Preparation method of durable hydrophobic fabric

A fabric and hydrophobic technology, applied in the directions of plant fibers, animal fibers, textiles and papermaking, can solve the problems of easy detachment of the silicone film layer, poor washing resistance, and complicated preparation methods for super-hydrophobic fabrics, and achieves remarkable hydrophobic effect and strong hydrophobicity. effect, the effect of stable hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

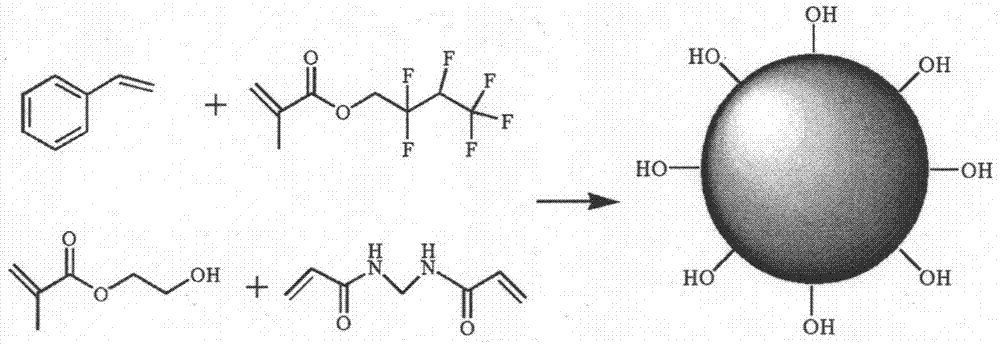

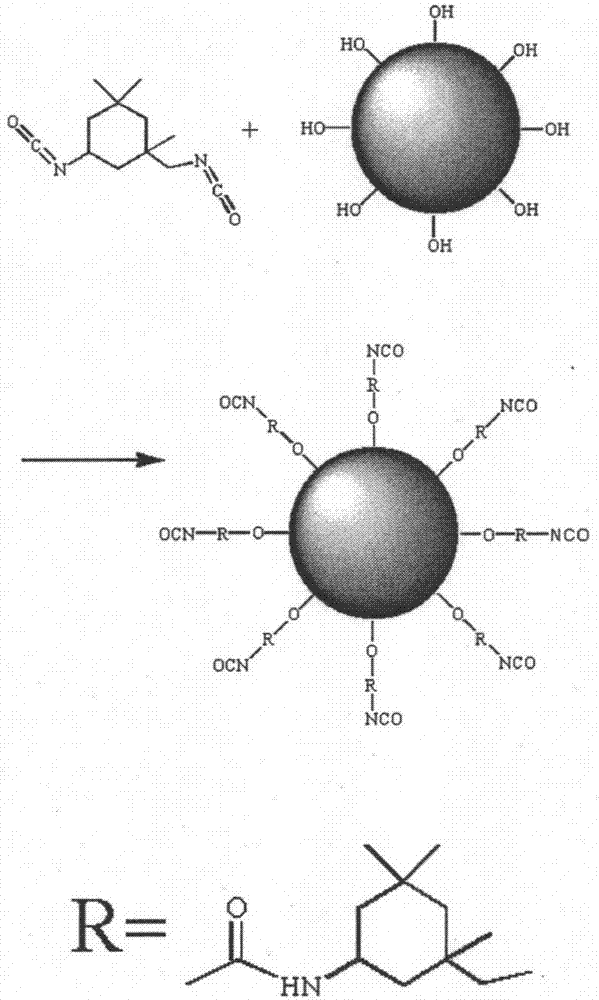

[0039] (1) Dissolve 1.8g styrene, 5g hexafluorobutyl methacrylate, 0.2g hydroxyethyl methacrylate, 0.1g N, N-methylenebisacrylamide in 100mL deionized water and place in a 250mL three-necked flask In the process, blow nitrogen for 30 minutes and stir to raise the temperature to 70°C, add 2mL aqueous solution containing 70mg of ammonium persulfate initiator APS dropwise, continue the reaction for 12h, and filter and purify the reaction product three times, and dry it in a vacuum oven at 40°C to obtain hydrophobic crosslinking Polystyrene microspheres.

[0040] (2) Dissolve 0.3g of hydrophobic cross-linked polystyrene microspheres in 100mL of acetone, ultrasonically disperse for 30min, add 2mL of isophorone diisocyanate dropwise, add 0.1mL of dibutyltin dilaurate dropwise, and The reaction was stirred at 50°C for 8 hours, the product was filtered and rinsed with a large amount of acetone, and dried in a vacuum oven at room temperature.

