A kind of hydrophobic dispersion material and preparation method thereof

A bulk material, hydrophobic technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of poor hydrophobic stability of hydrophobic bulk materials, large environmental impact, low compactness, etc., to achieve green Prospects for environmental protection applications, increasing heavy metal content, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

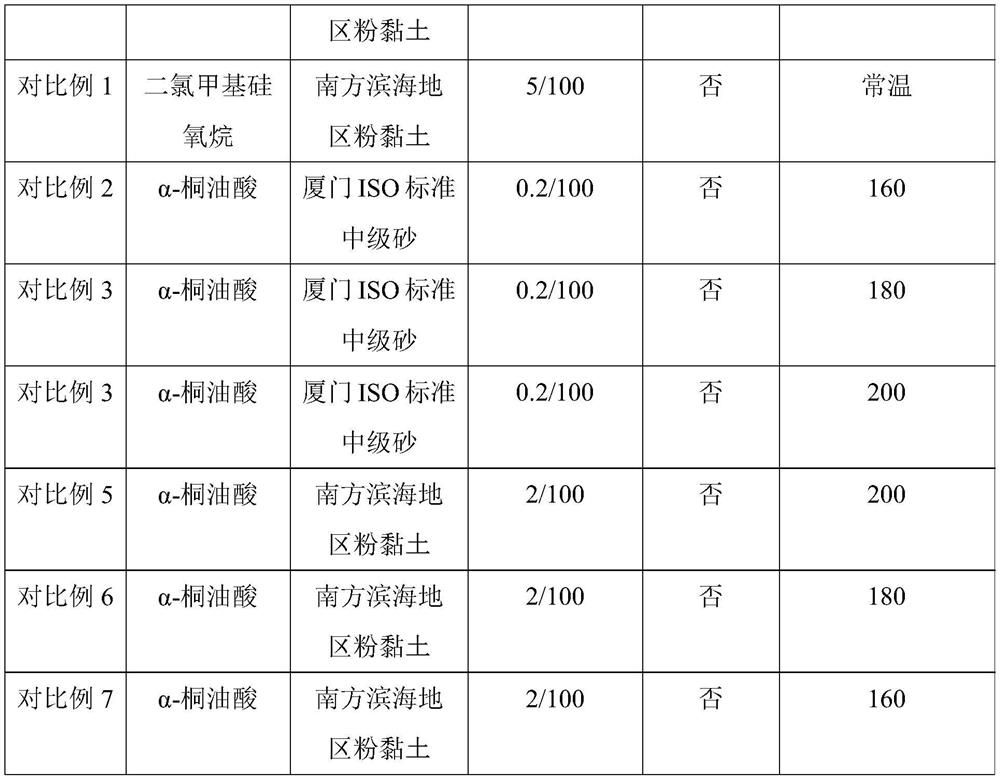

Examples

Embodiment 1

[0020] A preparation method of a hydrophobic dispersion material, comprising the steps of:

[0021] 1) Weigh 5000.0g Xiamen ISO standard intermediate sand (GB / T17671-1999 and ISO679:1989, sand particle size is 0.5-1.0mm, quartz content>96%, loss on ignition <0.5%);

[0022] 2) Adopt the wet sieving method to remove obvious organic impurities such as plant roots, fallen leaves, and animal carcasses in the soil;

[0023] 3) The sand of step 2) was placed in a soil aluminum box (200mm in diameter, 150mm in height), put into a hot air circulation oven (DO60, Dengying Instrument Equipment Co., Ltd.) and dried at 105 ° C for 24 hours until the soil was completely dry;

[0024] 4) After taking out the soil aluminum box of step 3) from the oven, stand and cool for 1 hour at normal temperature;

[0025] 5) Add 10.0g of α-tung oleic acid to the sand processed in step 4), and mix for 15 minutes at a speed of 500 rpm in a stainless steel powder mixer (Model 30, Huazhu Environmental Prote...

Embodiment 2

[0029] The difference between Example 2 and Example 1 is that the heating temperature in step 6) of Example 2 is 180°C, and the remaining components and preparation process are the same as those of Example 1, and the finished product of Example 2 of the hydrophobic dispersion material is obtained.

Embodiment 3

[0031] The difference between Example 3 and Example 1 is that the heating temperature in step 6) of Example 3 is 200°C, and the remaining components and preparation process are the same as those in Example 1, and the finished product of Example 3 of the hydrophobic dispersion material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com