Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Hydrophobic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of photocuring type superhydrophobic composite film

ActiveCN107226920ARapid preparation with superhydrophobic propertiesHas superhydrophobic propertiesCoatingsCross-linkComposite film

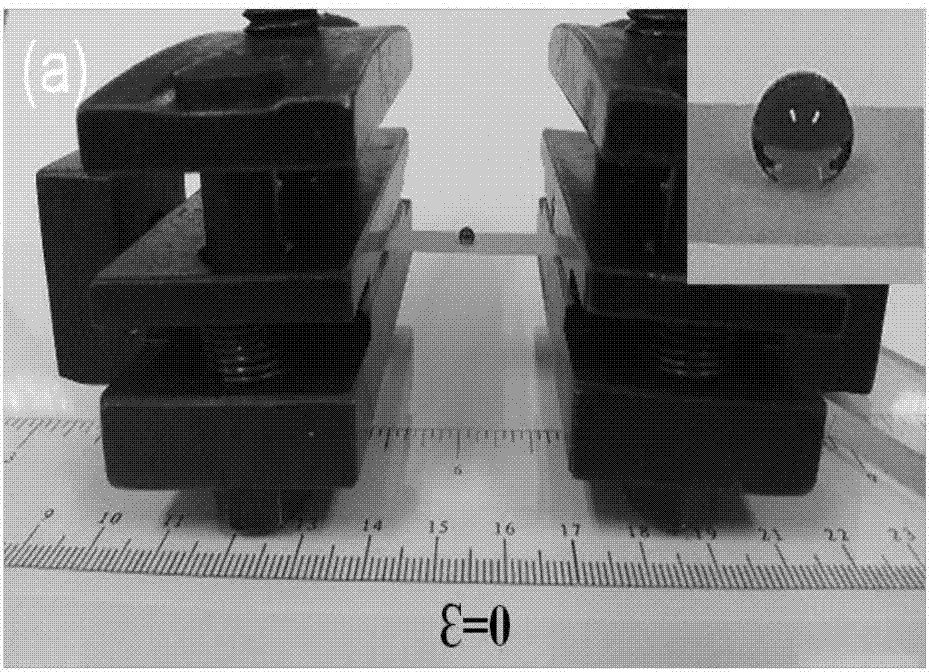

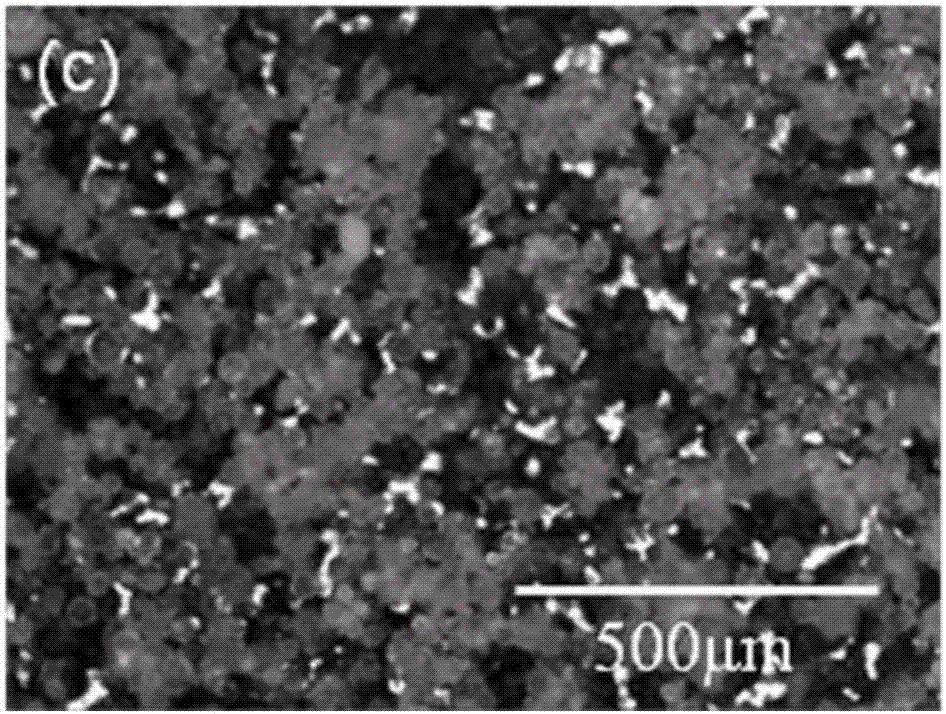

The invention discloses a preparation method of a photocuring type superhydrophobic composite film. The composite film comprises an elastic substrate and a surface superhydrophobic layer. The preparation method comprises the following steps: firstly, preparing the elastic substrate: uniformly mixing a photoinitiator with a prepolymer, and carrying out ultraviolet irradiation on an obtained mixture to obtain a precured elastic substrate; secondly, preparing turbid liquid: uniformly dispersing a polymer with low surface energy, the photoinitiator, a cross-linking agent and micro and / or nano hydrophobic particles in a solvent to obtain the turbid liquid; thirdly, preparing the superhydrophobic composite film: coating the elastic substrate with the turbid liquid, and then carrying out ultraviolet irradiation curing treatment to obtain the composite film with superhydrophobicity. According to the superhydrophobic composite film prepared by the preparation method disclosed by the invention, the elastic substrate and the superhydrophobic layer are integrated by chemical crosslinking; the uperhydrophobic composite film has the advantages of simple preparation process, good friction resistance and tensile resistance, stable superhydrophobic effect and the like; the coating is not easy to fall off.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

