilizer (EPDM grafted maleic anhydride) 4 parts by weight

[0046] Antioxidant (antioxidant 1098: antioxidant 168=1: 2) 0.5 parts by weight

[0047] Coupling agent (γ-glycidyl ether oxypropyl trimethyloxysilane) 0.3 parts by weight

[0048] Lubricant (ethylene-acrylic acid copolymer) 0.3 parts by weight

[0049] Stir the nylon 6 slices, compatibilizer, antioxidant, coupling agent and lubricant in the high-speed mixer at a speed of 1000r / min for 1 minute in the above ratio, and the mixed above-mentioned materials are weighed from the first section of the screw by weight loss. The barrel is added to the twin-screw extruder, the glass beads are added to the twin-screw extruder from the fourth section of the screw ...

Embodiment 3

[0051] Nylon 6 chips (relative viscosity 2.6Pa·S) 62.65 parts by weight

[0052] Glass fiber (560, purchased from Zhejiang Jushi Group) 24 parts by weight

[0053] Glass microspheres (3000CP, purchased from U.S. Potter Company) 6 parts by weight

[0054] Compatibilizer (ethylene-octene copolymer grafted maleic anhydride) 6 parts by weight

[0055] Antioxidant (antioxidant 1098: antioxidant 168=1: 2) 0.4 parts by weight

[0056] Coupling agent (γ-aminopropyltriethoxysilane) 0.5 parts by weight

[0057] Lubricant (TAF) 0.45 parts by weight

[0058] Stir the nylon 6 slices, compatibilizer, antioxidant, coupling agent and lubricant in the high-speed mixer at a speed of 1000r / min for 1 minute in the above ratio, and the mixed above-mentioned materials are weighed from the first section of the screw by weight loss. The barrel is added to the twin-screw extruder, the glass beads are added to the twin-screw extruder from the fourth section of the screw barrel through the weight lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com