A kind of fluorine-free durable superhydrophobic cotton cloth and its preparation method and application

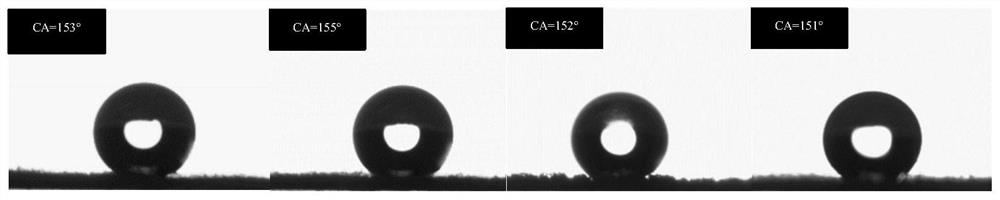

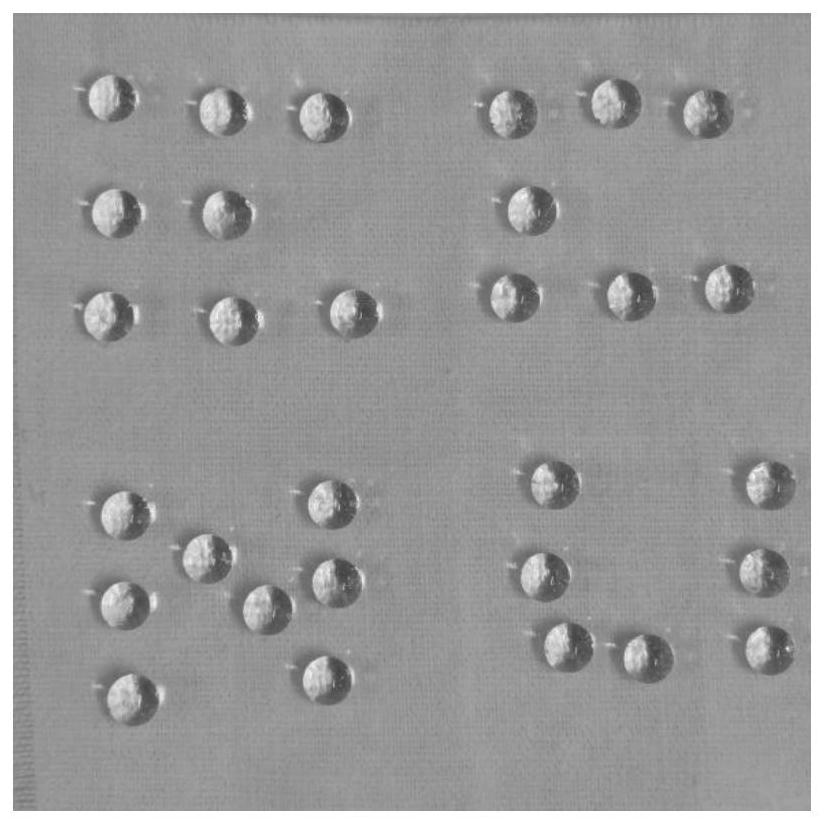

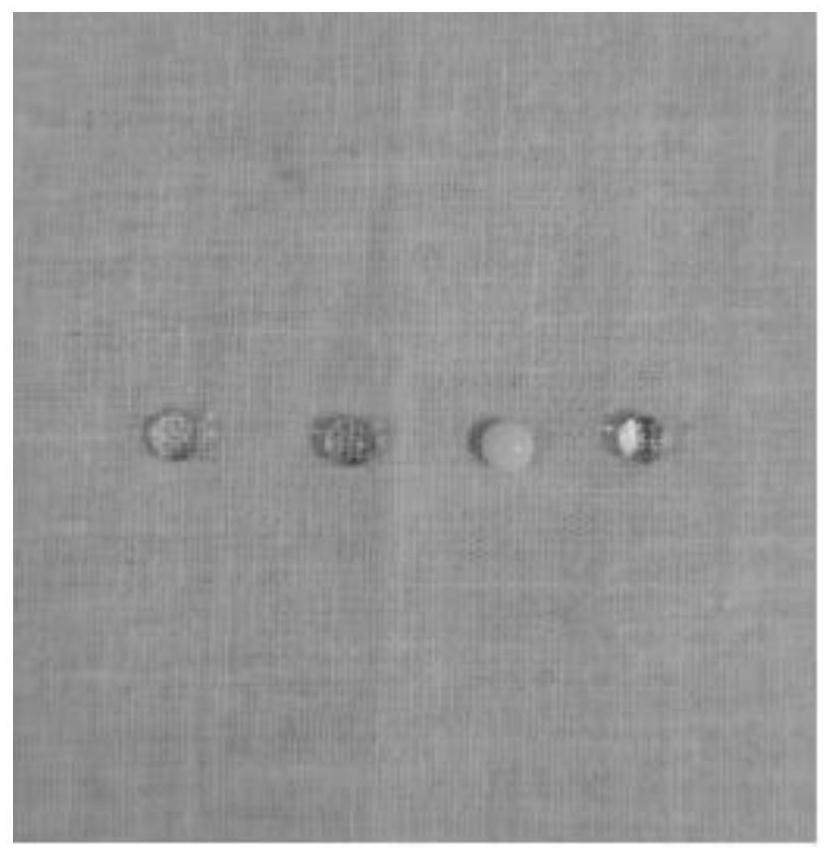

A super-hydrophobic, cotton technology, applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as the difficulty of industrialization of electrospinning process, the weak mechanical properties of super-hydrophobic fabrics, and the high price of fluorine-containing compounds. , to achieve the effect of good self-cleaning ability, huge industrial application potential, good hydrophobic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] First, ultrasonically disperse 1 part of silicon dioxide with a particle size of 20nm in 150 parts of solvent, add 50 parts of ammonia water, add 1.5 parts of 3-methacryloxypropyltrimethoxysilane, and then stir at 40°C 24h. After the solution is cooled, centrifuge at a speed of 6000 r / min for 5 min, and wash with an aqueous solution with a mass fraction of 75% ethanol. Repeat 3 times, and dry at 40° C. for 24 hours to obtain modified silica as a white solid. Add 10 parts of acetic acid to the mixture of 3 parts of KH-580 and 40 parts of ethanol, soak the cotton cloth in the solution, heat and react at 40°C for 2 hours, take out the cotton cloth, and wash off the excess KH-580 with ethyl acetate , and dried at 70°C for 3h. Add 0.1 parts of KH-570@SiO 2 Dissolve in 3 parts of acetone, add 0.05 parts of methacryloxy polydimethylsiloxane, 0.0025 parts of benzoin dimethyl ether, ultrasonically treat the solution, soak the pretreated cotton cloth in the ultrasonically trea...

Embodiment 2