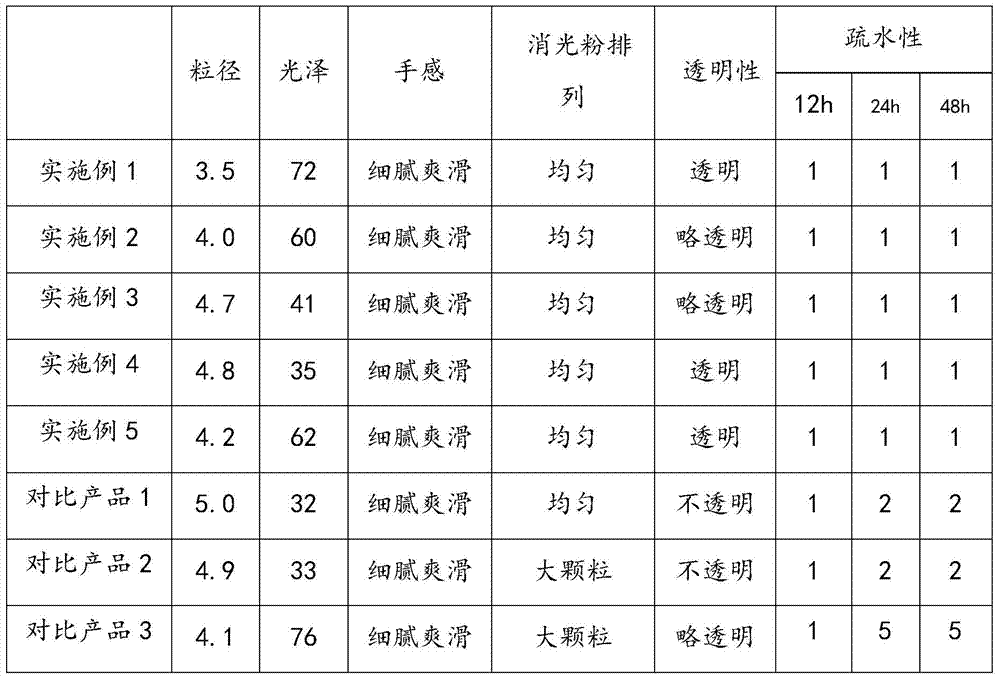

Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

ActiveCN105400239AReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

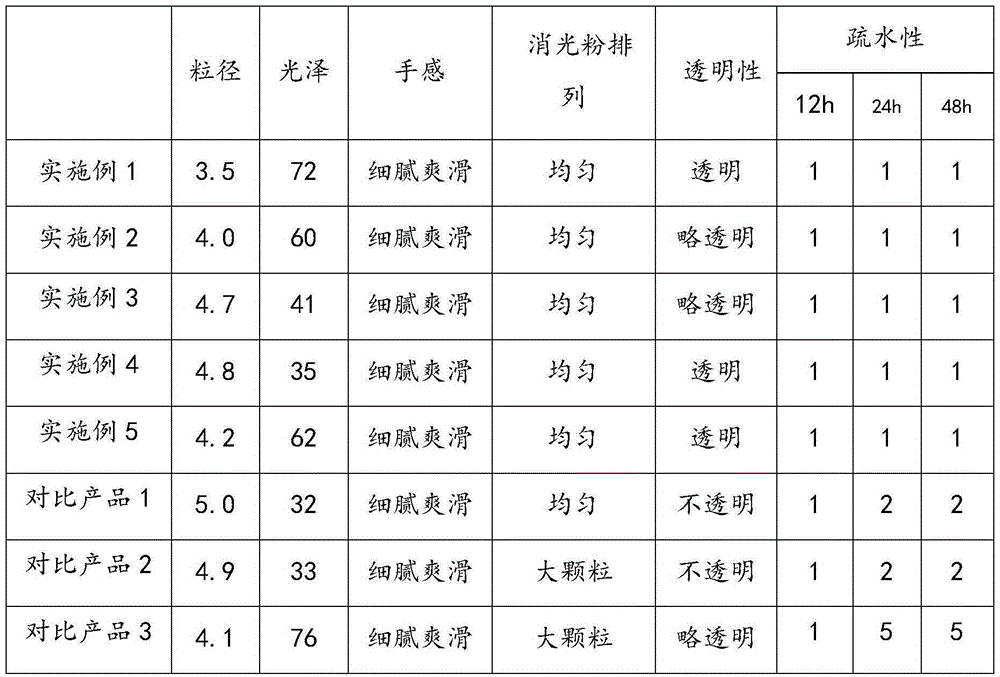

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

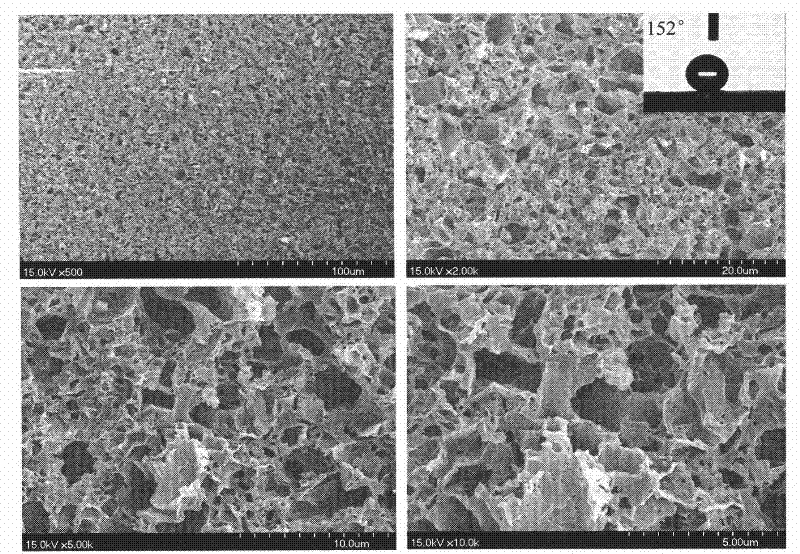

Aluminum product surface super-hydrophobic film and making method thereof

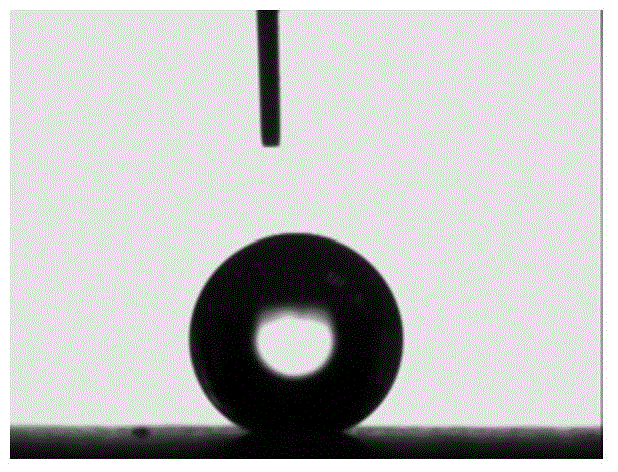

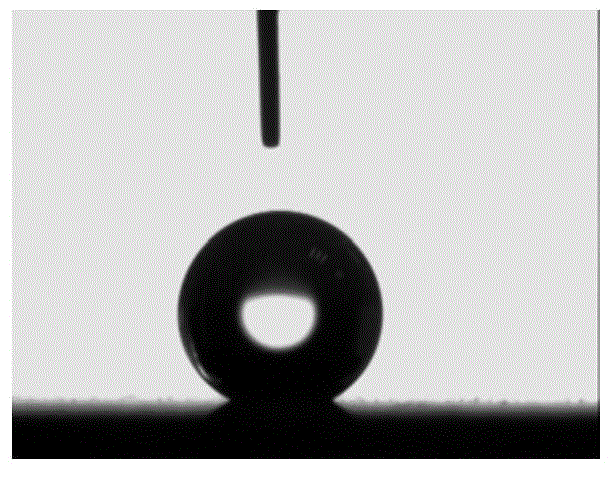

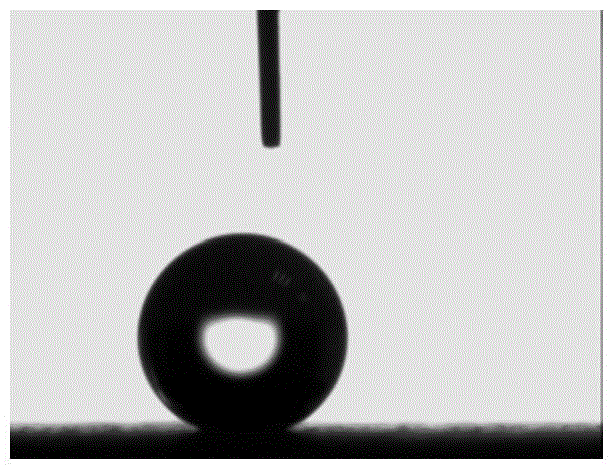

InactiveCN104131322AExcellent superhydrophobicityImprove self-cleaning functionAnodisationWear resistanceRolling angle

The invention relates to an aluminum product surface super-hydrophobic film and a making method thereof. The method comprises the following steps: 1, placing an aluminum product in an electrolyte as an anode, and anodizing under a current density of 0.1-0.5A.cm<-2> for 1-20min to obtain an anodized aluminum surface; and 2, immersing the anodized aluminum surface in an ethanol solution containing silicon fluoride for at least 1min, carrying out heat treatment on the obtained workpiece at 100-200DEG C for 5-40min, and naturally cooling to obtain the aluminum product surface super-hydrophobic film. The making method of the super-hydrophobic surface has the advantages of simplicity, low cost and easy industrialization. The super-hydrophobic surface made in the invention has a contact angle exceeding 150DEG, a roll angle of below 10DEG and stable hydrophobicity. The surface has the advantages of very good super-hydrophobic function, very good automatic cleaning function, excellent wear resistance and excellent corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH

Method for etching and preparing ultra-hydrophobic aluminum surface by using saline solution containing copper ions and chloride ions

InactiveCN102677058AEasy to operateReduce pollutionCoatingsSpecial surfacesMegasonic cleaningChloride Ion Level

The invention discloses a method for etching and preparing an ultra-hydrophobic aluminum surface by using a saline solution containing copper ions and chloride ions. The method comprises the steps that firstly an aluminum plate is polished and is additionally cleaned to remove oil; afterwards, the oil-removed aluminum plate is soaked in the saline solution containing the copper ions and the chloride ions for a certain time, and after the aluminum plate is taken out, deposited copper is cleaned by using an ultrasonic cleaner and the aluminum plate is dried; and finally, the etched aluminum plate is soaked in an ethanol solution containing a low surface energy material for 1h, and after the etched aluminum plate is taken out and is dried, the ultra-hydrophobic aluminum surface can be obtained. The method has the advantages that complex and expensive equipment is not needed, the process is simple, the repeatability is good, the obtained ultra-hydrophobic aluminum surface has excellent hydrophobic performance, contact angles of water drops on the ultra-hydrophobic aluminum surface exceed 160 DEG and rolling angles of the water drops are smaller than 2 DEG.

