Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "High quality and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

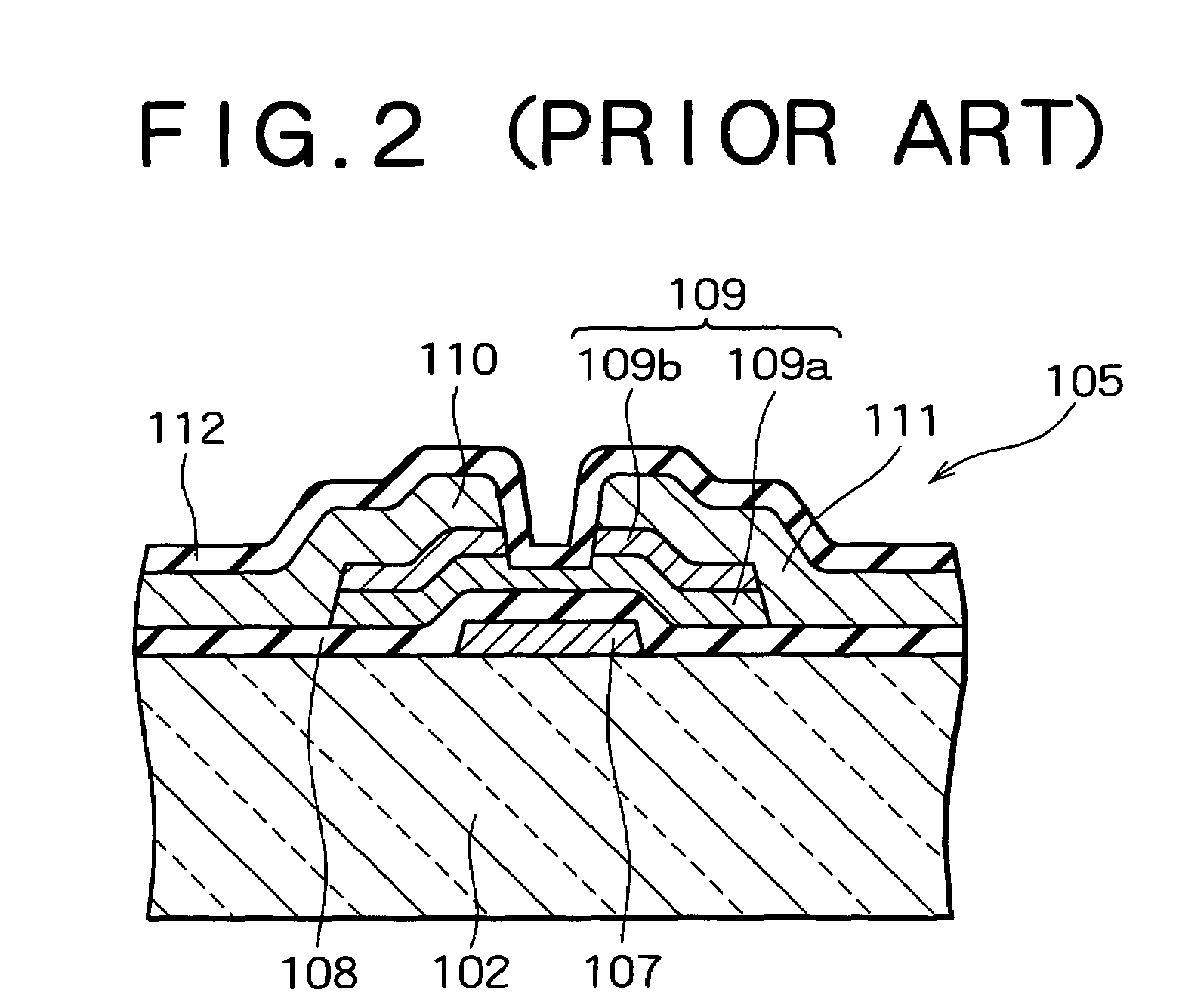

Photodiode

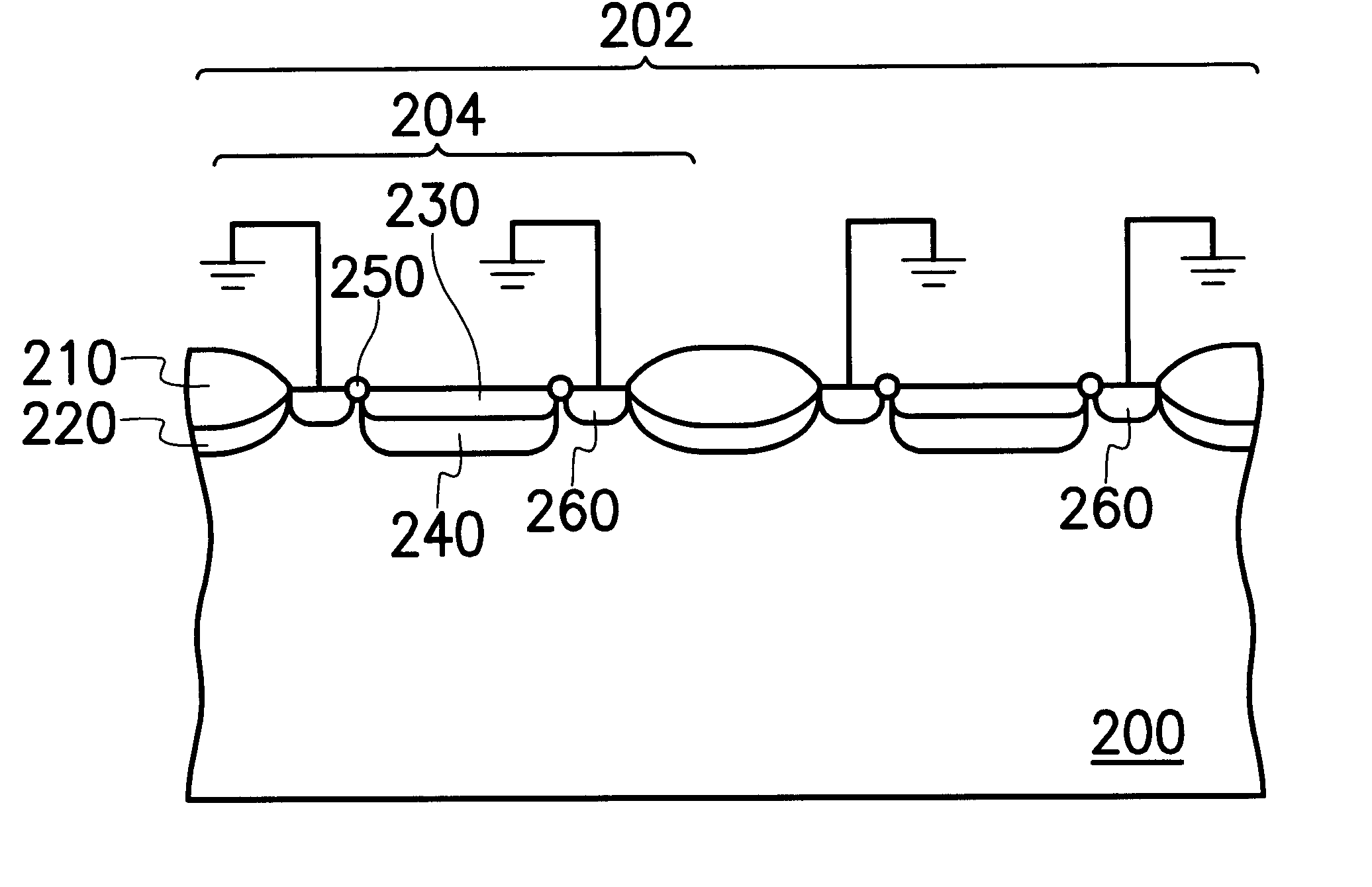

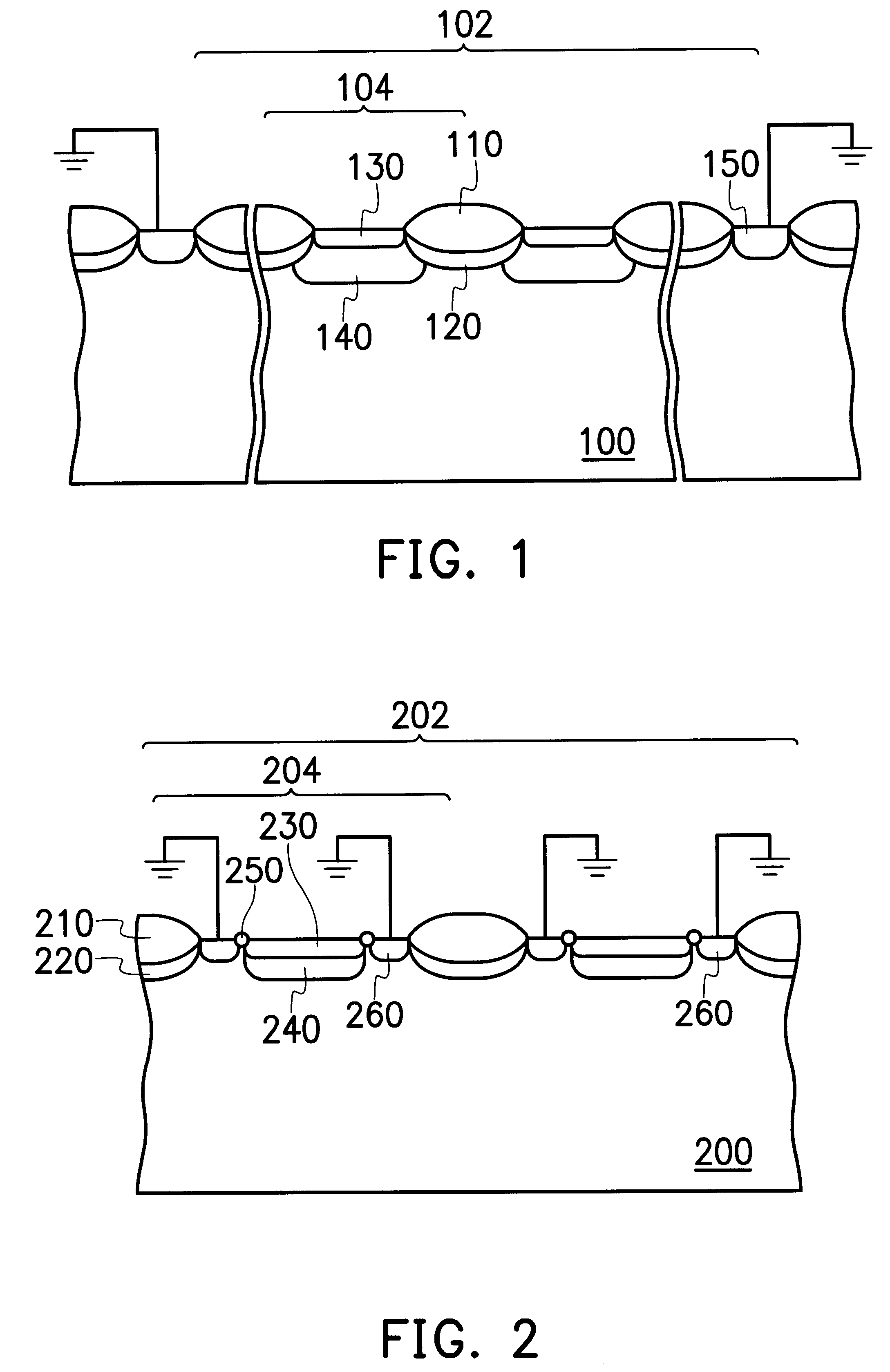

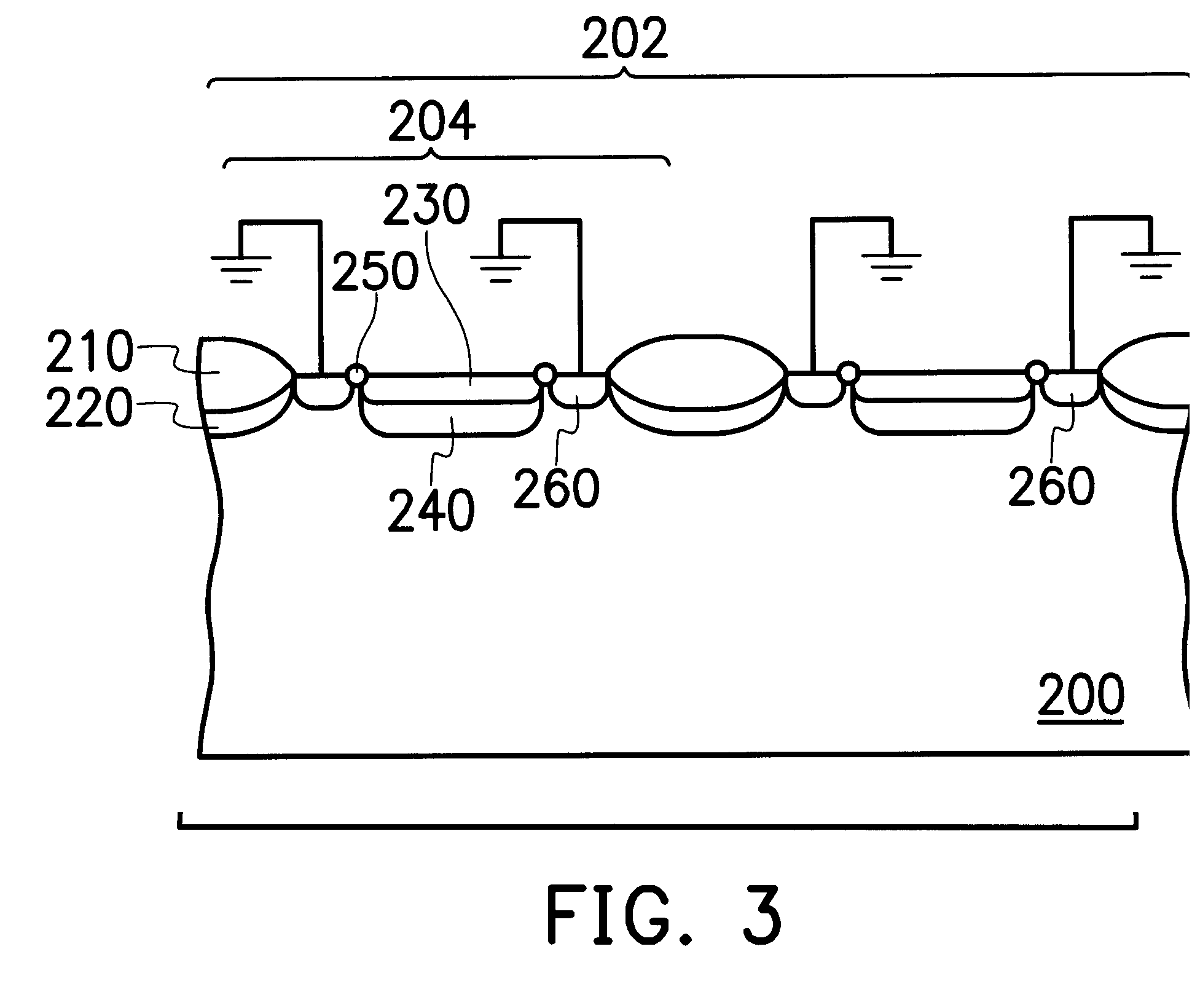

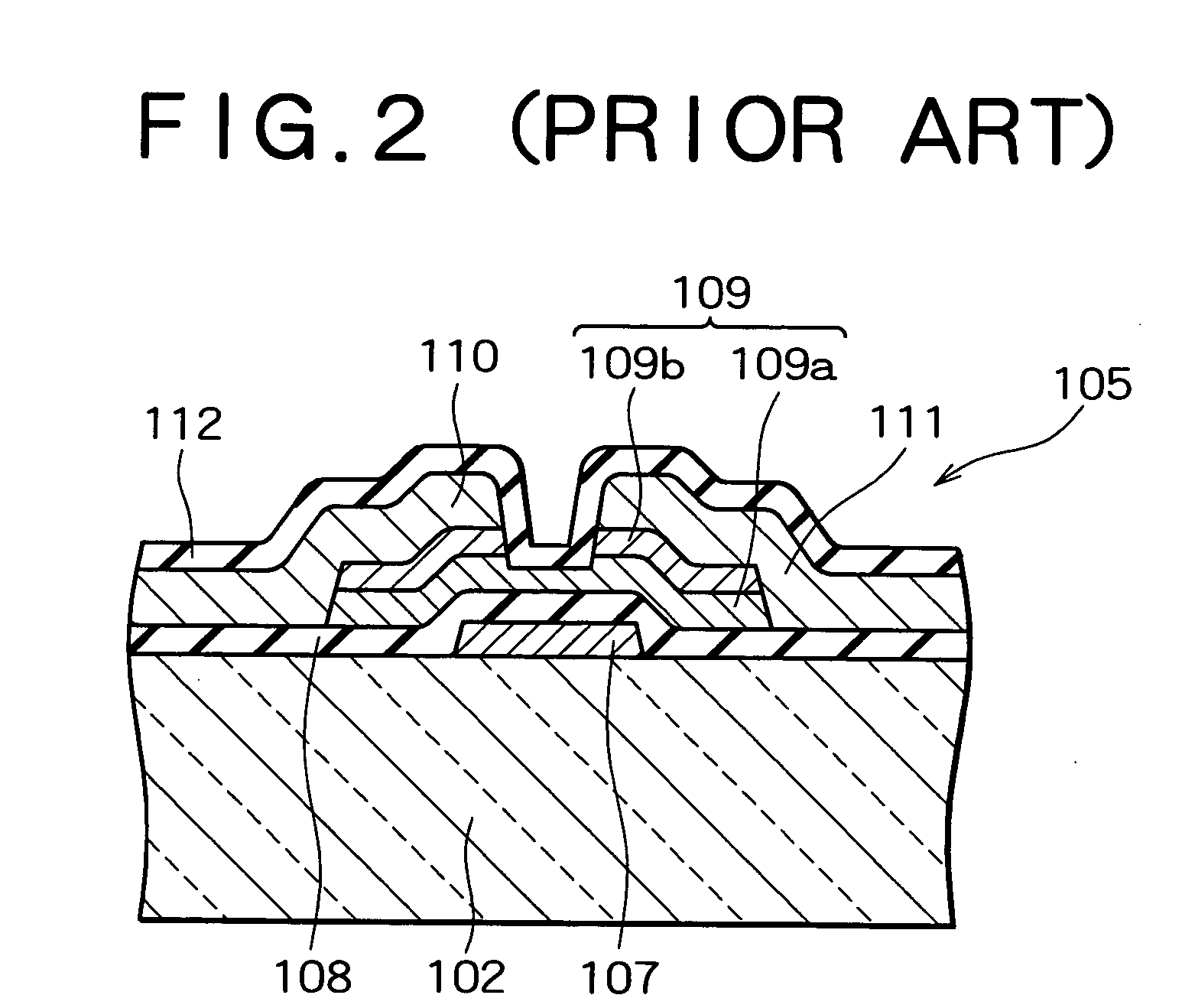

InactiveUS6351002B1Reduce read noiseHigh quality and reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingIsolation layerPhotodiode

A photodiode. A second conductive type heavily doped region is located in a first conductive type doped substrate, and a dopant concentration of the second conductive type heavily doped region is larger than that of the first conductive type doped substrate. A dummy isolation is at a periphery of the second conductive type heavily doped region. A first conductive type heavily doped region is located at a periphery of the dummy isolation layer in the first conductive type doped substrate. A dopant concentration of the first conductive type heavily doped region is larger than that of the first conductive type substrate. An isolation layer is located at a periphery of the first conductive type doped region with a width much larger than that of the dummy isolation layer.

Owner:UNITED MICROELECTRONICS CORP

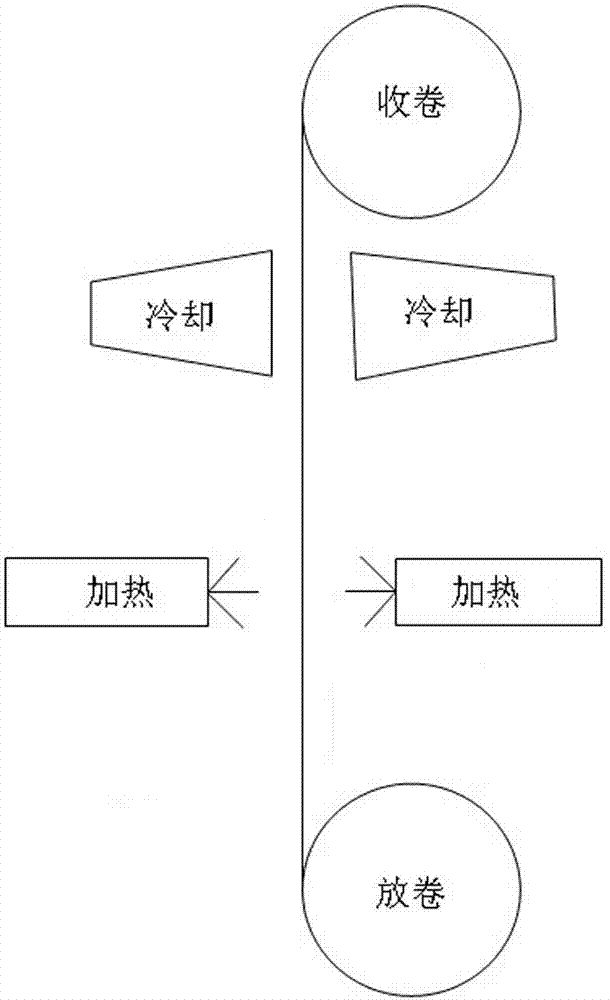

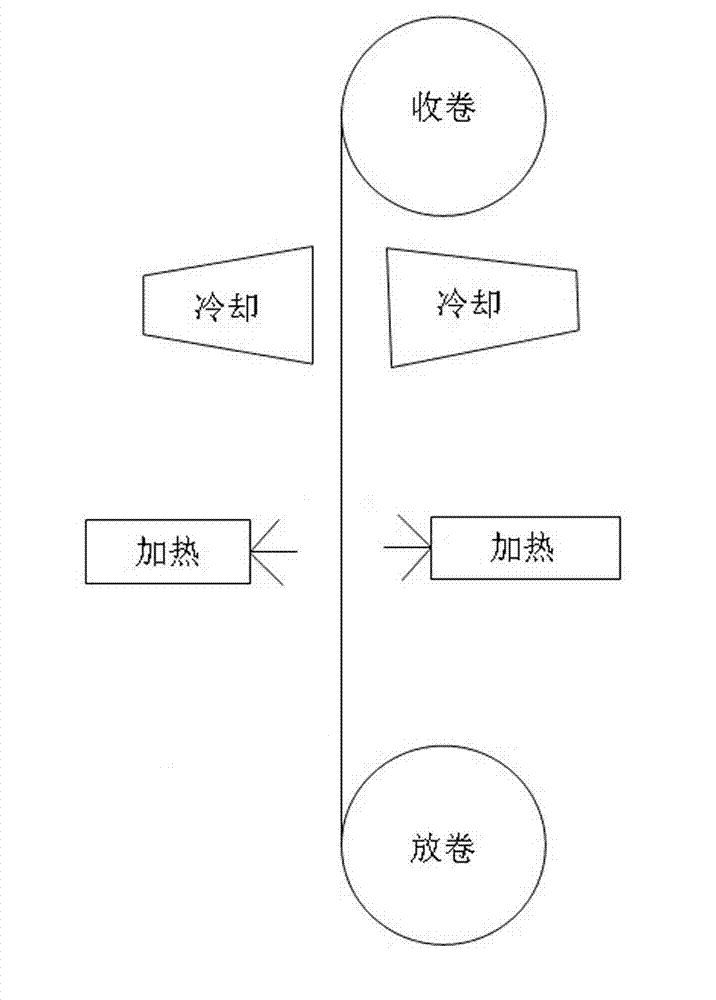

Method for preparing lithium battery current collector by plasma spraying polymer composite positive temperature coefficient (PTC) powder

InactiveCN103794801AHigh quality and reliabilityFast thermal responseElectrode carriers/collectorsManufacture by sprayingState of artReaction speed

The invention discloses a method for preparing a lithium battery current collector by plasma spraying polymer composite PTC powder. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the lithium battery current collector up to 100-300 DEG C by a heating device, and coating the lithium battery current collector with the polymer composite PTC powder obtained in the step (1) through a plasma spraying device to form a polymer composite PTC powder coating on the lithium battery current collector; (3) baking the lithium battery current collector coated with the polymer composite PTC powder coated in the step (2), and carrying out a recrystallization technology to obtain the lithium battery current collector provided with the polymer composite PTC powder coating. Compared with the prior art, the method has the advantages that the processing process is simple and convenient, the production efficiency is improved, the yield is increased, the product thickness consistency is high, the product quality reliability is high, the thermosensitive reaction speed is high, and capacity adjustment is accurate and convenient.

