A kind of waterproofing agent for concrete and preparation method thereof

A waterproofing agent and concrete technology, which is applied in the field of building materials, can solve the problems of surface waterproofing layer falling off waterproofing effect, waterproofing performance, waterproofing performance defects, failure, etc., to achieve good waterproofing effect, strengthen hydrophobic effect, and firm waterproofing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

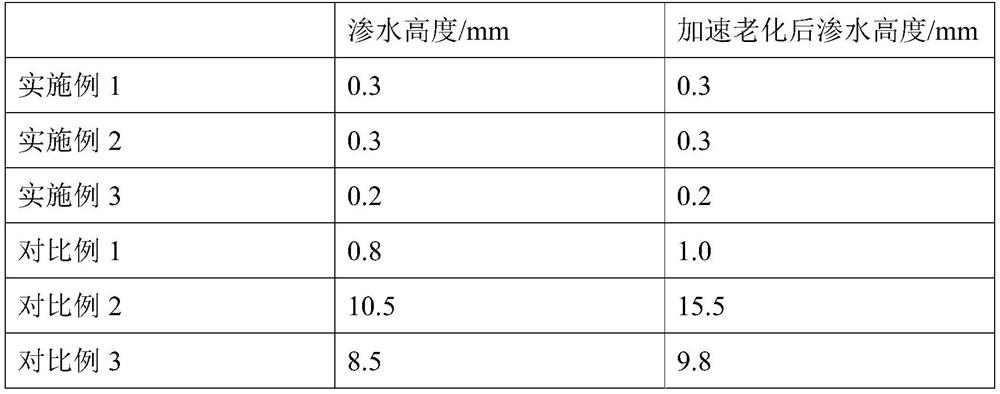

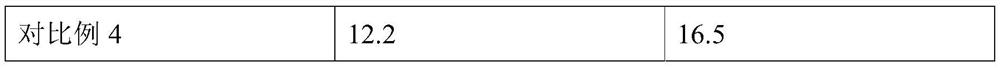

Examples

Embodiment 1

[0036] After mixing graphene oxide and water in a mass ratio of 1:5, at a temperature of 80 °C and an ultrasonic frequency of 100 kHz, the temperature was 80 ° C and the ultrasonic frequency was 100 kHz, and the ultrasonic dispersion was carried out for 10 min, and then 10% of the graphene oxide mass was added. At a temperature of 85 °C, after heating and refluxing for 4 hours, filter, collect the filter cake, and wash the filter cake with deionized water 3 times, and then transfer the washed filter cake to an oven, and dry it at a temperature of 100 °C To constant weight, get dry filter cake, namely pretreatment graphene oxide;

[0037] In parts by weight, take 10 parts of bacterial cellulose, 60 parts of concentrated sulfuric acid, and 100 parts of n-hexanol in sequence, first mix the concentrated sulfuric acid and n-hexanol, cool to room temperature, then add bacterial cellulose, and at room temperature, use The stirrer was stirred at 150r / min for 2 hours, then washed with ...

Embodiment 2

[0043] After mixing graphene oxide and water at a mass ratio of 1:8, at a temperature of 85 °C and an ultrasonic frequency of 110 kHz, the temperature was 85 ° C and the ultrasonic frequency was 110 kHz, and the ultrasonic dispersion was carried out for 50 min, and then 12% of the graphene oxide mass was added. At a temperature of 88 °C, after heating and refluxing for 6 hours, filter to collect the filter cake, and wash the filter cake with deionized water for 5 times, and then transfer the washed filter cake to an oven and dry it at a temperature of 110 °C To constant weight, get dry filter cake, namely pretreatment graphene oxide;

[0044]In parts by weight, sequentially take 20 parts of bacterial cellulose, 70 parts of concentrated sulfuric acid, and 110 parts of n-hexanol, first mix the concentrated sulfuric acid and n-hexanol, cool to room temperature, then add bacterial cellulose, and at room temperature, use The stirrer was stirred at 200r / min for 3 hours, washed with ...

Embodiment 3

[0050] After mixing graphene oxide and water at a mass ratio of 1:10, at a temperature of 90 ° C and an ultrasonic frequency of 120 kHz, the temperature was 90 ° C and the ultrasonic frequency was 120 kHz, and the ultrasonic dispersion was carried out for 60 min, and then 15% of the graphene oxide mass was added. At a temperature of 90 °C, after heating and refluxing for 8 hours, filter, collect the filter cake, and wash the filter cake with deionized water 6 times, and then transfer the washed filter cake to an oven, and dry it at a temperature of 120 °C To constant weight, get dry filter cake, namely pretreatment graphene oxide;

[0051] In parts by weight, take 30 parts of bacterial cellulose, 80 parts of concentrated sulfuric acid, and 120 parts of n-hexanol in turn, mix concentrated sulfuric acid and n-hexanol, cool to room temperature, then add bacterial cellulose, and at room temperature, use The stirrer was stirred at 300r / min for 4 hours, then washed with sodium hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com