Owner:DALIAN UNIV OF TECH

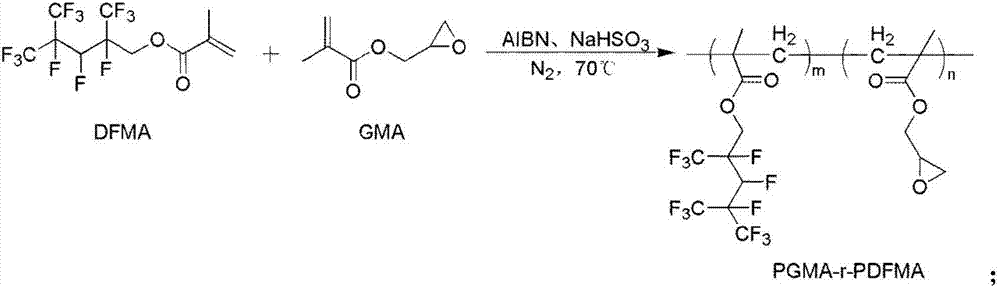

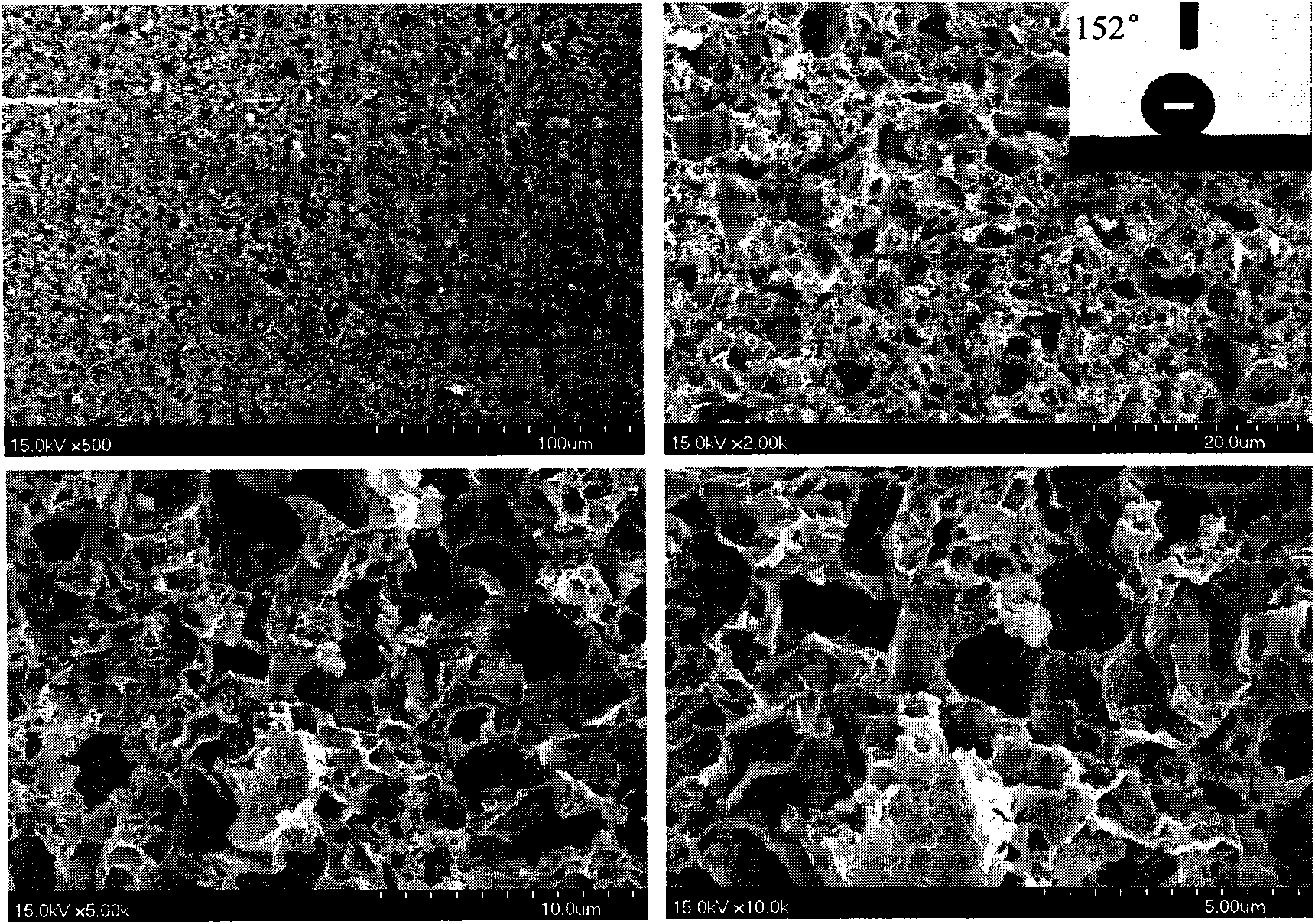

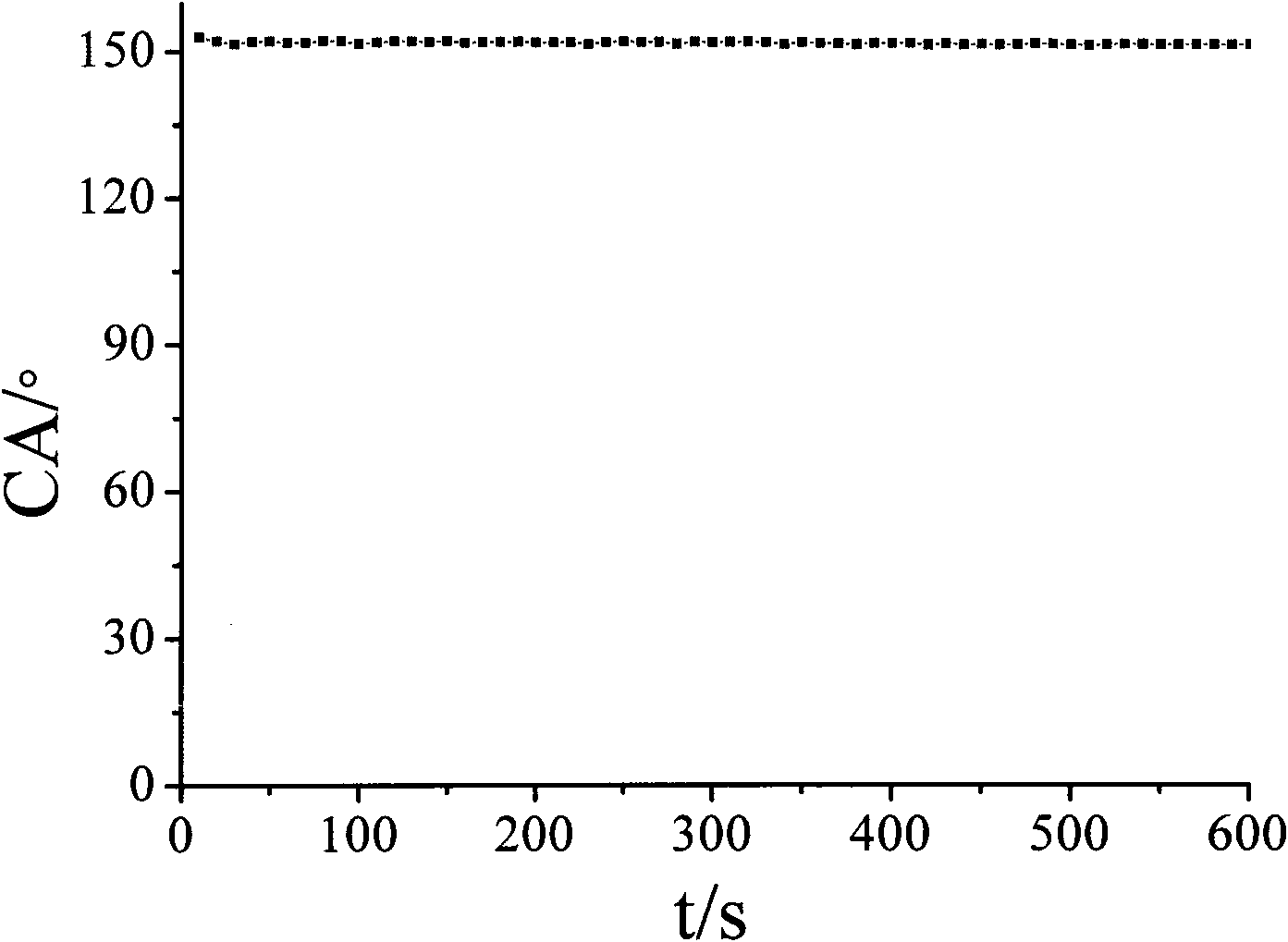

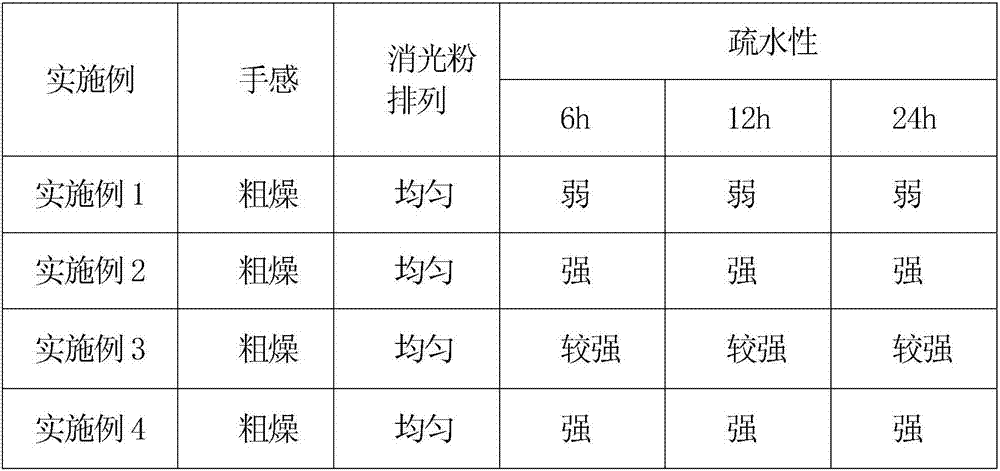

Preparation method for super-hydrophobic coating

The invention discloses a preparation method for a super-hydrophobic coating. The method comprises the following steps: mixing dodecafluoroheptyl methacrylate, methacrylic acid glycidol, azodiisobutyronitrile and sodium hydrogen sulfite, adding tetrahydrofuran, reacting under a heating state so as to form a reactant, and standing to acquire the super-hydrophobic coating; mixing nanometer silicon dioxide, ethyl alcohol and water and then ultrasonically dispersing, thereby forming a turbid solution; regulating the PH value of the turbid solution to 7, adding a coupling reagent into the turbid solution, condensing and back-flowing under heating and stirring state, thereby acquiring the modified silicon dioxide; performing suction filtration by using an ethyl alcohol solution, thereby acquiring purified amino modified silicon dioxide; drying and grinding, thereby acquiring amino modified nanometer silicon dioxide; dissolving the super-hydrophobic coating by using tetrahydrofuran and then adding triethylamine and amino modified nanometer silicon dioxide in turn, thereby forming a modified solution; soaking the substrate into the modified solution, taking out and then drying. The super-hydrophobic coating prepared according to the preparation method disclosed by the invention has stable and long-lasting super-hydrophobic property and is reusable.

Owner:XIAN UNIV OF TECH

Method for preparing lyophobic silicon dioxide for VOC (Volatile Organic Compound) adsorption

The invention discloses a method for preparing lyophobic silicon dioxide for VOC (Volatile Organic Compound) adsorption. The method comprises the following steps: (1) mixing nitric acid, deionized water and absolute ethyl alcohol in a container so as to obtain a mixed liquid; (2) mixing a silicon dioxide source, the absolute ethyl alcohol and the deionized water so as to obtain another mixed liquid, adding a composite coupling agent, and uniformly stirring; (3) pouring the solution obtained in the step (2) into the mixed liquid obtained in the step (1), keeping the pH value of the solution within 2-6, and stirring for several hours; (4) sealing the container, and aging for 2 hours; (5) performing suction filtration on gel which is subjected to surface modification and is interchanged with a solvent, washing, and leaving to stand at normal temperature; and (6) drying the washed gel, and performing airflow superfine crushing, thereby obtaining a finished product. By adopting the method for preparing the lyophobic silicon dioxide for VOC adsorption, the lyophobic silicon dioxide is capable of adsorbing different types of VOC molecules, and not only is the environment protected, but also the cost is low.

Owner:德清美联新材料科技有限公司

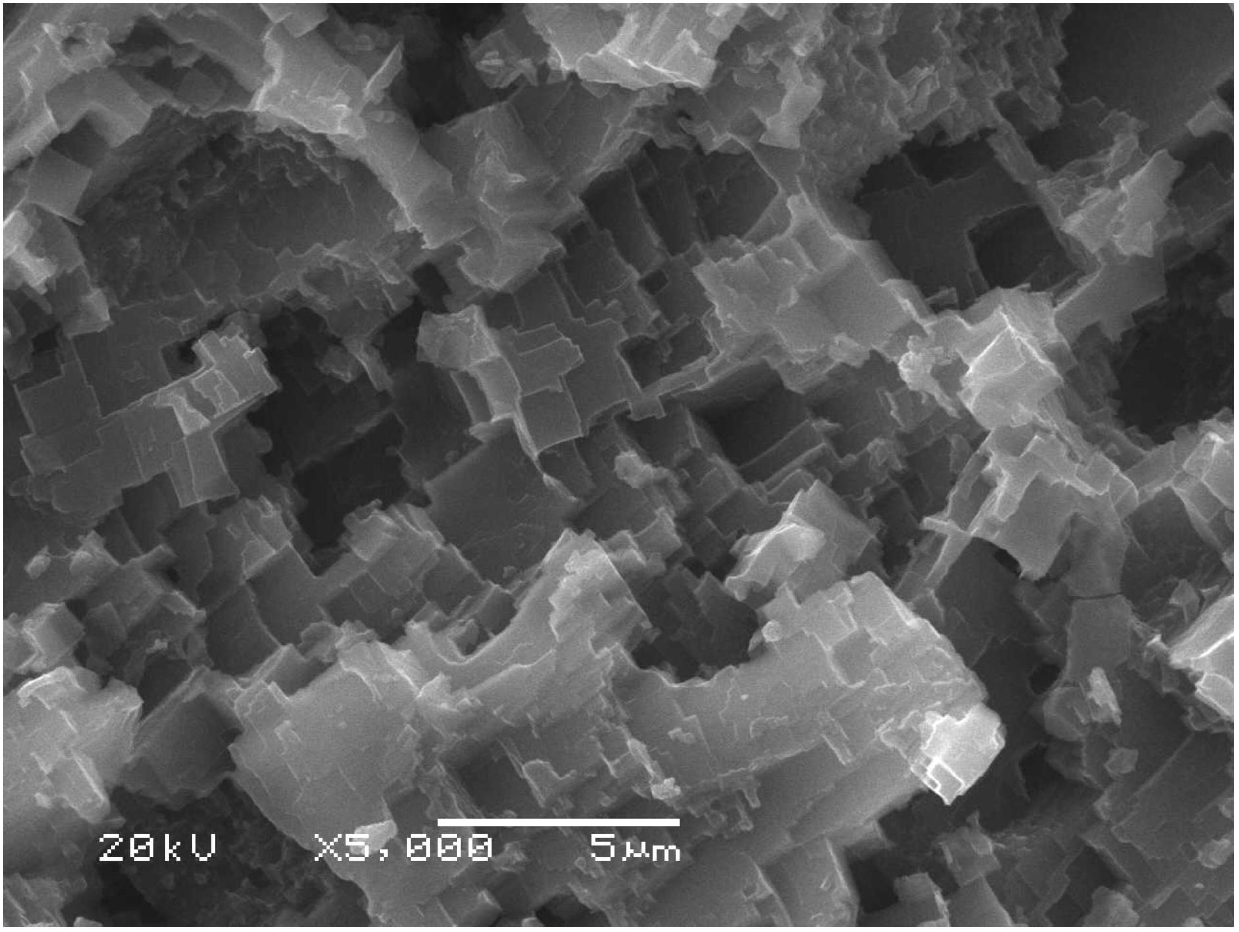

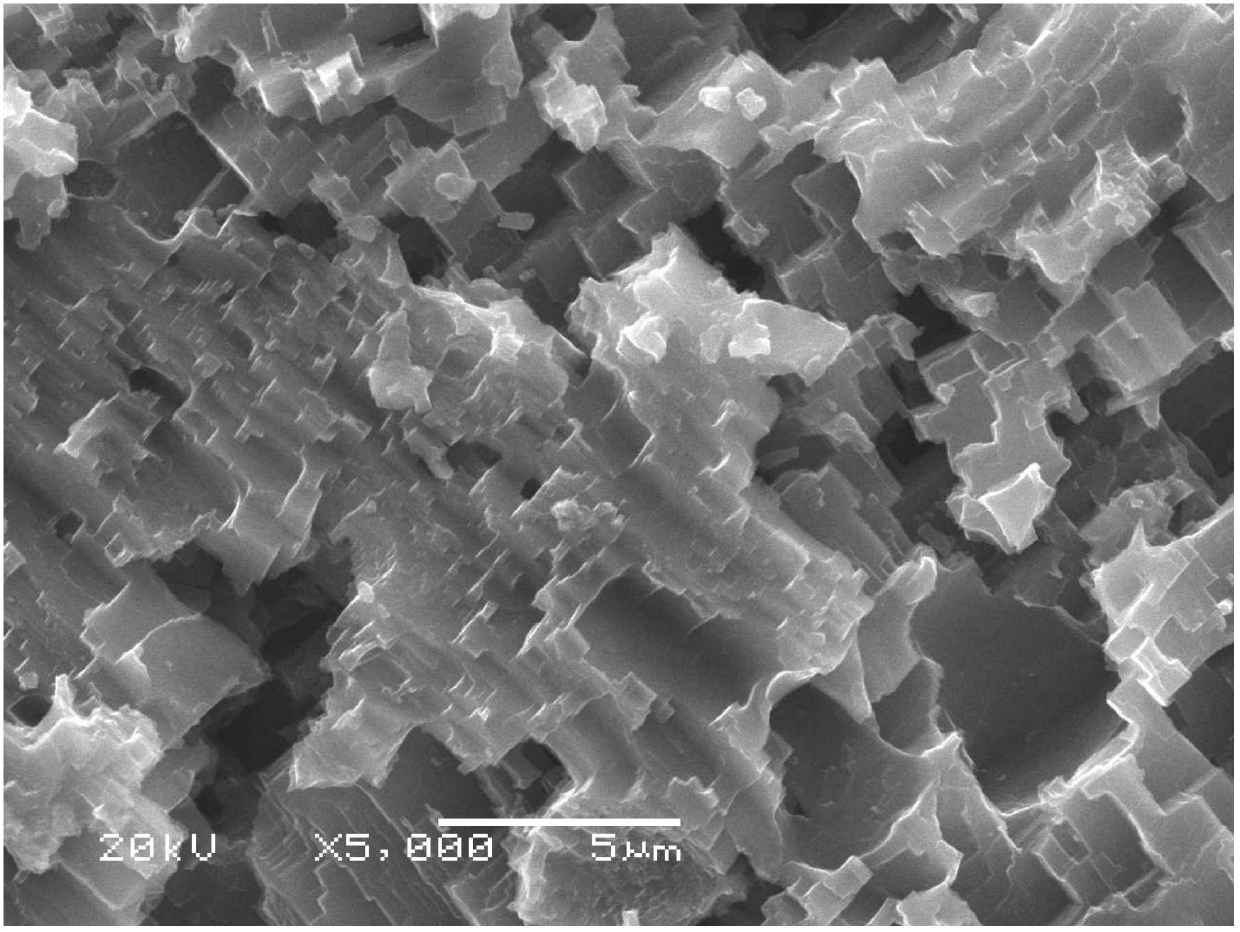

Method for preparing polymer superhydrophobic surface by CaCO3 template method

The invention provides a method for preparing a polymer superhydrophobic surface by a CaCO3 template method, comprising the following steps of: firstly adhering a thin CaCO3 layer with the thickness of 0.1 to 20mm and the particles of 800 to 3000 meshes on a plane or a roll surface base; then hot pressing a polymer on the thin CaCO3 layer, and after peeling off a composite layer, and finally immersing the polymer in an acid liquor to corrode the calcium carbonate particles on the surface of the polymer, thus obtaining the polymer superhydrophobic surface with irregular network structure. The invention mainly has the following beneficial effects that the method has simple operation technology, low cost, high efficiency, and good controllability and repeatability, furthermore, the method is easy for large-area preparation, and provides a simple and effective way for the industrialization of the superhydrophobic surface, thus having wide application value and broad market prospect.