[0073] First, ultrasonically disperse 0.5 parts of silicon dioxide with a particle size of 40 nm in 100 parts of ethyl acetate, add 40 parts of ammonia water, add 0.5 parts of 3-methacryloxypropyltrimethoxysilane, and then Under stirring for 12h. After the solution is cooled, centrifuge at a speed of 7000r / min for 10min, and wash with an aqueous solution with a mass fraction of 50% ethanol. Repeat twice, and dry at 40° C. for 22 hours to obtain modified silica as a white solid. Add 5 parts of acetic acid to the mixture of 2 parts of KH-580 and 20 parts of ethyl acetate, soak the cotton cloth in the solution, heat and react at 40°C for 2 hours, take out the cotton cloth, and wash off the excess KH-580 with ethanol , and dried at 40°C for 4h. Add 0.1 parts of KH-570@SiO 2 Dissolve in 1 part of tetrahydrofuran, add 0.05 part of methacryloxy polydimethylsiloxane, 0.0025 part of benzoin butyl ether, ultrasonically treat the solution, soak the pretreated cotton cloth in the ultra...

Embodiment 3

[0075] First, ultrasonically disperse 2 parts of silicon dioxide with a particle size of 100nm in 200 parts of tetrahydrofuran, add 60 parts of ammonia water, add 3 parts of 3-methacryloxypropyltrimethoxysilane, and stir at 40°C 24h. After the solution is cooled, centrifuge it at a speed of 5000r / min for 8min, and wash it with an aqueous solution with a mass fraction of 75% ethanol. Repeat 4 times, and dry at 70° C. for 12 hours to obtain white solid modified silica. Add 10 parts of acetic acid to the mixed solution of 5 parts of KH-580 and 40 parts of tetrahydrofuran, soak the cotton cloth in the solution, heat and react at 70°C for 4 hours, take out the cotton cloth, wash off the excess KH-580 with isopropanol, Dry at 120°C for 2h. Add 0.5 parts of KH-570@SiO 2 Dissolve in 5 parts of dichloromethane, add 0.5 parts of methacryloxy polydimethylsiloxane, 0.005 parts of benzoin isopropyl ether, ultrasonically treat the solution, soak the pretreated cotton cloth in the ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com