Owner:ZHONGYUAN ENGINEERING COLLEGE

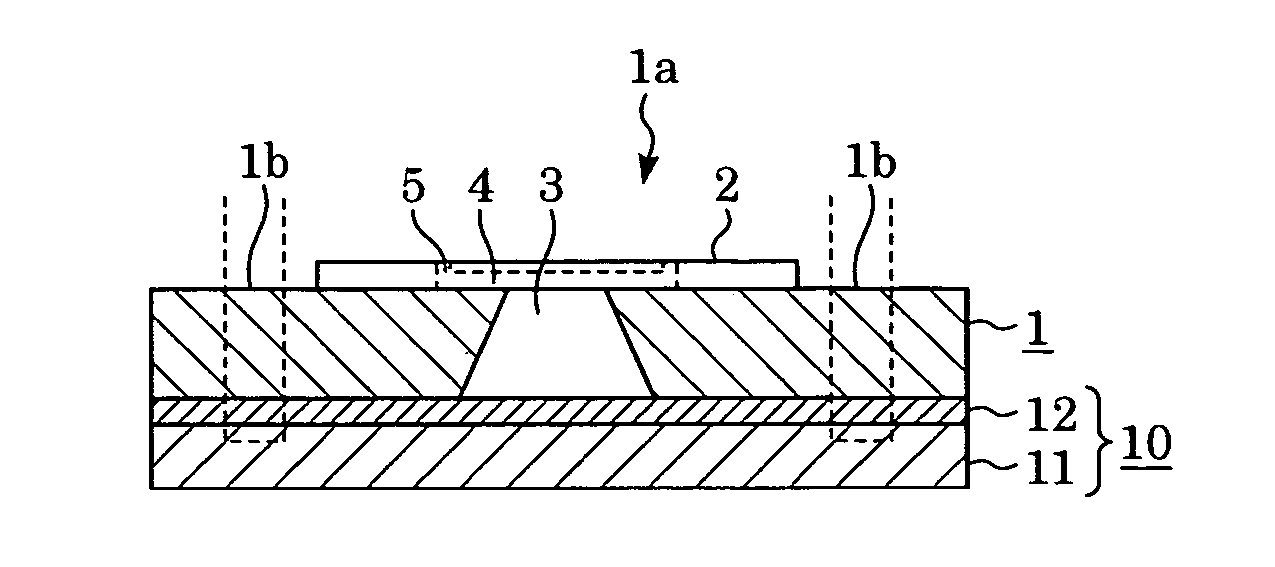

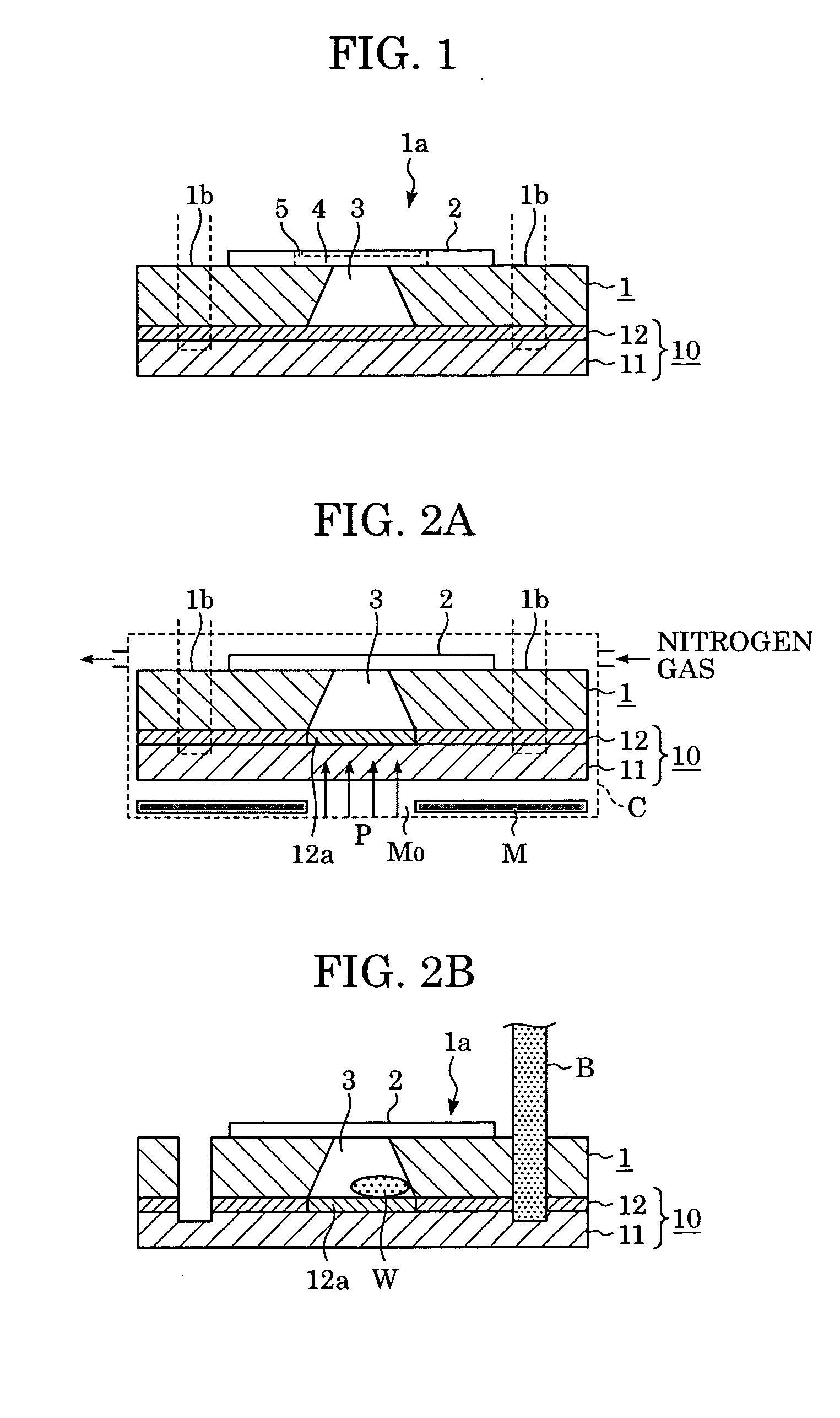

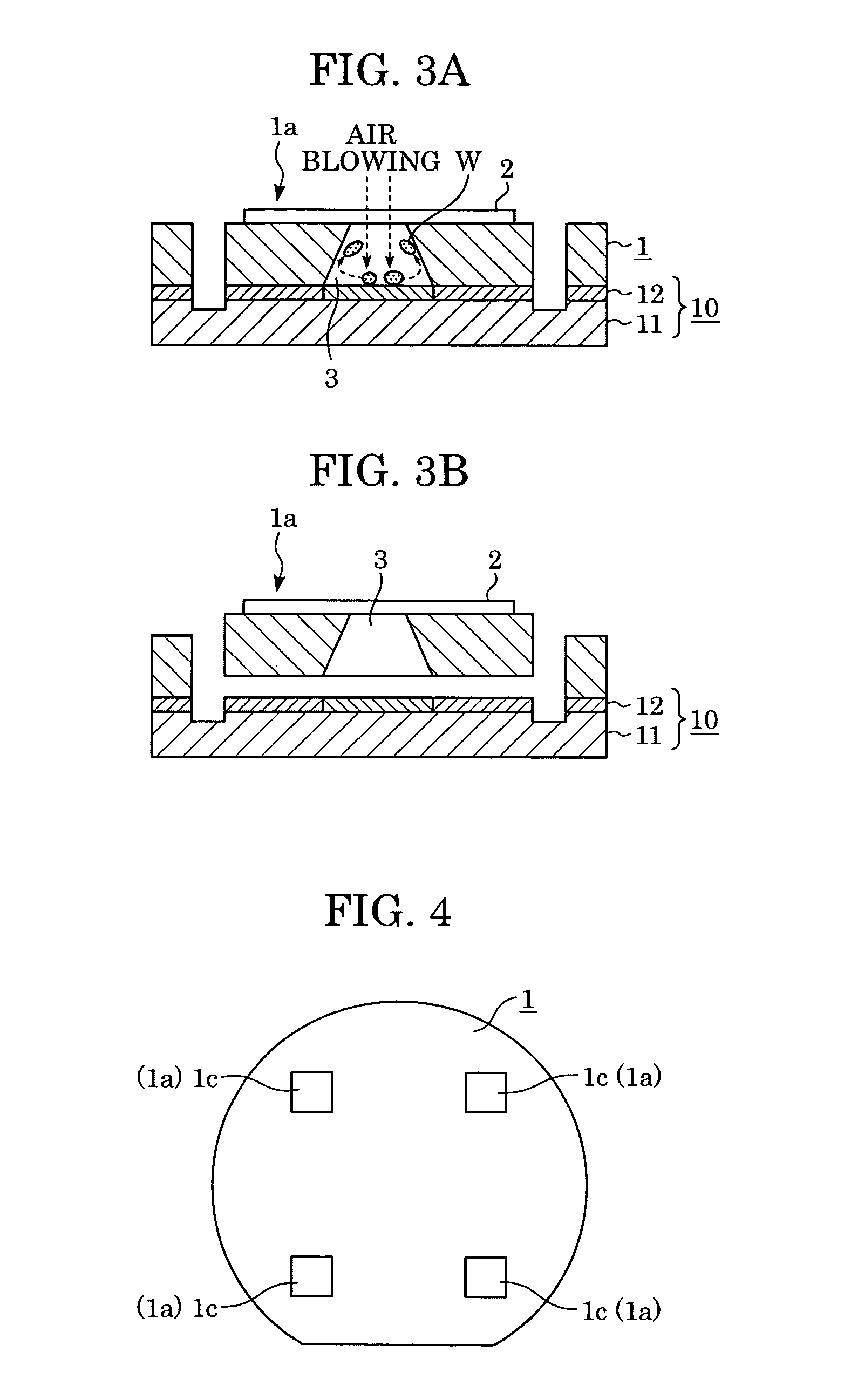

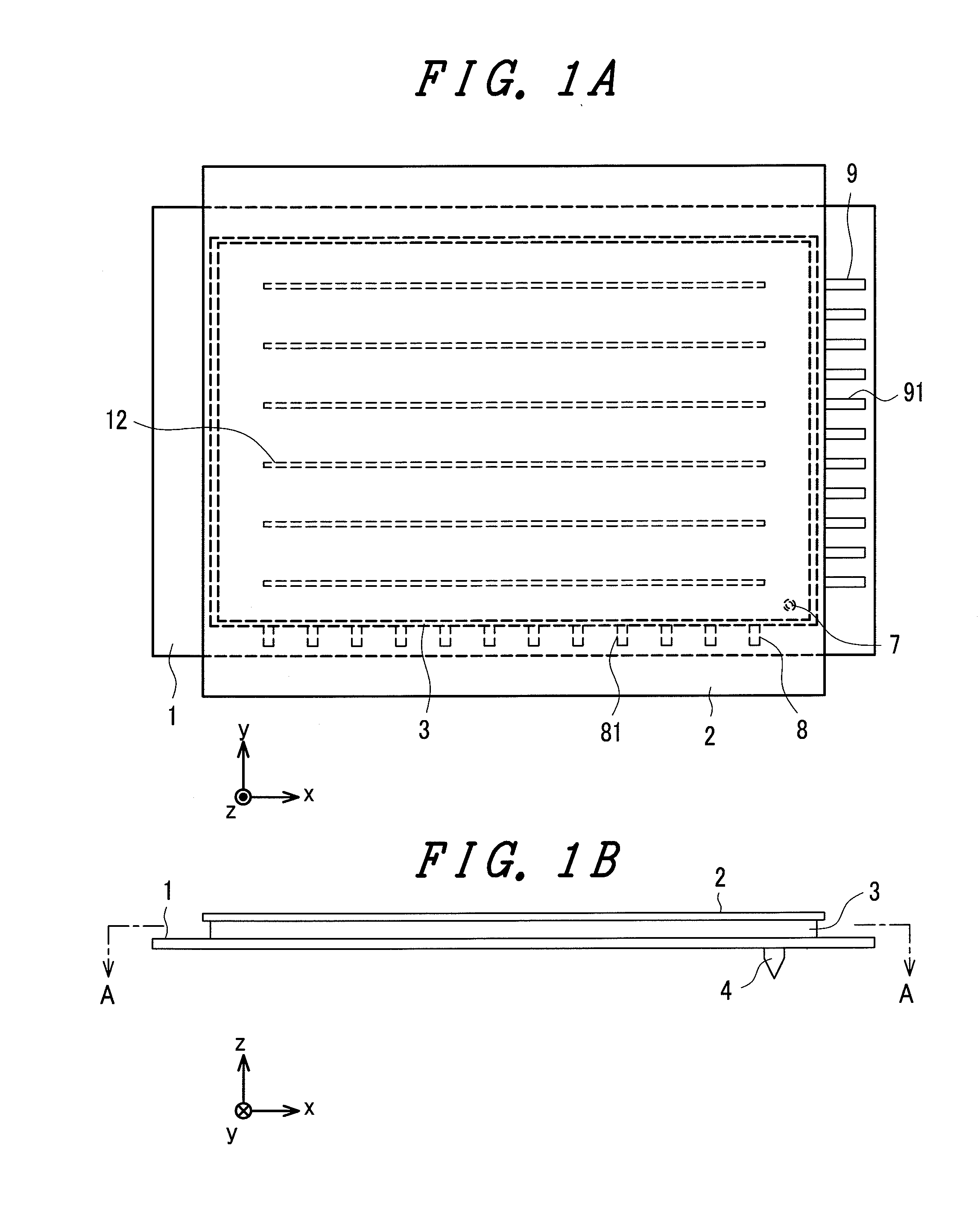

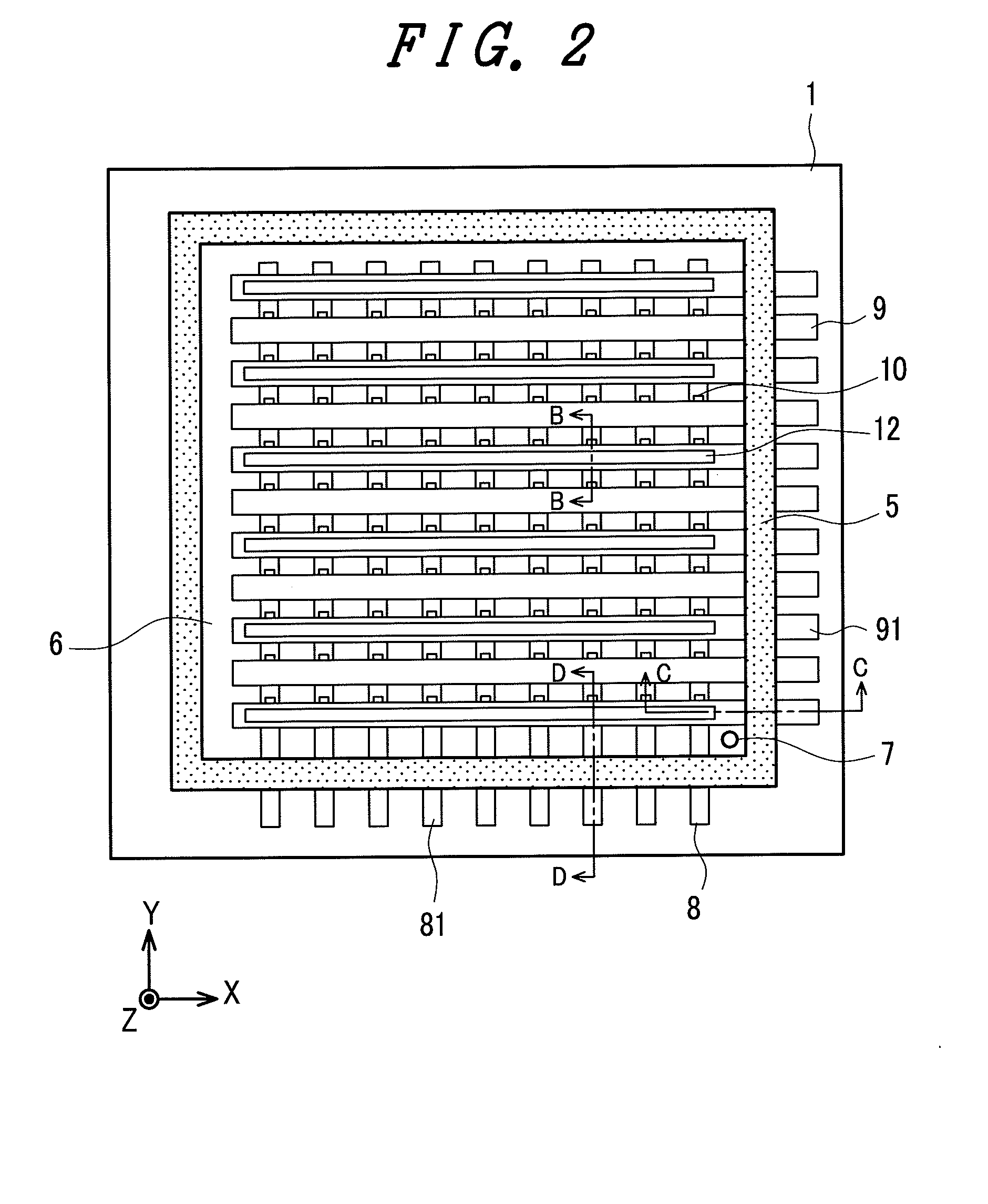

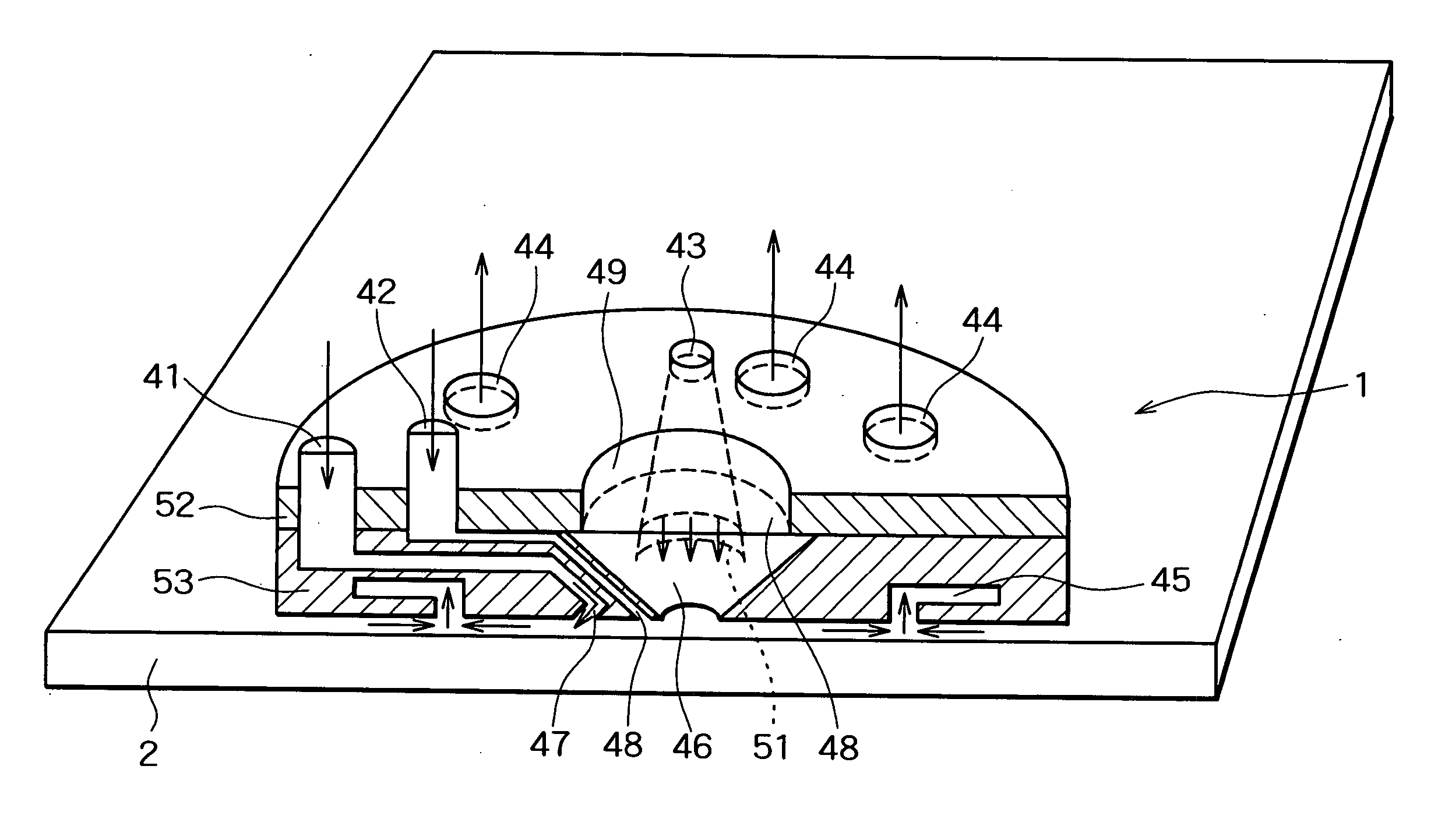

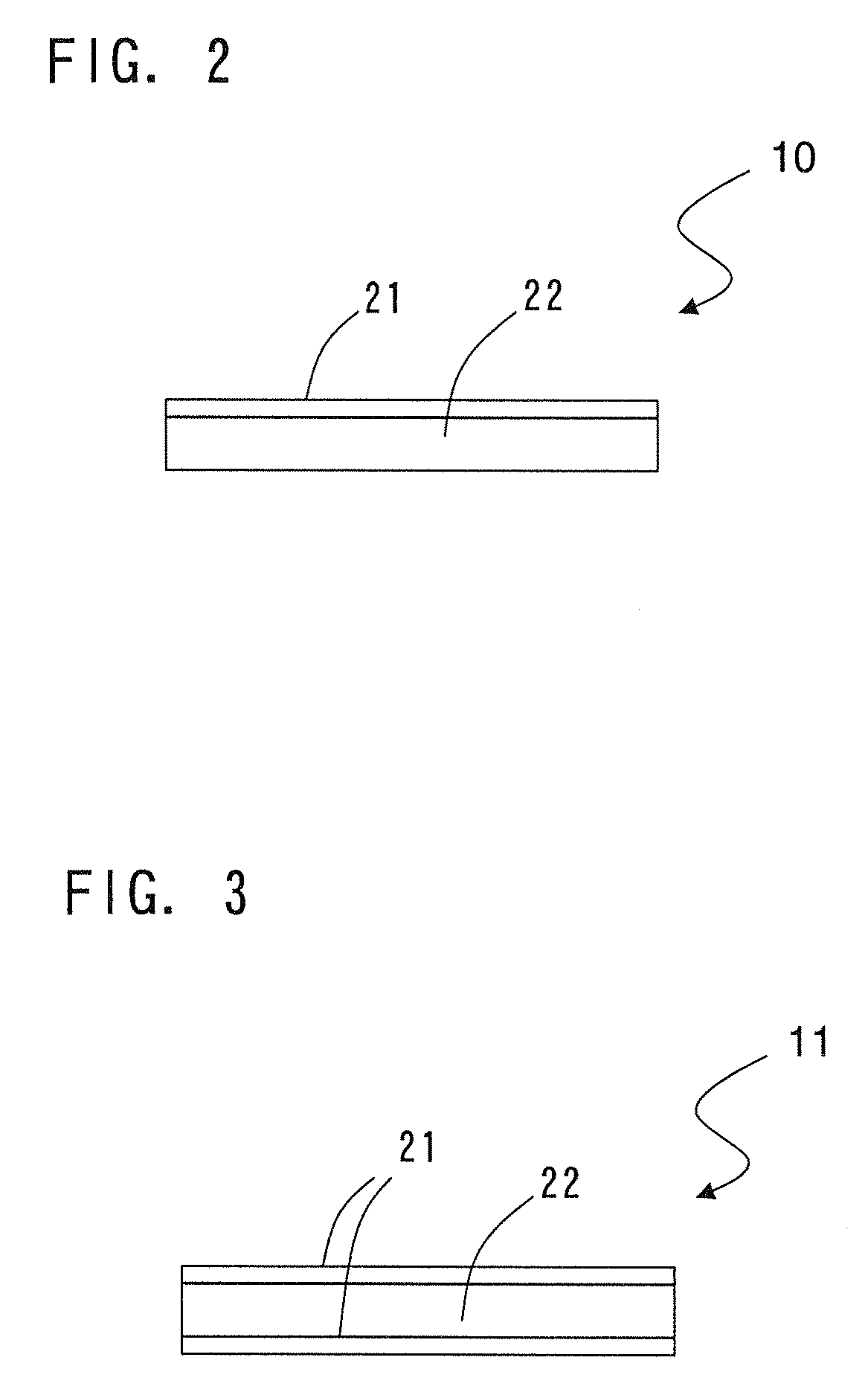

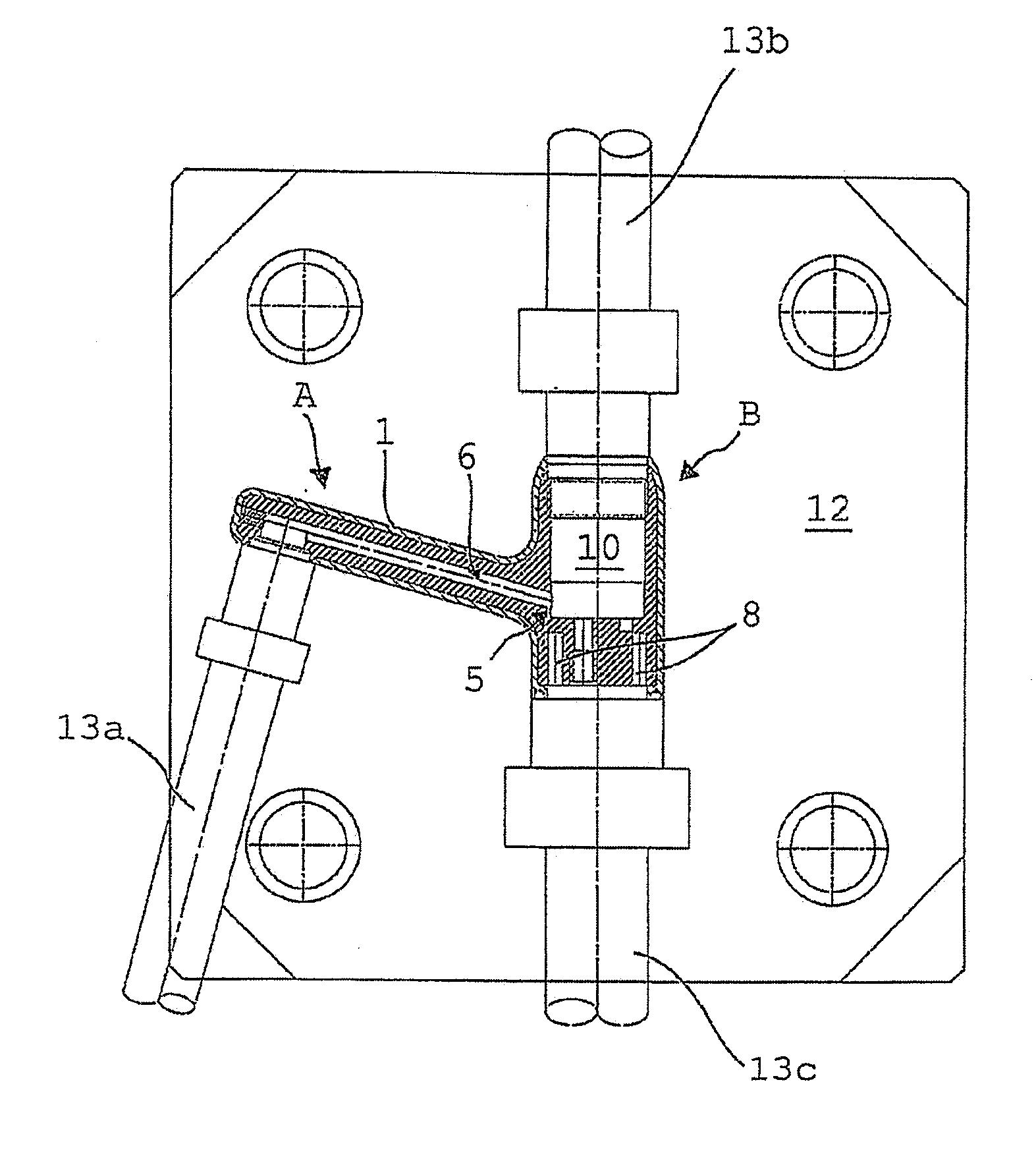

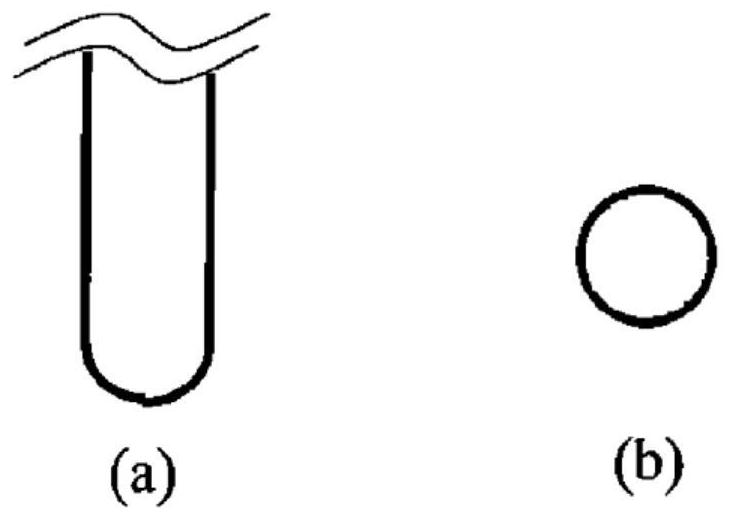

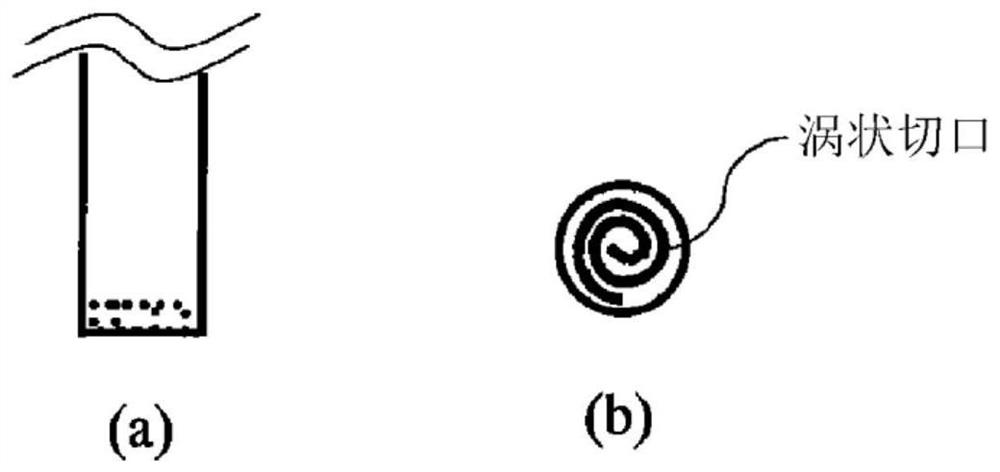

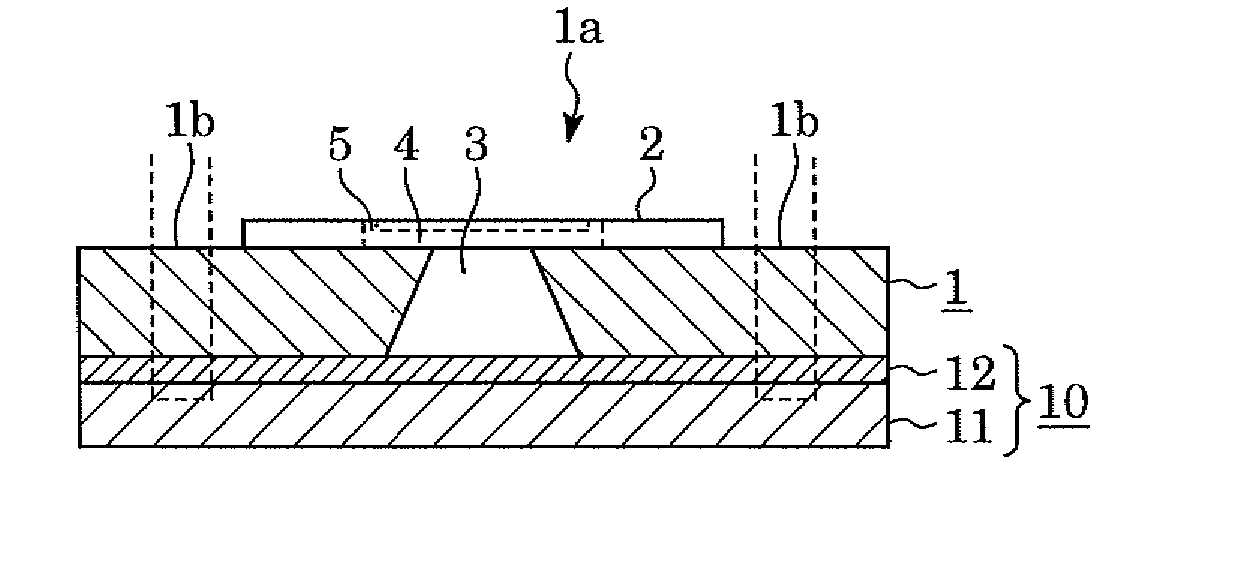

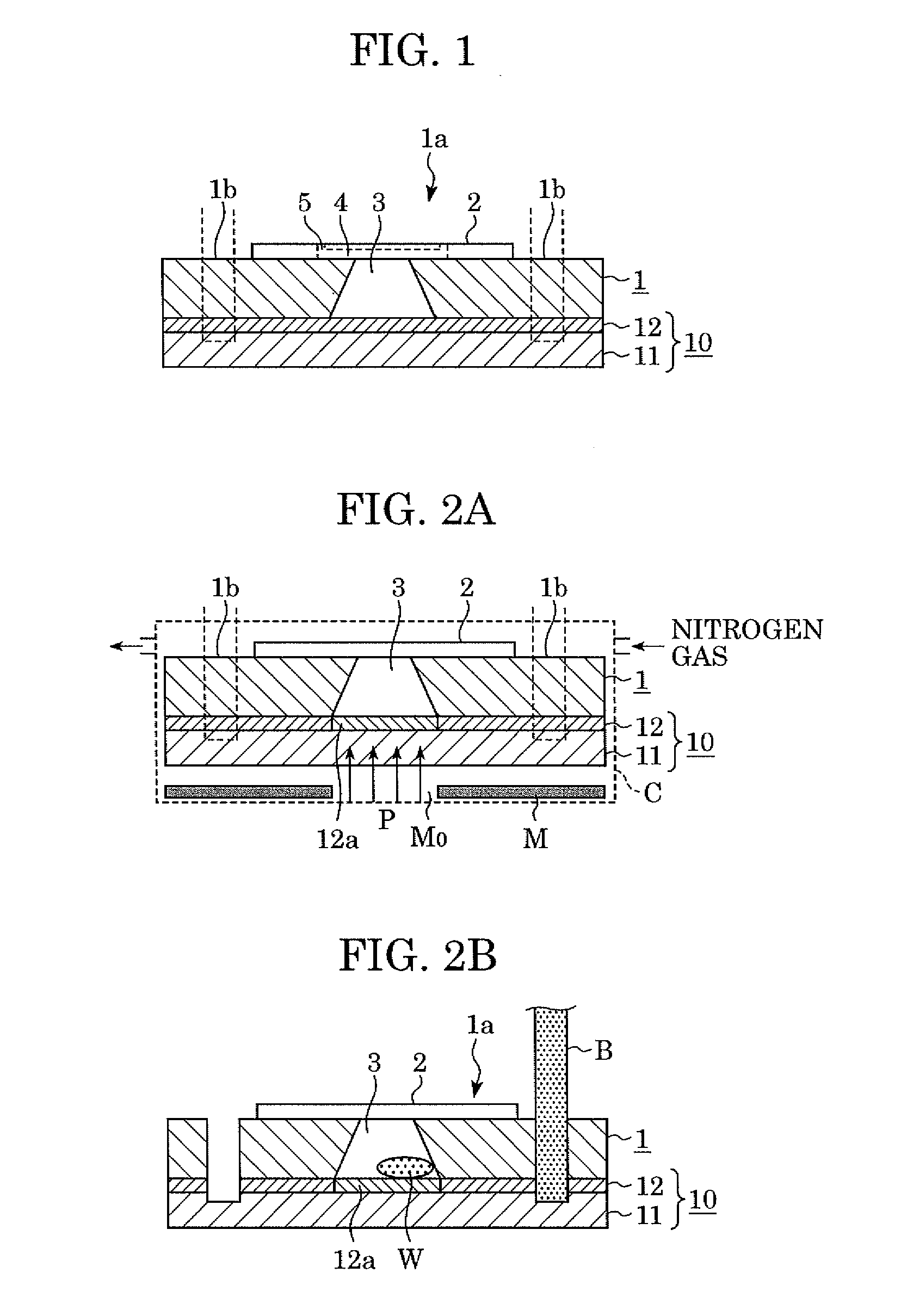

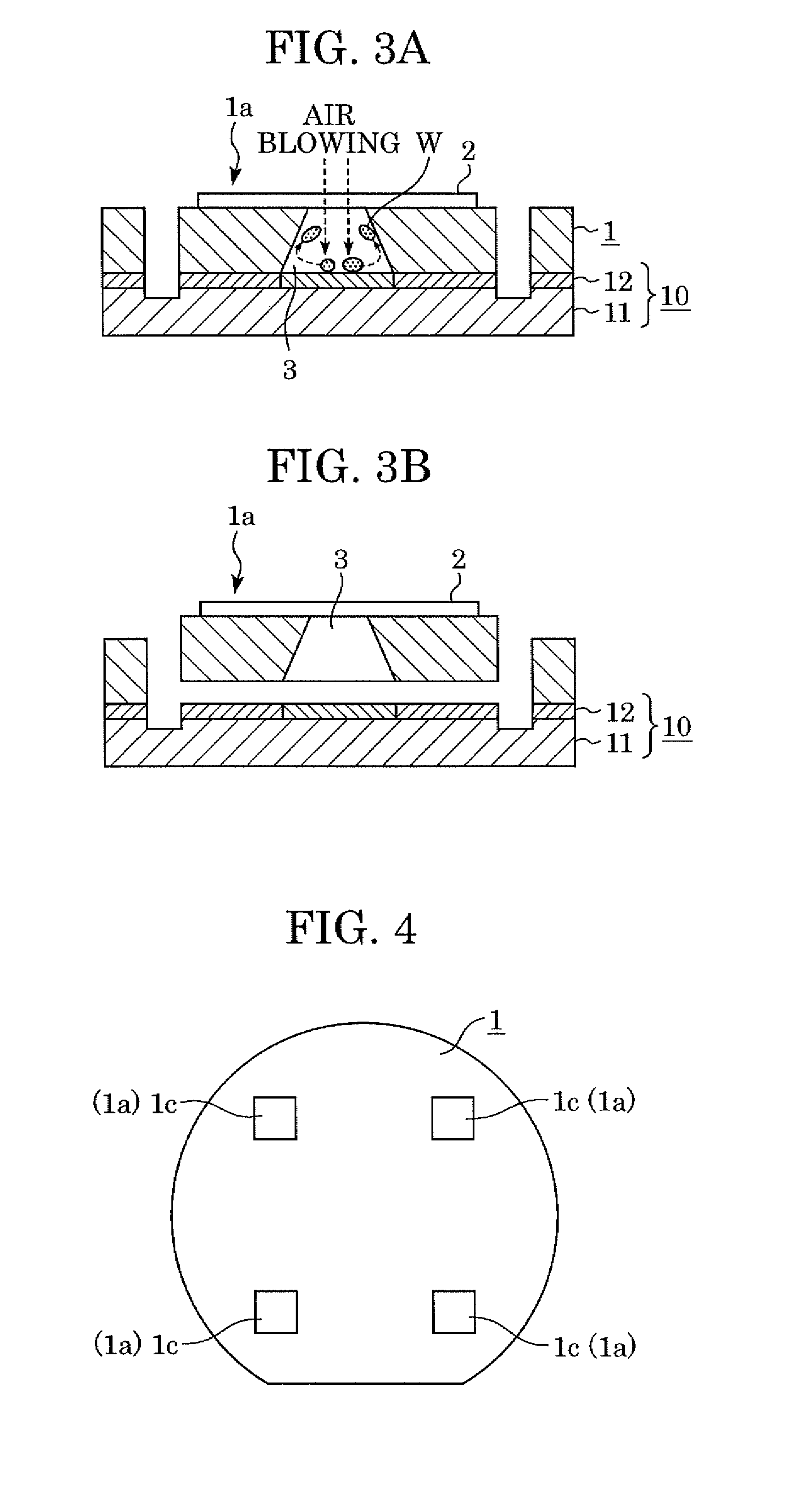

Method for dicing wafer and process for manufacturing liquid-discharging head using the dicing method

InactiveUS20050241754A1High quality and reliabilityReduced adhesion strengthLamination ancillary operationsSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A method for dicing a wafer having a first face in which opening are arranged along dicing streets. The method includes a step of affixing a dicing tape to the first face such that the dicing tape lies over the openings and adhesive regions of the dicing tape are exposed in the openings and a step of treating the dicing tape to reduce the adhesive strength of the adhesive regions.