Owner:ZHEJIANG UNIV OF TECH

Transparent antibacterial super-hydrophobic coating and preparation method thereof

InactiveCN108384336AImprove hydrophobicityHigh strengthAntifouling/underwater paintsPaints with biocidesTriethoxysilanePolystyrene

The invention discloses a transparent antibacterial super-hydrophobic coating and a preparation method thereof. The transparent antibacterial super-hydrophobic coating consists of polystyrene nanospheres and PS-TiO2 structural composite particles, after the polystyrene nanospheres are etched by virtue of concentrated sulfuric acid, the polystyrene nanospheres are hydrolyzed and condensed with nanozinc oxide and tetrabutyl titanate to prepare the PS-TiO2 structural composite particles, and the surface of the PS-TiO2 structural composite particle is hydrophobized by virtue of octyltriethoxysilane, so that a transparent antibacterial super-hydrophobic coating is formed. The coating prepared by the invention is high in strength and high in hydrophobic capability, and the obtained super-hydrophobic surface is bacteria-free and excellent in stability.

Owner:FOSHAN SHIRUI LEADING MATERIAL RES INST GENERAL PARTNERSHIP

High-waterproofness heat preservation rock wool board and manufacturing method thereof

InactiveCN106639011AReasonable density gradientSurface layer densityRoof covering using slabs/sheetsHeat proofingAbsorption capacitySilanes

The invention discloses a high-waterproofness heat preservation rock wool board and a manufacturing method thereof and belongs to the field of building materials. The rock wool board is made from the raw materials of, by weight, 55-65 parts of iron ore, 10-15 parts of perlite, 12-16 parts of slag, 10-13 parts of glass, 6-8 parts of a water repellent, 5-6 parts of urea, 8-10 parts of phenol-formaldehyde resin, 1-2 parts of 3-aminopropyltriethoxysilane and 3-5 parts of vinyltri tert-butyl peroxide silane. By adoption of a formula of the rock wool board, the proportion of manganese, calcium and iron can reach triangular balance, high-quality rock wool fibers are obtained and used in cooperation with the water repellent and a bonding agent to enable the rock wool board to have a reasonable density gradient, the rock wool board is high in surface layer density and compact in fiber structure, the water absorption capacity is greatly lowered, and therefore the hydrophobic property of the whole system structure is improved.

Owner:MAANSHAN HONGDA INSULATION MATERIAL

Preparation method of hydrophobic ultrafine silicon dioxide for coating agent

InactiveCN107011719AUniform particle sizeStable pore structureCoatingsPigment treatment with organosilicon compoundsReaction temperatureSilicon dioxide

The invention discloses a preparation method of hydrophobic ultrafine silicon dioxide for a coating agent. The preparation method includes steps: (1) well mixing dry powdered silicon dioxide being 8-12micron in particle size and dry powdered silicon dioxide being 3-7micron in particle size in a glass container; (2) mixing formic acid aqueous solution being 2% in weight percent with methyl alcohol, slowly pouring formic acid and methyl alcohol mixed solution into the glass container, and keeping stirring for 20-40min; (3) atomizing a hydrophobic modified silane coupling agent, uniformly spraying into the glass container, and stirring at a constant speed to allow complete reaction of raw materials for 30-60min at a reaction temperature of 40-70 DEG C; (4) hermetically placing reaction products, and ageing for 3-6h; (5) drying the aged materials, and performing airflow ultrafine grinding to obtain a finished product. The preparation method of hydrophobic ultrafine silicon dioxide for the coating agent has the advantage that an uneven state is achieved while a hydrophobic property of silicon dioxide on the surface of the coating agent is realized.

Owner:德清美联新材料科技有限公司

Method for preparing super-hydrophobic coating on steel substrate by virtue of Fe-based nano composite brush electroplating

InactiveCN104746118ALow costImprove the bonding force of the coatingElectrolytic coatingsSurface energyMicro nano

The invention provides a method for preparing a super-hydrophobic coating on a steel substrate by virtue of Fe-based nano composite brush electroplating and belongs to methods for preparing super-hydrophobic coatings on steel substrates. According to a process for preparing a super-hydrophobic coating on the surface of a steel substrate by using nano composite brush electroplating iron, a nano composite brush electroplating iron process and coating blackening treatment are adopted to prepare the super-hydrophobic coating with a contact angle of more than 150 degrees and a roll angle of less than 3 degrees on the surface of the steel substrate. The method comprises the following steps: (1) finishing preparatory works; (2) carrying out a process flow of preparing a micro nano coarse structure on the steel surface by using the nano composite brush electroplating iron; (3) carrying out the process steps of electric purification, activation, bottom layer plating, nano Cu / Al2O3 composite coating plating and alkali liquor soaking, performing water flushing after each process step to prevent the plating solution from polluting the next process, and performing blackening treatment on the coating; and (4) finishing the coarse surface by using a low-surface-energy substance. The method, which is used for constructing a super-hydrophobic surface by performing brush electroplating of iron on the surface of a hard metal and then performing blackening treatment, has the advantages of light and portable equipment, simple process, low cost, strong coating bonding force and the like.

Owner:CHINA UNIV OF MINING & TECH

Method for realizing weak surface hydrophobicity for alternating-current (AC) composite insulator

The invention discloses a method for realizing weak surface hydrophobicity (HC6) for an alternating-current (AC) composite insulator. According to the method, diatomite and kaolin are mixed according to a certain ratio and then are coated on the surface of the insulator, and the weak surface hydrophobicity for the composite insulator is realized after a certain migration time. By using the method, the voltage of the AC composite insulator is higher than that of flashover under hydrophilic conditions and is far lower than that of the flashover under strong hydrophobic conditions, and the situation that the hydrophobicity of the composite insulator of an AC transmission line during operation is lowered is better simulated. Thus, AC composite insulator contamination tests are carried out by using the method, and obtained results are applied to the design of external insulation of a power transmission line, so that the construction cost of the power transmission line can be reduced while the reliability of the external insulation of the power transmission line is guaranteed.

Owner:STATE GRID CORP OF CHINA +2

Super-hydrophobic coating, preparation method and application of super-hydrophobic coating

InactiveCN107384104AIncreased durabilityAcid resistantCoatingsTextiles and paperMethacrylateHydrogen

The invention discloses a super-hydrophobic coating. The super-hydrophobic coating is a polymer which is formed by the reaction of dodecafluoroheptyl methacrylate, methacrylic acid glycidol, azodiisobutyronitrile and sodium hydrogen sulfite. The polymer is PGMA-r-PDFMA. The invention also discloses a preparation method and application of the super-hydrophobic coating. The super-hydrophobic coating disclosed by the invention has high durability in use; the preparation method for the super-hydrophobic coating disclosed by the invention is simple; the super-hydrophobic coating is simply applied; a super-hydrophobic coating layer can be formed on the fabric surface.

Owner:XIAN UNIV OF TECH

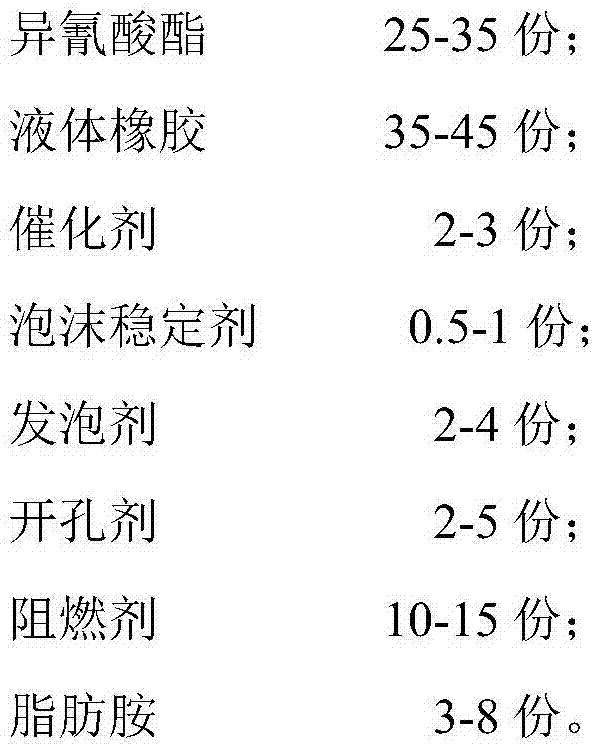

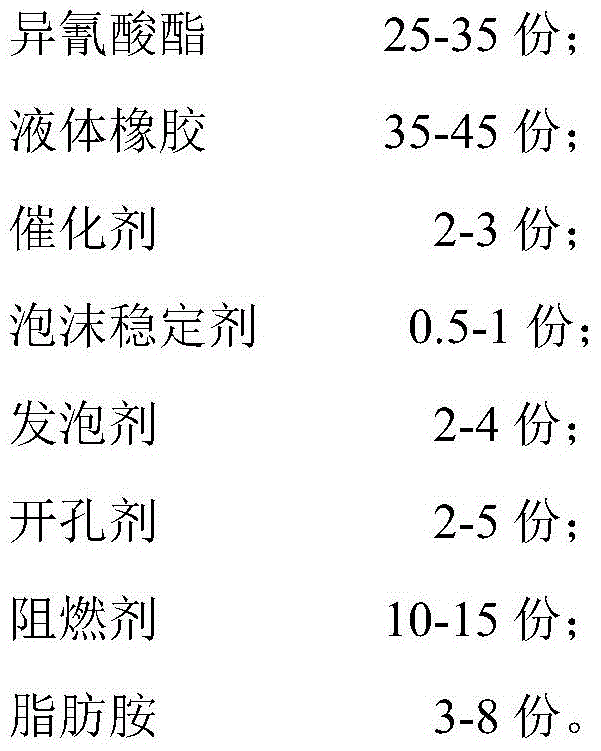

Polyurethane foam and preparation method and application thereof

ActiveCN104327492AIncrease roughnessRapid adsorption recoveryOther chemical processesEpoxyFoaming agent

The invention discloses polyurethane foam and a preparation method and application thereof, and the purpose is to solve the problems of poor hydrophobic performance of the existing polyurethane foam. The polyurethane foam includes isocyanate, hydroxyl terminated liquid rubber, a catalyst, a foaming agent, a foam stabilizer, a hole opening agent, a flame retardant, fatty amine and the like. Through use of low surface energy and high hydrophobic performance of the fatty amine and reaction performance of nitrile group (-CN) and epoxy group (-CH (O) CH-), the fatty amine is introduced into the nitrile group or epoxy group-containing hydroxyl terminated liquid rubber and nitrile group or epoxy group-containing carboxyl terminated liquid rubber, and by reaction with the isocyanate, the super hydrophobic polyurethane foam is prepared. When the super hydrophobic polyurethane foam absorbs oil-water mixtures, or oil and liquid organic matters leaking onto the water surface, only oil and liquid organic matters are absorbed, no water is absorbed, so that recovery of leaked oil and liquid organic matters and water purification can be realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH +3

Method for preparing nepenthes bionic super-lubricating surface by using laser etching method

ActiveCN113522684AIncrease contact angleImprove hydrophobicityCoatingsSpecial surfacesLaser beamsMaterials science

The invention discloses a method for preparing a nepenthes bionic super-lubricating surface by using a laser etching method. The method comprises the following steps of 1) cutting, grinding and polishing an aluminum plate into a mirror surface, conducting ultrasonic cleaning for 15 min in deionized water, and drying at 80 DEG C for 30 minutes; (2) placing the aluminum plate on the lower surface of a nanosecond laser device to be etched, and moving a laser beam in a line-by-line scanning manner to irradiate in two vertical directions respectively to form a micron-sized square column array; 3) after laser etching, performing ultrasonic cleaning and drying, immersing the aluminum plate into a mixed solution of heptadecafluorodecyl triethoxysilane (PFDTES) and absolute ethyl alcohol in a volume ratio of 1: 100, standing at room temperature of 25 DEG C for 12 hours, washing with distilled water, and drying at 80 DEG C for 30 minutes; and (4) immersing the dried aluminum plate into perfluoropolyether lubricating oil at the inclination angle of 45 degrees and the speed of 3 mm / s, after the aluminum plate is completely immersed in the lubricating oil, horizontally standing for 30 minutes, taking out the aluminum plate, standing for 30 minutes at the inclination angle of 15 degrees with the horizontal plane, and then vertically placing the aluminum plate, and removing excessive lubricating oil to obtain the super-lubricating surface with excellent hydrophobicity and long-term effectiveness.

