Aluminum product surface super-hydrophobic film and making method thereof

A super-hydrophobic, aluminum surface technology, applied in anodizing and other directions, can solve problems such as corrosion resistance and friction resistance of super-hydrophobic surfaces that are not involved, and achieve the effect of simple and controllable oxidation process, simple treatment process and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

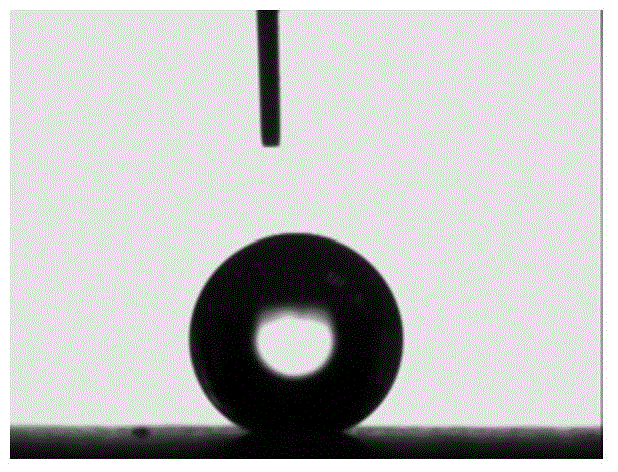

Embodiment 1

[0030] The aluminum sheet substrate was polished with 800-grit sandpaper, rinsed with pure water, dried, and used as an anode, and an aluminum sheet of the same size was used as a cathode. At 0.2mol·L -1 Sodium chloride aqueous solution is used as the electrolyte, and the current density is 0.4A cm -2 The anodic oxidation reaction was carried out under the conditions, the reaction temperature was room temperature, and the reaction time was 7 minutes. After the reaction, the alumina material was taken out, washed with water, and dried. Then, soak the alumina material in the ethanol solution of heptadecafluorodecyltriethoxysilane with a volume concentration of 10% for 5 minutes, take out the sample after soaking and place it in an oven for 30 minutes at 100°C to obtain superhydrophobic film. The hydrophobicity, corrosion resistance and friction resistance of the surface were tested, the results are shown in Table 1, and the contact angle diagram is as follows figure 1 shown....

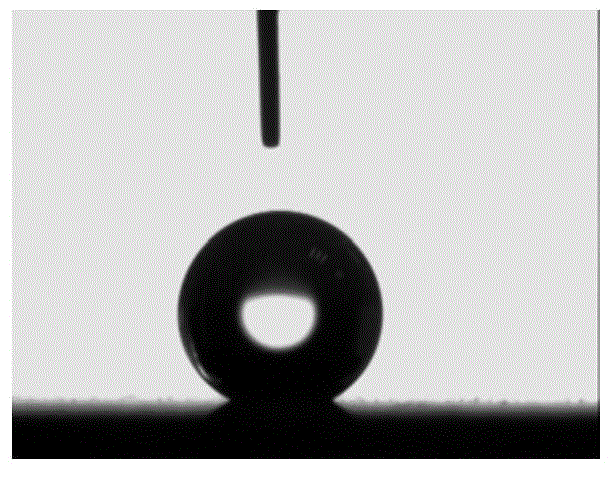

Embodiment 2

[0032] The aluminum sheet substrate was polished with 1000-grit sandpaper, rinsed with pure water, dried, and used as an anode, and an aluminum sheet of the same size was used as a cathode. at 0.1mol·L -1 Potassium chloride aqueous solution is used as the electrolyte, and the current density is 0.3A cm -2 The anodic oxidation reaction is carried out under the conditions, the reaction temperature is room temperature, and the reaction time is 5 minutes. After the reaction, the alumina material was taken out, washed with water, and dried. Then, soak the alumina material in ethanol solution with a volume concentration of 1% tridecafluorooctyltrimethoxysilane for 7 minutes, take out the sample after soaking and place it in an oven for 10 minutes at 130°C to obtain super Hydrophobic film. The hydrophobicity, corrosion resistance and friction resistance of the surface were tested, the results are shown in Table 1, and the contact angle diagram is as follows figure 2 shown.

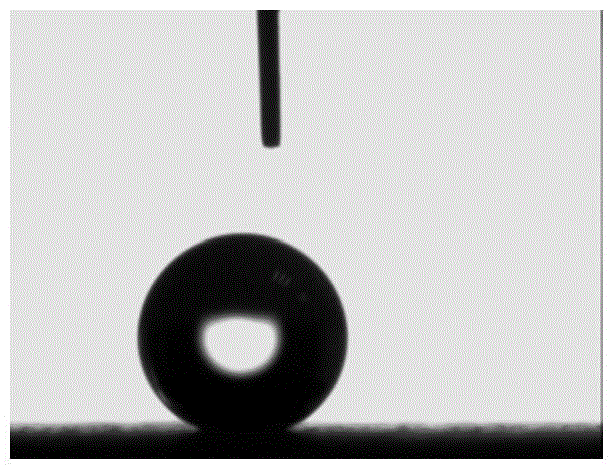

Embodiment 3

[0034] The aluminum sheet substrate was polished with 600-grit sandpaper, rinsed with pure water, dried, and used as an anode, and an aluminum sheet of the same size was used as a cathode. at 0.3mol·L -1 Sodium sulfate aqueous solution is used as the electrolyte, and the current density is 0.3A cm -2 The anodic oxidation reaction was carried out under the conditions, the reaction temperature was room temperature, and the reaction time was 9 minutes. After the reaction, the alumina material was taken out, washed with water, and dried. Then, soak the alumina material in ethanol solution with a volume concentration of 5% heptadecafluorodecyltrimethoxysilane for 10 minutes, take out the sample after soaking and place it in an oven for 15 minutes at 110°C to obtain super Hydrophobic film. The hydrophobicity, corrosion resistance and friction resistance of the surface were tested, the results are shown in Table 1, and the contact angle diagram is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com