Owner:CANON KK

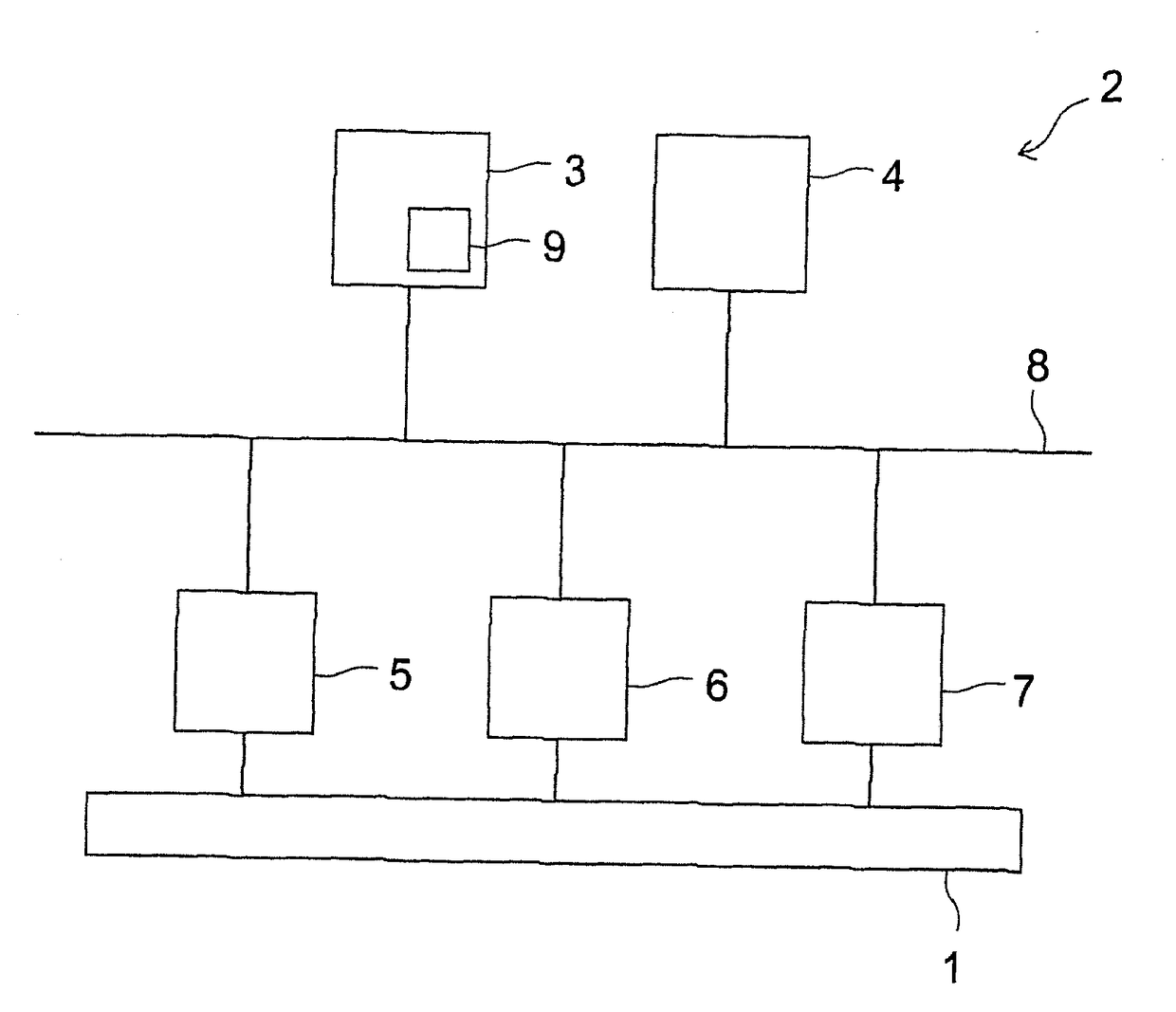

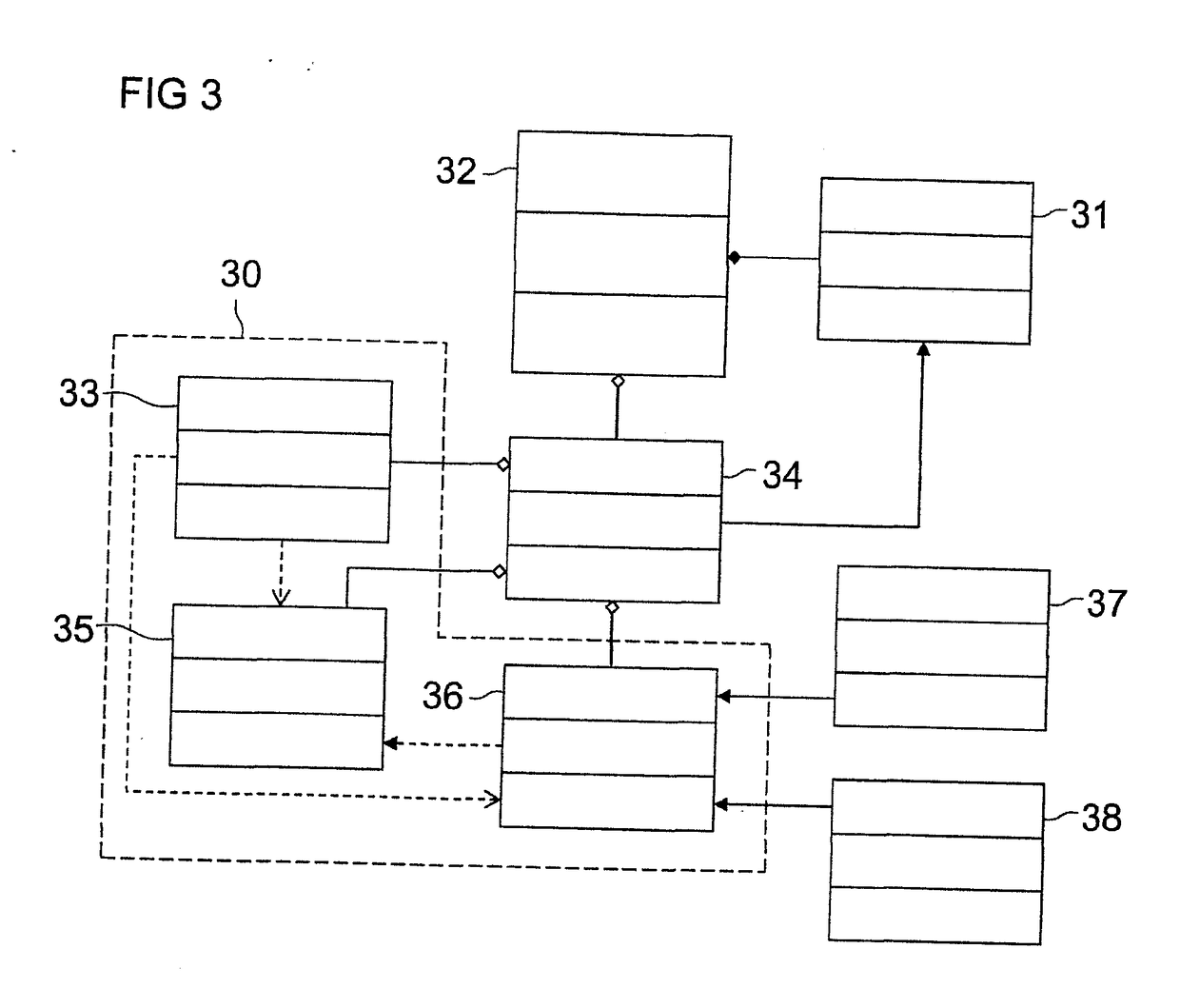

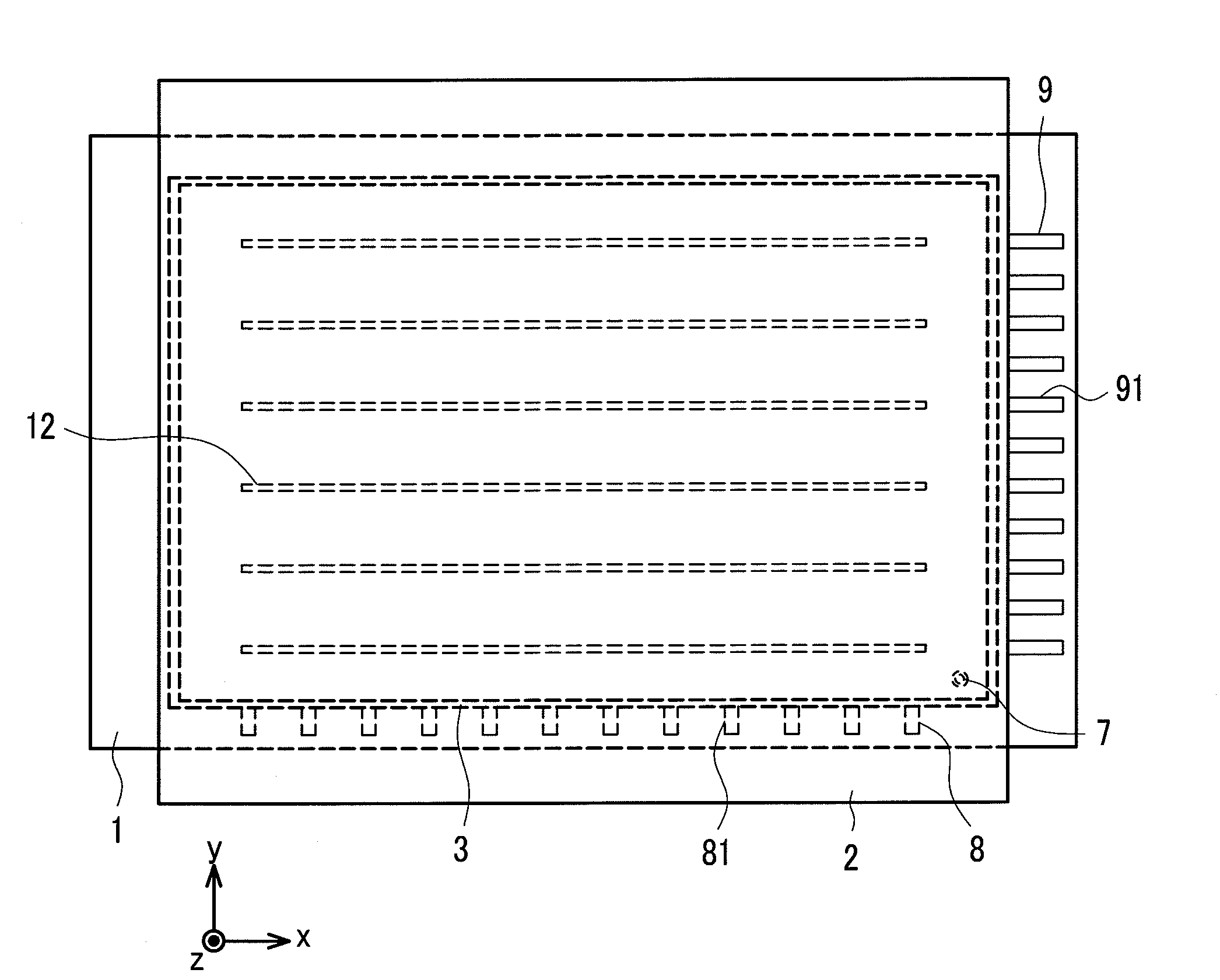

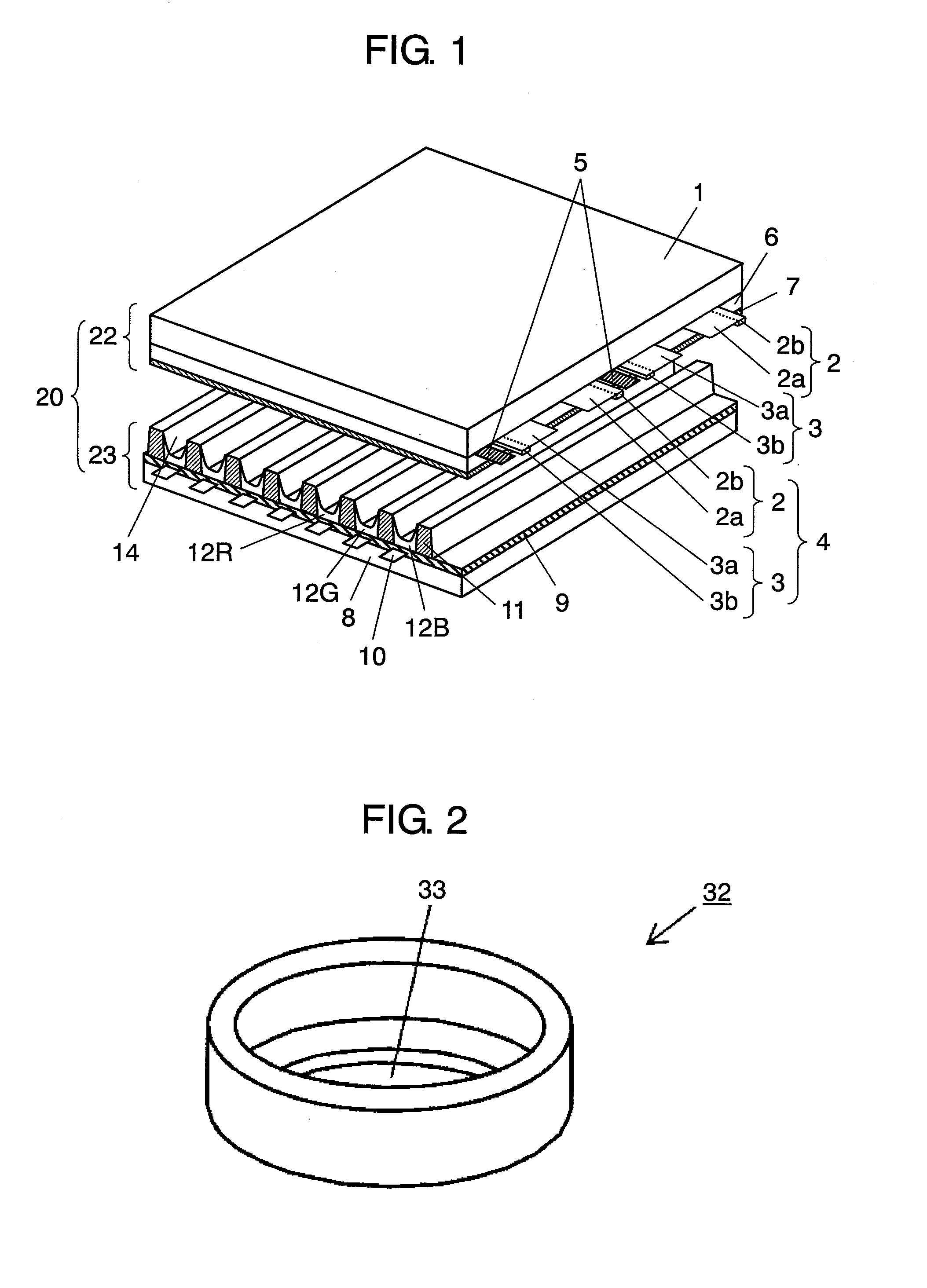

Image Display Device

InactiveUS20090002573A1Quality improvementImprove reliabilityTelevision system detailsCathode-ray/electron-beam tube electrical connectionDisplay deviceEngineering

A first translucent conductive layer is disposed on a front surface of a front substrate, a translucent insulating member is disposed on a front surface of the first translucent conductive layer, and a second translucent conductive layer held at the ground potential is disposed on a front surface of the translucent insulating member. According to the invention, an image display device, which prevents the abnormal discharge in the vacuum panel from occurring, and has high quality and reliability and long life, can be provided.

Owner:HITACHI LTD

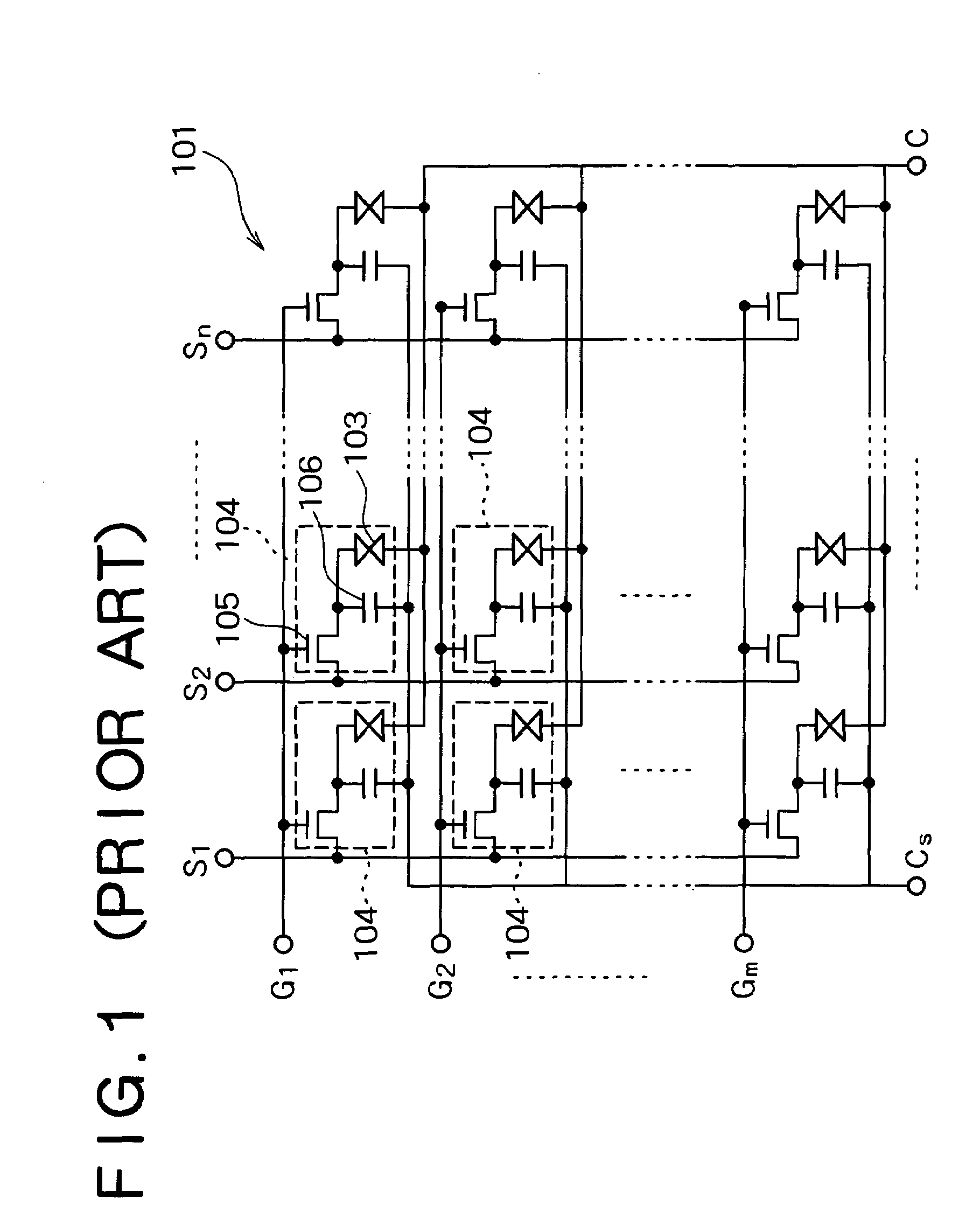

Wiring repair apparatus

InactiveUS20050061780A1Efficient repairQuality improvementTransistorSemiconductor/solid-state device detailsOptoelectronicsLaser source

A wiring repair apparatus includes an XY stage on which a substrate is placed, a laser source unit disposed above the XY stage, first and second gas windows disposed between the laser source unit and the XY stage, and first and second CVD gas units. The laser source unit emits a laser beam to a part of the substrate to be repaired. This laser beam passes through either the first or second gas window. The first CVD gas unit supplies an Al source gas (DMAH gas) to the first gas window while the second CVD gas unit supplies a Cr source gas (Cr(CO)6 gas) to the second gas window.

Owner:LASERFRONT TECH

Die cast component and a method for producing a die cast component

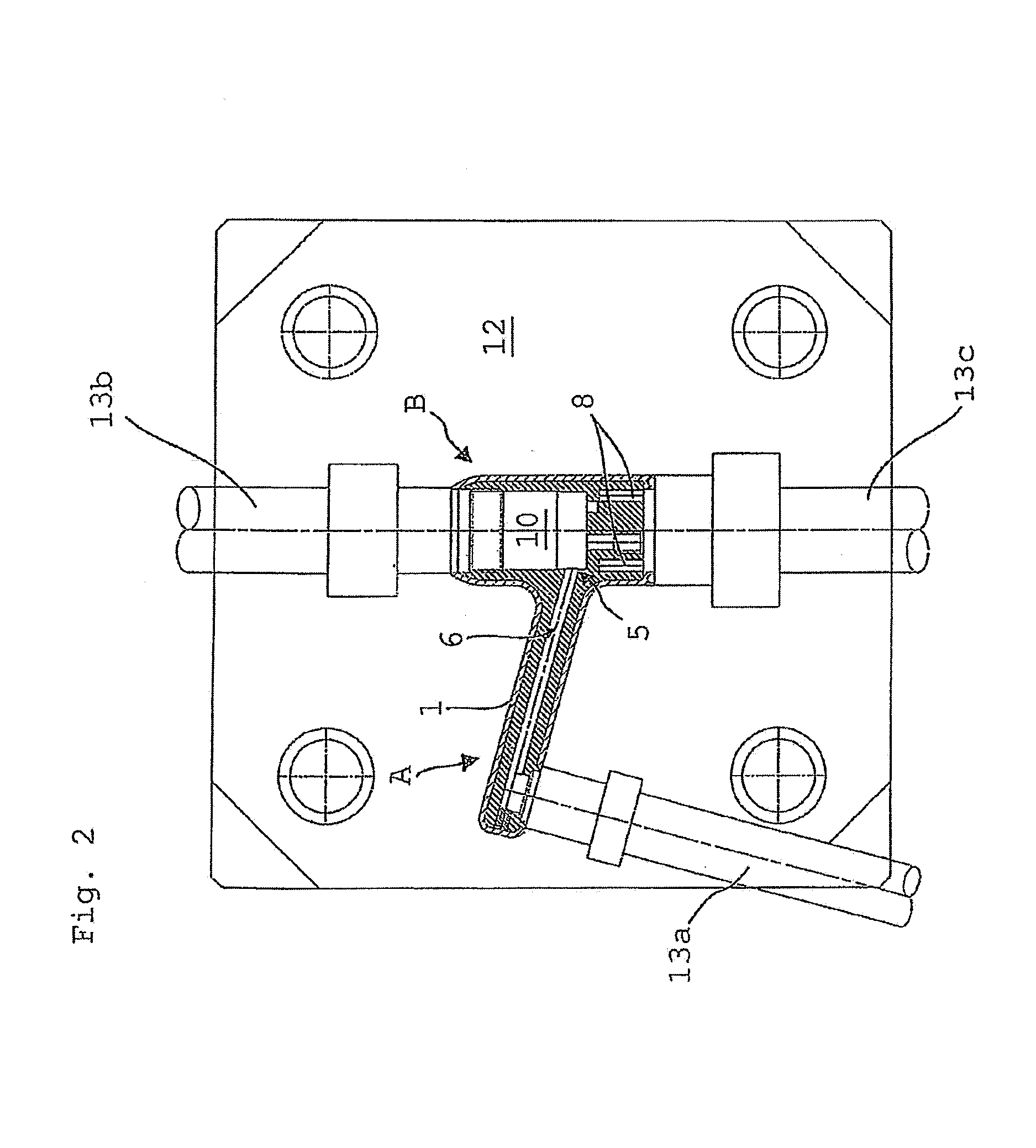

ActiveUS20130299026A1Easy and inexpensive to produceHigh qualityServomotor componentsDomestic plumbingMetal alloyMetallurgy

The present invention relates to a die cast component, in particular a water outlet fitting, comprising a base body produced from metal or a metal alloy by the die casting method and having a cavity in which a number of openings are provided by means of which the cavity is accessible from the outside, the cavity being at least partially filled with a casting core that is in two-dimensional contact with the inside of the base body and in which at least one channel is provided for the conveyance of fluid, the casting core being made of a material the melting point of which is lower than the melting point of the material from which the base body is produced, and that the outside of the casting core rests with at least substantially all of its surface against the inside of the base body. Furthermore, the invention relates to a method for producing this type of die casting component.

Owner:HDO DRUCKGUSS & OBERFLAECHENTECHN

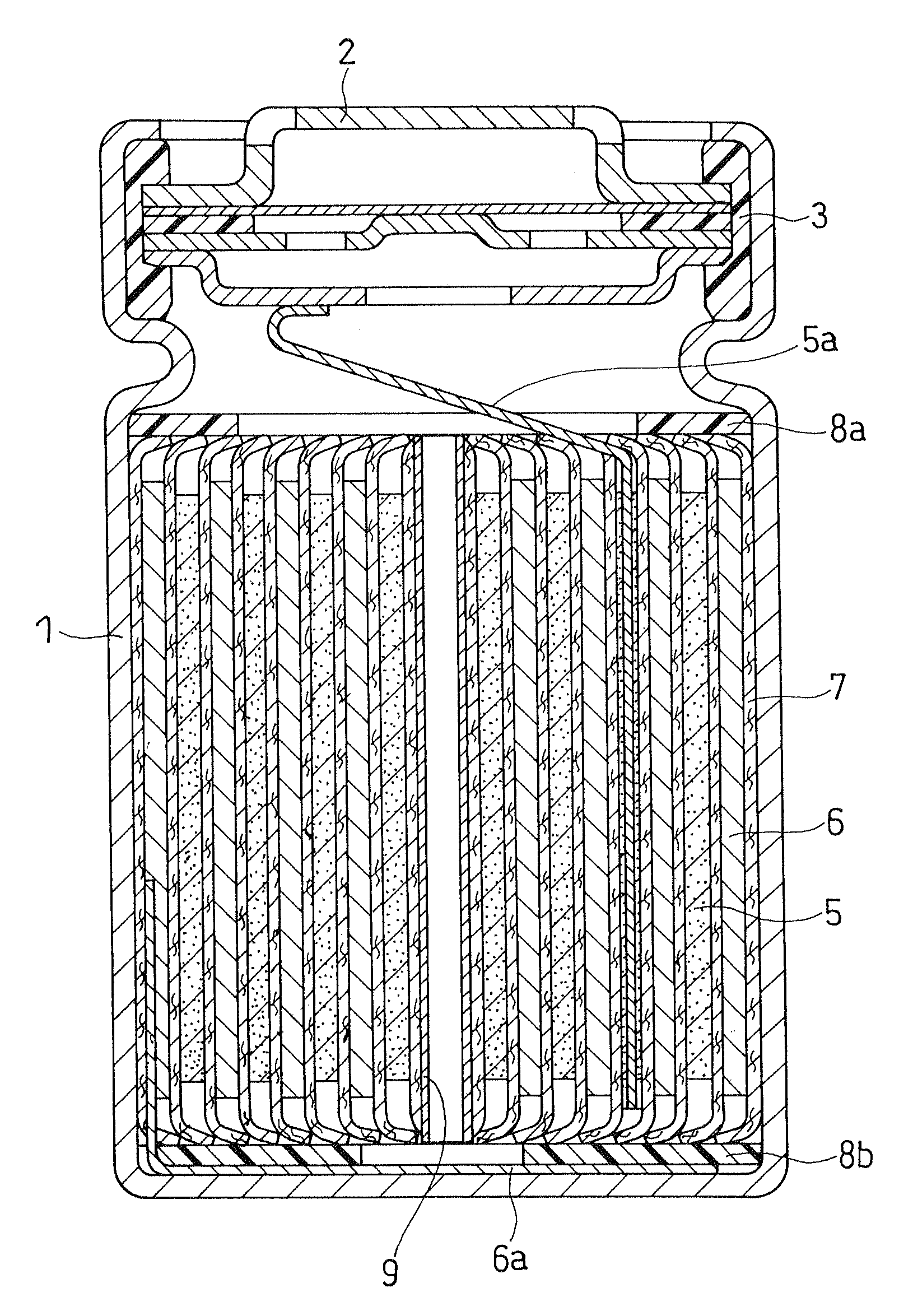

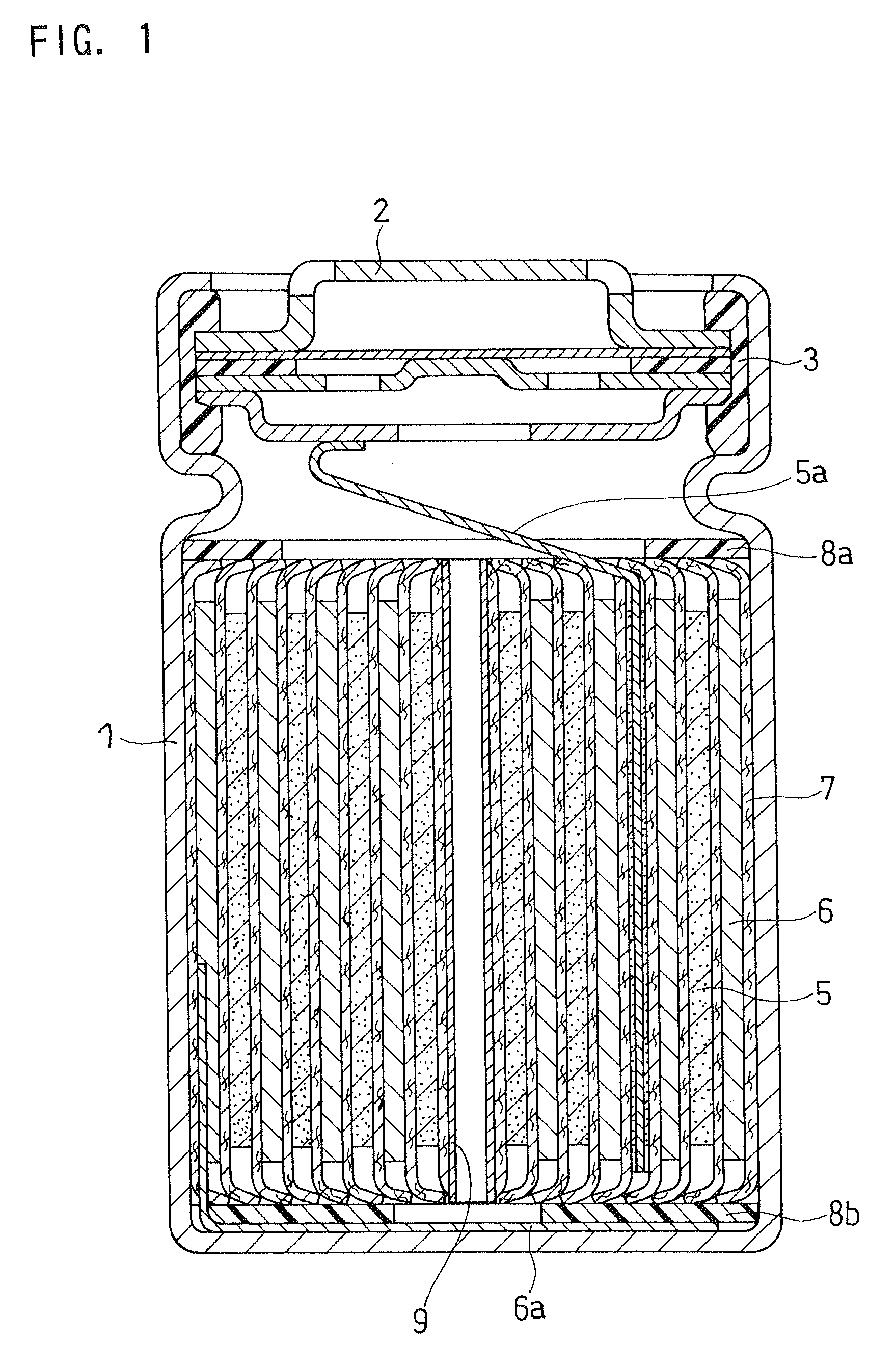

Non-aqueous electrolyte secondary battery

InactiveUS20080008932A1Improve heat resistanceEfficient preparationLi-accumulatorsCell component detailsAntistatic agentPhysical chemistry

In a non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode, and a separator, the separator is immersed in a non-aqueous electrolyte, and the separator contains an aromatic resin and an antistatic agent. The precision upon rolling out a reel-like rolled product of the separator is thus improved, and winding misalignment in separators decreases. Also, minute short circuit occurrence decreases drastically. As a result, a reliable quality, high capacity non-aqueous electrolyte secondary battery can be efficiently and advantageously manufactured.

Owner:PANASONIC CORP

Die cast component and a method for producing a die cast component

InactiveUS20130299028A1Quality improvementImprove reliabilityServomotor componentsDomestic plumbingMetal alloyDie casting

The present invention relates to a die cast component, in particular a water outlet fitting, comprising a base body produced from metal or a metal alloy by the die casting method and having a cavity in which a number of openings are provided by means of which the cavity is accessible from the outside, the cavity being at least partially filled with a casting core that is in two-dimensional contact with the inside of the base body and in which at least one channel is provided for the conveyance of fluid, wherein the casting core is provided with reinforcing ribs and / or bars, wherein in particular bars which pass through the channel are provided in the channel. Furthermore, the invention relates to a method for producing this type of die casting component.