Owner:UNIV OF JINAN

A kind of preparation method of superhydrophobic modified silicon dioxide

ActiveCN105400239BReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

Biological anti-freezing protein water-based emulsion for preventing icy pavement as well as preparation method thereof

InactiveCN110295009AAvoid getting lostGuaranteed continuityOther chemical processesConjugated diene hydrocarbon coatingsWater basedEmulsion

Owner:GUANGXI UNIV

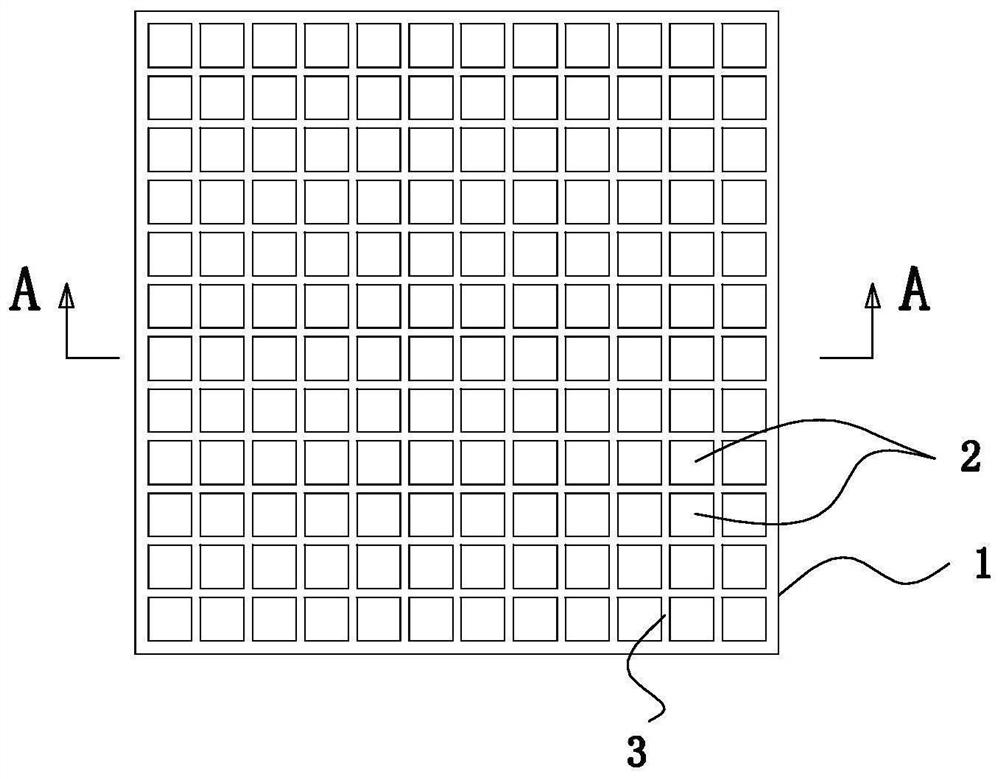

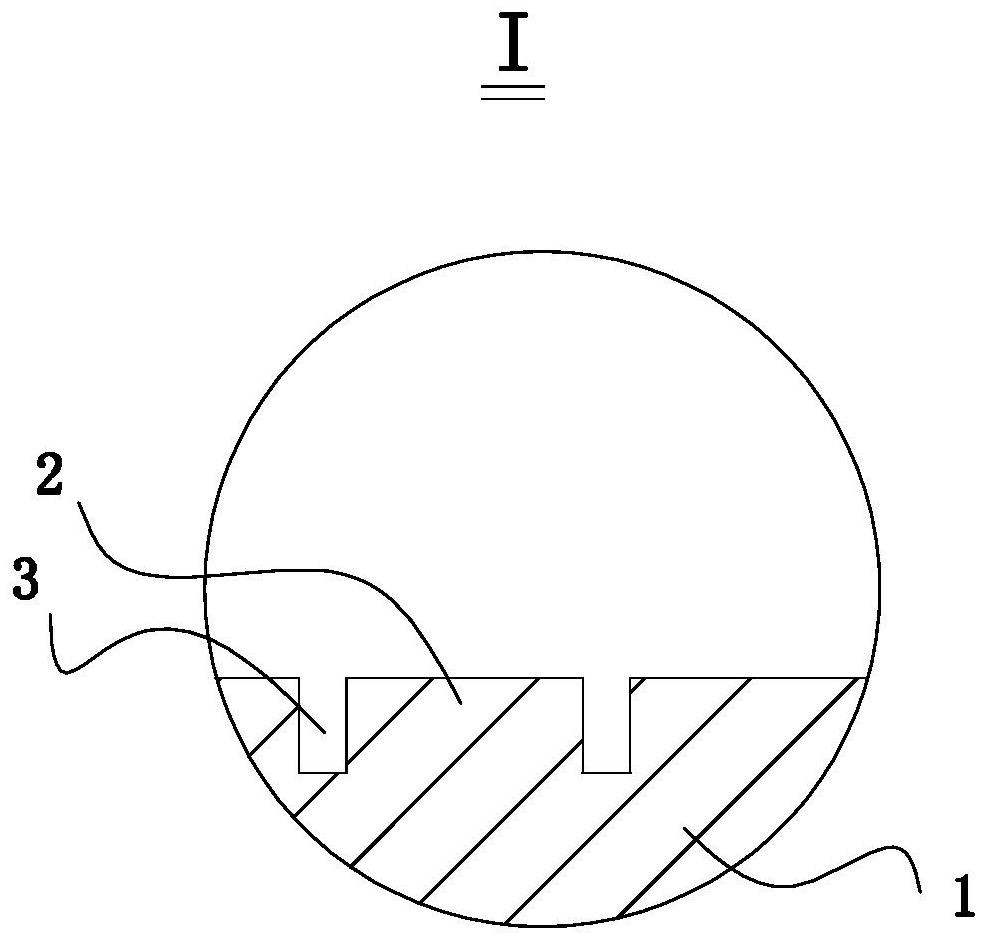

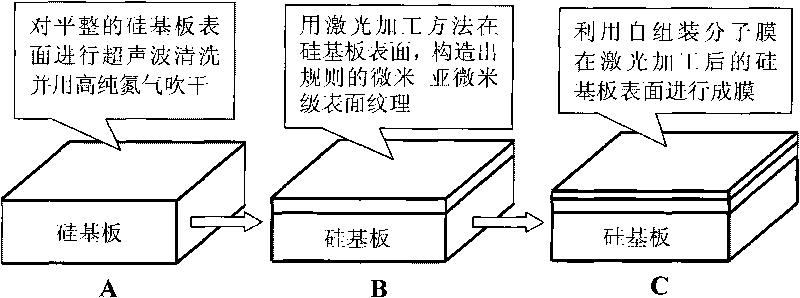

Silicon material substrate and construction method thereof

InactiveCN101704496ASuperhydrophobicEasy to getTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesDot matrixLaser processing

The invention discloses a silicon material substrate and a construction method thereof. The silicon material substrate comprises a silicon substrate, a texture layer and a film forming layer, wherein the texture layer is between the silicon layer and the film forming layer and has a micrometer-submicron grade surface texture structure which is dot matrix texture, straight line texture or grid texture. The construction method comprises the steps of obtaining the texture layer on the surface of the silicon substrate by laser processing and obtaining the film forming layer by the film formation of a self-assembly molecular film on the texture layer. In the invention, a laser method is adopted for processing the surface texture structure on the surface of the silicon substrate and a self-assembly technology is utilized for conducting film formation of the self-assembly molecular film on the laser-processed surface, thus leading the surface contact angle of the original hydrophilic silicon substrate to achieve about 160 degrees and allowing the silicon substrate to become to a silicon material substrate with super hydrophobicity. The technology has simple operation procedures, easily-obtained required chemical reagents, and relatively low cost; in addition, the hydrophobicity of the prepared silicon substrate is relatively stable.

Owner:DALIAN MARITIME UNIVERSITY

High-weather-resistance rock wool product for external thermal insulation of building exterior wall and preparation method of high-weather-resistance rock wool product

ActiveCN114315227AUniform compositionGuaranteed water repellencyClimate change adaptationHeat proofingAdhesive cementWeather resistance

The invention provides a high-weather-resistance rock wool product for external thermal insulation of a building external wall and a preparation method of the high-weather-resistance rock wool product. The high-weather-resistance rock wool product is prepared by spraying a composite adhesive aqueous solution on rock wool fibers, the composite adhesive aqueous solution comprises phenolic resin which can be polymerized and cured at 180-250 DEG C, and sodium methyl silicate and / or potassium methyl silicate; on the basis of the dry weight of the rock wool product, 0.8-1.2% of phenolic resin solids and 0.08-0.15% of sodium methyl silicate and / or potassium methyl silicate are coated; according to the prepared rock wool board, the rock wool fibers are stable in strength and water and moisture absorption capacity, the water and moisture absorption capacity is low, the index requirements of GB / T 25975-2018 are met, and the long-term performance, especially the weather resistance, of the rock wool board is guaranteed.

