Horizontal decanter solid-bowl centrifuge

A settling centrifuge, horizontal screw technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve problems such as environmental pollution and liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail in conjunction with the accompanying drawings.

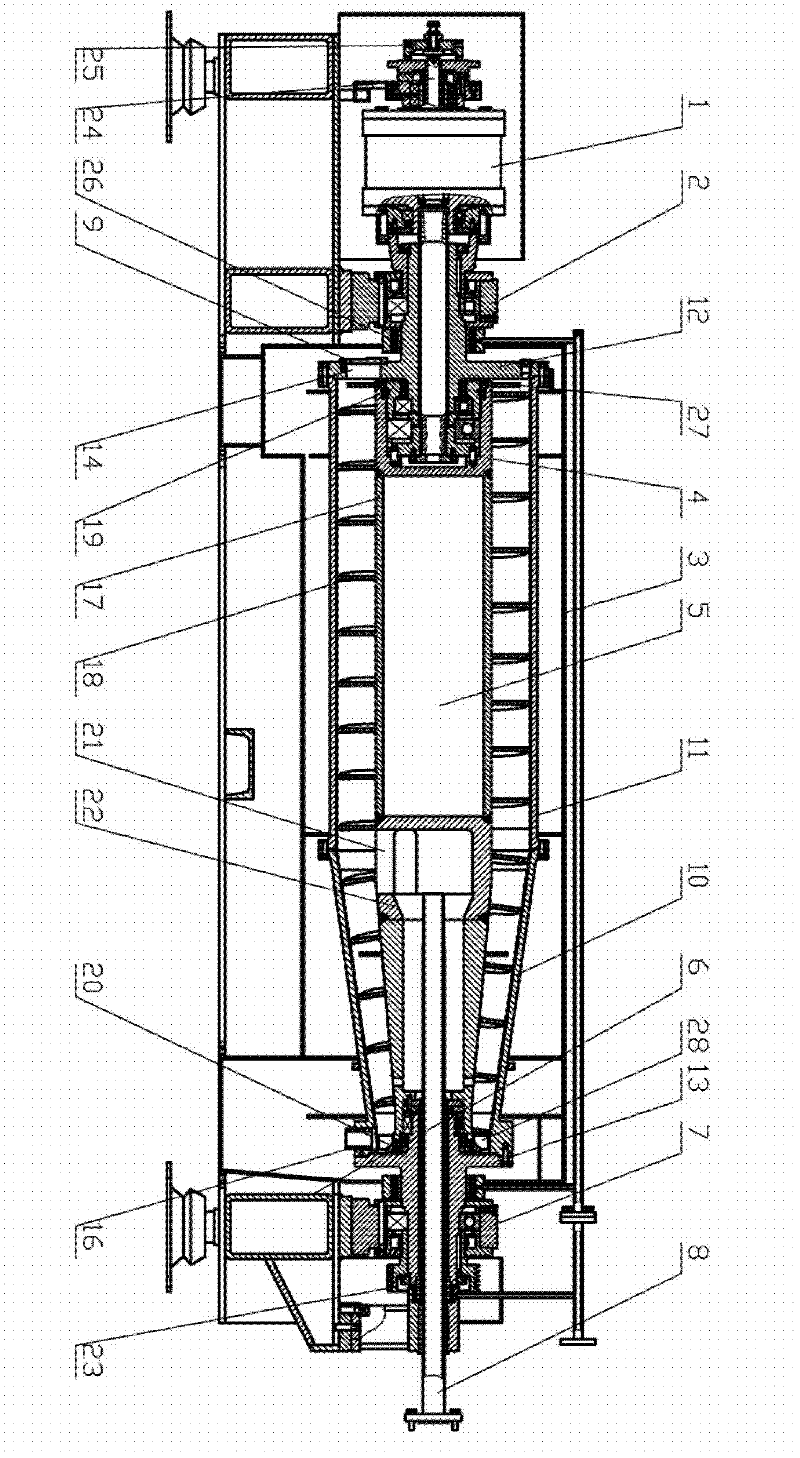

[0016] The horizontal screw unloading sedimentation centrifuge consists of a screw conveyor 5, a feed pipe 8, a cylindrical drum 11, a conical drum 10, a large end cover of the drum 12, a small end cover of the drum 13, a large end bearing seat 2, a small End bearing seat 7, differential gear 1, transmission parts and machine base 6, casing 3 etc. constitute. The following is divided into several parts:

[0017] (1) Drum part.