Owner:HDO DRUCKGUSS & OBERFLAECHENTECHN

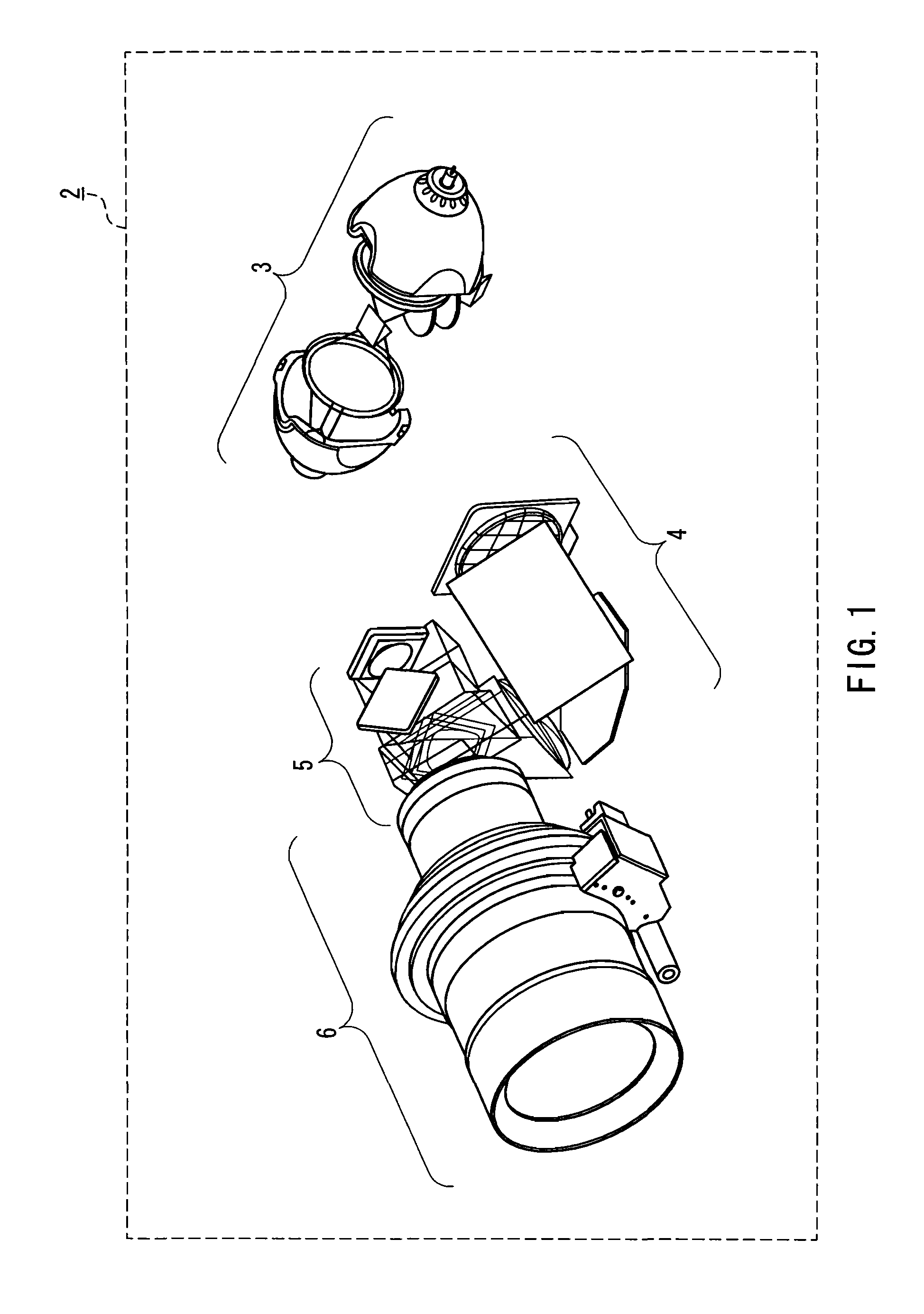

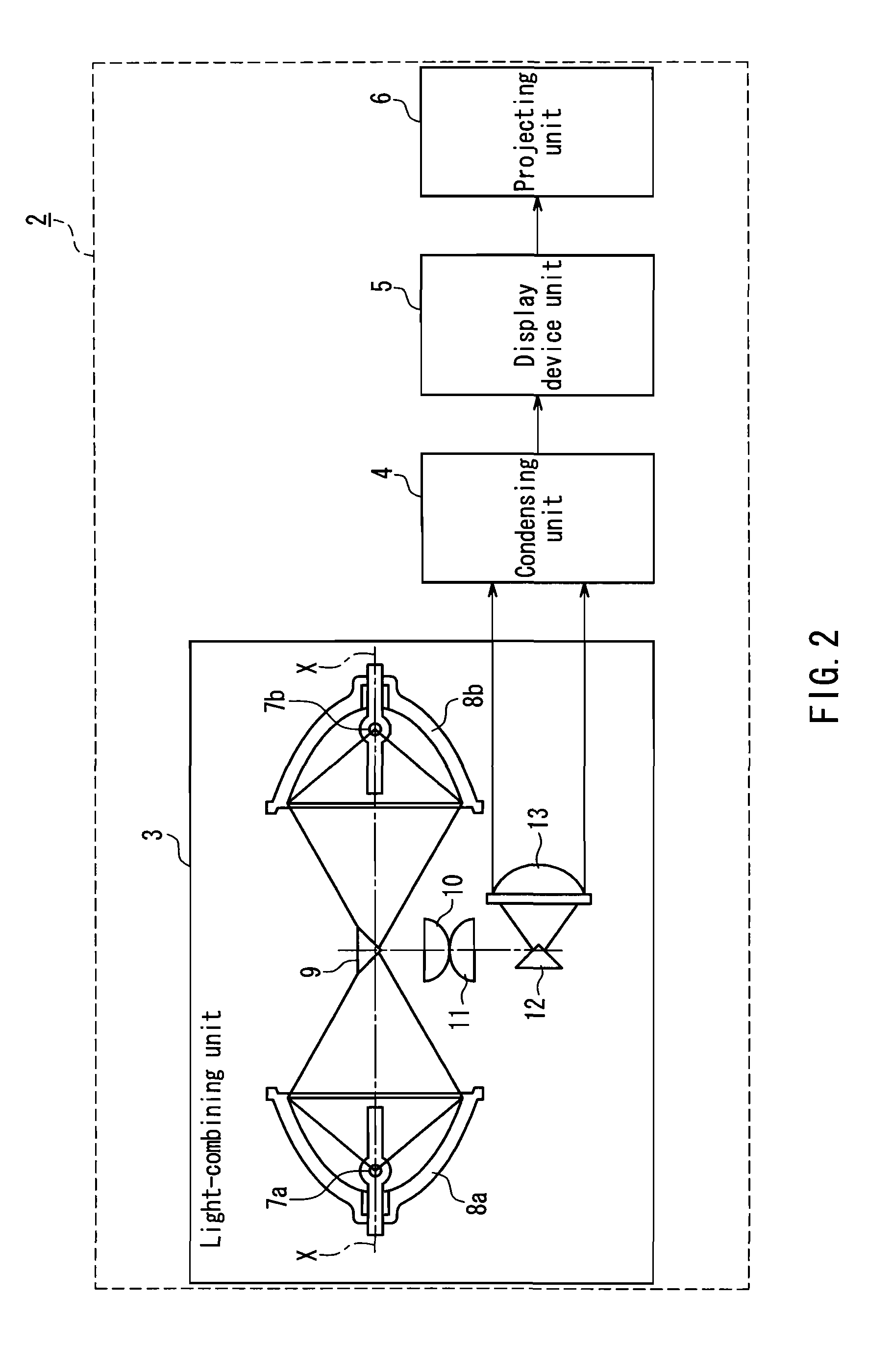

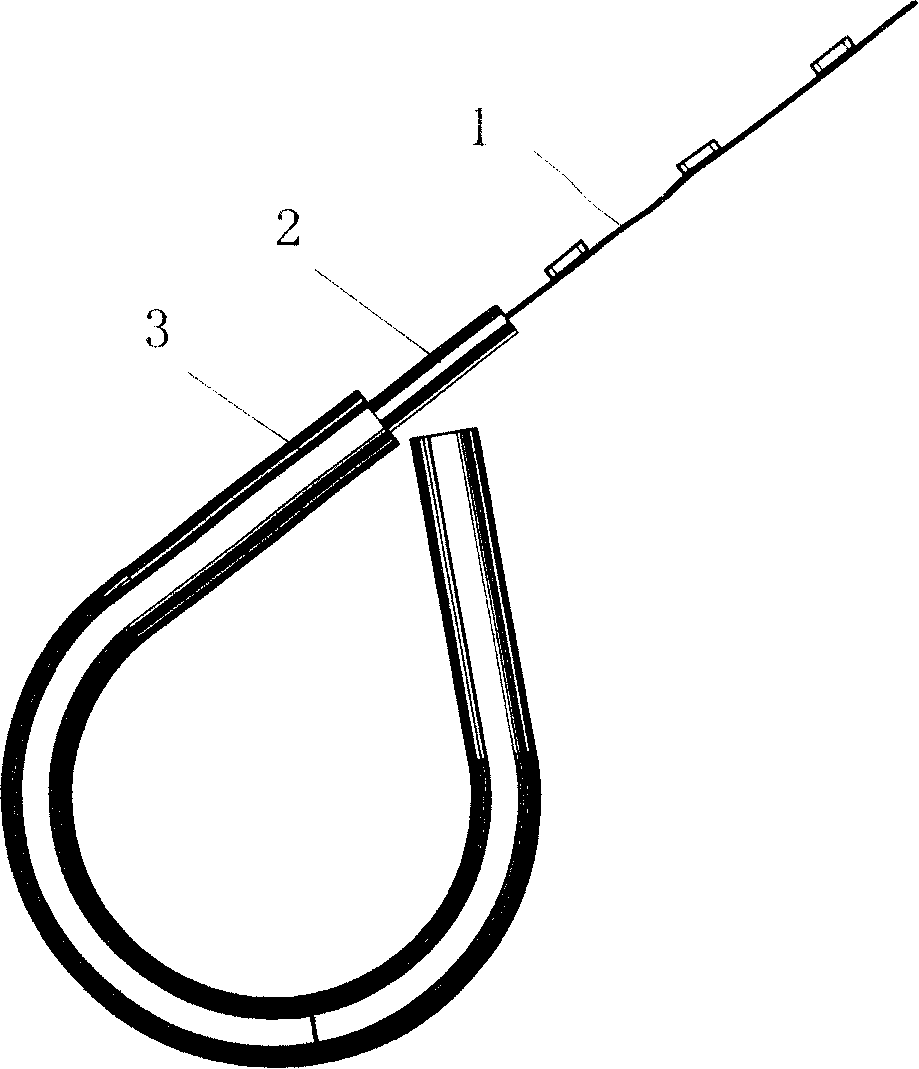

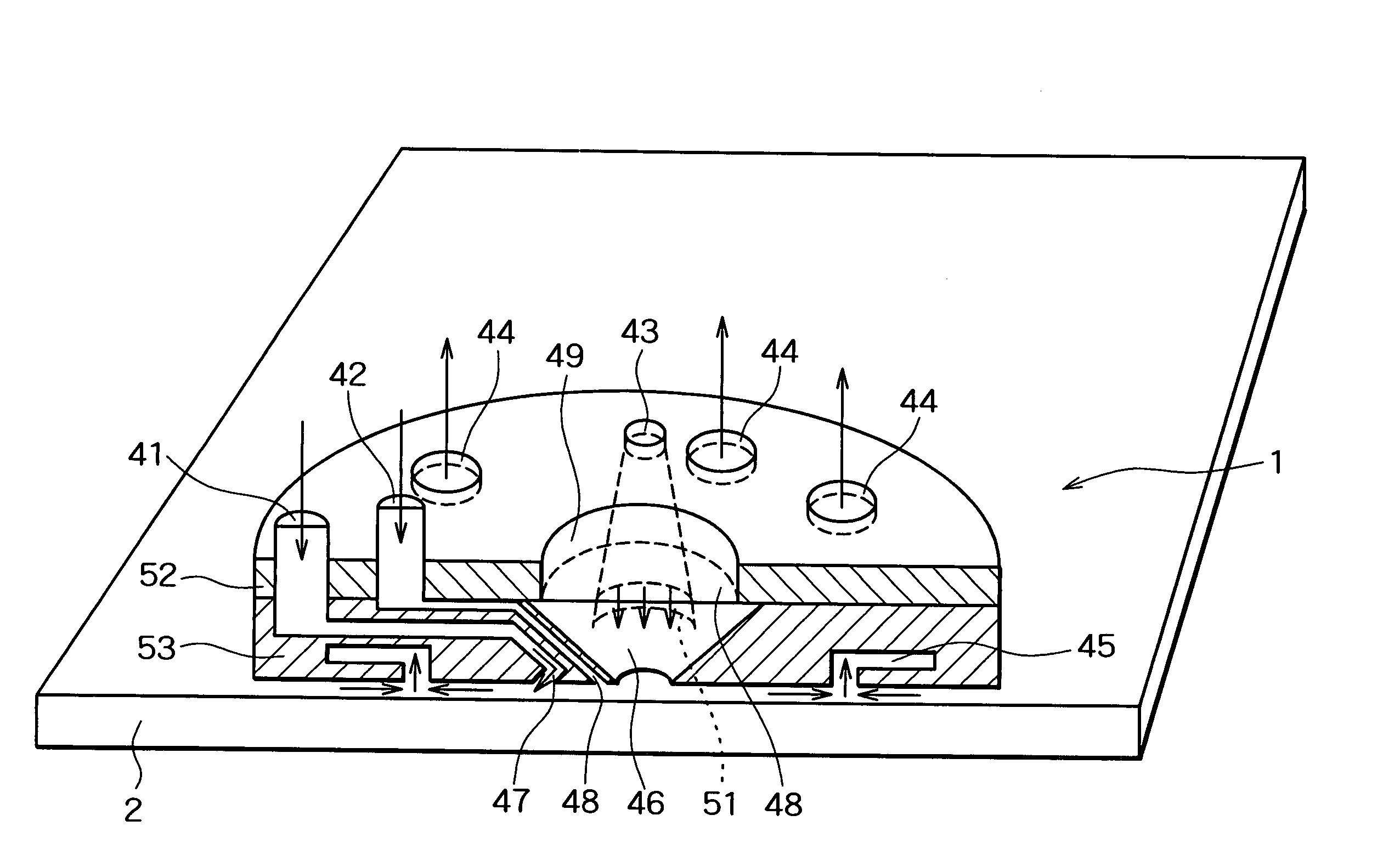

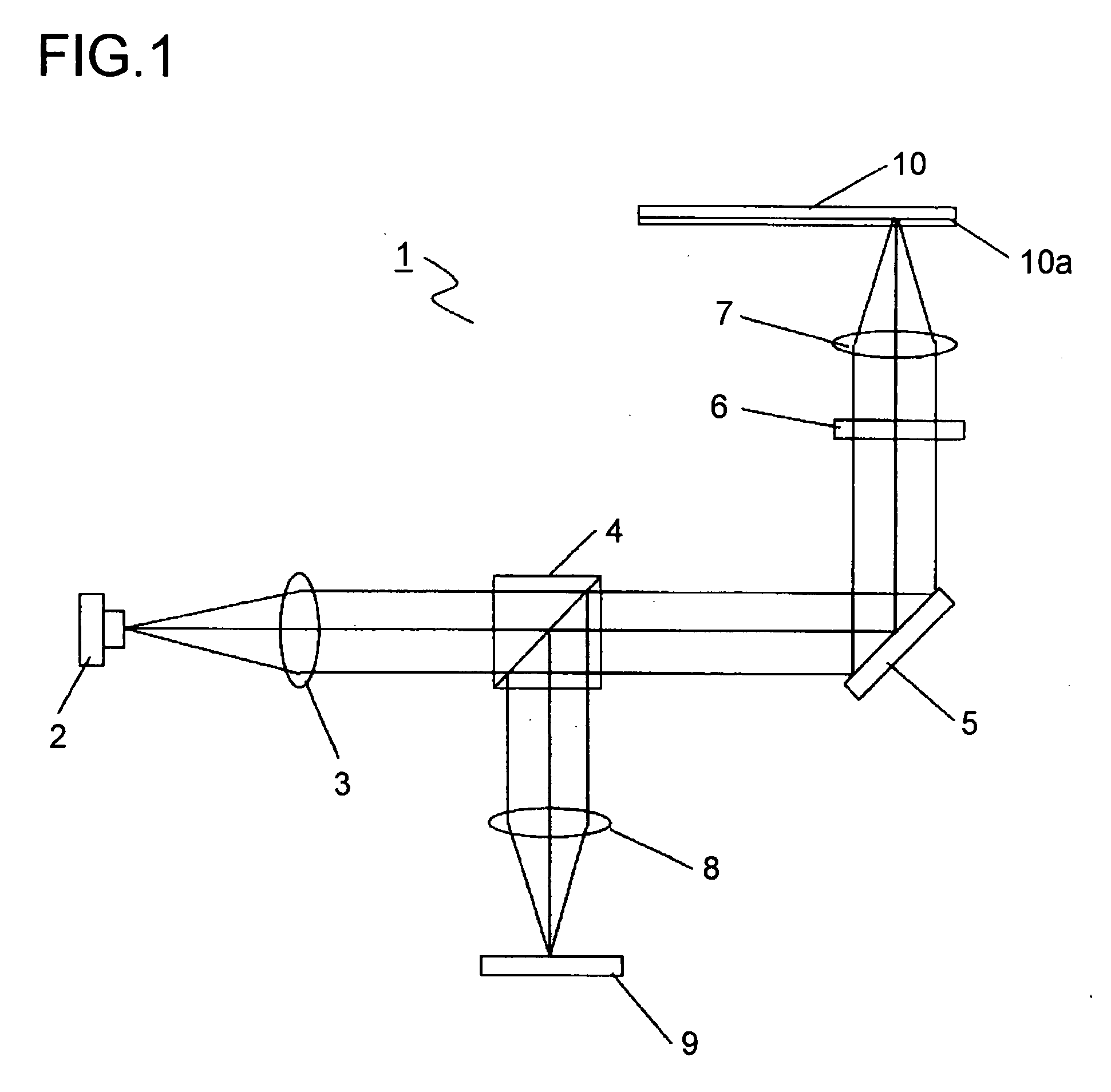

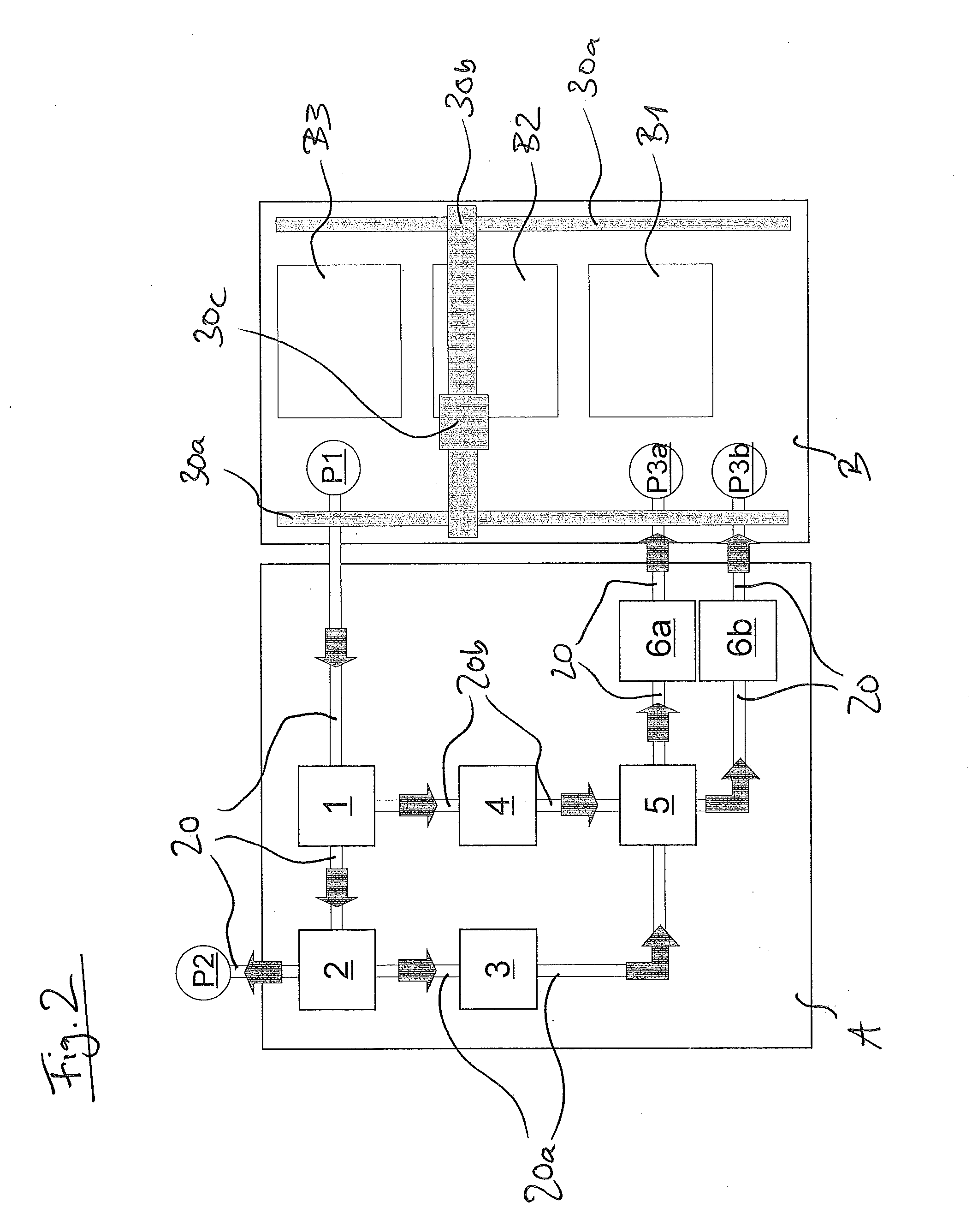

Projection type display device

InactiveUS20100177282A1Reliable controlHigh quality and reliabilityLighting heating/cooling arrangementsProjectorsOptical axisLight beam

A projection type display device including: a plurality of light sources; a display device; a light-combining unit for combining output light beams from the plurality of light sources; a condensing unit for propagating an output light beam from the light-combining unit to the display device; a projecting unit for projecting an image with the use of an output light beam from the display device; and a cooling unit having a ventilating fan and disposed on each of the plurality of light sources. The projection type display device further includes a flow direction adjusting unit for switching blow-off positions where air from the fan is discharged and a control unit for controlling switching of the blow-off positions operated by the flow direction adjusting unit. The control unit controls the flow direction adjusting unit to switch the blow-off positions on the basis of posture information on at least one of an inclination angle of an optical axis of the plurality of light sources and a rotation angle about the optical axis. In a configuration using a plurality of light sources, reliable control of temperature management of the light sources is performed and problems, such as whitening of the light sources, life property degradation, blacking and brightness degradation are suppressed.