Owner:潍坊三禄经贸有限公司 +1

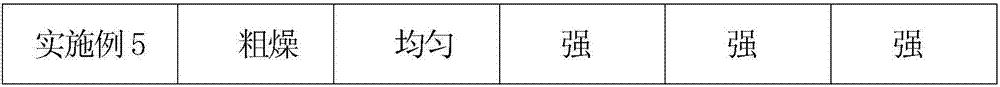

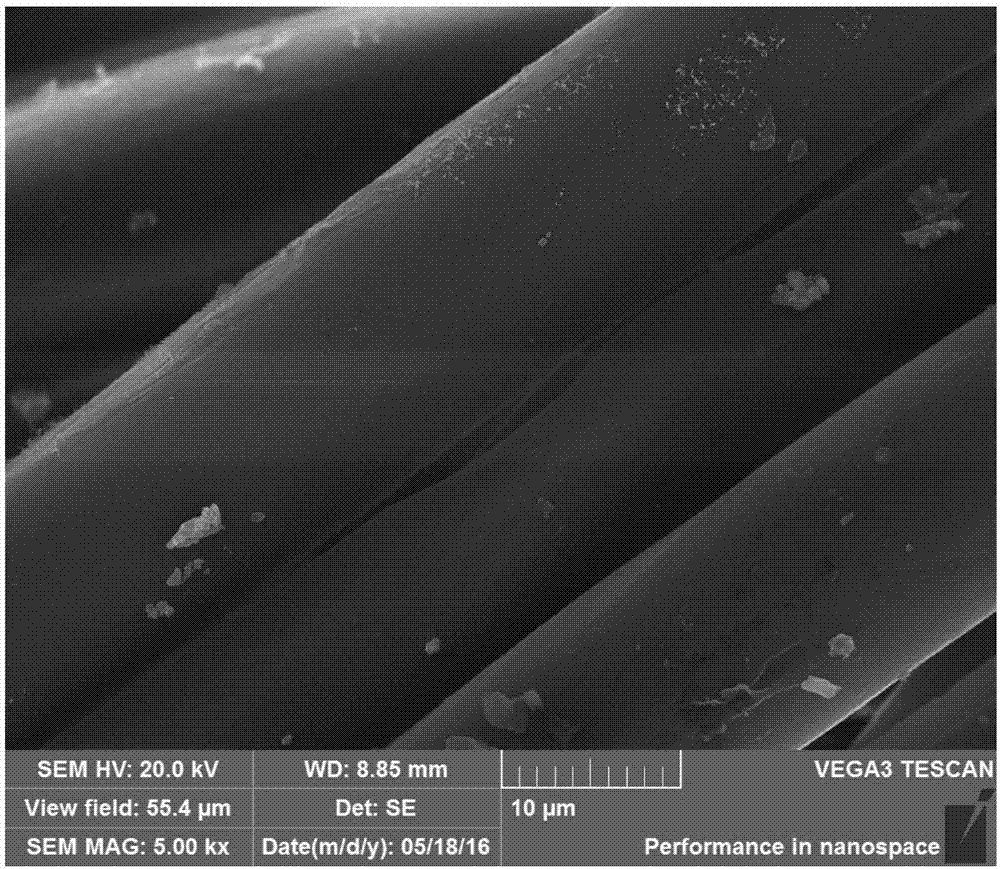

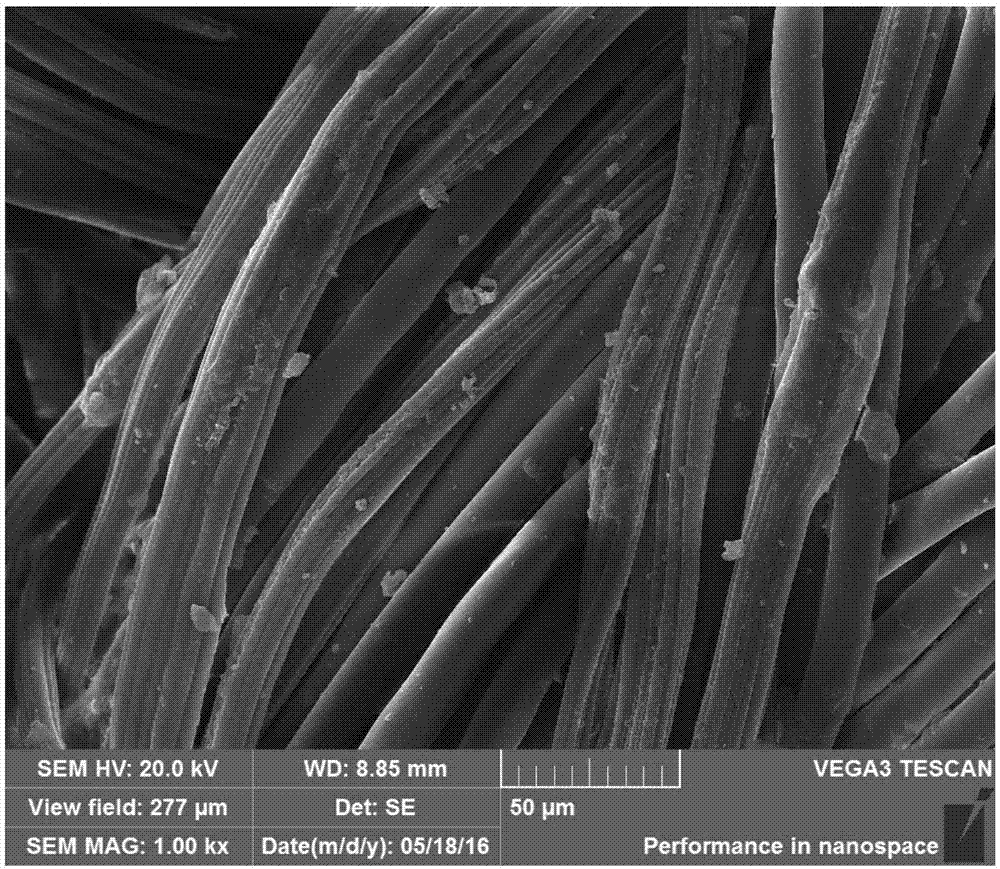

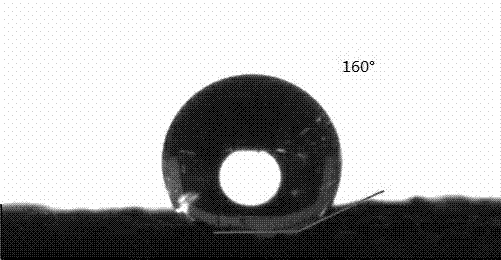

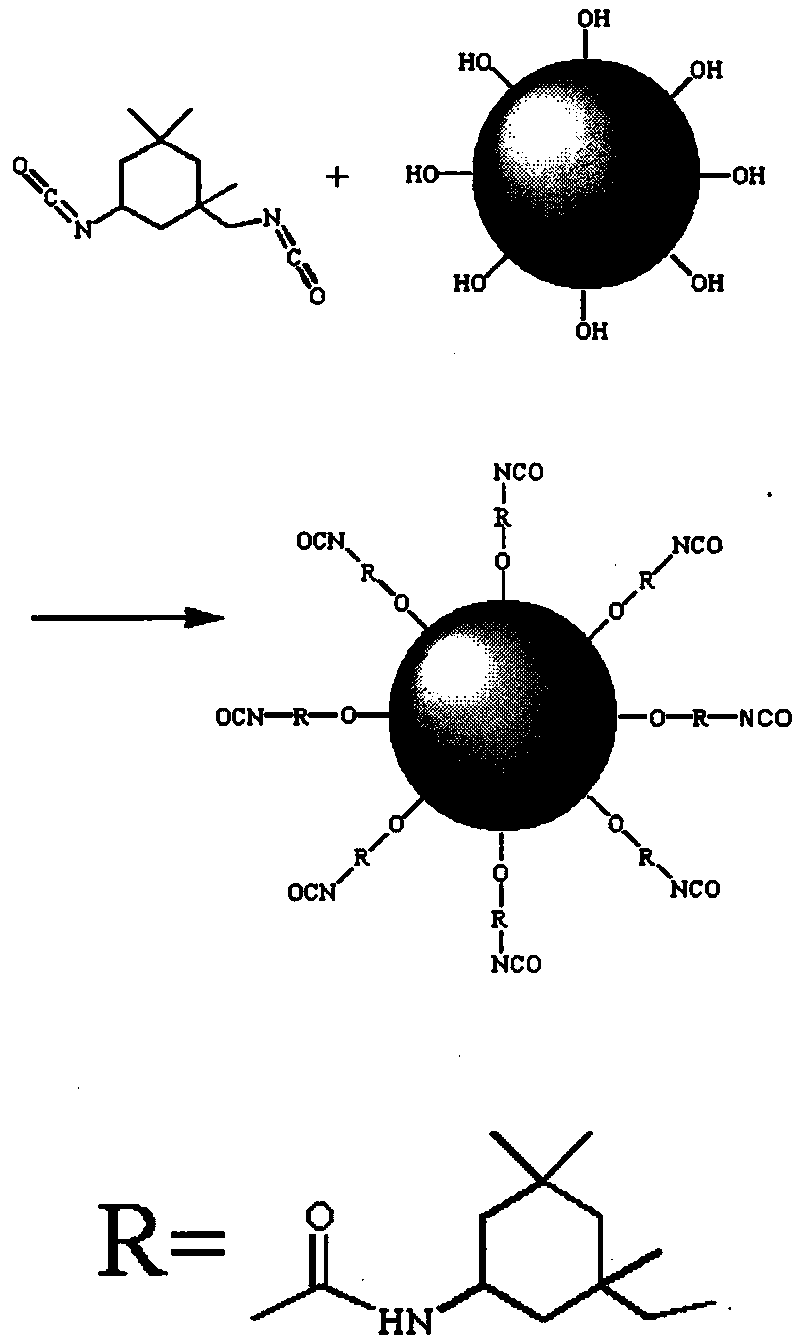

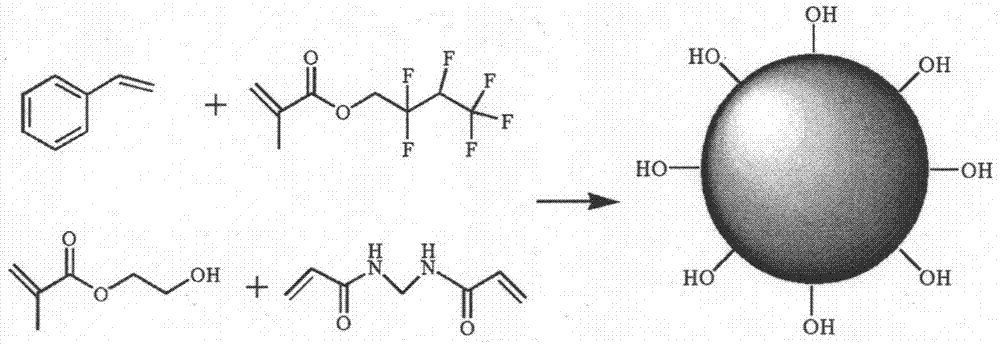

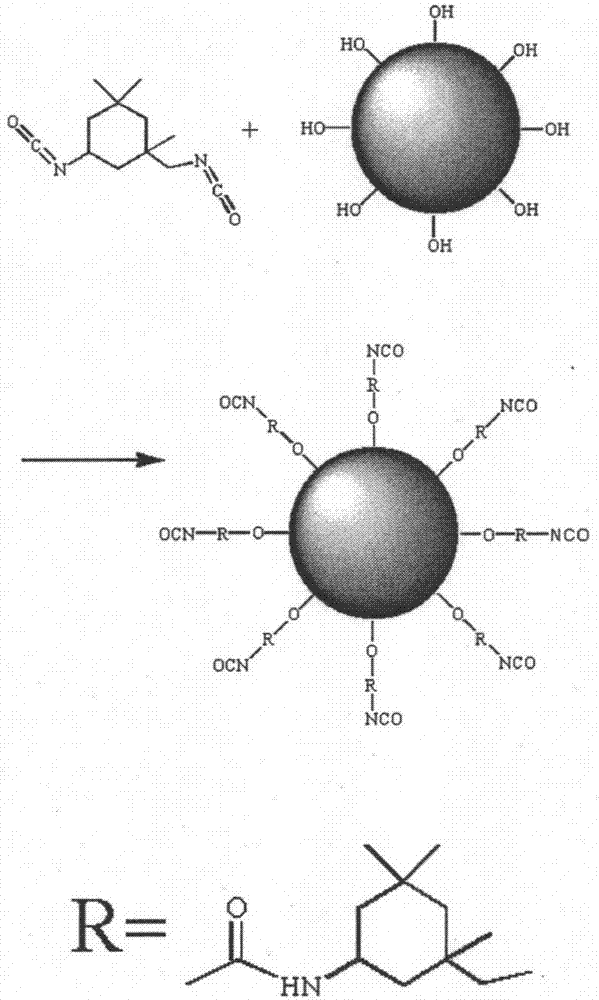

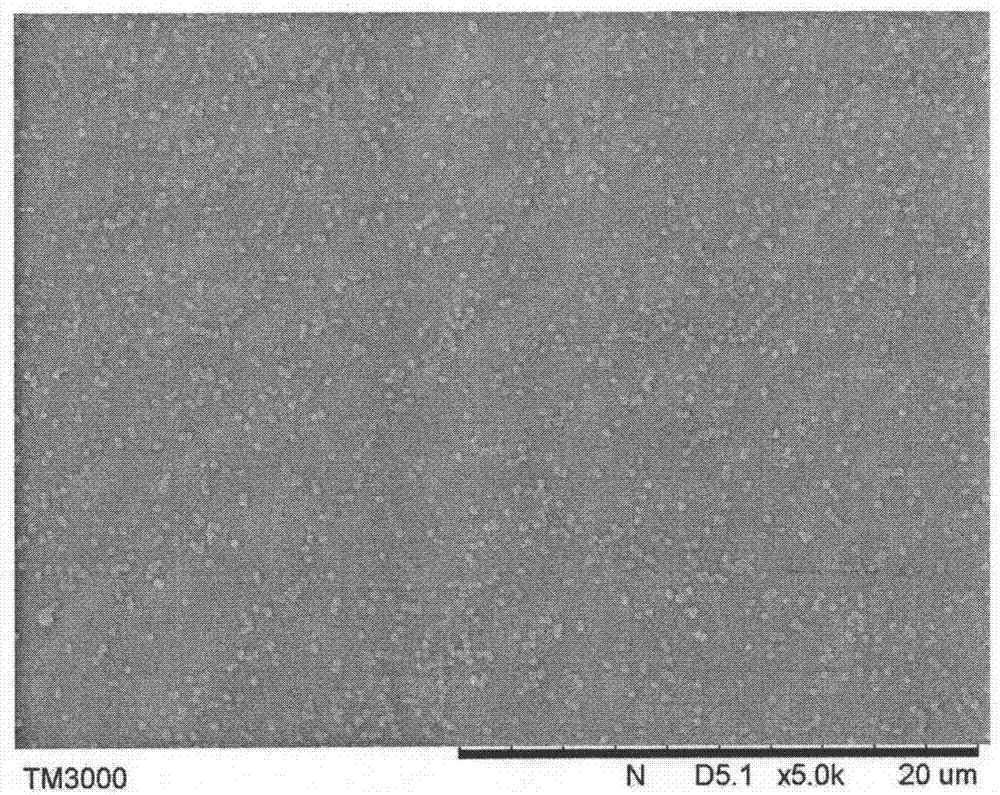

A kind of preparation method of durable hydrophobic fabric

ActiveCN107460733BHydrophobic stabilitySimple processing technologyLiquid repellent fibresVegetal fibresCross-linkChemical Linkage