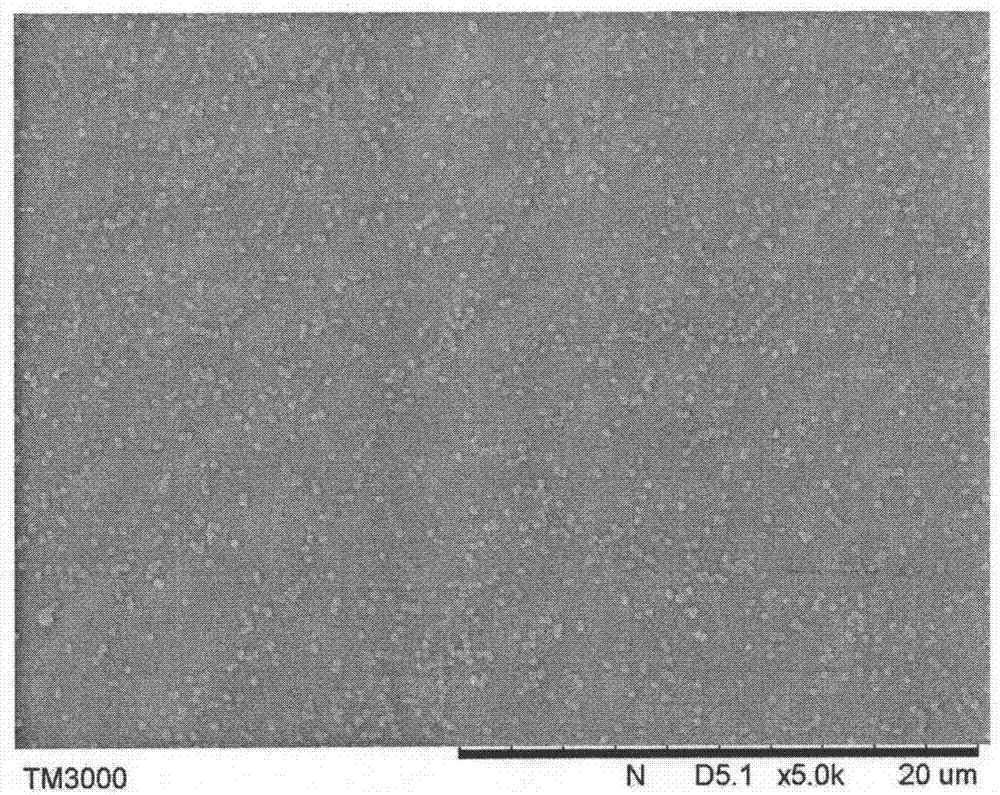

[0041] (3) Dissolve 0.2 g of surface-mod...

Embodiment 2

[0049] (1) Dissolve 1.8g styrene, 8g trifluoroethyl methacrylate, 0.2g hydroxyethyl methacrylate, 0.1g N, N-methylenebisacrylamide in 100mL deionized water and place in a 250mL three-necked flask , blow nitrogen for 30 minutes and stir to raise the temperature to 70°C, add 2mL aqueous solution containing 70mg ammonium persulfate initiator dropwise, continue to react for 12h, the reaction product is filtered and purified three times, and dried in a vacuum oven at 40°C to obtain hydrophobic cross-linked polystyrene Microspheres.

[0050] (2) Dissolve 0.3g of hydrophobic cross-linked polystyrene microspheres in 100mL of acetone, ultrasonically disperse for 30min, add 2mL of isophorone diisocyanate dropwise, add 0.1mL of dibutyltin dilaurate dropwise, and The reaction was stirred at 50°C for 8 hours, the product was filtered and rinsed with a large amount of acetone, and dried in a vacuum oven at room temperature.

[0051] (3) Dissolve 0.2 g of surface-modified polystyrene cross-...

Embodiment 3

[0054] (1) Dissolve 1.8g styrene, 5g hexafluorobutyl methacrylate, 0.2g hydroxyethyl methacrylate, 0.1g N, N-methylenebisacrylamide in 100mL deionized water and place in a 250mL three-necked flask , blow nitrogen for 30 minutes and stir to raise the temperature to 70°C, add 2mL aqueous solution containing 70mg ammonium persulfate initiator dropwise, continue to react for 12h, the reaction product is filtered and purified three times, and dried in a vacuum oven at 40°C to obtain hydrophobic cross-linked polystyrene Microspheres.

[0055] (2) Dissolve 0.3g of hydrophobic cross-linked polystyrene microspheres in 100ml of petroleum ether, disperse by ultrasonic wave for 30min, add 2mL of diphenylmethane diisocyanate dropwise, add 0.1mL of dibutyltin dilaurate dropwise, and The reaction was stirred at 50°C for 8 hours, the product was filtered and rinsed with a large amount of acetone, and dried in a vacuum oven at room temperature.

[0056] (3) Dissolve 0.2 g of surface-modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com