Owner:PANASONIC CORP

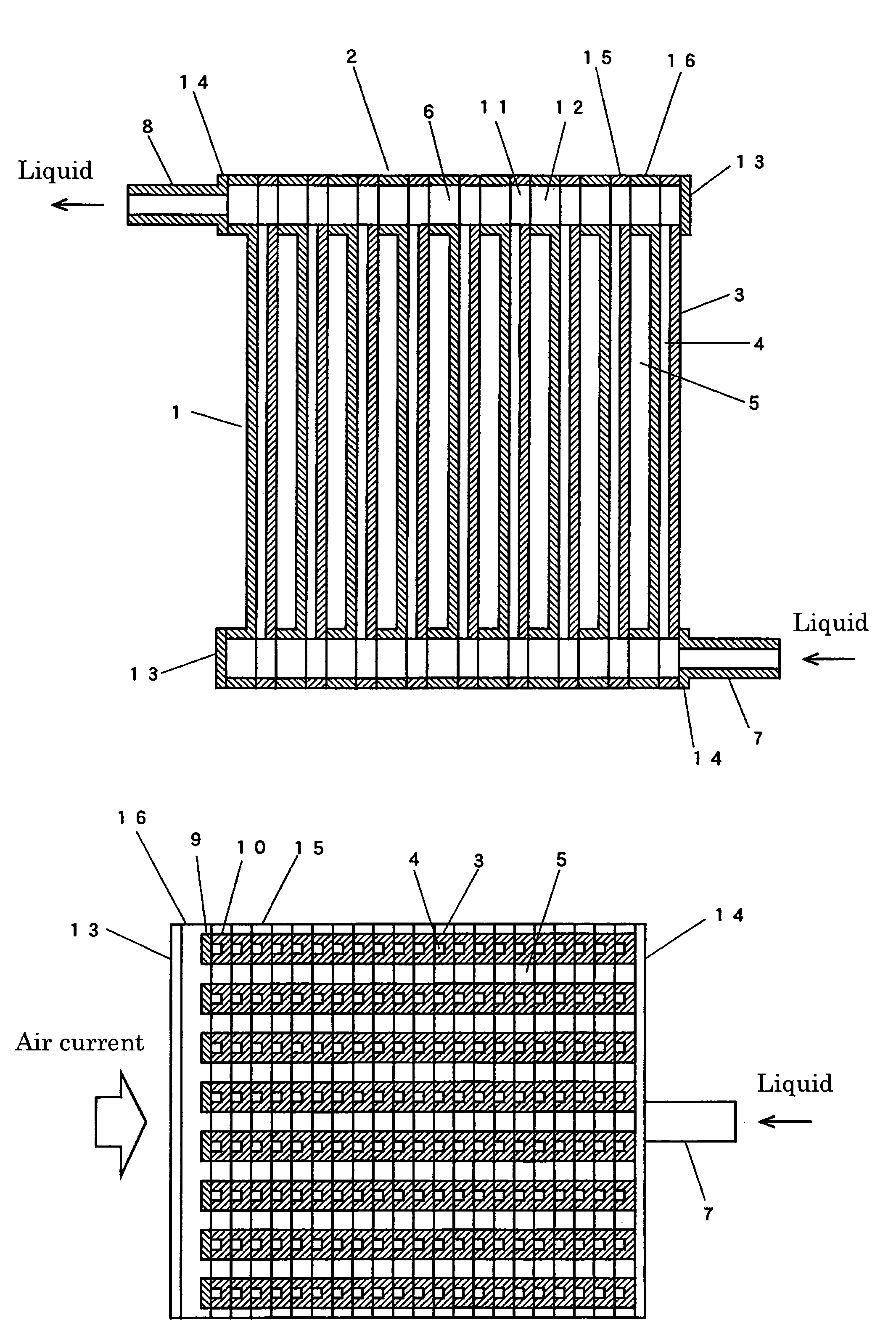

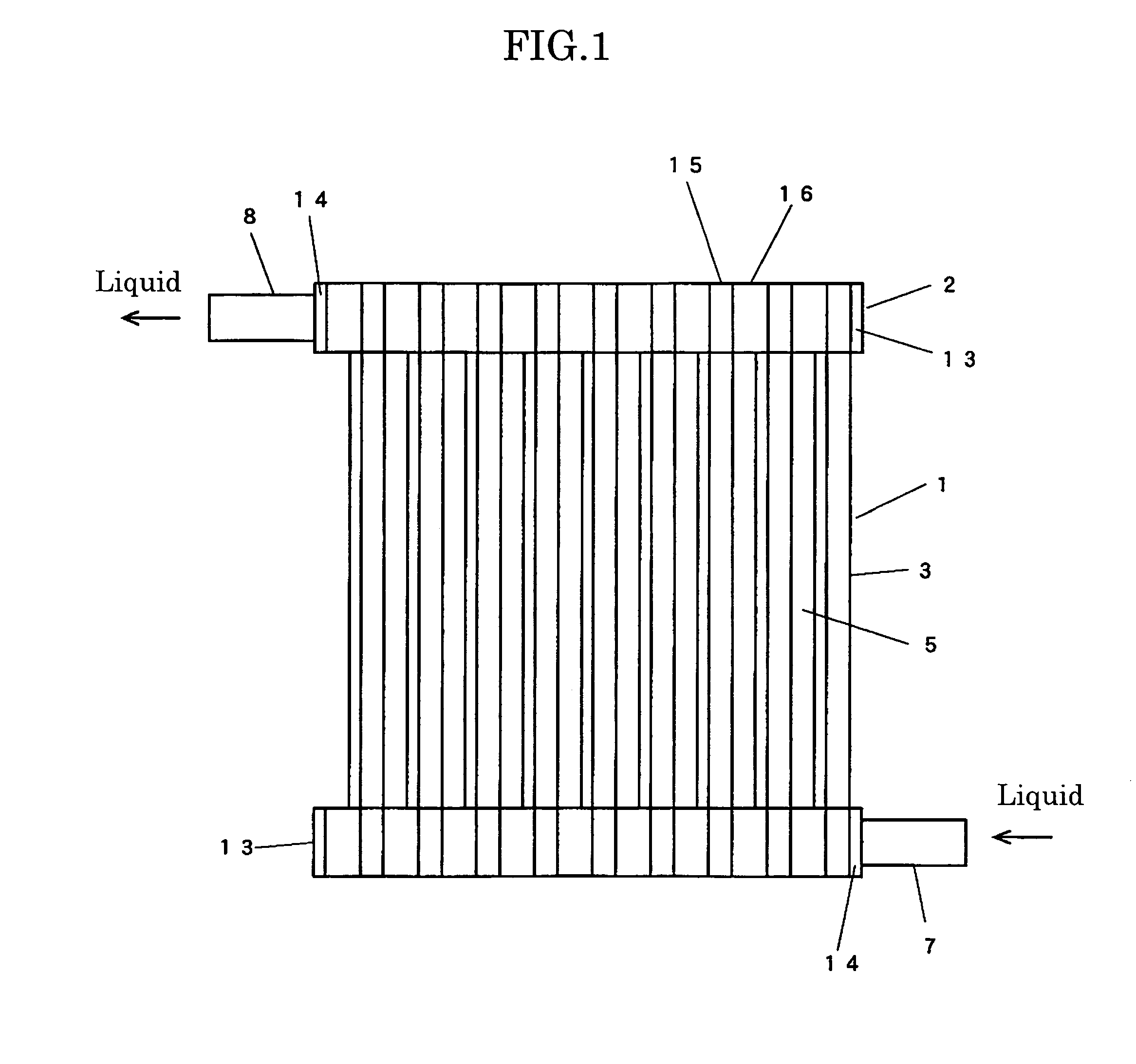

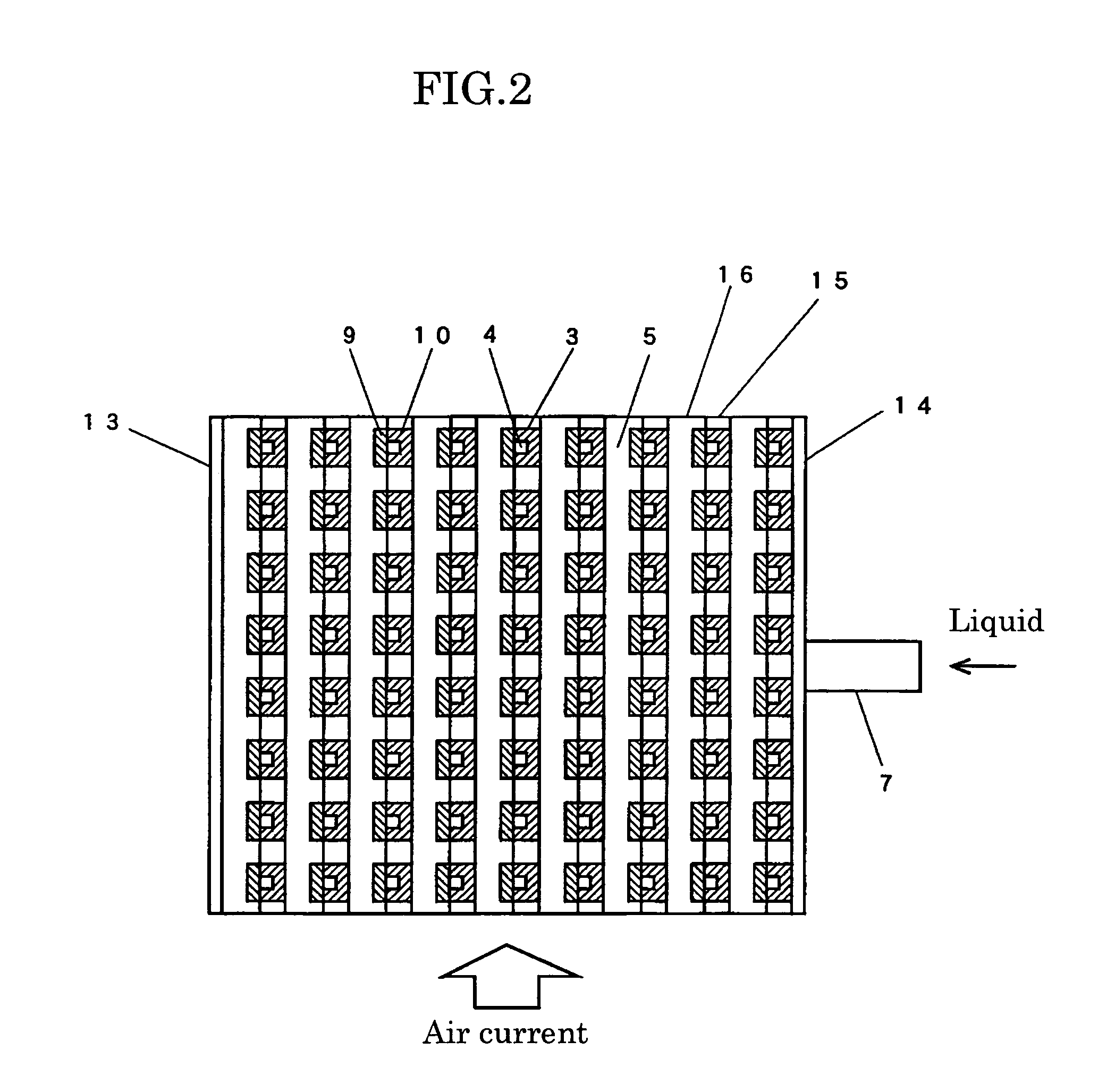

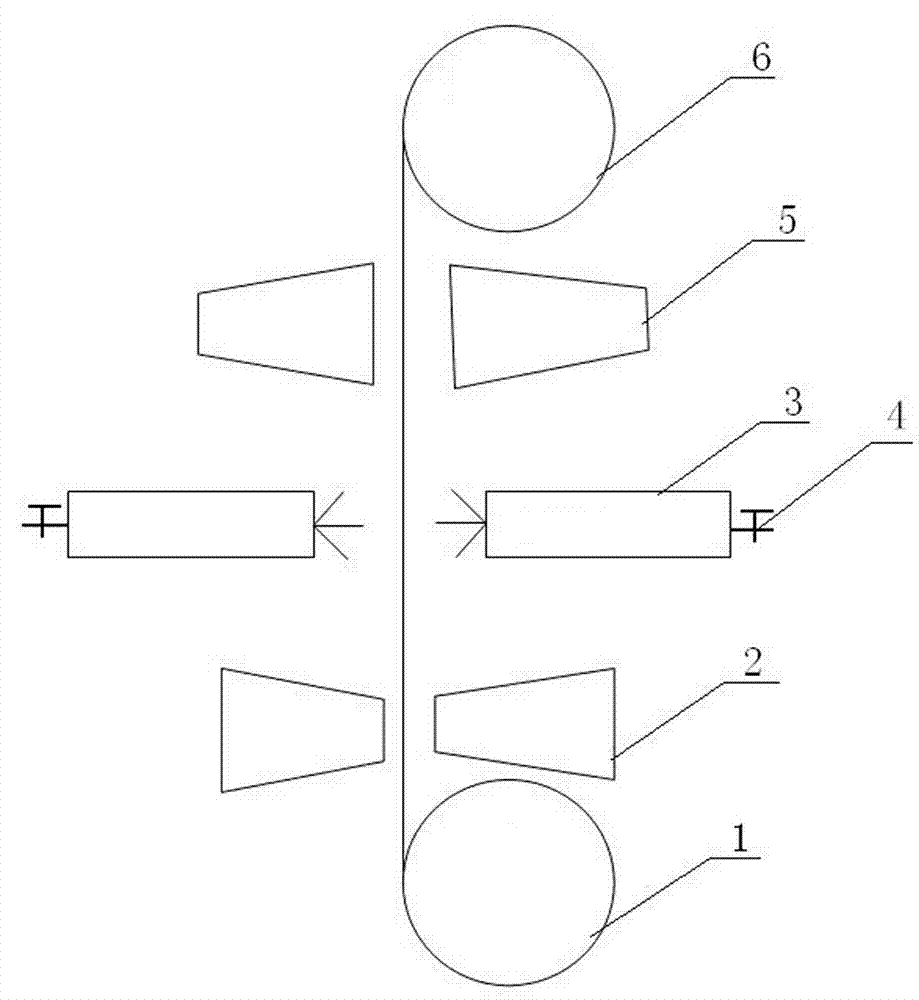

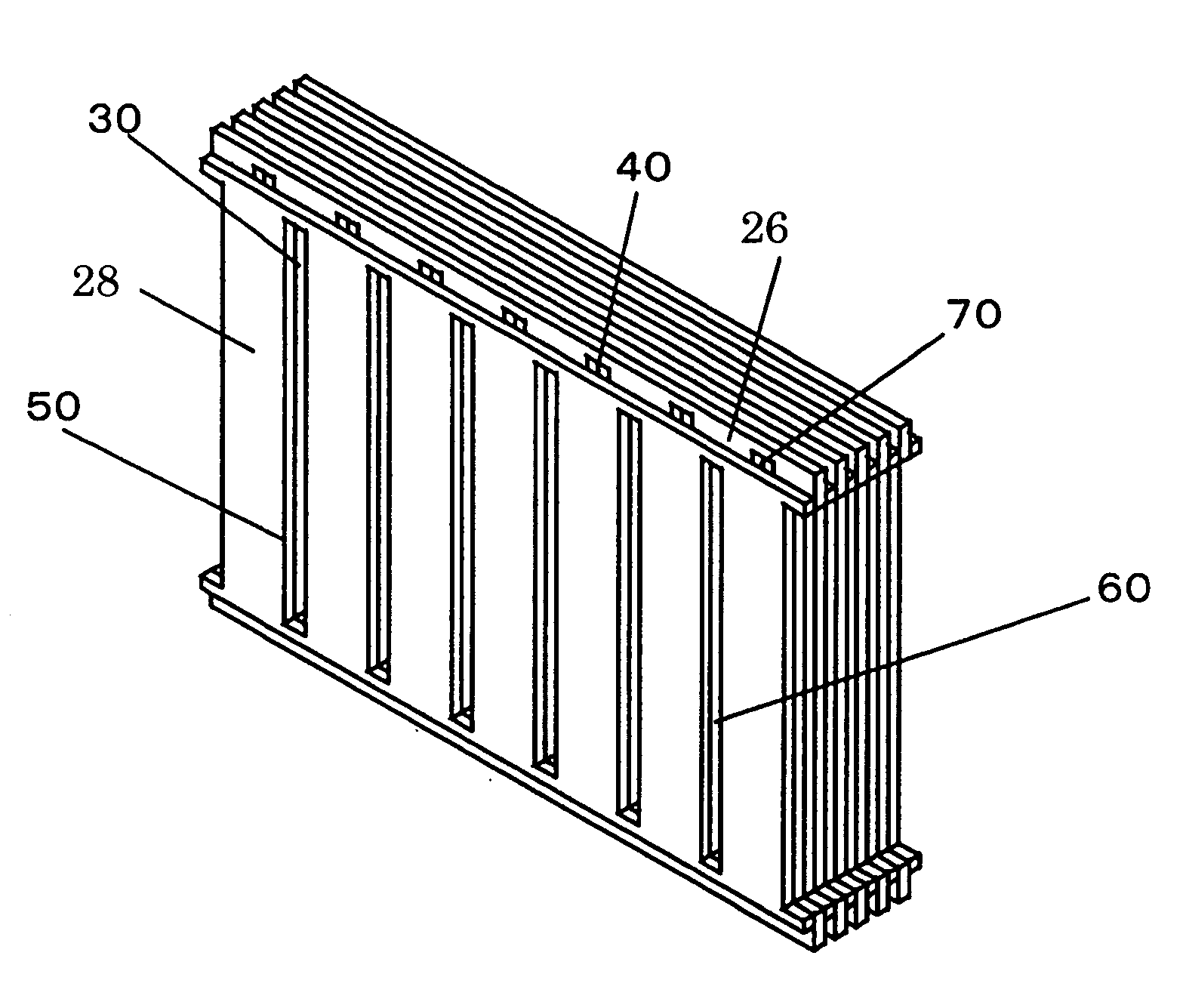

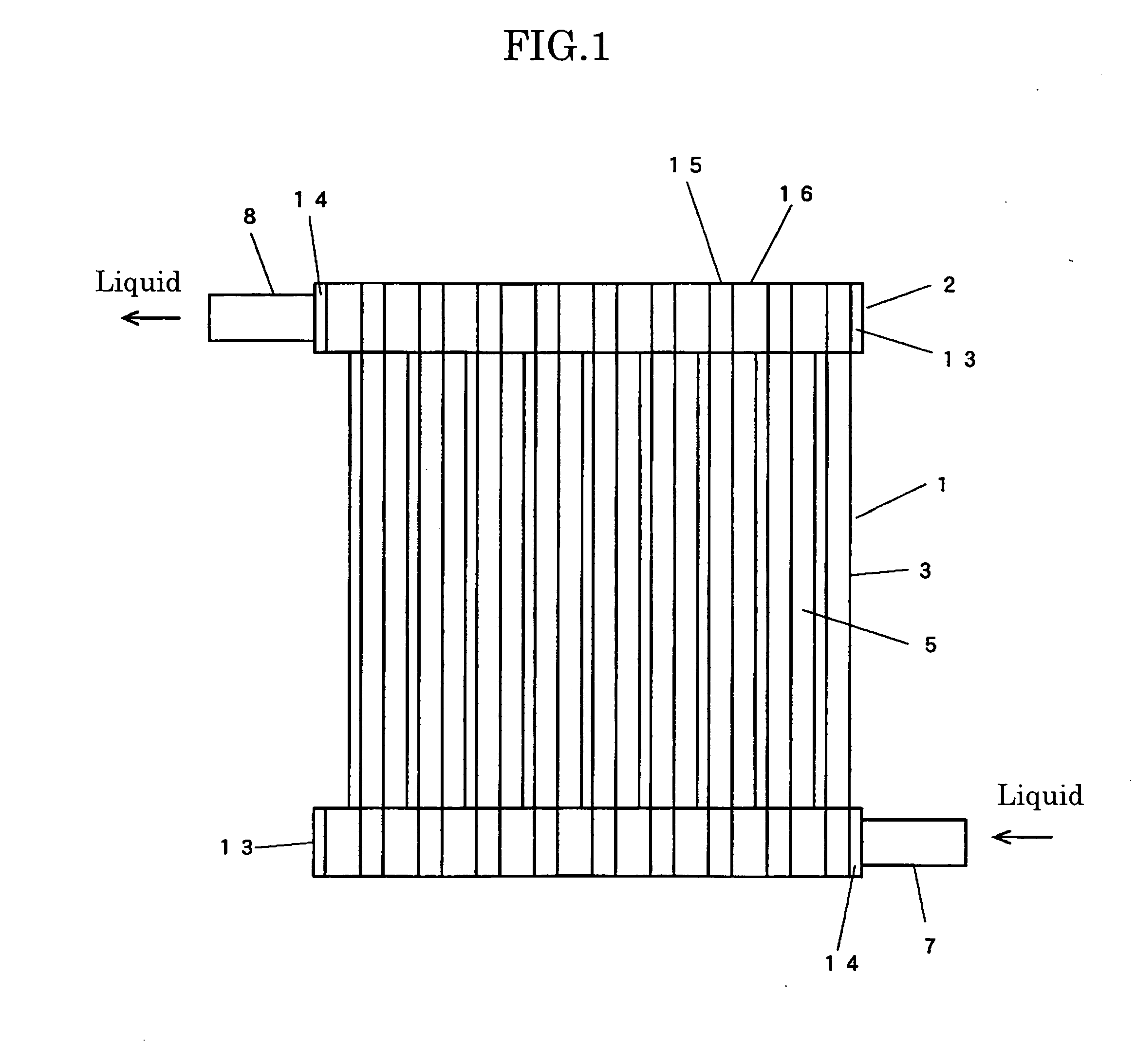

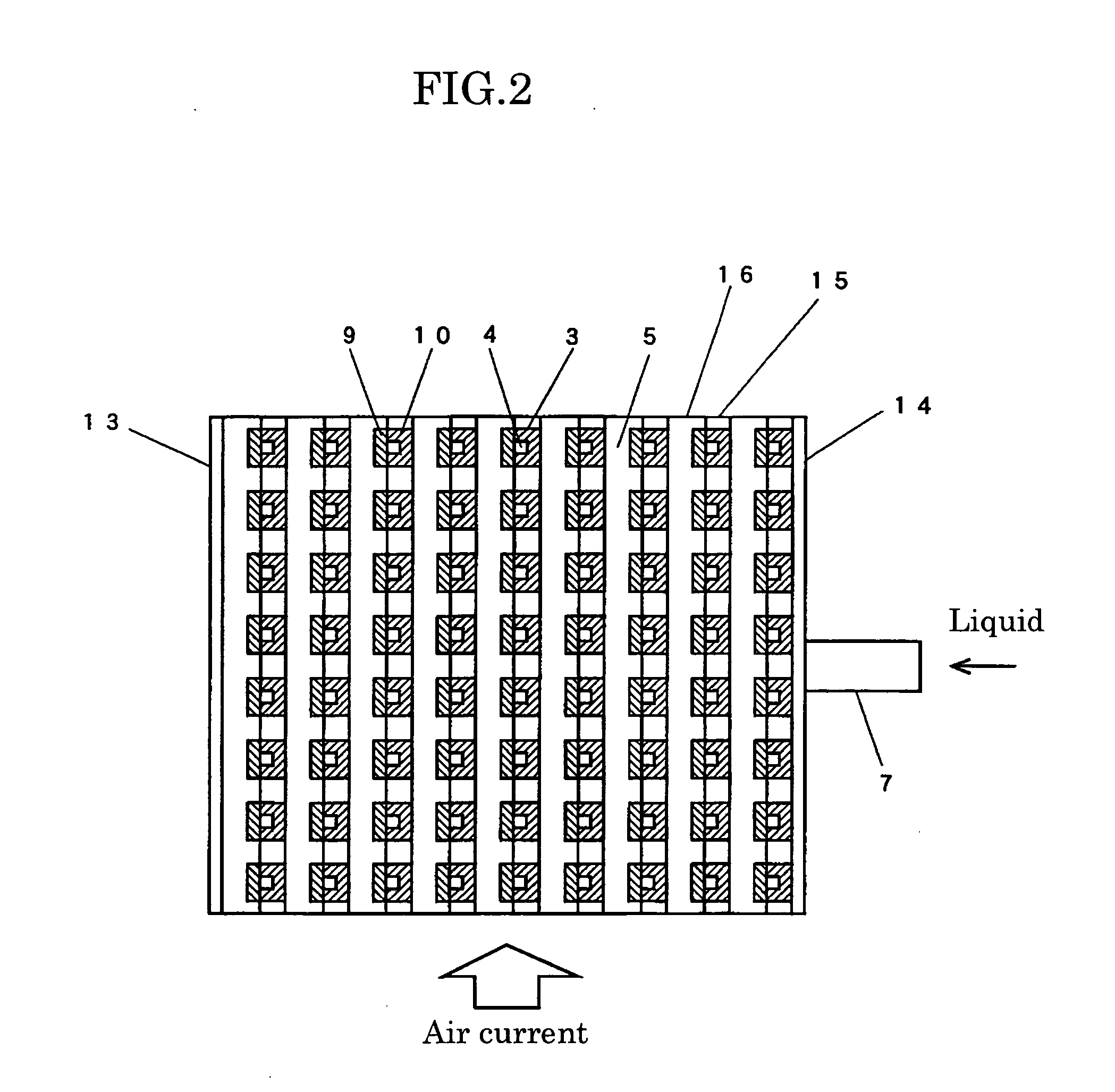

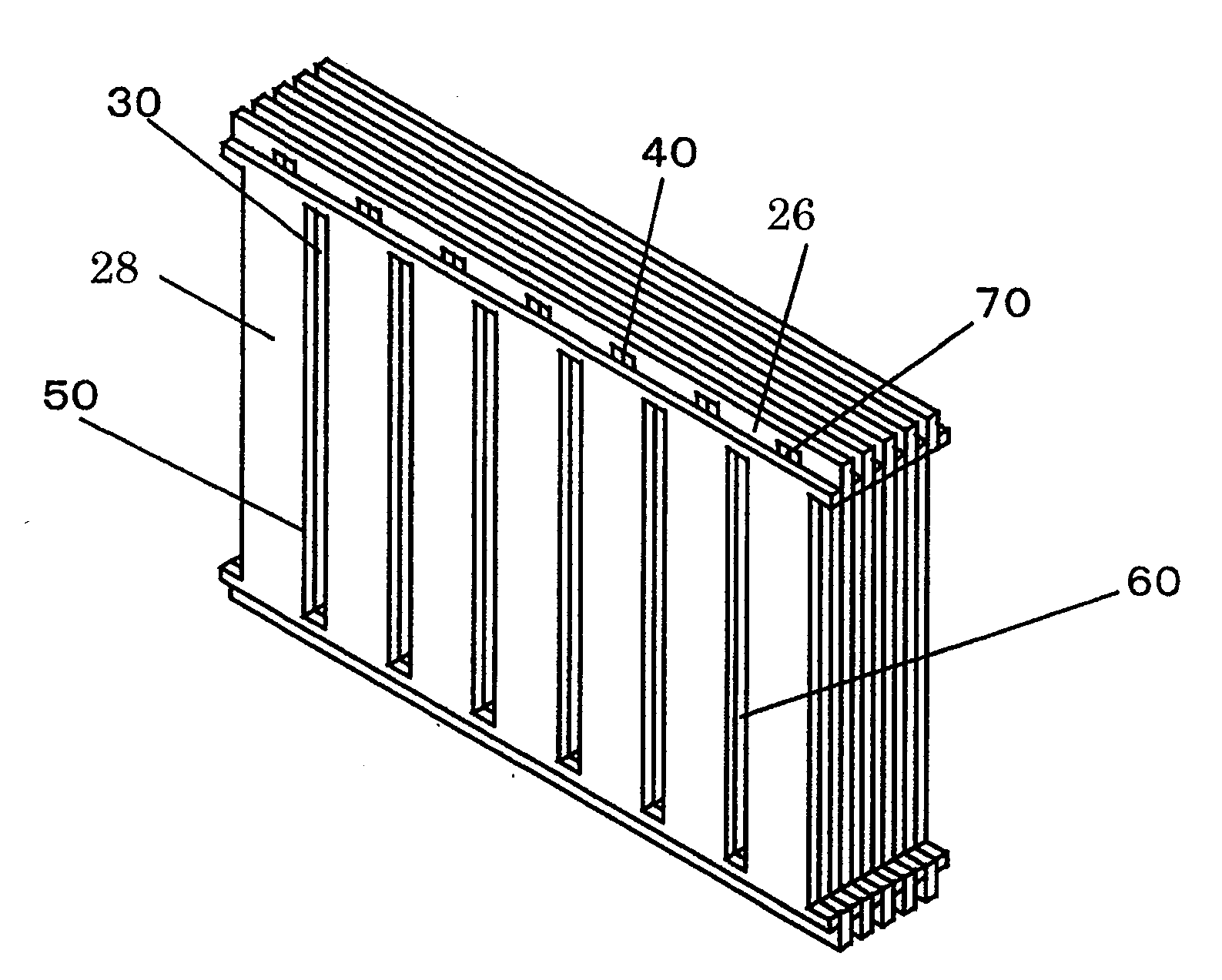

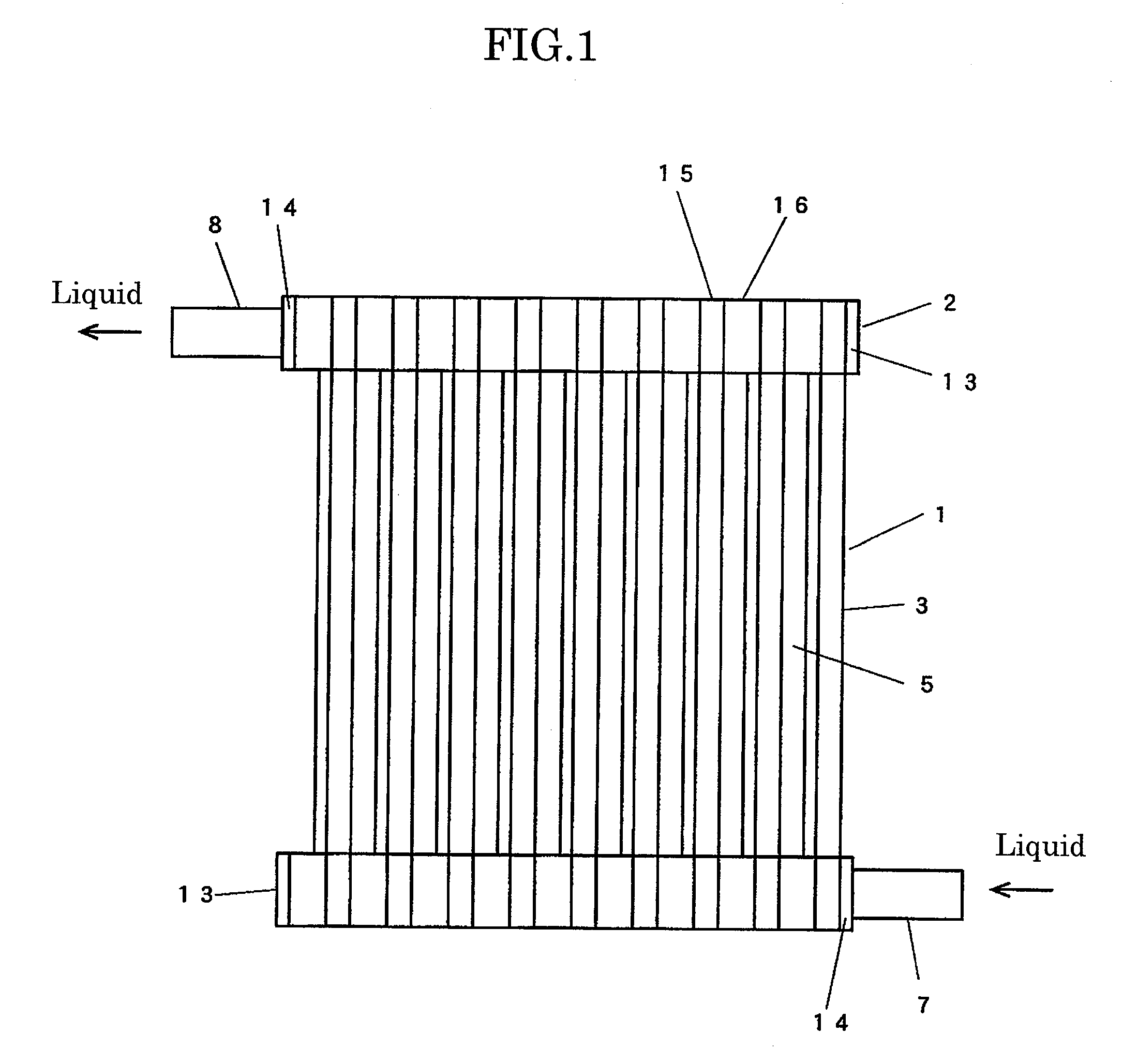

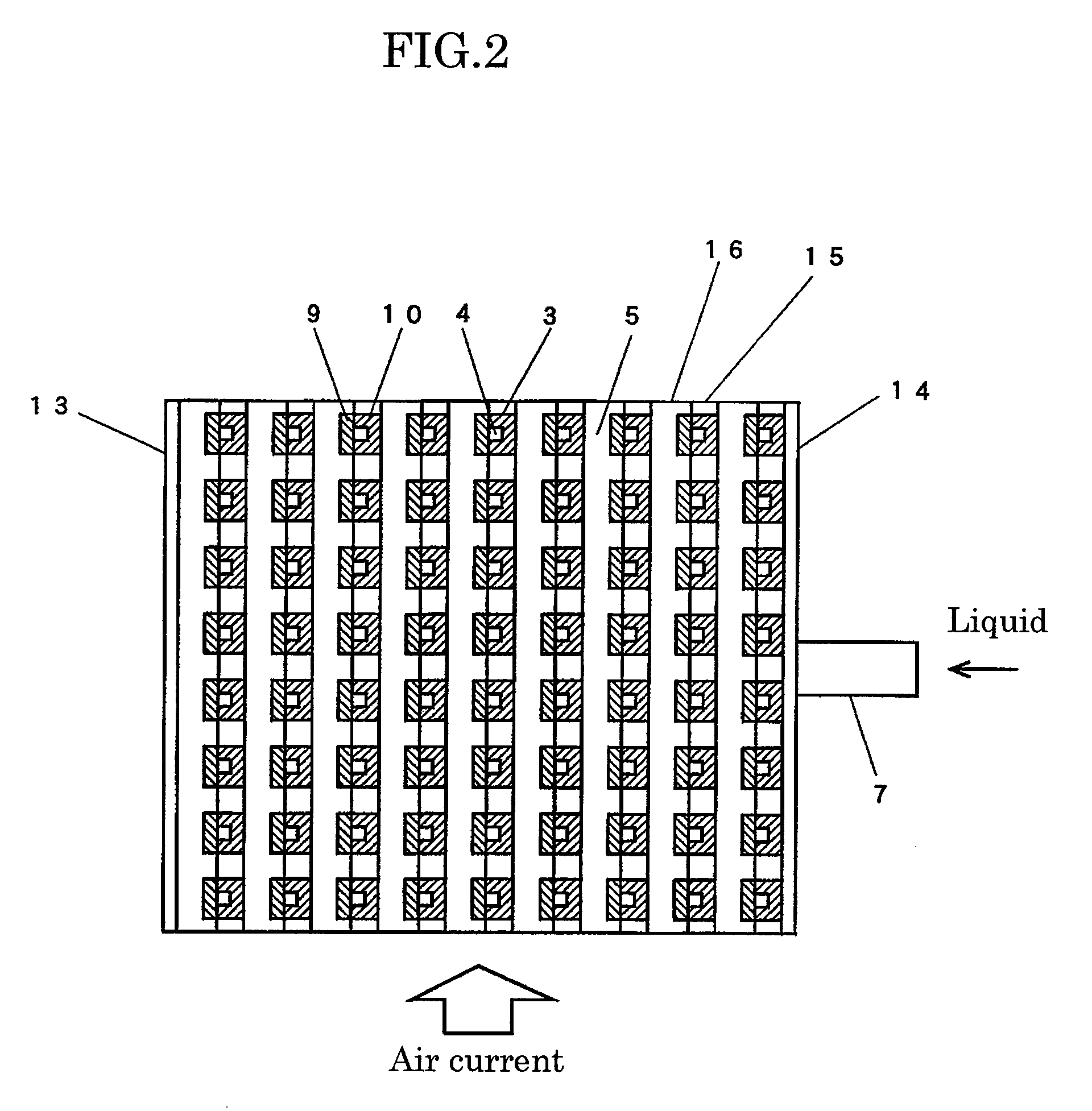

Heat exchanger and its manufacturing method

InactiveUS7637313B2Simple processSimple structureStationary conduit assembliesLaminated elementsEngineeringHeat exchanger

A heat exchanger which, while having excellent heat exchanging performance, has a structure easy to produce, is of low cost, and has high quality and reliability. The heat exchanger has first base plates (26), in each of which first slits (30) and second slits (40) are provided in substantially parallel to each other, and has second base plates (28), in each of which third slits (50) with substantially the same shape as a first slit (30) are provided. The length in the longitudinal direction of a second base plate (28) is set to be less than the length of a second slit (40). The first base plates (26) and the second base plates (28) are layered over each other such that the first slits (30) provided in the first base plates (26) and the third slits (50) provided in the second base plates (28) are communicated. Flow paths (60) outside tubes are constructed by the first slits (30) provided in the first base plates (26) and the third base plates (50) provided in the second base plates (28). Flow paths (70) inside the tubes are constructed by the second slits (40) provided in the first base plates (26) and the second base plates (28). Since a heat exchanging section formed only by tubes can be constructed by the base plates with the slits, the heat exchanger can be easily produced. Further, the heat exchanger can be provided at low cost.

Owner:PANASONIC CORP

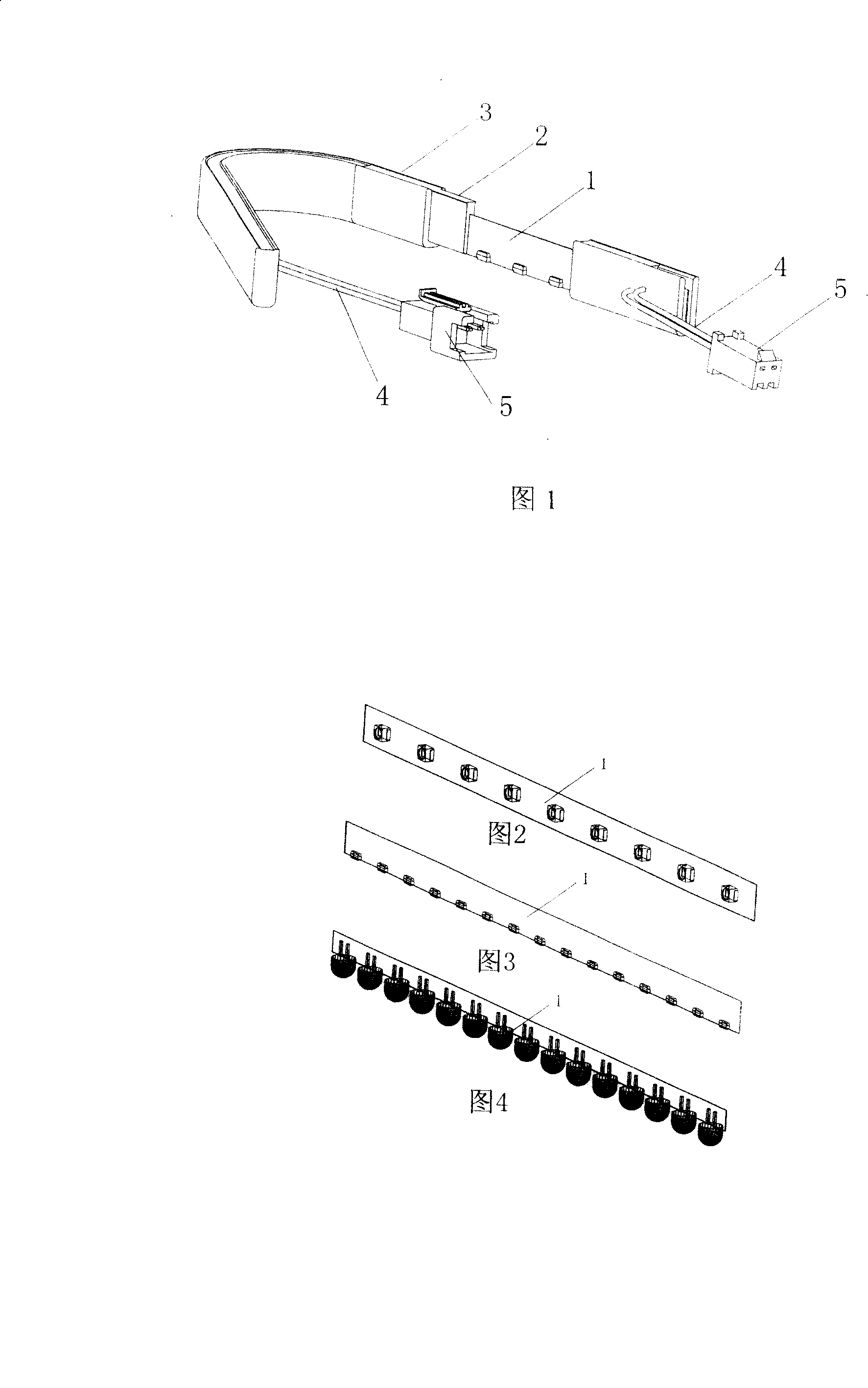

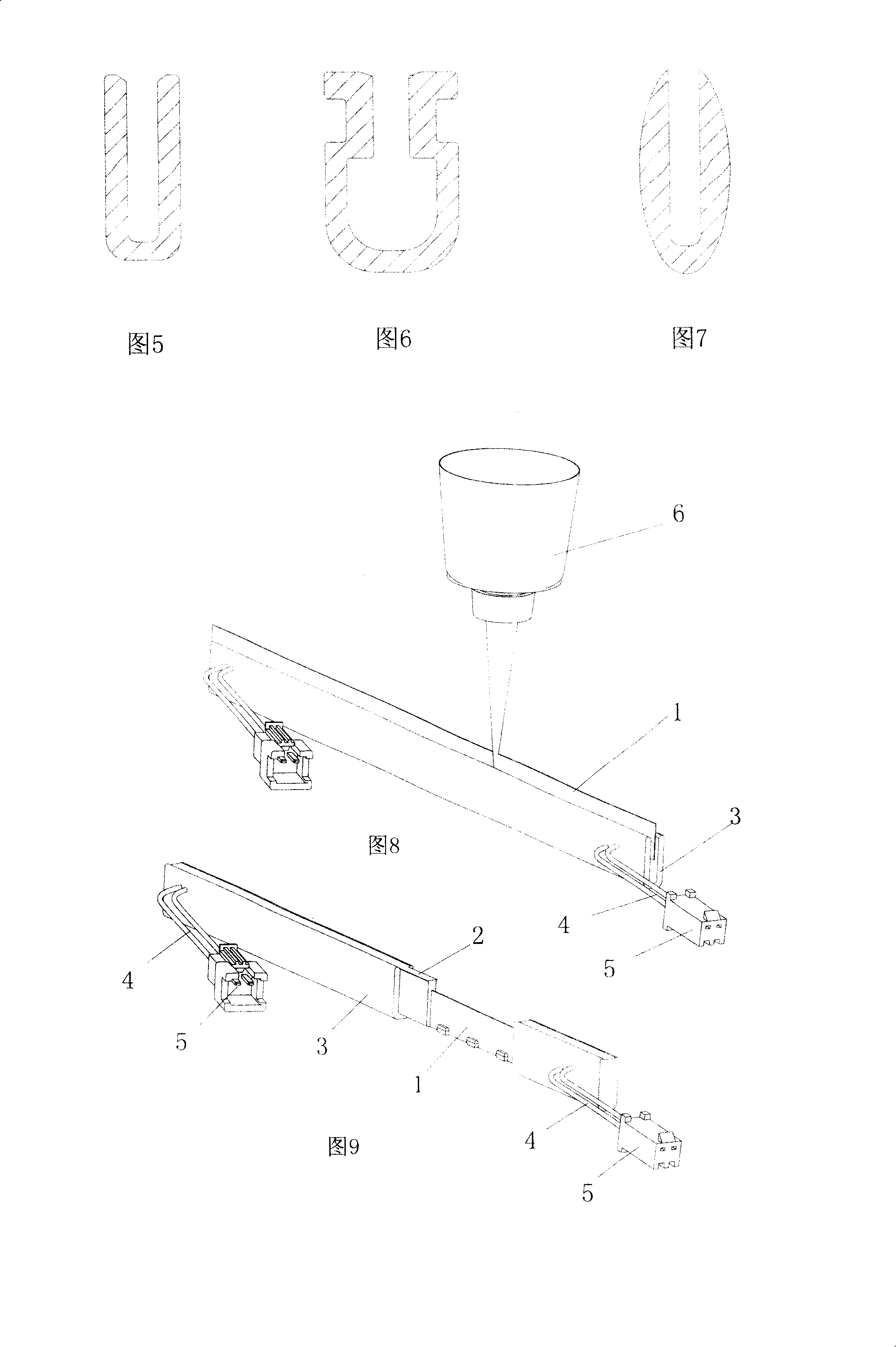

Water-proof LED flexible light stripe and its manufacturing method

InactiveCN101220947AHigh quality and reliabilitySafe to usePoint-like light sourceElectric circuit arrangementsColloidEngineering

The invention provides a waterproof LED flexible optical strip, including an LED flexible optical strip which is coated with a colloid layer which is spliced with a tegmen; meanwhile, the invention also provides a preparation method of the waterproof LED flexible optical strip. The invention has the advantages that the products of the waterproof LED flexible optical strip have high quality reliability and good application safety, the method has low manufacturing cost, and mass yield can be realized; furthermore, the invention can produce arbitrary length according to requirement, which has extremely high product yield and superiority which is incomparable with other waterproof LED flexible optical strips.