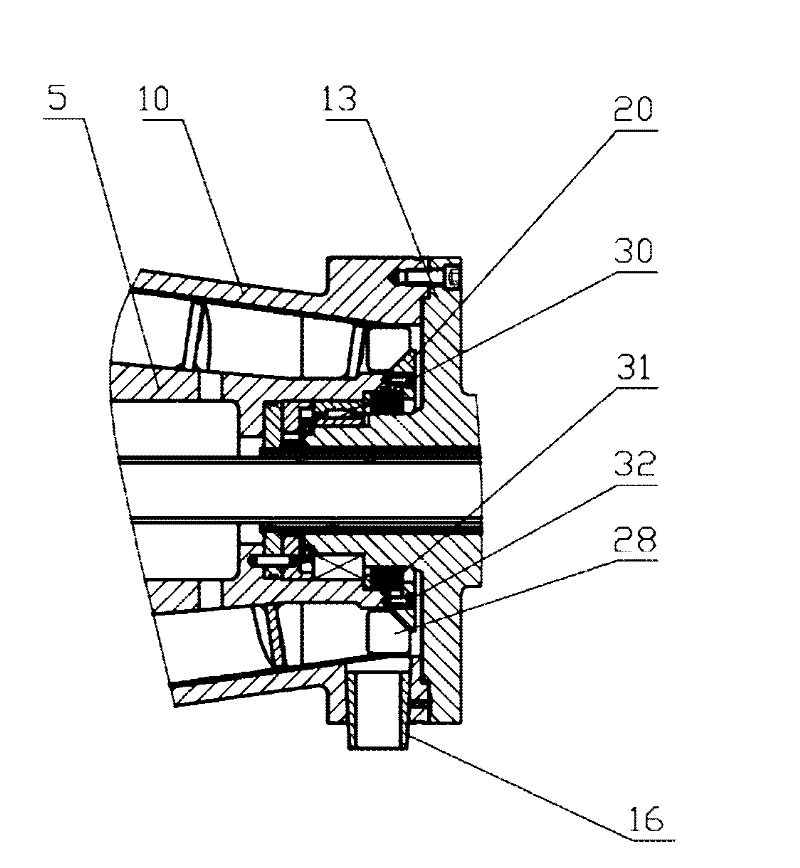

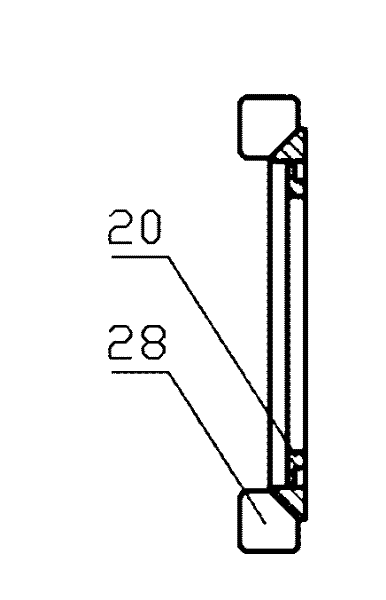

[0018] It consists of a conical drum 10, a cylindrical drum 11, a large end cover 12 of the drum, a small end cover 13 of the drum, etc. There are six liquid outlet holes 14 axially distributed on the large end of the drum, and the liquid level is controlled by the regulating plate 9 . In order to meet the needs of various materials and solid phases with different dryness, the machine adjusts the liquid level size by changing the overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com