Method for producing citric acid by citric acid wastewater reflux fermentation

A citric acid wastewater and citric acid technology, applied in the field of fermentation engineering, can solve problems such as unsatisfactory effect, long cycle, incomplete wastewater treatment, etc., and achieve the effects of saving process water and steam consumption, stable fermentation, and saving sewage treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

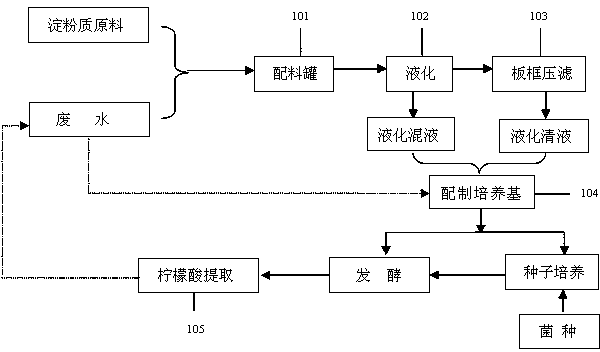

Image

Examples

Embodiment 1

[0023] 200kg of corn flour and 600kg of citric acid waste sugar water were mixed evenly in a batching tank at 50°C, and calcium hydroxide was added to adjust the pH to 5.8, and 250g of high-temperature-resistant α-amylase with an enzyme activity unit of 20,000U / g was added. After the second injection liquefaction, the temperature of the first injection is 97°C, the temperature of the second injection is 130°C, keep in the tank for 0.5~1h, the iodine test is light brown and it is qualified, and the liquefaction mixture is obtained, and then 70% of the liquefaction mixture is put into Plate and frame filter press to obtain liquefied supernatant.

[0024] Prepare seed medium and fermentation nutrient solution, wherein the seed medium is to mix the liquefied clear liquid and the liquefied mixed solution at a ratio of 1:1.5, and add citric acid waste water to replenish water; the fermented nutrient solution is to mix the liquefied clear liquid and the liquefied mixed solution at a r...

Embodiment 2

[0028] 100kg of cassava flour and 150kg of citric acid waste sugar water were mixed evenly in a batching tank at 60°C, and calcium hydroxide was added to adjust the pH to 5.9, and 125g of high-temperature-resistant α-amylase with an enzyme activity unit of 20,000U / g was added. After the second injection liquefaction, the temperature of the first injection is 99°C, the temperature of the second injection is 125°C, maintain in the maintenance tank for 0.5~1h, the iodine test is light brown, and the liquefaction mixture is obtained, and then 60% of the liquefaction mixture is put into Plate and frame filter press to obtain liquefied supernatant.

[0029] Prepare seed medium and fermentation nutrient solution, wherein the seed medium is to mix the liquefied clear liquid and the liquefied mixed solution at a ratio of 1:1.5, and add citric acid waste water to replenish water; the fermented nutrient solution is to mix the liquefied clear liquid and the liquefied mixed solution at a ra...

Embodiment 3

[0033] 300kg of corn flour, 200kg of cassava flour raw materials, 2000kg of citric acid waste sugar water, mixed evenly in a batching tank at 55°C, adding calcium hydroxide to adjust the pH to 5.9, adding 800g of high temperature resistant α-amylase with an enzyme activity unit of 20000U / g. Liquefied by two injections, the temperature of the first injection is 101°C, the temperature of the second injection is 120°C, maintain in the maintenance tank for 0.5~1h, and pass the iodine test to light brown to obtain a liquefied mixed liquid, and then 80% of the liquefied mixed liquid Enter the plate and frame filter to obtain the liquefied supernatant.

[0034] Prepare seed medium and fermentation nutrient solution, wherein the seed medium is to mix the liquefied clear liquid and the liquefied mixed solution at a ratio of 1:2, and add citric acid waste water to replenish water; the fermented nutrient solution is to mix the liquefied clear liquid and the liquefied mixed solution at a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com