Owner:上海宜美电子科技有限公司

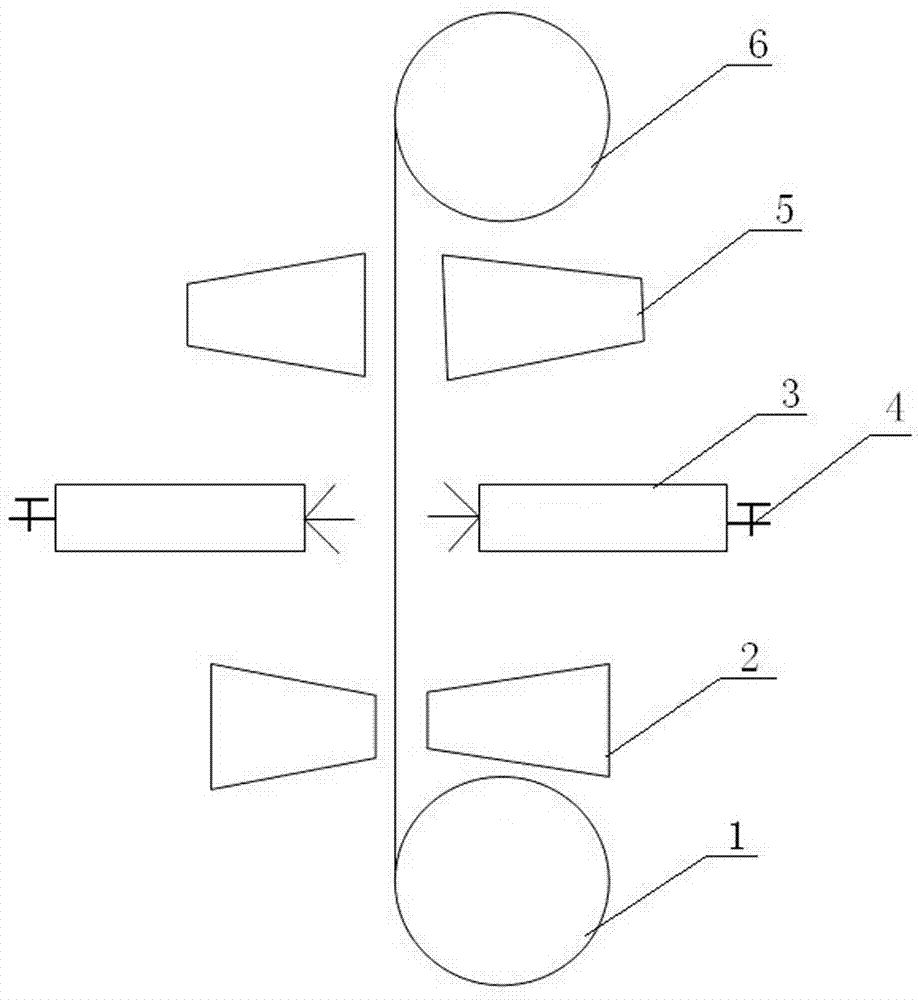

Method for preparing lithium battery current collector by electrostatic coating polymer composite PTC powder

InactiveCN103794802AHigh quality and reliabilityFast thermal responseElectrode carriers/collectorsSecondary cellsCombustionElectrostatic coating

The invention discloses a method for preparing lithium battery current collector by electrostatic coating polymer composite PTC powder. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the lithium battery current collector up to 100-300 DEG C by a heating device, and coating the lithium battery current collector with the polymer composite PTC powder obtained in the step (1) through an electrostatic coating device to form a polymer composite PTC powder coating on the lithium battery current collector; (3) baking the lithium battery current collector coated with the polymer composite PTC powder coating in the step (2), and carrying out a recrystallization technology to obtain the lithium battery current collector provided with the polymer composite PTC powder coating. After the method is adopted, the problems of damage and explosion caused by heating of a lithium battery can be solved, so that the problems of combustion and explosion caused by rapid heating and chain reaction since the current of the current collector is overhigh due to overheating of the interior of the lithium battery can be further solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Multilayer rigid-flex board plated filled through-hole manufacturing process

ActiveCN104219898AHigh densityHigh precisionPrinted element electric connection formationCopper platingCopper sulfate

The invention discloses a multilayer rigid-flex board plated filled through-hole manufacturing process, and belongs to the technical field of circuit board manufacturing processes. The multilayer rigid-flex board plated filled through-hole manufacturing process is technically characterized by including the steps: (1) cutting; (2) drilling; (3) electroless copper plating; (4) copper plating; (5) circuit manufacture; (6) sealing; (7) press fit; (8) drilling; (9) plasma cleaning; (10) electroless copper plating; (11) copper pre-plating; (12) filled hole plating. In the step (2), the drilling aperture is smaller than or equal to 0.12mm. Electroplate liquid comprises sulfuric acid H2SO4, copper sulfate CuSO4, acidic brightening agents, inhibitors, leveling agents and hydrochloric acid HCl. The multilayer rigid-flex board plated filled through-hole manufacturing process is simple and used for plated filled through-holes in circuit board manufacture, the assembly size of a board is decreased, and assembly flexibility is improved.

Owner:BOMIN ELECTRONICS CO LTD

Heat Exchanger And Its Manufacturing Method

InactiveUS20080135218A1Speed up heat exchangeImprove reliabilityMetal-working apparatusStationary conduit assembliesEngineeringHeat exchanger

A heat exchanger which, while having excellent heat exchanging performance, has a structure easy to produce, is of low cost, and has high quality and reliability. The heat exchanger has first base plates (26), in each of which first slits (30) and second slits (40) are provided in substantially parallel to each other, and has second base plates (28), in each of which third slits (50) with substantially the same shape as a first slit (30) are provided. The length in the longitudinal direction of a second base plate (28) is set to be less than the length of a second slit (40). The first base plates (26) and the second base plates (28) are layered over each other such that the first slits (30) provided in the first base plates (26) and the third slits (50) provided in the second base plates (28) are communicated. Flow paths (60) outside tubes are constructed by the first slits (30) provided in the first base plates (26) and the third base plates (50) provided in the second base plates (28). Flow paths (70) inside the tubes are constructed by the second slits (40) provided in the first base plates (26) and the second base plates (28). Since a heat exchanging section formed only by tubes can be constructed by the base plates with the slits, the heat exchanger can be easily produced. Further, the heat exchanger can be provided at low cost.

Owner:PANASONIC CORP

Wiring repair apparatus

InactiveUS7371286B2Quality improvementLower Reliability RequirementsTransistorSemiconductor/solid-state device detailsOptoelectronicsLaser source

A wiring repair apparatus includes an XY stage on which a substrate is placed, a laser source unit disposed above the XY stage, first and second gas windows disposed between the laser source unit and the XY stage, and first and second CVD gas units. The laser source unit emits a laser beam to a part of the substrate to be repaired. This laser beam passes through either the first or second gas window. The first CVD gas unit supplies an Al source gas (DMAH gas) to the first gas window while the second CVD gas unit supplies a Cr source gas (Cr(CO)6 gas) to the second gas window.

