A method for modifying polyvinyl alcohol fibers used in high ductility cement-based composites

A polyvinyl alcohol fiber and composite material technology, applied in the field of surface modified polyvinyl alcohol fiber, can solve the problems of high ductility cement-based composite material performance impact, damage to the surface of polyvinyl alcohol fiber, and affect the performance of cement matrix, etc., to achieve hydrophobicity Stable performance and wear-resistant slip performance, weakened interface strength, and stable bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A method for modifying polyvinyl alcohol fibers used in high-ductility cement-based composite materials.

[0025] 1) Prepare epoxy resin pretreatment solution; prepare diluted epoxy resin pretreatment solution, choose alcohol as diluent for epoxy resin, and the mass fraction of epoxy resin is 5%.

[0026] 2) Soak the polyvinyl alcohol fiber in the epoxy resin pretreatment solution; soak the untreated polyvinyl alcohol fiber in the epoxy resin pretreatment solution, the soaking temperature is 50°C, and the soaking time is 3h.

[0027] 3) Dry the polyvinyl alcohol fiber after pretreatment; take out the polyvinyl alcohol fiber soaked in the epoxy resin pretreatment solution, and vacuum-dry it in a vacuum drying oven to constant weight at a drying temperature of 50°C.

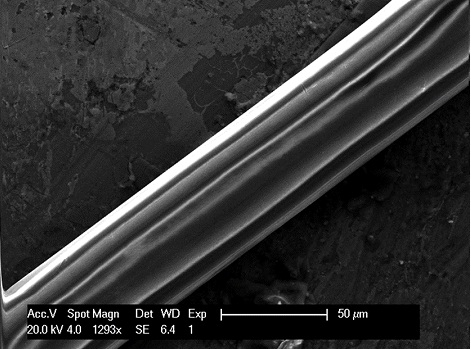

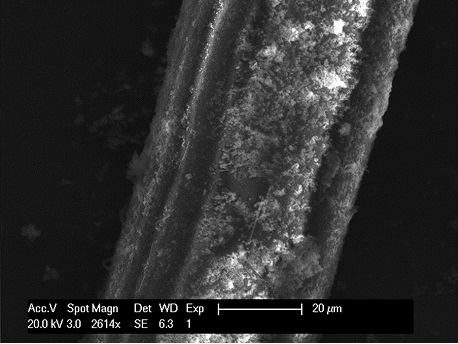

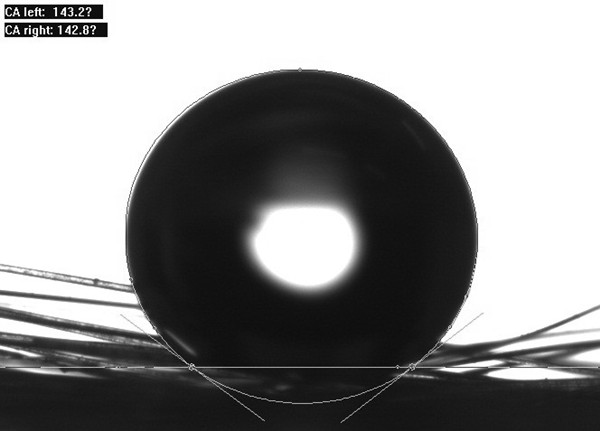

[0028] 4) The surface of the polyvinyl alcohol fiber is coated with hydrophobic fumed silica; the dried polyvinyl alcohol fiber and hydrophobic nano fumed silica are mechanically stirred and mixed...

Embodiment 2

[0030] Example 2: A method for modifying polyvinyl alcohol fibers used in high-ductility cement-based composite materials.

[0031] 1) Prepare epoxy resin pretreatment solution; prepare diluted epoxy resin pretreatment solution, acetone is selected as the epoxy resin diluent, and the mass fraction of epoxy resin is 2%.

[0032] 2) Soak the polyvinyl alcohol fiber in the epoxy resin pretreatment solution; soak the untreated polyvinyl alcohol fiber in the epoxy resin pretreatment solution, the soaking temperature is 60°C, and the soaking time is 2h.

[0033] 3) Dry the polyvinyl alcohol fiber after pretreatment; take out the polyvinyl alcohol fiber soaked in the epoxy resin pretreatment solution, and vacuum-dry it in a vacuum drying oven to constant weight at a drying temperature of 60°C.

[0034] 4) The surface of the polyvinyl alcohol fiber is coated with hydrophobic fumed silica; the dried polyvinyl alcohol fiber and hydrophobic nano fumed silica are mechanically stirred and ...

Embodiment 3

[0036] Example 3: A method for modifying polyvinyl alcohol fibers used in high-ductility cement-based composite materials.

[0037] 1) Prepare epoxy resin pretreatment solution; prepare diluted epoxy resin pretreatment solution, choose alcohol as diluent for epoxy resin, and the mass fraction of epoxy resin is 6%.

[0038] 2) Soak the polyvinyl alcohol fiber in the epoxy resin pretreatment solution; soak the untreated polyvinyl alcohol fiber in the epoxy resin pretreatment solution, the soaking temperature is 60°C, and the soaking time is 3h.

[0039] 3) Dry the polyvinyl alcohol fiber after pretreatment; take out the polyvinyl alcohol fiber soaked in the epoxy resin pretreatment solution, and vacuum-dry it in a vacuum drying oven to constant weight at a drying temperature of 60°C.

[0040] 4) The surface of the polyvinyl alcohol fiber is coated with hydrophobic fumed silica; the dried polyvinyl alcohol fiber and hydrophobic nano fumed silica are mechanically stirred and mixed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com