The invention provides a preparation method of a durable hydrophobic fabric. The preparation method of the durable hydrophobic fabric comprises the steps of, firstly, preparing hydrophobic cross-linked polystyrene microspheres; secondly, performing surface modification on the prepared hydrophobic cross-linked polystyrene microspheres to form reaction-active -NCO functional groups on the surface of the hydrophobic cross-linked polystyrene microspheres; thirdly, grafting the modified hydrophobic cross-linked polystyrene microspheres onto the surface of a fabric to obtain the durable hydrophobic fabric. The prepared hydrophobic cross-linked polystyrene microspheres are stable in performance, simple in technical processes, low in raw material cost and easy to produce; by structuring a hydrophobic structure on the surface of the fabric through the surface-modified hydrophobic cross-linked polystyrene microspheres, significant hydrophobic effects can be achieved and maintained for a relatively long term; the processing temperature is mild and can effectively reduce influence on the original performance of the fabric; through a chemical bonding mode, the surface-modified hydrophobic cross-linked polystyrene microspheres are grafted to the surface of the fabric, so that the fabric can keep good hydrophobic effects after being washed for a number of times.

Owner:DONGHUA UNIV +1

A method for preparing superhydrophobic coatings on steel substrates by Fe-based nanocomposite brush plating

InactiveCN104746118BImprove bindingLong-lasting and effective protectionElectrolytic coatingsHard metalBiological activation

The invention relates to a method for preparing a super-hydrophobic coating on a steel base by Fe-based nanocomposite brush plating, which belongs to the method for preparing a super-hydrophobic coating on a steel base. Nano-composite brush iron plating process to prepare super-hydrophobic coating on the surface of steel substrate, using nano-composite brush iron plating process and coating blackening treatment, to prepare super-hydrophobic coating with contact angle greater than 150° and rolling angle less than 3° on the surface of steel substrate , consists of the following steps: (1) preparatory work; (2) the process flow of preparing micro-nano rough structure on the steel surface by nano-composite brush iron plating; Al 2 o 3 Composite coating → lye soaking, rinse with water after each step of the process to prevent the plating solution from polluting the next process; blacken the coating; (4) modify the rough surface with low surface energy substances. Advantages: Brush iron plating on the hard metal surface and then blacken it to construct a super-hydrophobic surface, which has the advantages of light equipment, simple process, low cost, and strong bonding force of the coating.

Owner:CHINA UNIV OF MINING & TECH

A kind of preparation method of photocurable superhydrophobic composite film

ActiveCN107226920BRapid preparation with superhydrophobic propertiesHas superhydrophobic propertiesCoatingsPolymer scienceElastic substrate

The invention discloses a preparation method of a photocuring type superhydrophobic composite film. The composite film comprises an elastic substrate and a surface superhydrophobic layer. The preparation method comprises the following steps: firstly, preparing the elastic substrate: uniformly mixing a photoinitiator with a prepolymer, and carrying out ultraviolet irradiation on an obtained mixture to obtain a precured elastic substrate; secondly, preparing turbid liquid: uniformly dispersing a polymer with low surface energy, the photoinitiator, a cross-linking agent and micro and / or nano hydrophobic particles in a solvent to obtain the turbid liquid; thirdly, preparing the superhydrophobic composite film: coating the elastic substrate with the turbid liquid, and then carrying out ultraviolet irradiation curing treatment to obtain the composite film with superhydrophobicity. According to the superhydrophobic composite film prepared by the preparation method disclosed by the invention, the elastic substrate and the superhydrophobic layer are integrated by chemical crosslinking; the uperhydrophobic composite film has the advantages of simple preparation process, good friction resistance and tensile resistance, stable superhydrophobic effect and the like; the coating is not easy to fall off.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

A kind of polyurethane foam, its preparation method and its application

ActiveCN104327492BIncrease roughnessRapid adsorption recoveryOther chemical processesEpoxyFoaming agent

Owner:SOUTHWEAT UNIV OF SCI & TECH +3

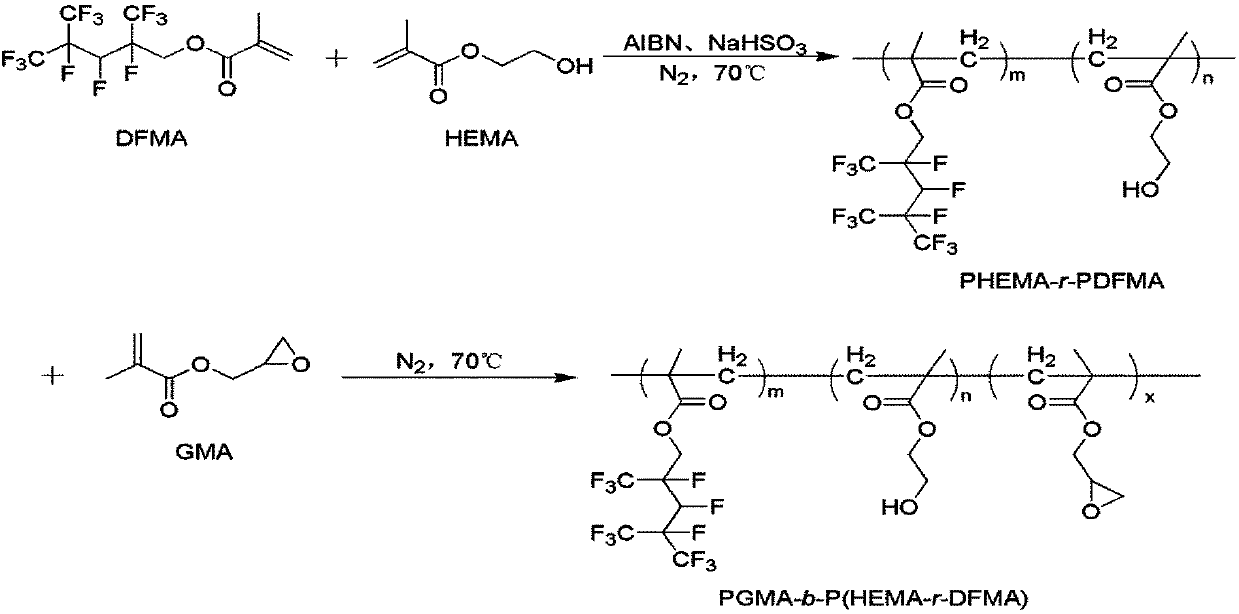

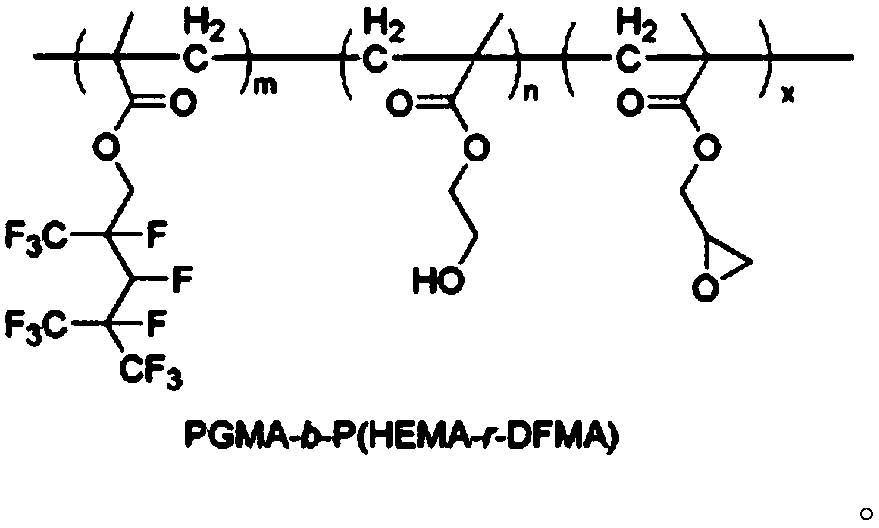

Super-hydrophobic coating as well as preparation method and application thereof

InactiveCN109594340AExcellent superhydrophobic propertiesReduce pollutionLiquid repellent fibresGlycidyl methacrylate(Hydroxyethyl)methacrylate

The invention discloses a super-hydrophobic coating which is characterized by being a polymer which is prepared from dodecafluoroheptyl methacrylate, glycidyl methacrylate, hydroxyethyl methylacrylate, azodiisobutyronitrile and sodium hydrogen sulfite through reactions, and the polymer is PGMA-b-P(HEMA-r-DFMA). The invention further discloses a preparation method and an application method of the super-hydrophobic coating. The super-hydrophobic coating disclosed by the invention is small in environmental pollution and good in super-hydrophobic property, and the super-hydrophobic coating disclosed by the invention is simple in preparation method, very convenient in application method and good in repeated use performance.