Owner:LASERFRONT TECH

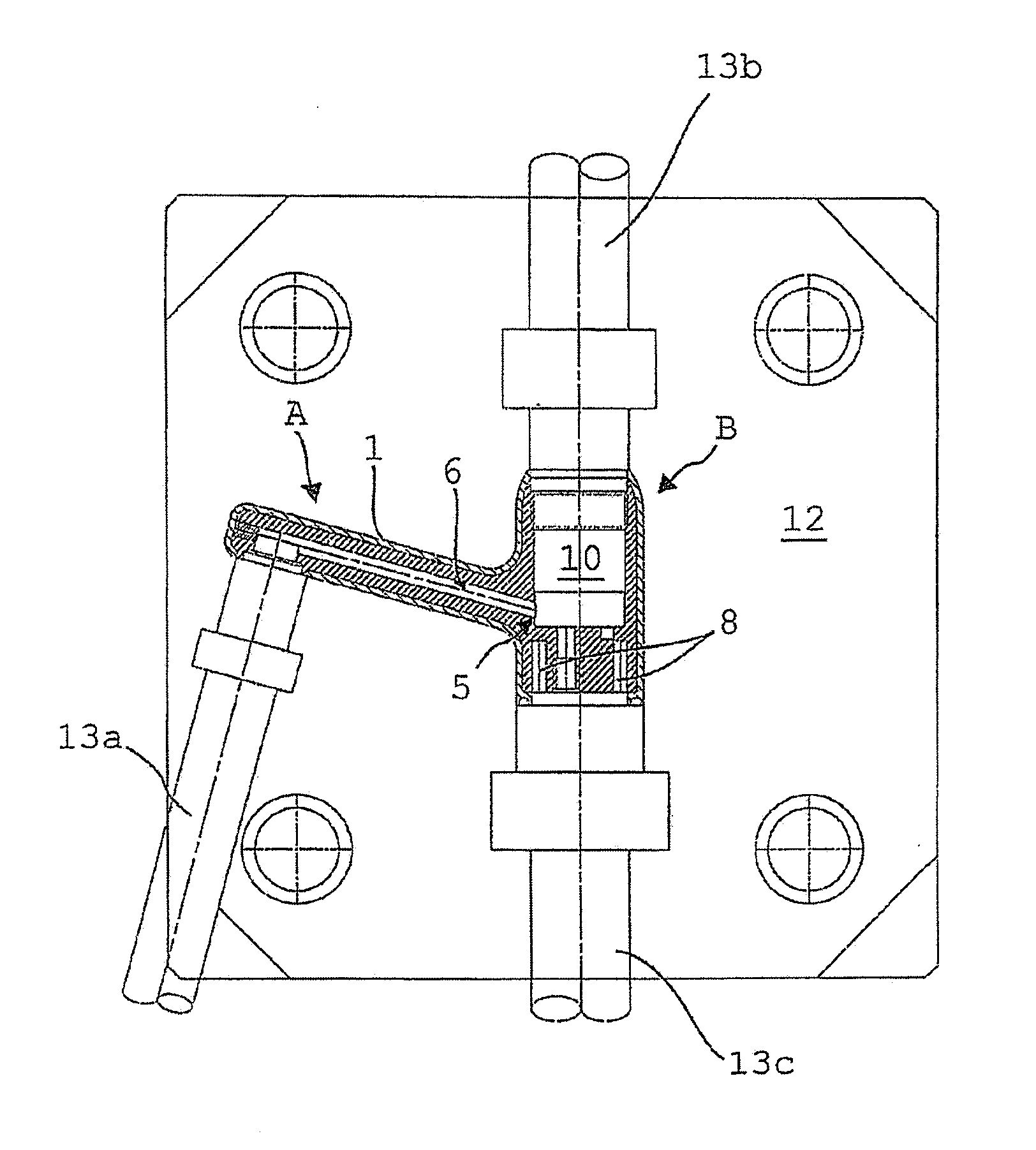

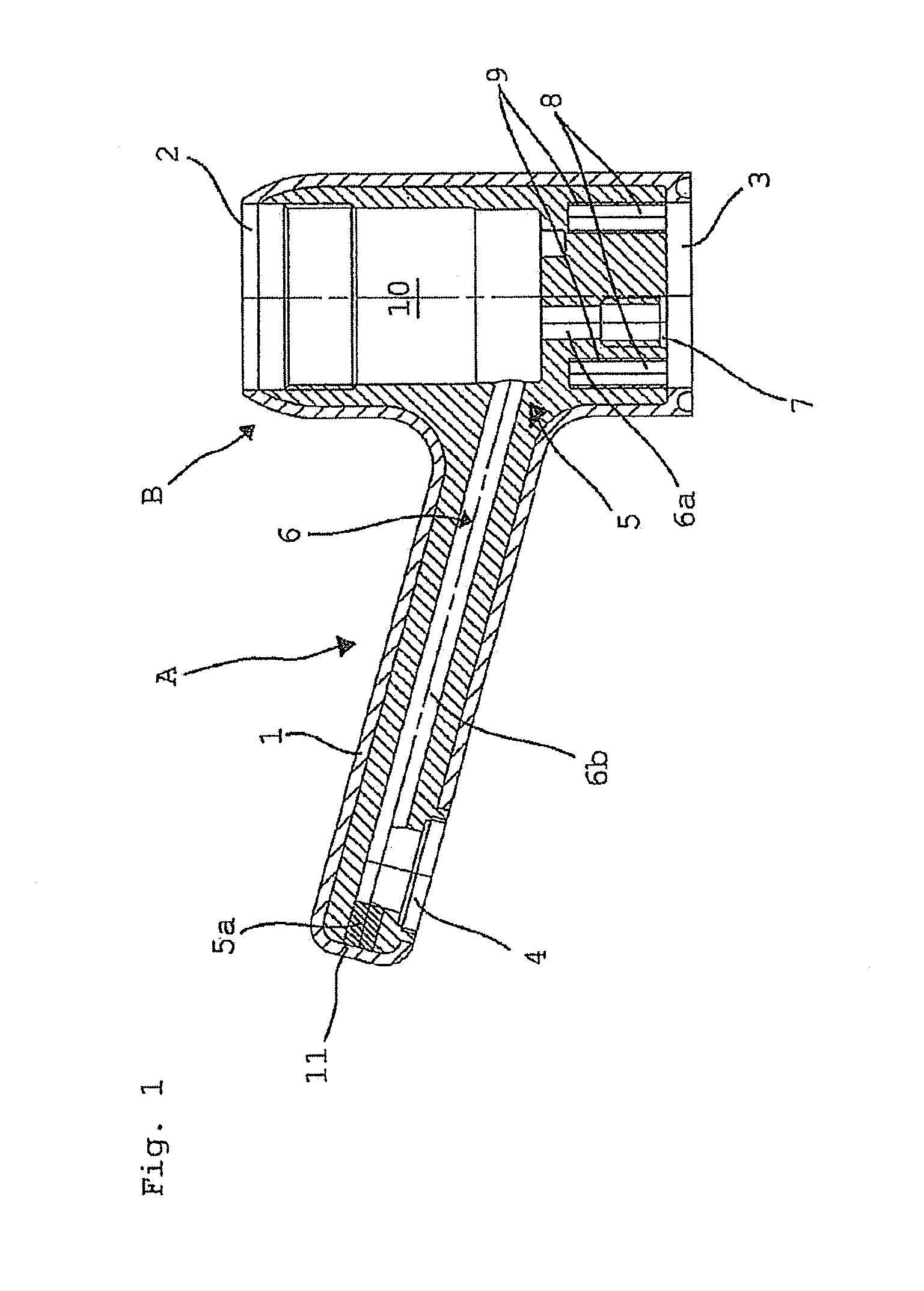

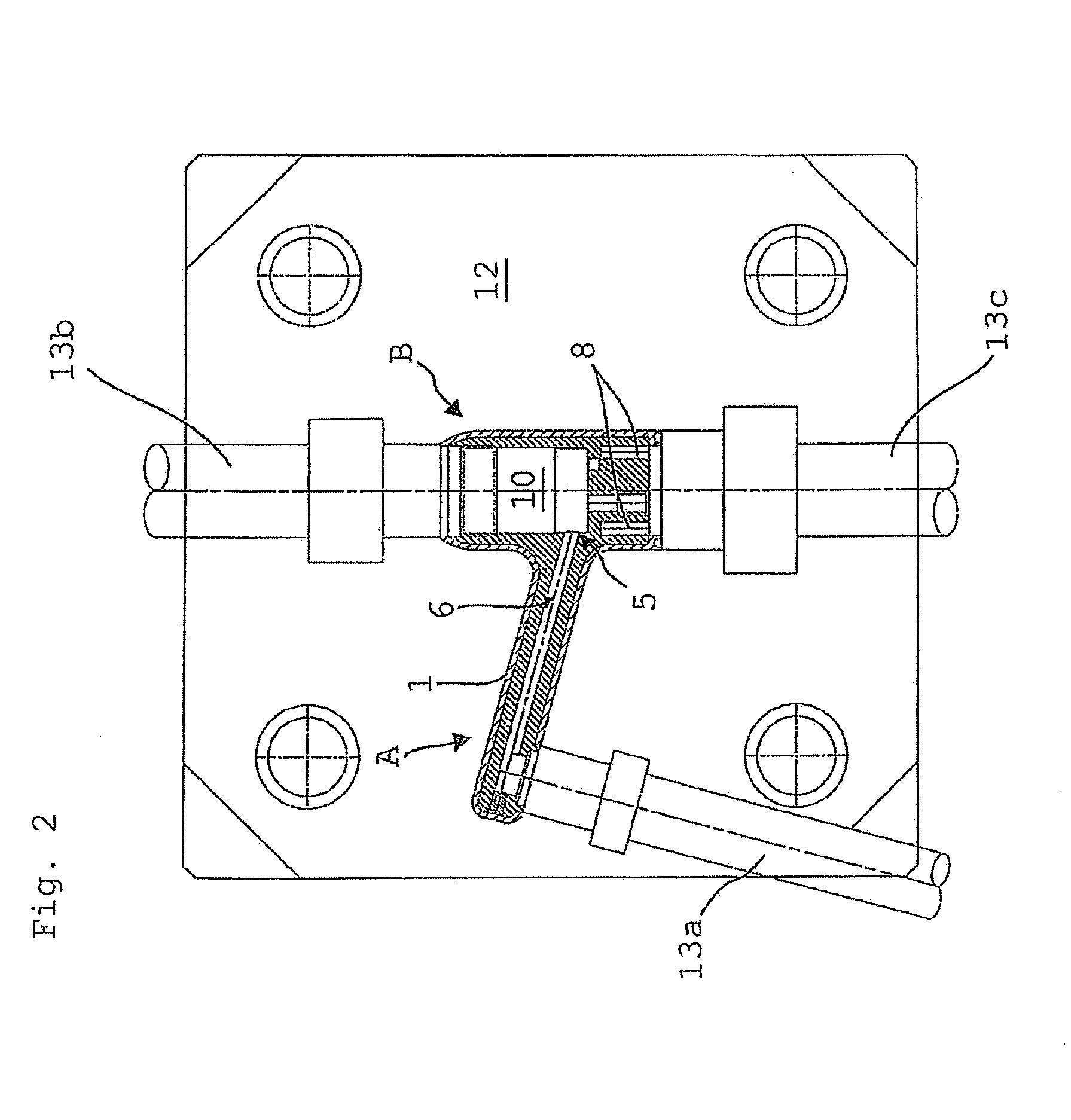

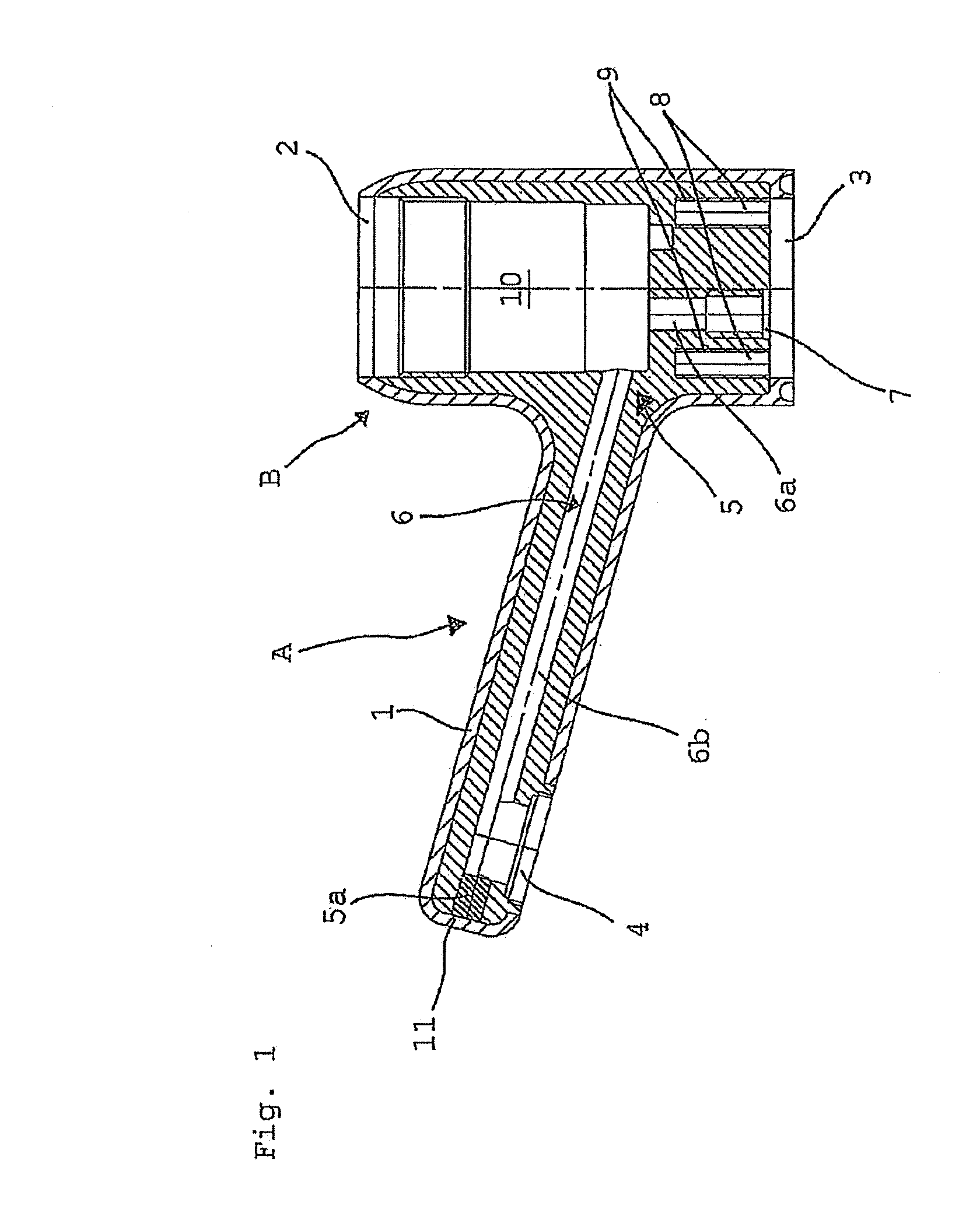

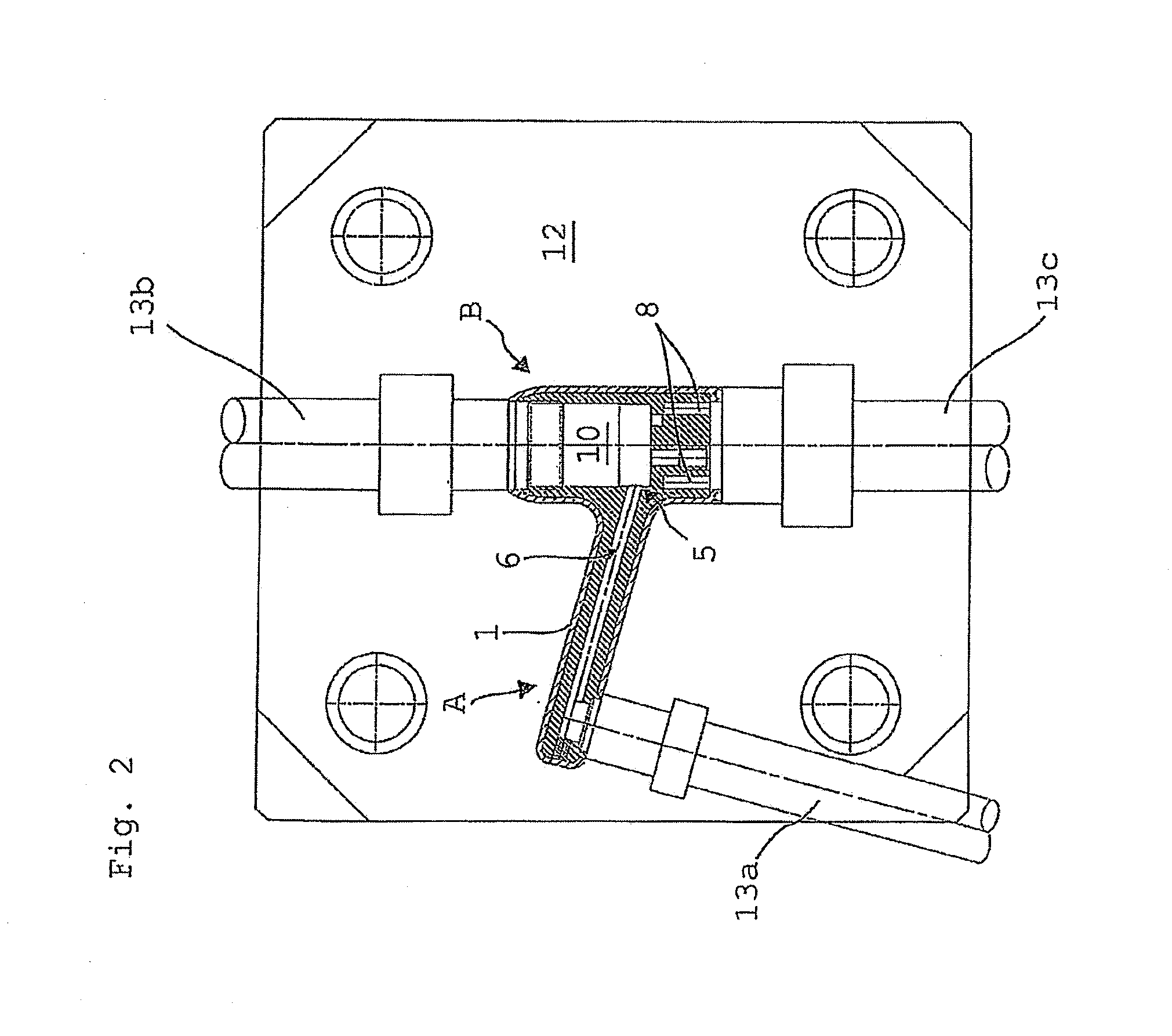

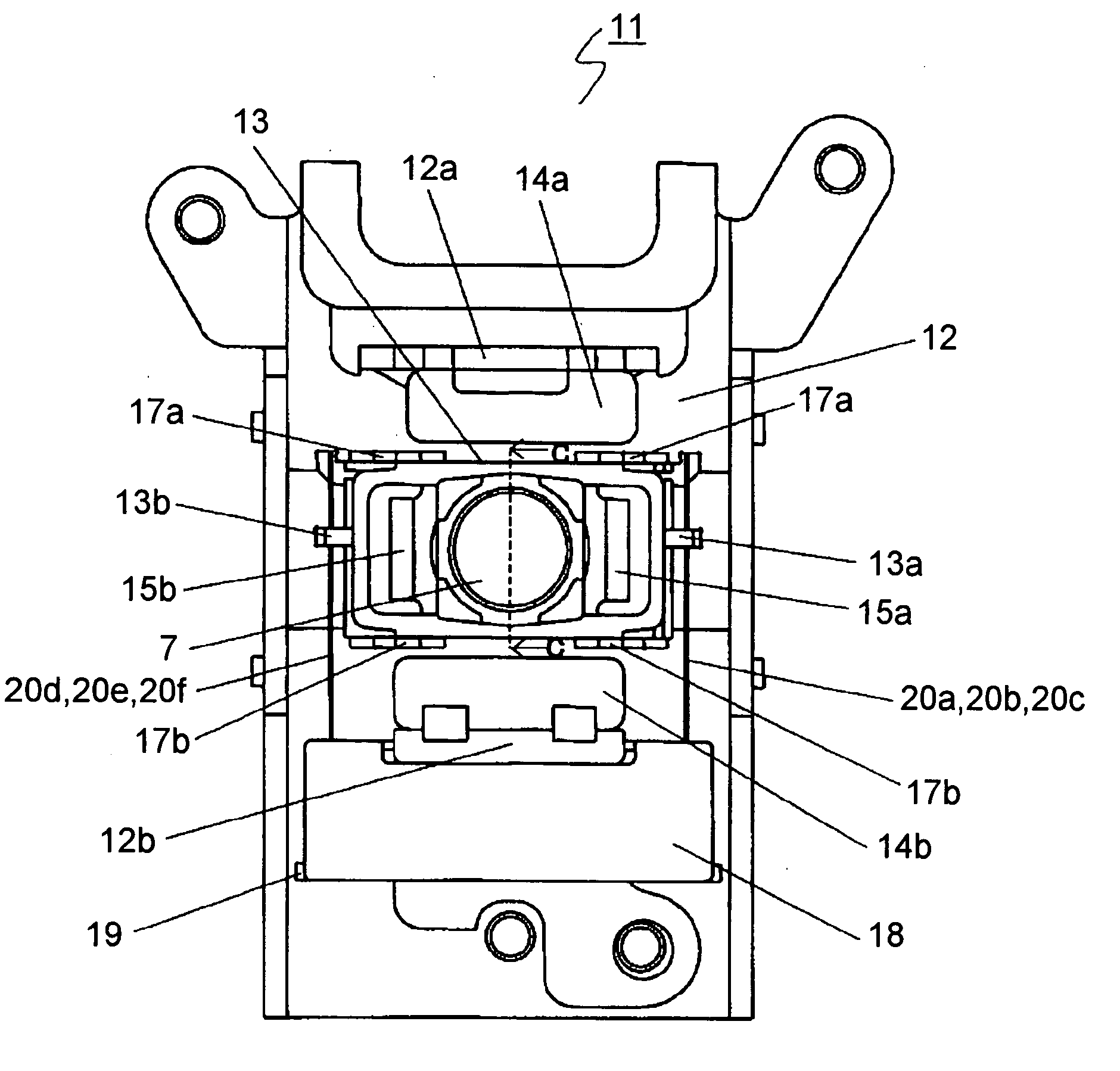

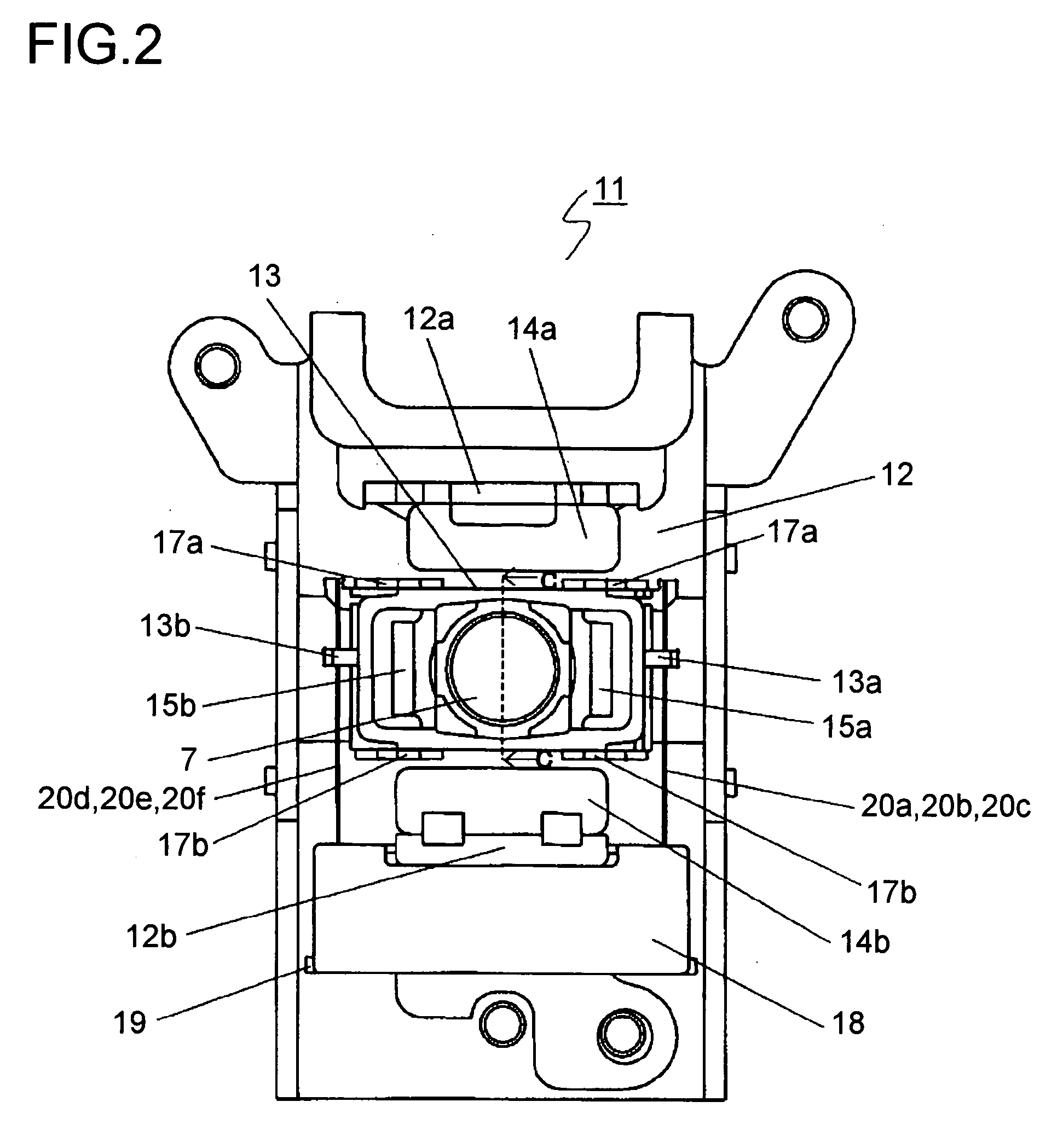

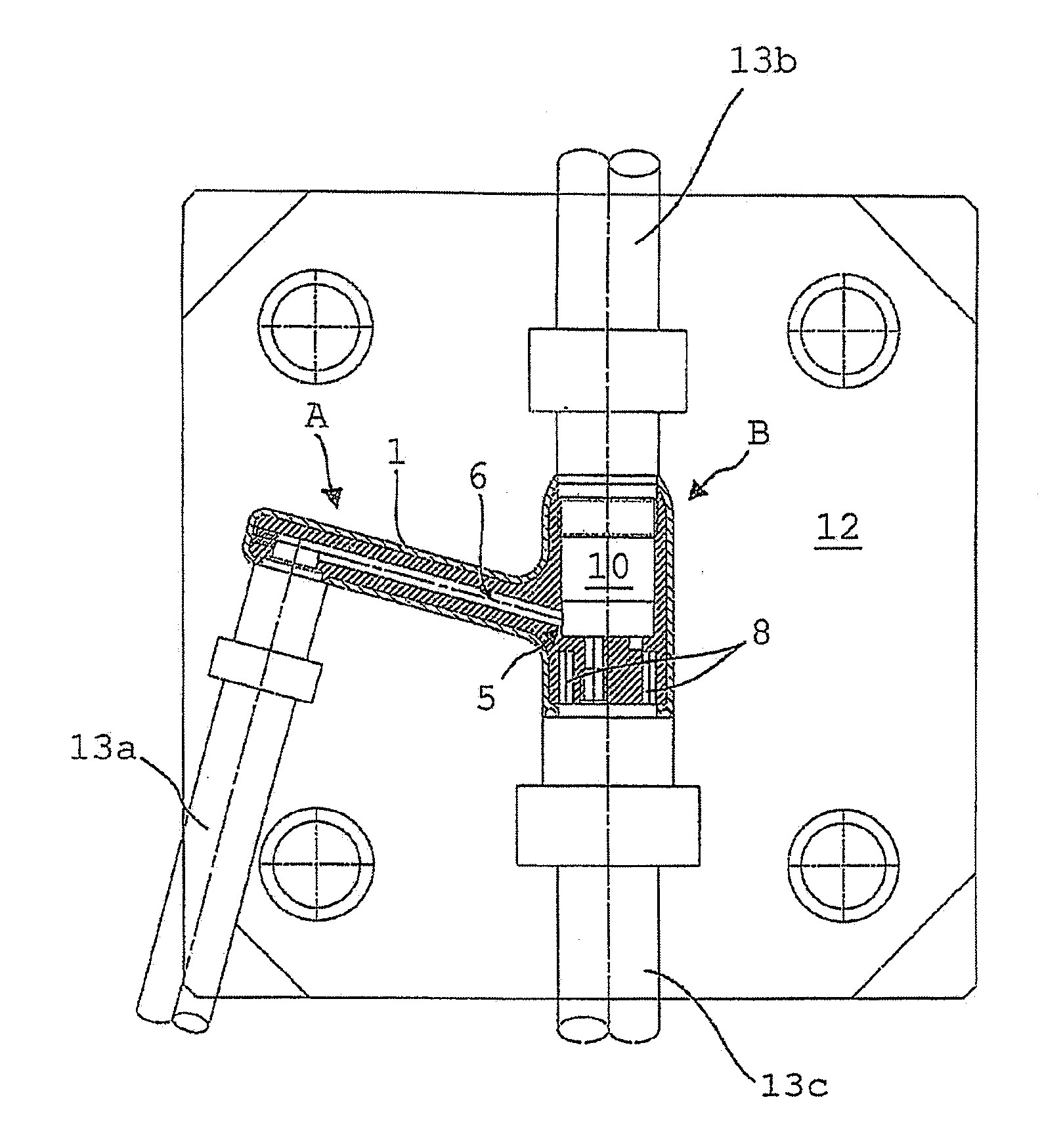

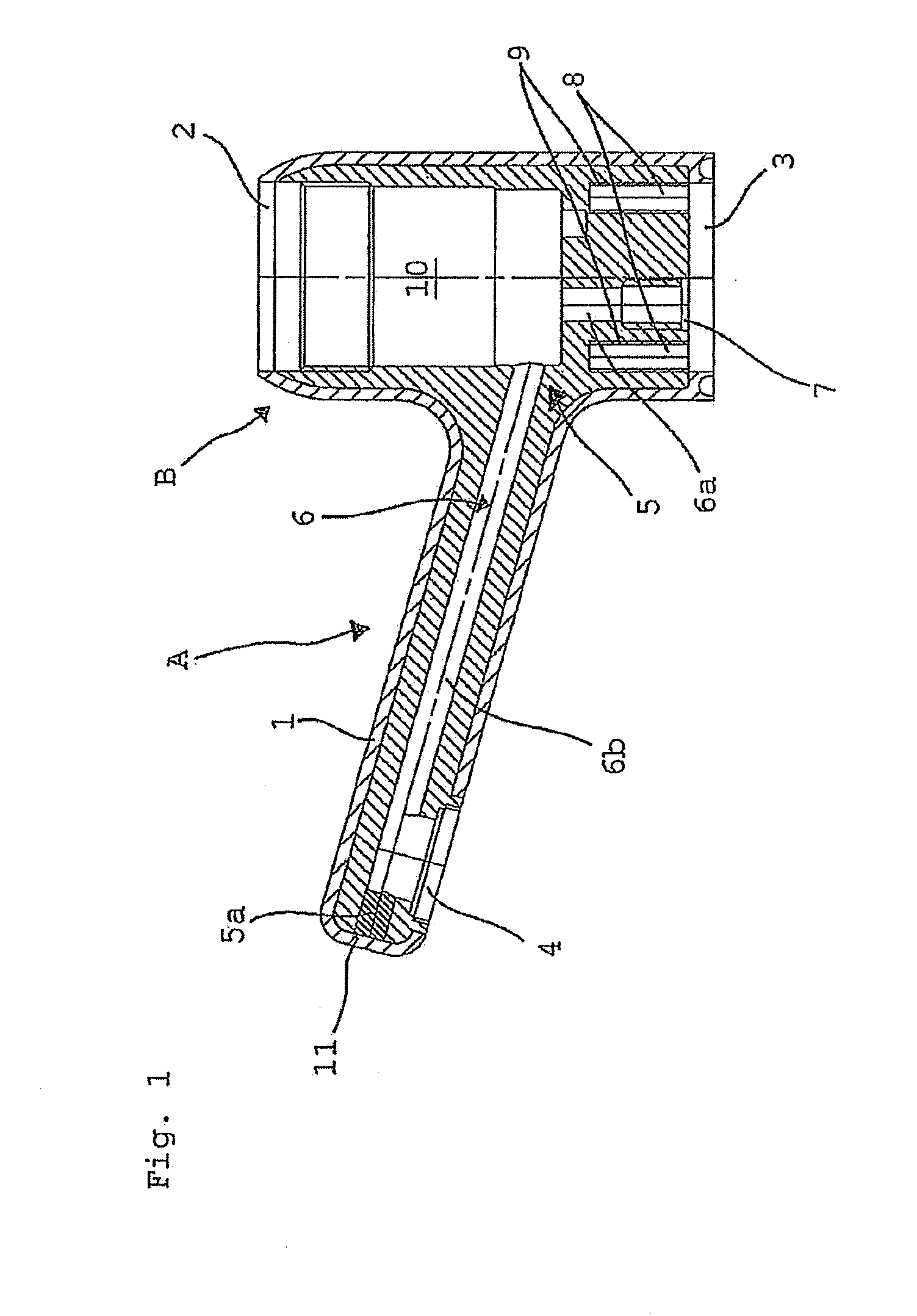

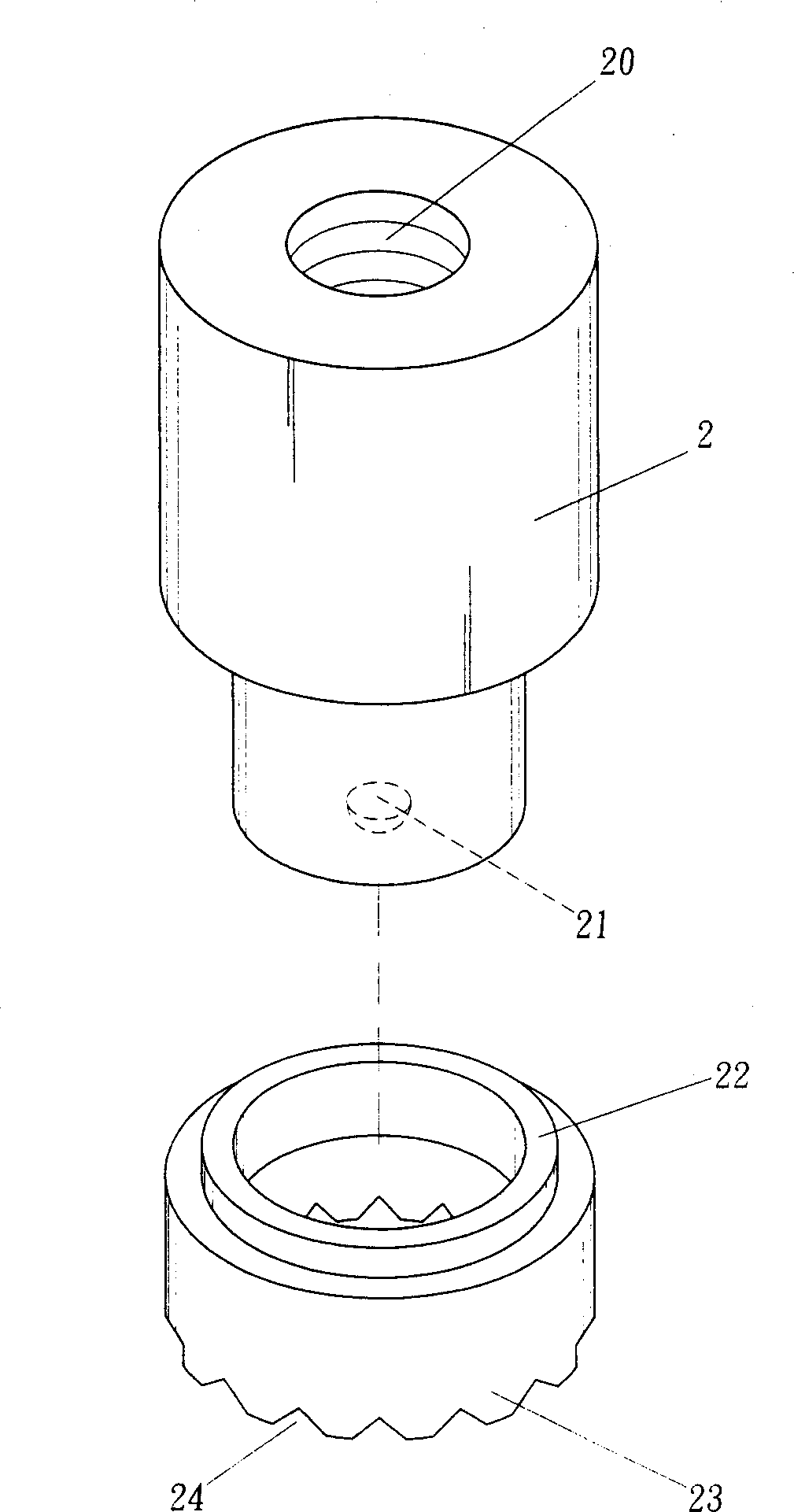

Objective lens driving unit and optical pickup device having the same

InactiveUS20070183294A1Performed easily and preciselyPromote repairRecord information storageOptical beam guiding meansOptical pickupAdhesive

The movable holder of the objective lens driving unit is provided with an opening hole. An objective lens retaining portion for retaining an objective lens is disposed at the upper portion of the opening hole, while a liquid crystal element retaining portion for retaining a liquid crystal element is disposed at the lower portion of the opening hole. The movable holder is further provided with a bore that extends from the side face of the movable holder in the direction substantially perpendicular to the optical axis of the objective lens and reaches a side face 6b of the liquid crystal element retained by the liquid crystal element retaining portion so that adhesive can be injected from the bore.

Owner:FUNAI ELECTRIC CO LTD

Die cast component and a method for producing a die cast component

InactiveUS20130299027A1Easy and inexpensive to produceHigh qualityServomotor componentsDomestic plumbingMetal alloyMetallurgy

The present invention relates to a die cast component, in particular a water outlet fitting, comprising a base body produced from metal or a metal alloy by the die casting method and having a cavity in which a number of openings are provided by means of which the cavity is accessible from the outside, the cavity being at least partially filled with a casting core that is in two-dimensional contact with the inside of the base body and in which at least one channel is provided for the conveyance of fluid, wherein in a predominant part of the contact surface, in particular in the entire or almost the entire contact surface region between the casting core and the base body, the wall thickness of the casting core is as great as or greater than the wall thickness of the base body. Furthermore, the invention relates to a method for producing this type of die casting component.

Owner:HDO DRUCKGUSS & OBERFLAECHENTECHN

Heat exchanger and its manufacturing method

InactiveUS20100051249A1Simple processSimple structureMetal-working apparatusStationary conduit assembliesEngineeringHigh heat

A heat exchanger is provided which has an easy-to-manufacture structure, is inexpensive, and has high quality and reliability while keeping high heat exchanging performance. The heat exchanger has first substrates (26) having first slits (30) and second slits (40) disposed substantially in parallel, and second substrates (28) having third slits (50) with substantially the same shape as that of first slits (30). The longitudinal length of second substrates (28) is set shorter than that of second slits (40). First substrates (26) and second substrates (28) are stacked so that first slits (30) communicate with third slits (50). First slits (30) and third slits (50) form tube external flow channels (60). Second slits (40) and second substrates (28) form tube internal flow channels (70). The heat exchanging section including only tubes can be formed of substrates having a slit, so that the heat exchanger can be manufactured easily and inexpensively.

Owner:PANASONIC CORP

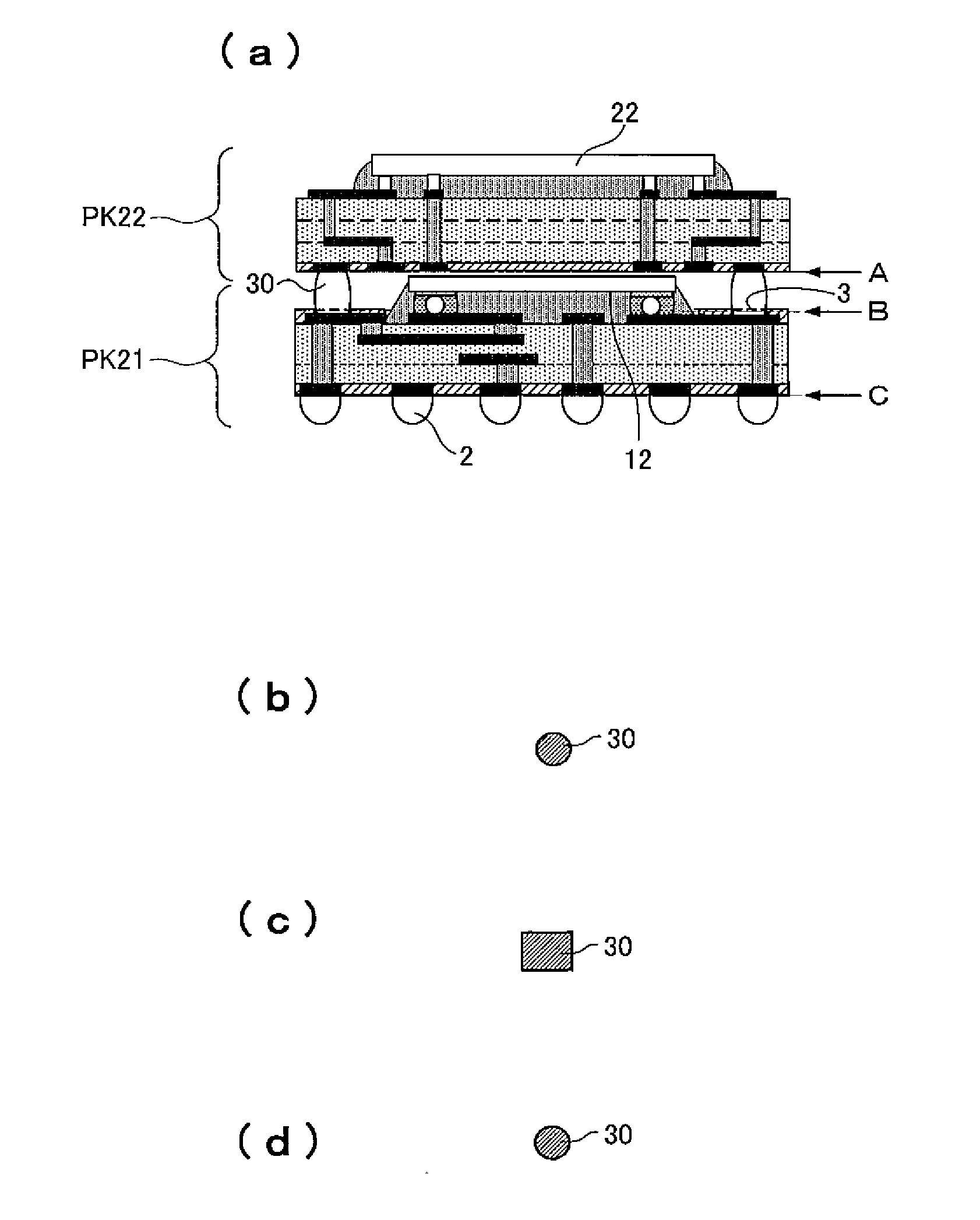

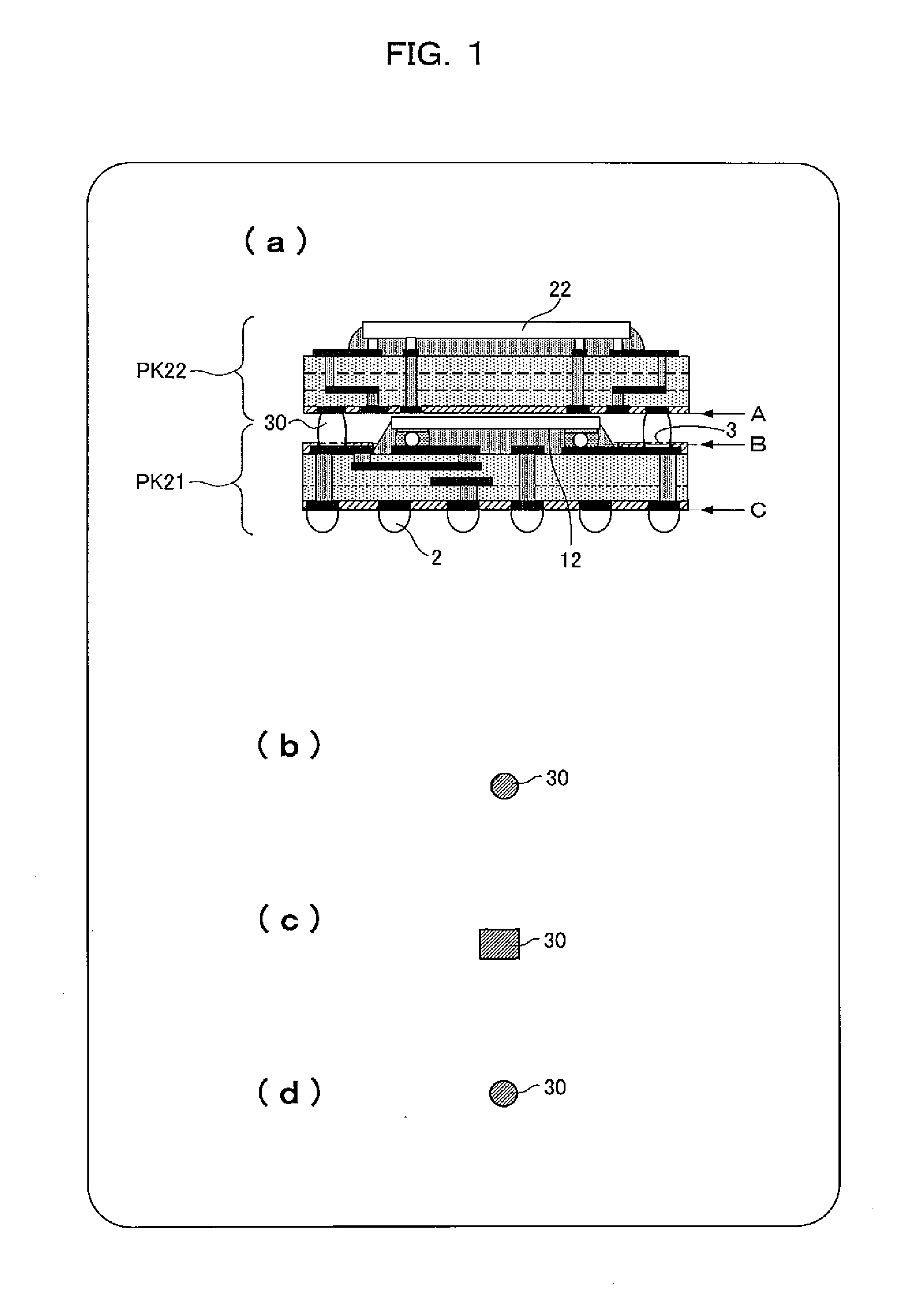

Semiconductor module for stacking and stacked semiconductor module

ActiveUS20100295186A1Quality improvementImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesNon destructiveEngineering

Owner:PANASONIC CORP

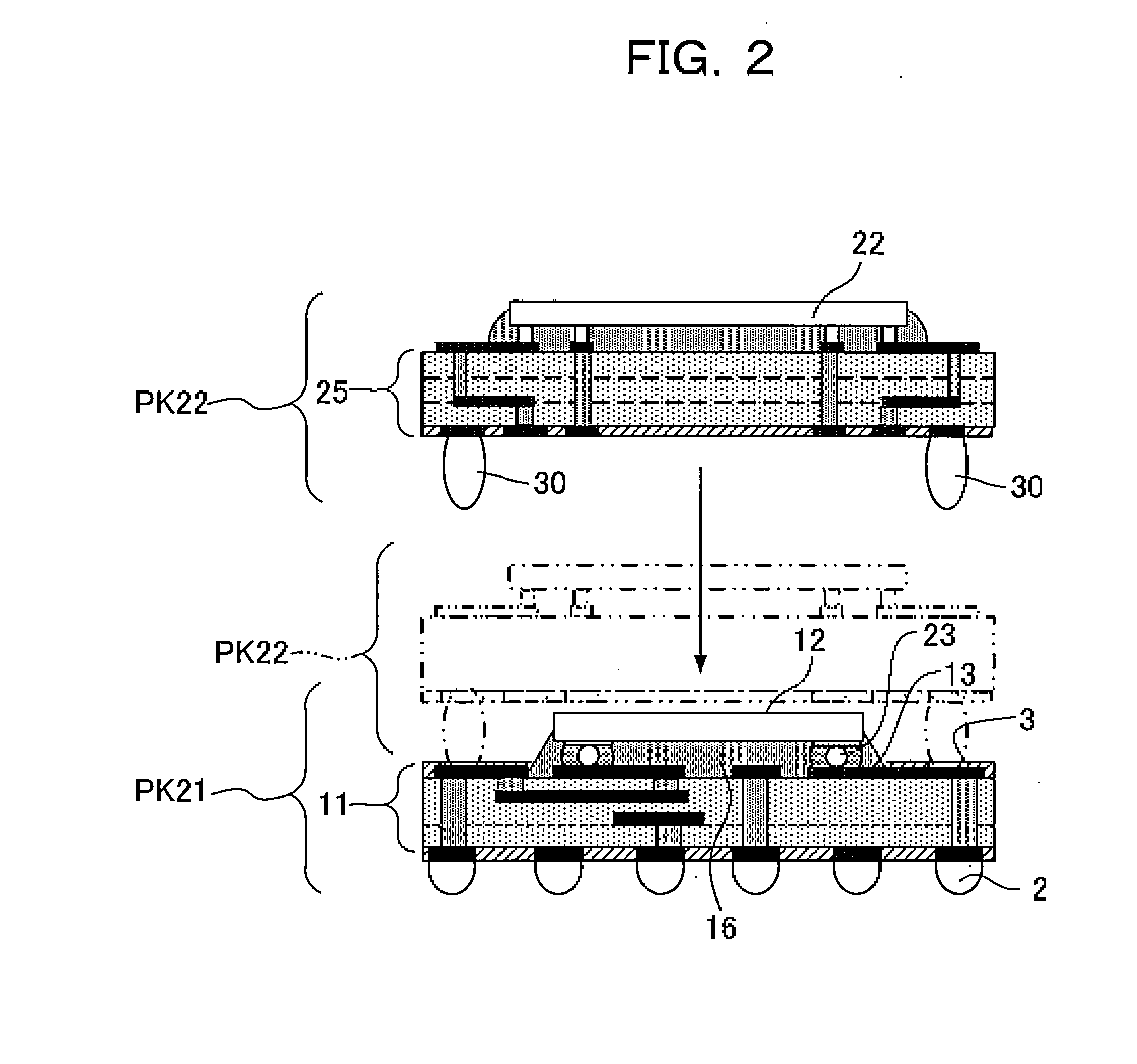

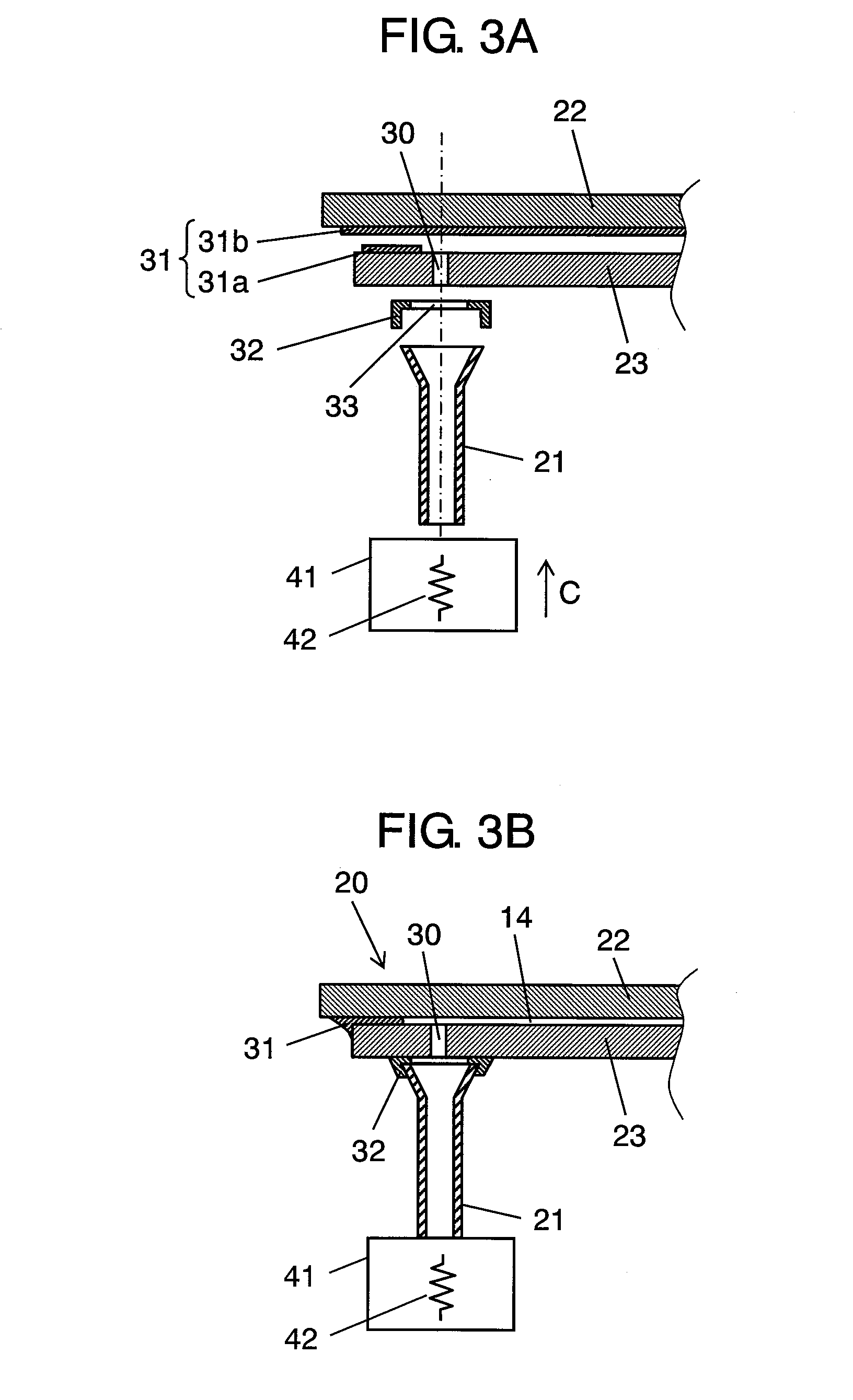

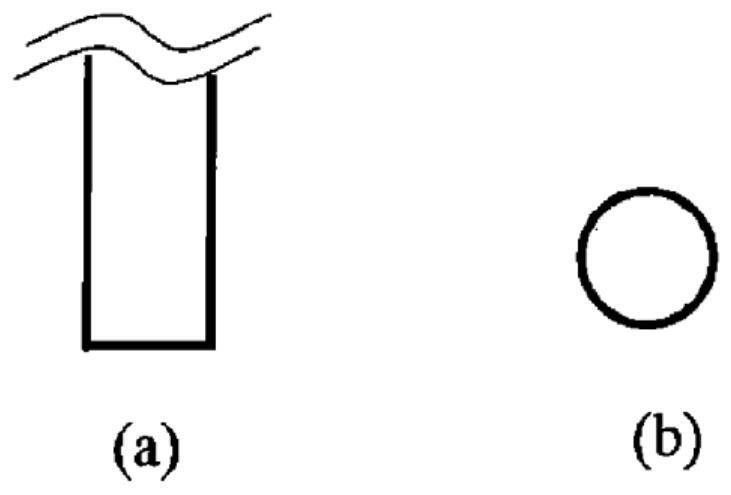

Method of manufacturing plasma display panel

InactiveUS20100130090A1Prevents deterioration in airtightnessQuality improvementGas discharge connecting/feedingAlternating current plasma display panelsFritSealant

A method for manufacturing a PDP equipped with an exhaust tube (21) for evacuating a discharge space formed by arranging a front plate (22) and a hack plate (23) oppositely and sealing the circumferential edge portions of the front plate and the back plate by sealant (31) and then filling the discharge space with discharge gas, the method comprising steps for arranging the sealing side of the exhaust tube around a thin exhaust hole (30) provided in the back plate through a tablet (32) formed of frit glass not containing sealing lead but containing bismuth oxide, assembling the front plate and the back plate while arranging them oppositely, mounting the exhaust pipe on an exhauster while directing the side connected with the exhauster downward, and performing the sealing at a predetermined sealing temperature.

Owner:PANASONIC CORP

Repair/modification method for metallic substrates

ActiveCN111684097AReduced interface areaReduce defectsWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringMetallic substrate

The purpose of the present invention is to provide a repair / modification method for metallic substrates that is capable of reducing both defects and regions of interface in the interior of a structural body by means of modifying the arrangement deep into the interior of a structural body while preventing impurities that, for example, originate with a probe on a friction stir welding tool from being mixed into the interior of the structural body. The repair / modification method for metallic substrates pertaining to the present invention involves: a step for preparing a metallic substrate havinga first region that is divided in the in-plane direction of the substrate and contains a defect and / or a structurally discontinuous part; and a step for repairing the defect and / or modifying the structurally discontinuous part by causing a probeless friction tool to be rotatingly pressed against the surface of the first region, thereby generating frictional heat while pressing on the surface.

Owner:FURUYA KINZOKU KK

Method for dicing wafer and process for manufacturing liquid-discharging head using the dicing method

InactiveUS20090242111A1High quality and reliabilityReduced adhesion strengthLamination ancillary operationsLaminationWaferingDicing tape

A method for dicing a wafer having a first face in which opening are arranged along dicing streets. The method includes a step of affixing a dicing tape to the first face such that the dicing tape lies over the openings and adhesive regions of the dicing tape are exposed in the openings and a step of treating the dicing tape to reduce the adhesive strength of the adhesive regions.

