Preparation method of composite sodium ion battery negative electrode material with long-lifetime and few layer

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity, poor stability, and low specific capacity of molybdenum disulfide, improve electronic conductivity and facilitate penetration. Diffusion, the effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 2g of chlorella and 5g of phosphomolybdic acid into 0.4L of distilled water, stir for 12h, centrifuge once and place in an oven at 60℃ for drying;

[0035] 2) After mixing the dark green block solid obtained in step 1) with 2 times the mass of sulfur powder, the mixture is heated at Ar 95%\H 2 Calcined in a 5% atmosphere tube furnace at 600°C for 2 hours, and collect a black solid sample, which is a low-layer molybdenum disulfide-chlorella-derived carbon composite material;

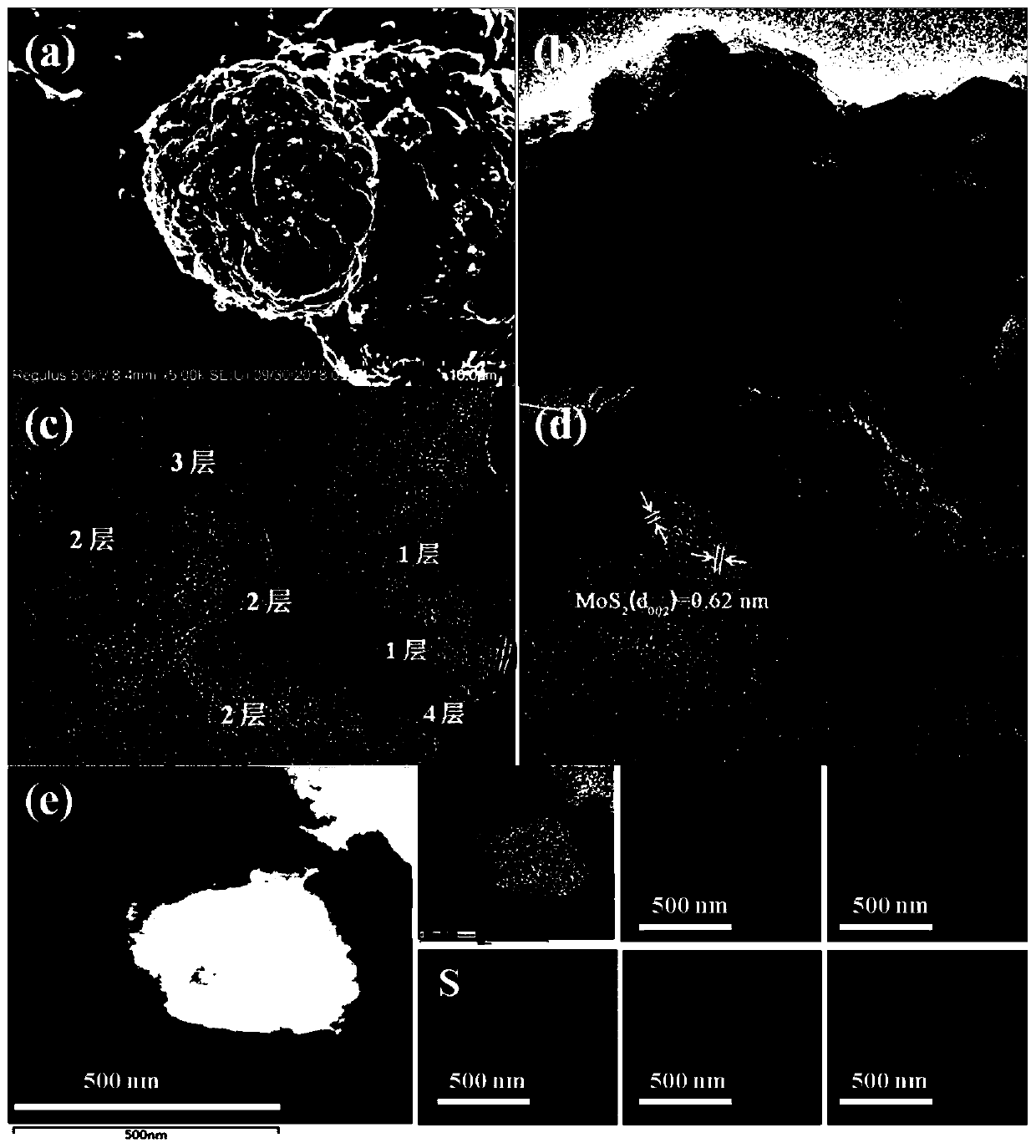

[0036] Obtained by XRD experiment figure 1 The XRD pattern of the few-layer molybdenum disulfide-Chlorella-derived carbon composite material, by figure 1 It can be seen that the synthesized material is molybdenum disulfide, and its diffraction peak position matches the standard pattern of molybdenum disulfide (JCPDS, 089-5112). And it has a wide diffraction peak, which means that the synthesized molybdenum disulfide has an ultra-small particle size. It is worth noting that the diffraction peak...

