Cement grinding aid and preparation method thereof

A technology of cement grinding aids and amide compounds, which is applied in the field of cement grinding aids and its preparation, can solve problems such as poor product quality stability, and achieve good superimposed synergistic effect, low reaction temperature, and excellent grinding aid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

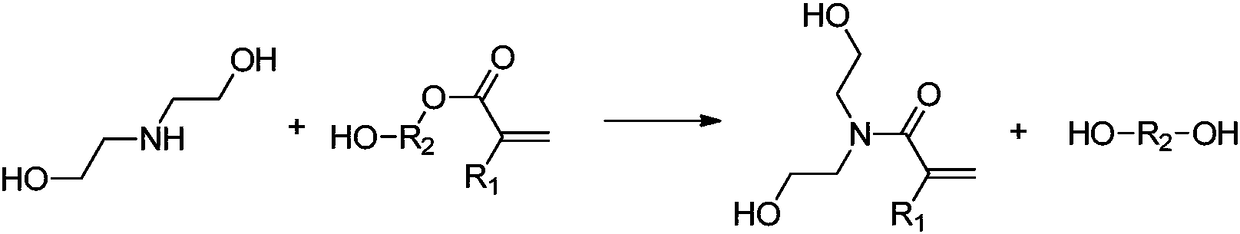

Method used

Image

Examples

Embodiment 1

[0043] Each raw material consumption of the cement grinding aid described in the present embodiment is respectively:

[0044] Diethanolamine 105g and hydroxyethyl acrylate 116g.

[0045] The preparation method of cement grinding aid described in the present embodiment, comprises the steps:

[0046] Weigh 105g of diethanolamine, add it to the reaction vessel, start stirring, set the stirring speed to 300rpm / min, and add 116g of hydroxyethyl acrylate dropwise to the reaction vessel at 20°C, and the dropping time is controlled at 1.5h. After the dropwise addition, react for 4 hours. After the reaction, the reaction liquid returns to room temperature, and the cement grinding aid can be obtained.

[0047] The cement grinding aid prepared by the present invention, after testing, consists of 48% by weight 19% ethylene glycol, 15% diethanolamine and 17% hydroxyethyl acrylate.

Embodiment 2

[0049] Each raw material consumption of the cement grinding aid described in the present embodiment is respectively:

[0050] Diethanolamine 157.5g and hydroxypropyl acrylate 130g.

[0051] The preparation method of cement grinding aid described in the present embodiment, comprises the steps:

[0052] Weigh 157.5g of diethanolamine, add it to the reaction vessel, start stirring, set the stirring speed to 300rpm / min, and add 130g of hydroxypropyl acrylate dropwise into the reaction vessel at 50°C, and the dropping time is controlled in 1h. After the dropwise addition, react for 0.5 h, and cool to room temperature after the reaction, the cement grinding aid can be obtained.

[0053] The cement grinding aid prepared by the present invention, after testing, consists of 49% by weight percentage Composition of 24% 1,2-propanediol, 22% diethanolamine and 5% hydroxypropyl acrylate.

Embodiment 3

[0055] Each raw material consumption of the cement grinding aid described in the present embodiment is respectively:

[0056] Diethanolamine 105g, hydroxyethyl methacrylate 60g and hydroxypropyl acrylate 60g.

[0057] The preparation method of cement grinding aid described in the present embodiment, comprises the steps:

[0058] Weigh 105g of diethanolamine, put it into the reaction container, start stirring, set the stirring speed to 300rpm / min, mix 60g of hydroxyethyl methacrylate and 60g of hydroxypropyl acrylate, and add dropwise at 40°C In the reaction vessel, the dropwise addition time is controlled at 1h. After the dropwise addition, react for 2 hours and cool to room temperature after the reaction, the cement grinding aid can be obtained.

[0059] The cement grinding aid prepared by the present invention, after testing, consists of 29% by weight 26% 13% 1,2-propanediol, 10% ethylene glycol, 12% diethanolamine, 5% hydroxyethyl methacrylate and 5% hydroxypropyl acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com