Owner:XIAN UNIV OF TECH

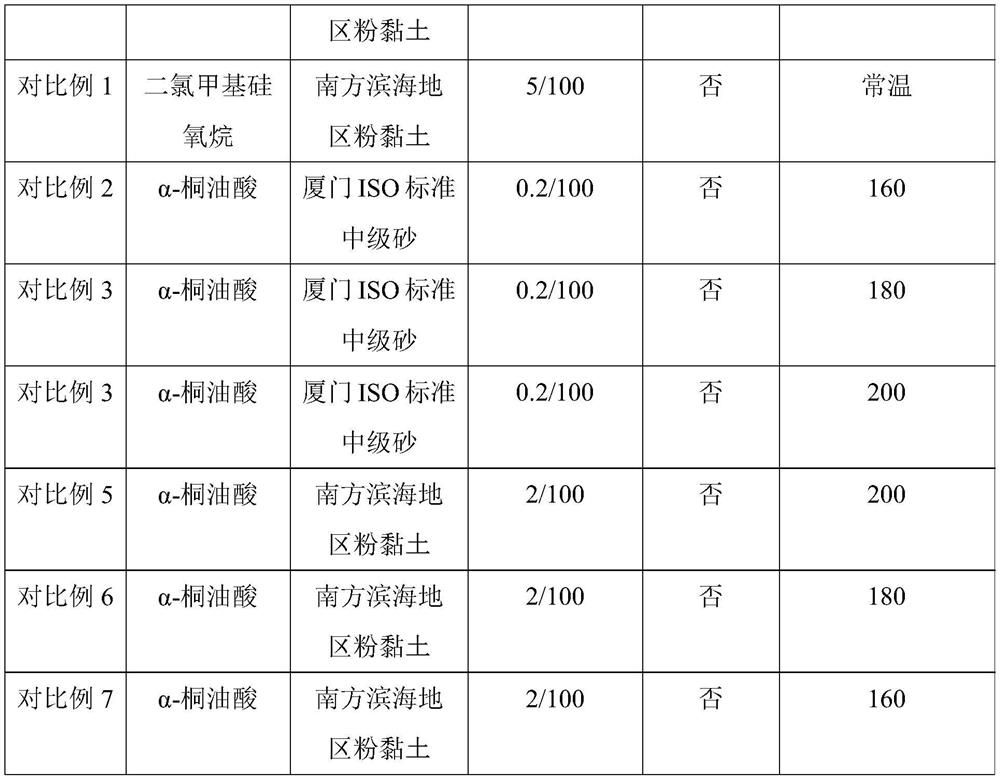

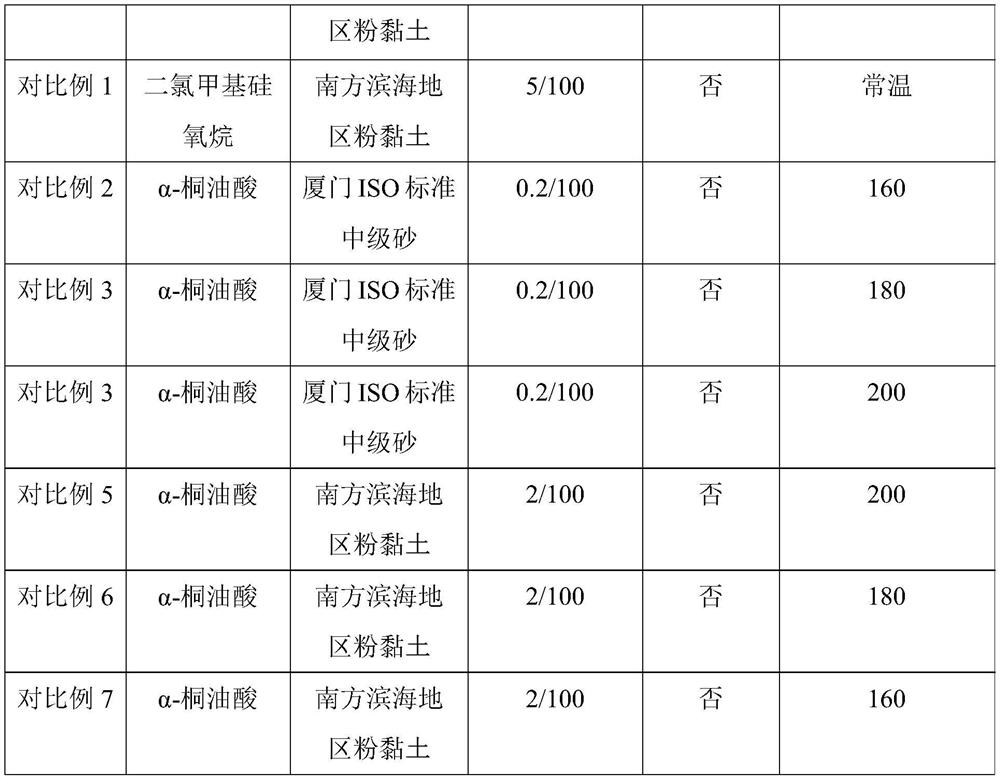

A kind of hydrophobic dispersion material and preparation method thereof

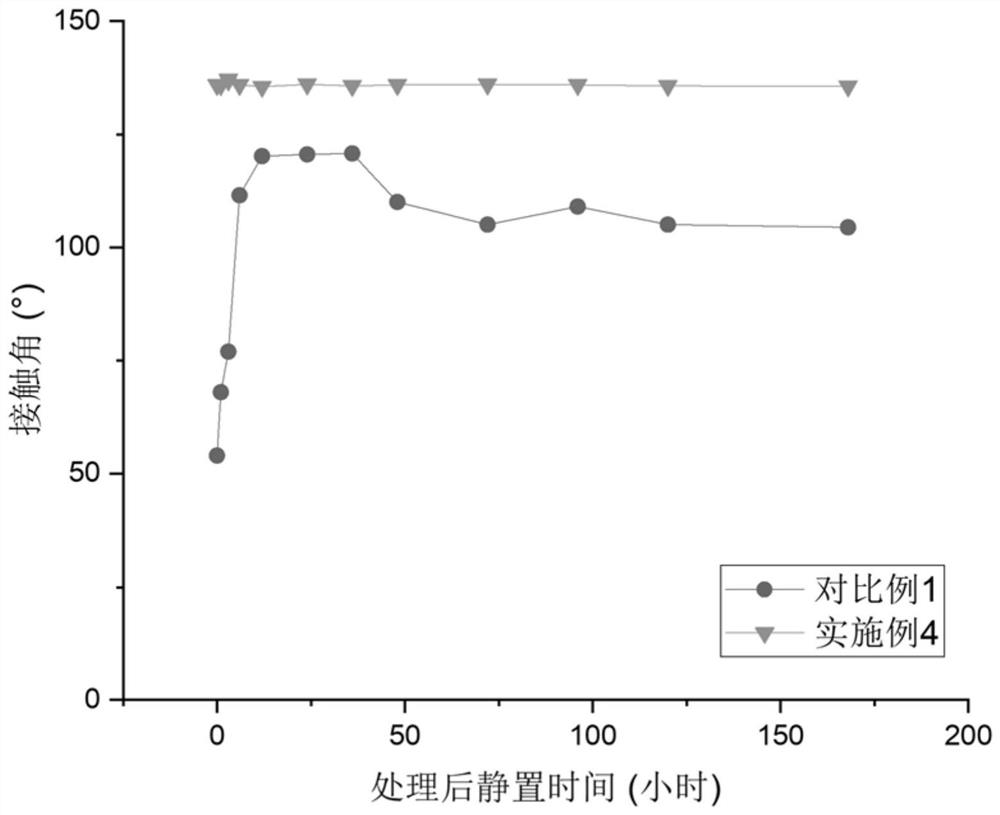

ActiveCN113502165BHydrophobic stabilityImprove hydrophobicityOrganic fertilisersSoil conditioning compositionsHydrophobeMaterials science

The invention belongs to the field of hydrophobic materials, and discloses a hydrophobic powder material and a preparation method thereof. Under the condition of cutting off oxygen, an unsaturated fatty acid containing at least two conjugated unsaturated bonds is used as a hydrophobic agent to combine soil with the hydrophobic agent. Mix and heat to obtain hydrophobic dispersion material. In the present invention, under the condition of isolating oxygen, the hydrophobic agent undergoes thermal polymerization reaction after heating, and the dry oil viscosity of the hydrophobic agent after anaerobic thermal polymerization is high, and it is in a semi-solid-solid state, and can be successfully attached to the surface of soil particles , forming a hydrophobic film, thereby obtaining a hydrophobic dispersion material with stable hydrophobic properties and high hydrophobic properties. In addition, the amount of hydrophobic agent used in the present invention is small, and the source is extensive, low in cost, high in cost performance, degradable, can be naturally degraded after use, and has no biological toxicity, and will not increase the content of heavy metals at the same time, and is environmentally friendly. The prospects are broad.

Owner:SUN YAT SEN UNIV

A Method for Realizing Weak Hydrophobicity on the Surface of AC Composite Insulators

ActiveCN103342909BReduce string lengthGuaranteed reliabilityCoatingsComposite insulatorsAlternating current

The invention discloses a method for realizing weak surface hydrophobicity (HC6) for an alternating-current (AC) composite insulator. According to the method, diatomite and kaolin are mixed according to a certain ratio and then are coated on the surface of the insulator, and the weak surface hydrophobicity for the composite insulator is realized after a certain migration time. By using the method, the voltage of the AC composite insulator is higher than that of flashover under hydrophilic conditions and is far lower than that of the flashover under strong hydrophobic conditions, and the situation that the hydrophobicity of the composite insulator of an AC transmission line during operation is lowered is better simulated. Thus, AC composite insulator contamination tests are carried out by using the method, and obtained results are applied to the design of external insulation of a power transmission line, so that the construction cost of the power transmission line can be reduced while the reliability of the external insulation of the power transmission line is guaranteed.

Owner:STATE GRID CORP OF CHINA +2

Method for preparing polymer superhydrophobic surface by CaCO3 template method

Owner:ZHEJIANG UNIV OF TECH

Hydrophobic bulk material and preparation method thereof

ActiveCN113502165AHydrophobic stabilityImprove hydrophobicityOrganic fertilisersSoil conditioning compositionsUnsaturated fatty acidSaturated bonds

The invention belongs to the field of hydrophobic materials, and discloses a hydrophobic bulk material and a preparation method thereof. Under the oxygen isolation condition, unsaturated fatty acid containing at least two conjugated unsaturated bonds serves as a hydrophobic agent, soil and the hydrophobic agent are mixed and heated, and the hydrophobic bulk material can be obtained. Under the condition of oxygen isolation, the hydrophobic agent is subjected to thermal polymerization reaction after being heated, the dry oil of the hydrophobic agent subjected to anaerobic thermal polymerization has high viscosity, is in a semi-solid-solid state, and can be successfully attached to the surfaces of soil particles to form a hydrophobic membrane, so that the hydrophobic bulk material with stable hydrophobic performance and high hydrophobic performance is obtained. In addition, the water repellent agent is small in usage amount, wide in source, low in cost, high in cost performance, degradable, capable of being naturally degraded after being used, free of biotoxicity, free of increase of the content of heavy metal, environmentally friendly and wide in application prospect.

Owner:SUN YAT SEN UNIV

Self-cleaning waterproof paint

InactiveCN107163753APossess superhydrophobic abilityWith self-cleaning functionCoatingsSucroseEthyl cinnamate

The invention discloses a self-cleaning waterproof paint. The self-cleaning waterproof paint is composed of, by weight, 40 to 60 parts of polyacrylate emulsion, 6 to 18 parts of grape seed extract, 8 to 16 parts of magnesium oxychloride cement, 2 to 10 parts of potato starch, 2 to 5 parts of chromic oxide, 4 to 11 parts of nano silver particle, 5 to 11 parts of nano boron oxide, 0.5 to 1 part of alpha-ketoglutaric acid, 2 to 5 parts of nano antimonous oxide, 2 to 5 parts of diatomite, 10 to 20 parts of methyl dihydrojasmonate, 8 to 10 parts of ethyl cinnamate, 5 to 11 parts of silver-loaded fruit shell activated carbon, 2 to 5 parts of sucrose ester, 2 to 5 parts of vanillin, and 150 to 200 parts of water. The self-cleaning waterproof paint possesses super-hydrophobic performance, and self-cleaning function, is excellent in hydrophobic performance and water resistance, and is stable; a preparation method is simple; aging cracking is not easily caused; and service life is prolonged.

Owner:惠安县灿鑫新材料科技有限公司

Preparation method of durable hydrophobic fabric

ActiveCN107460733AHydrophobic performance is stableSimple processing technologyLiquid repellent fibresVegetal fibresChemistrySurface modification

The invention provides a preparation method of a durable hydrophobic fabric. The preparation method of the durable hydrophobic fabric comprises the steps of, firstly, preparing hydrophobic cross-linked polystyrene microspheres; secondly, performing surface modification on the prepared hydrophobic cross-linked polystyrene microspheres to form reaction-active -NCO functional groups on the surface of the hydrophobic cross-linked polystyrene microspheres; thirdly, grafting the modified hydrophobic cross-linked polystyrene microspheres onto the surface of a fabric to obtain the durable hydrophobic fabric. The prepared hydrophobic cross-linked polystyrene microspheres are stable in performance, simple in technical processes, low in raw material cost and easy to produce; by structuring a hydrophobic structure on the surface of the fabric through the surface-modified hydrophobic cross-linked polystyrene microspheres, significant hydrophobic effects can be achieved and maintained for a relatively long term; the processing temperature is mild and can effectively reduce influence on the original performance of the fabric; through a chemical bonding mode, the surface-modified hydrophobic cross-linked polystyrene microspheres are grafted to the surface of the fabric, so that the fabric can keep good hydrophobic effects after being washed for a number of times.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com