Embodiment 2

[0039] 1) Weigh 2g of chlorella and 8g of ammonium molybdate into 0.4L of distilled water, stir for 12h, centrifuge once and place in an oven at 80℃ for drying;

[0040] 2) After mixing the dark green block solid obtained in step 1) with 2 times the mass of sulfur powder, the mixture is heated at Ar 95%\H 2 Calcined in a 5% atmosphere tube furnace at 700°C for 2 hours, and collect a black solid sample, which is a low-layer molybdenum disulfide-chlorella-derived carbon composite material;

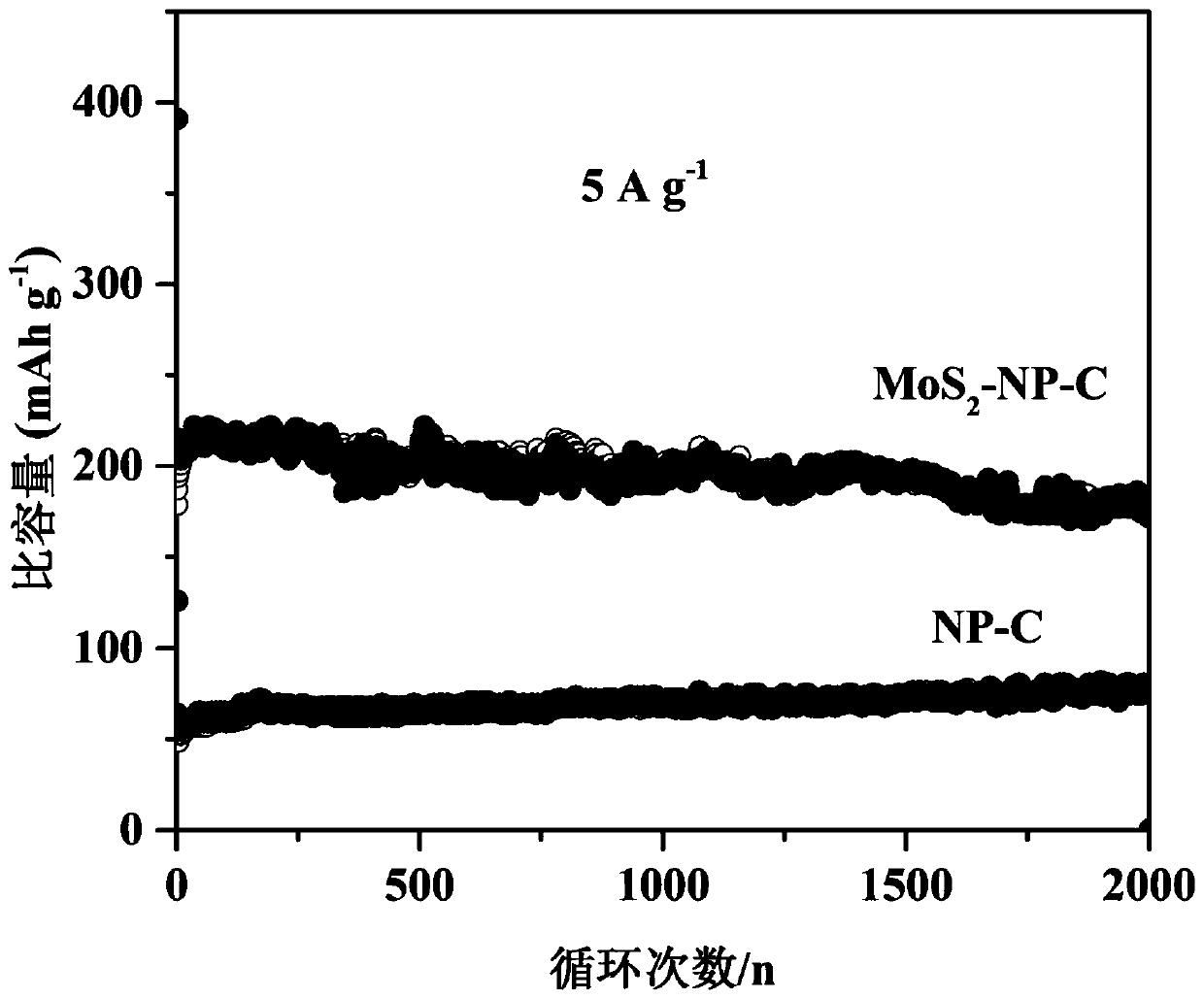

[0041] The few-layer molybdenum disulfide-chlorella-derived carbon composite material prepared by this embodiment: conductive agent super P carbon: binder CMC according to the mass percentage 80:10:10, mixed and ground, and evenly coated on the copper foil for work Electrode, metal sodium sheet is counter electrode and reference electrode, 1mol / L NaClO 4 / PC+EC is the electrolyte solution assembled into button cell; all assembly is carried out in an inert atmosphere glove box.

Embodiment 3

[0043] 1) Weigh 2g of chlorella and 5g of phosphomolybdic acid into 0.4L of distilled water, stir for 12h, centrifuge once and place in an oven at 60℃ for drying;

[0044] 2) After mixing the dark green block solid obtained in step 1) with 2 times the mass of sulfur powder, the mixture is heated at Ar 95%\H 2 Calcined in a 5% atmosphere tube furnace at 500°C for 2 hours, and collect a black solid sample, which is a low-layer molybdenum disulfide-chlorella-derived carbon composite material;

[0045] The few-layer molybdenum disulfide-chlorella-derived carbon composite material prepared by this embodiment: conductive agent super P carbon: binder CMC according to the mass percentage 80:10:10, mixed and ground, and evenly coated on the copper foil for work Electrode, metal sodium sheet is counter electrode and reference electrode, 1mol / L NaClO 4 / PC+EC is the electrolyte solution assembled into button cell; all assembly is carried out in an inert atmosphere glove box.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com