Owner:CANON KK

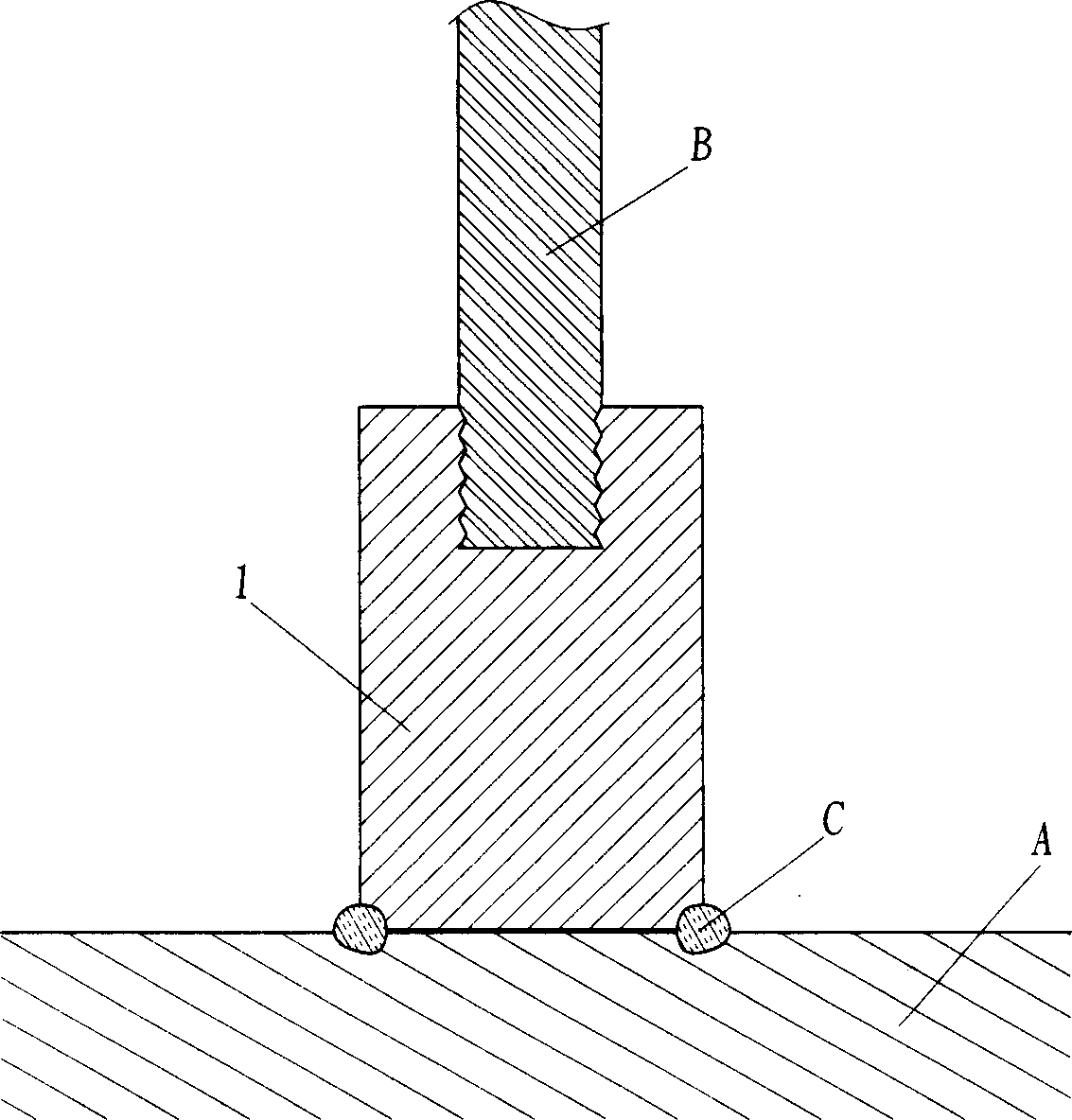

Steel bar splicing device implantation welding construction method

InactiveCN1367062AEnsure safetyHigh strengthBuilding reinforcementsWorkpiece edge portionsArchitectural engineeringWave form

The present ivnention discloses a steel bar splicing device implantation welding construction method, and is characterized by that the welding granules are implanted into the bottom end of the steel bar splicing device, the exterior of the steel bar splicing device is covered with a protection ring, on the protection body of protection ring several wave-formed air holes are set. When the construction is made, the steel bar splicing device is placed on the surface of steel skeleton structure, covered with protection ring, welded by implantation welding machine, so that the steel bar splicing device can be implanted into the steel skeleton structure. Said invention is applicable to welding of various steel bars splicing devices.

Owner:王台钦 +1

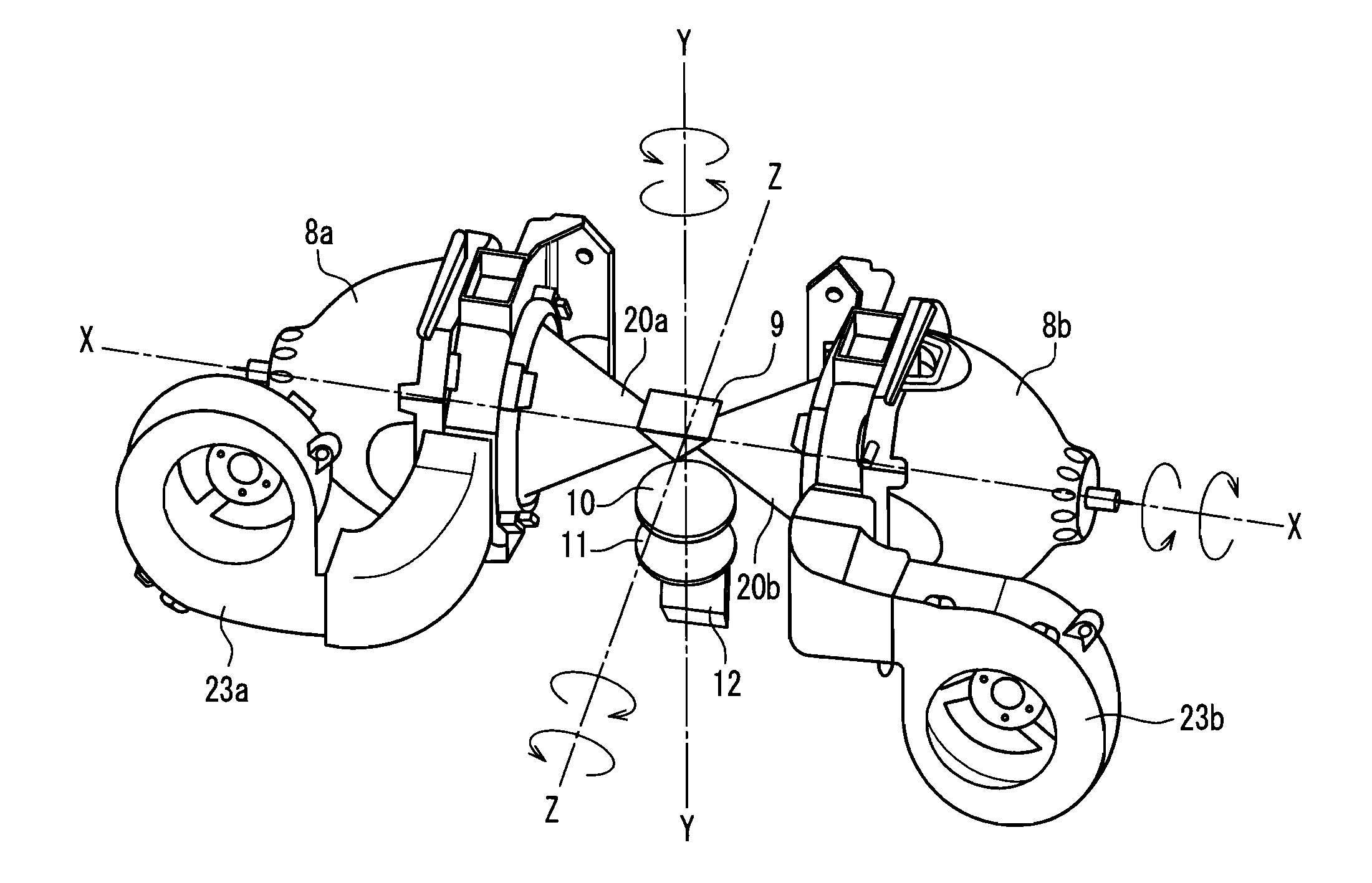

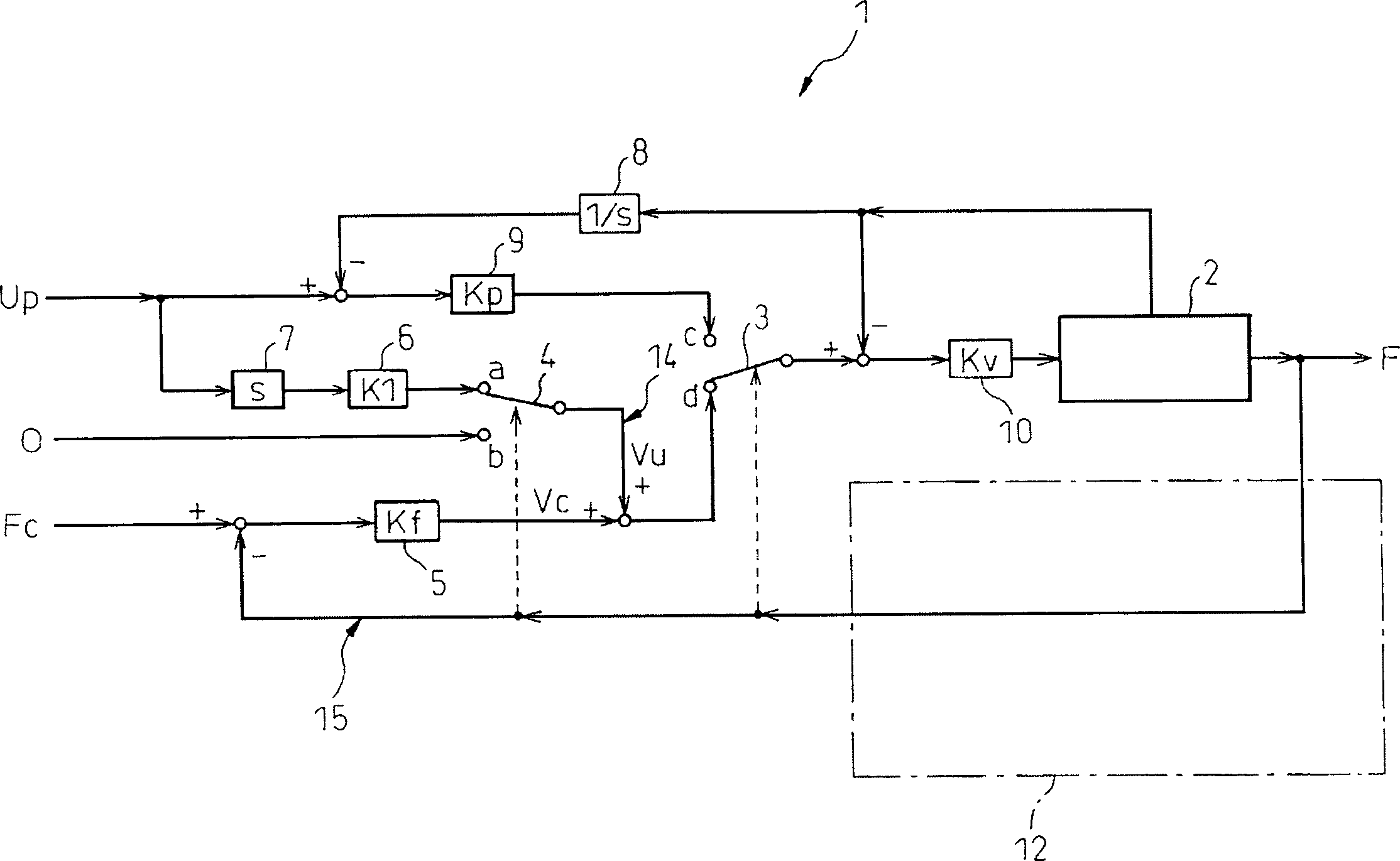

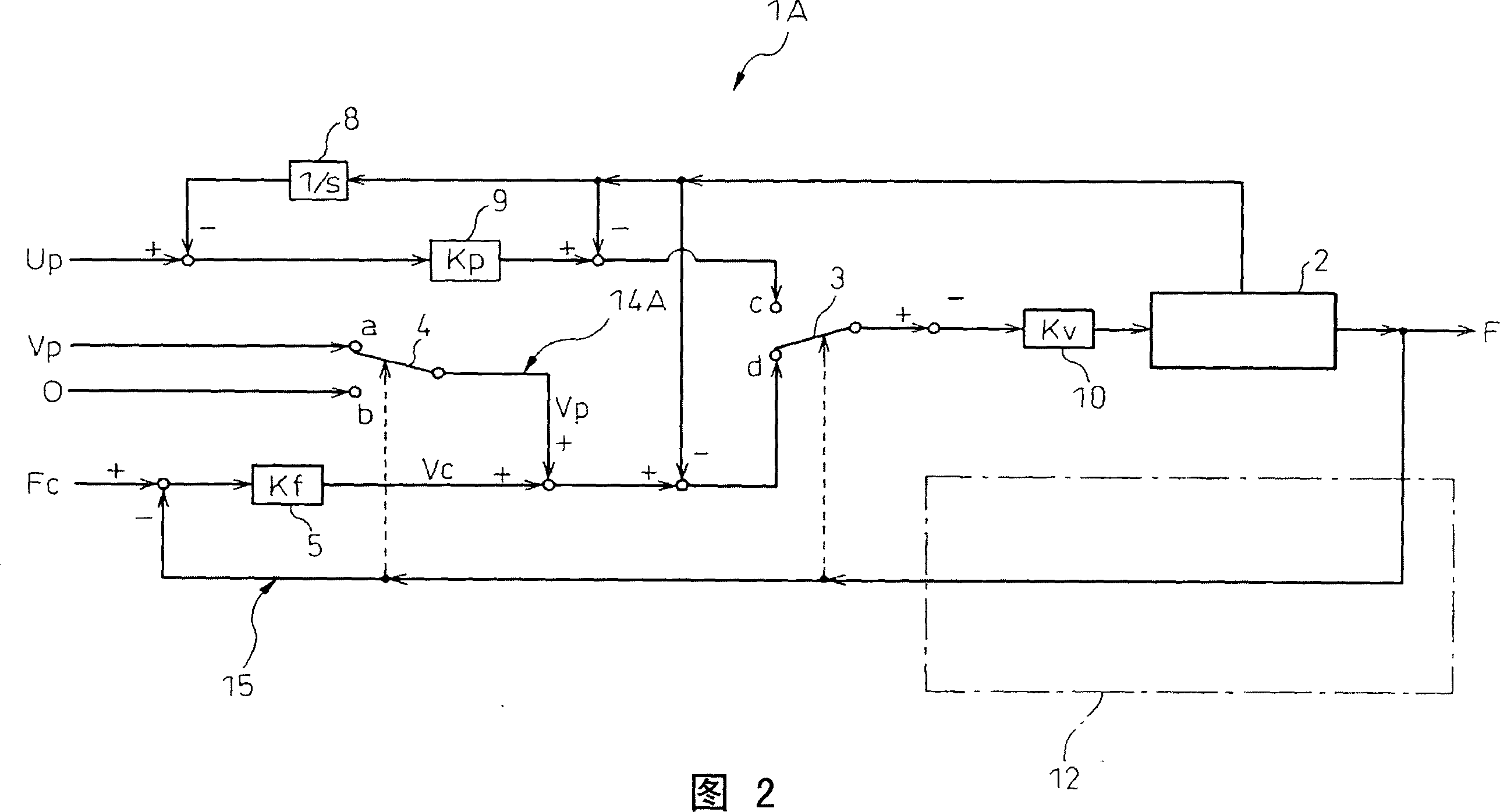

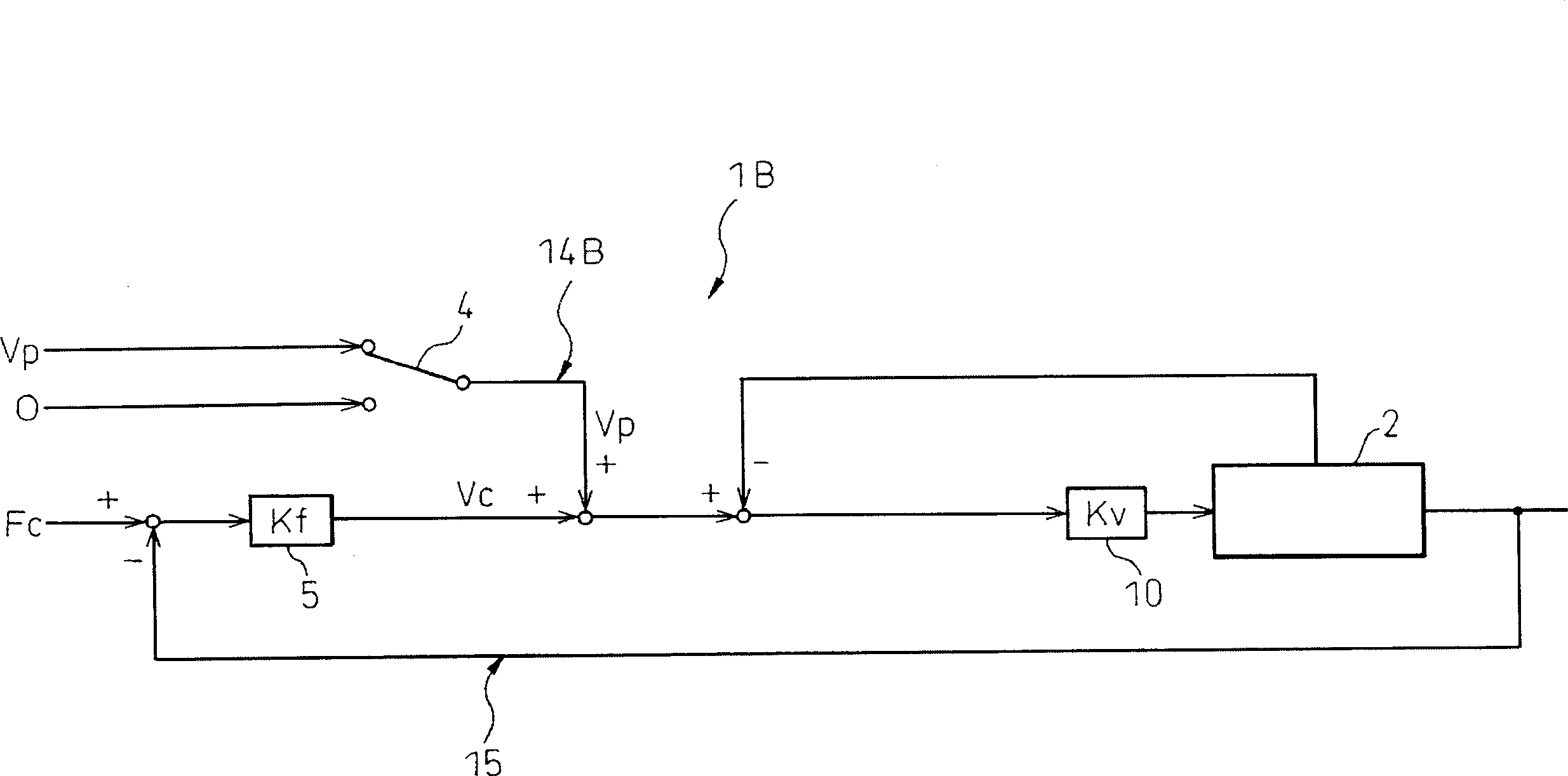

Servo controller for spot welding gun

InactiveCN1900866ADoes not affect positionHigh quality and reliabilityMechanical power/torque controlNumerical controlSpot weldingFeedback control

There is provided a servo controller for a spot welding gun for controlling a pressurizing force, applied by a pair of mutually-opposing gun chips, on an object to be welded, including at least one movable gun chip, which is held between the pair of gun chips, by causing a drive source of the movable gun chip to drive the movable gun chip in a direction in order to pressurize the object to be welded. The servo controller includes a feedback control section for calculating a difference value (F c - F) between an obtained pressurizing-force value F and a required pressurizing-force value F c , and a feedforward control section for adding a correcting command value, obtained from a position command value or a speed command value for the drive source, to the difference value (F c - F).

Owner:FANUC LTD

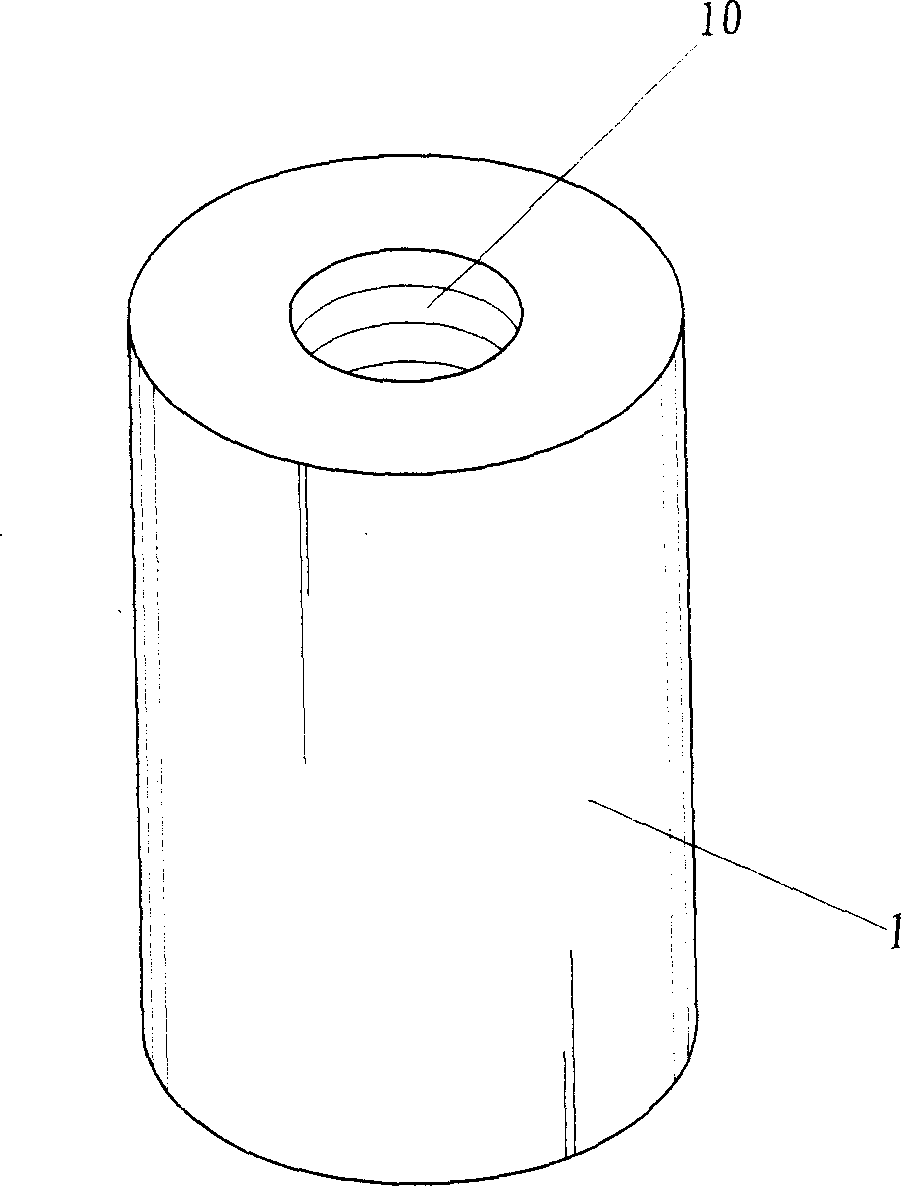

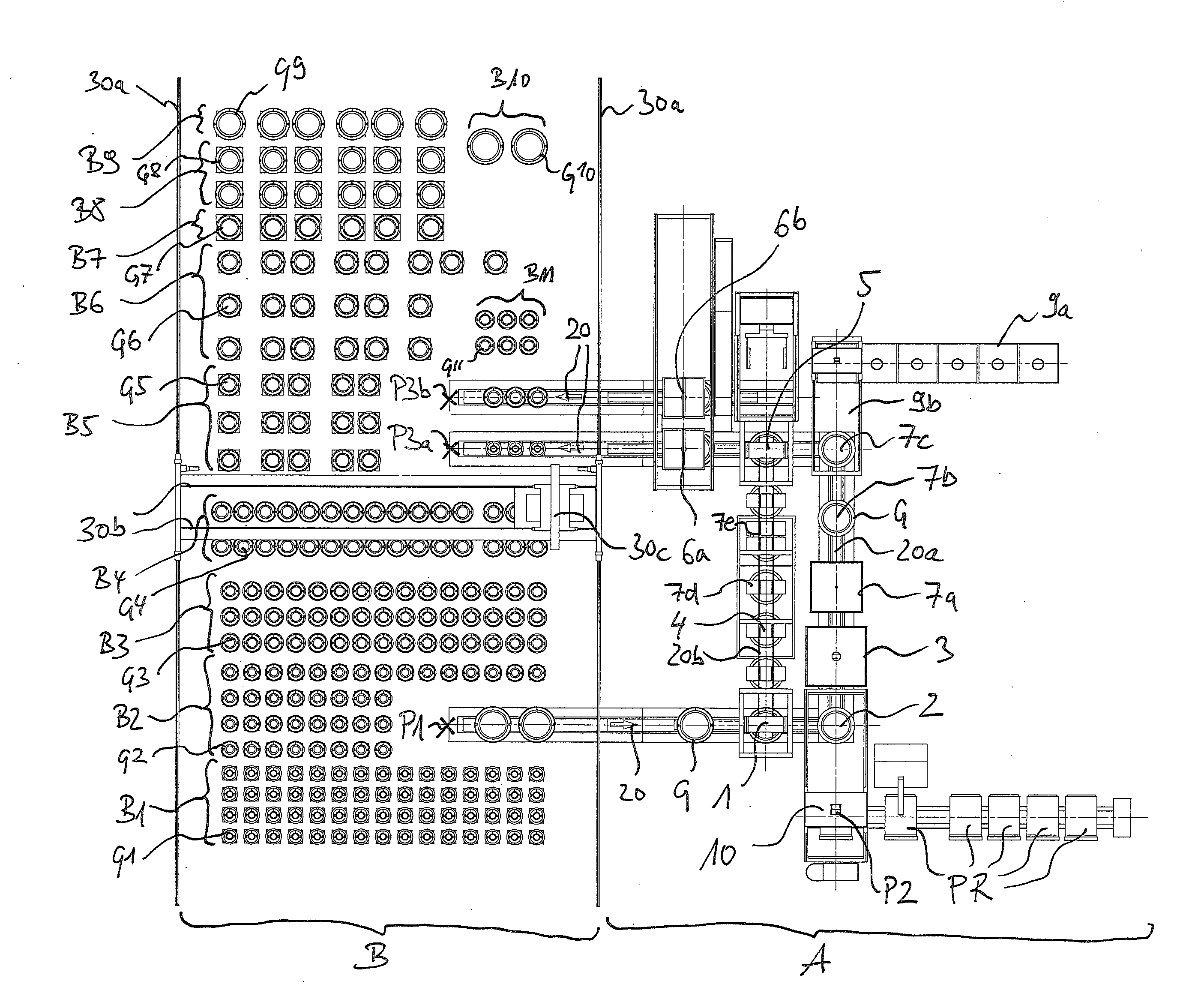

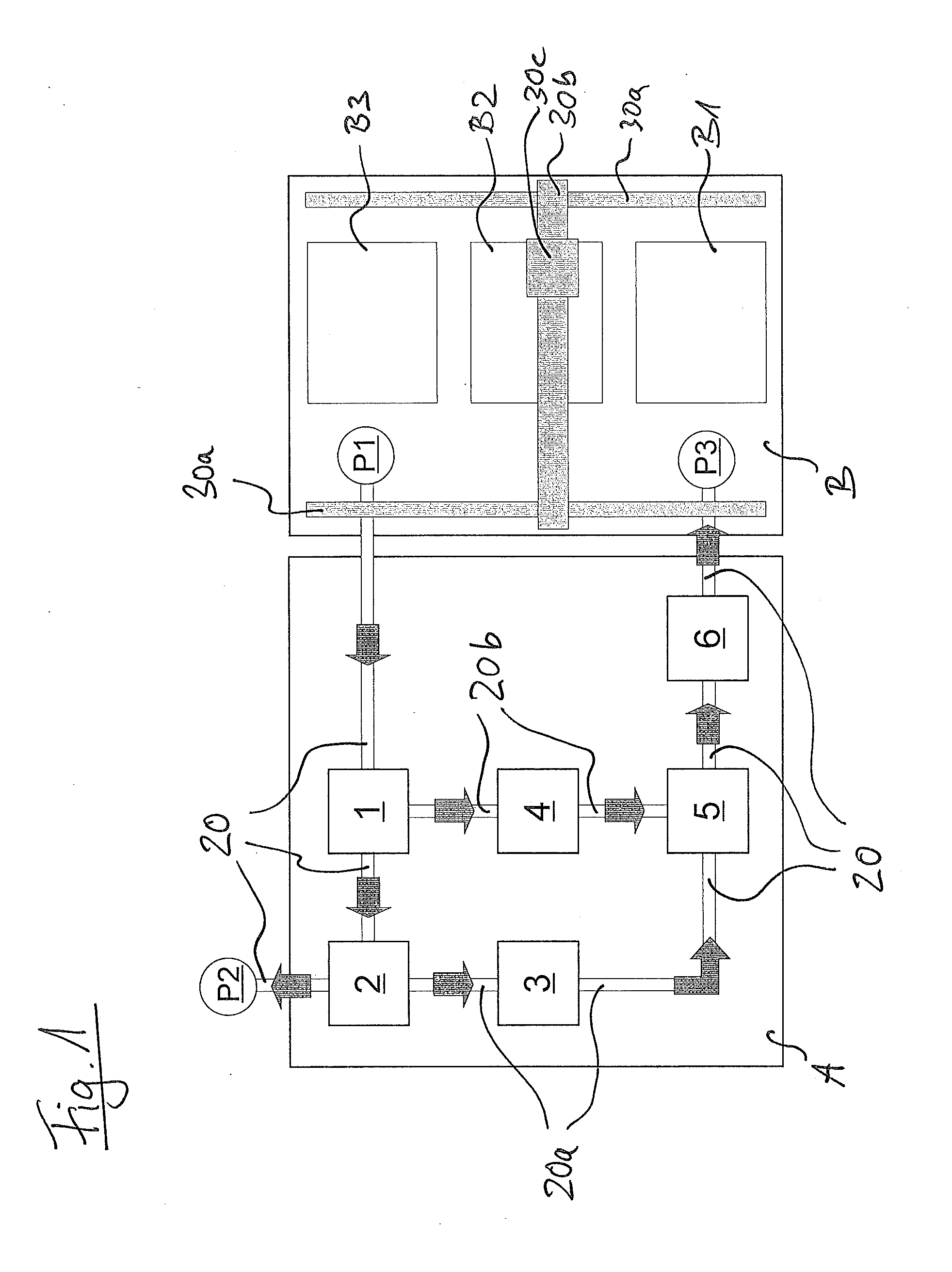

System and Method for Producing Tubular Concrete Products

ActiveUS20150246460A1Low costQuality improvementDischarging arrangementMouldsCleaning stationCasting mold

A method and system for producing tubular concrete products in a casting method using upright casting molds. The system includes a fabrication zone with a plurality of fully automated fabrication stations and a mold conveyor, the first zone having: a first demolding station for removing an outer mold from a casting mold positioned at the first demolding station, a second demolding station for removing a cured tubular concrete product form a mold core positioned at the second demolding station, a mold core cleaning station for cleaning a mold core positioned at the mold core cleaning station, an outer mold cleaning station for cleaning an outer mold positioned at the outer mold cleaning station, a mold assembly station for assembling a casting mold from an outer mold and a mold core, and at least one filling station for filling an assembled casting mold with concrete.

Owner:SCHLUSSELBAUER JOHANN

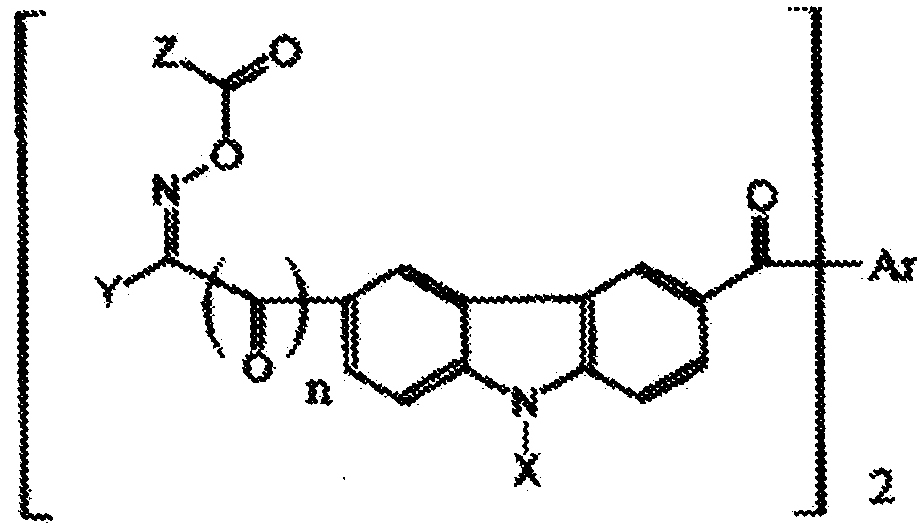

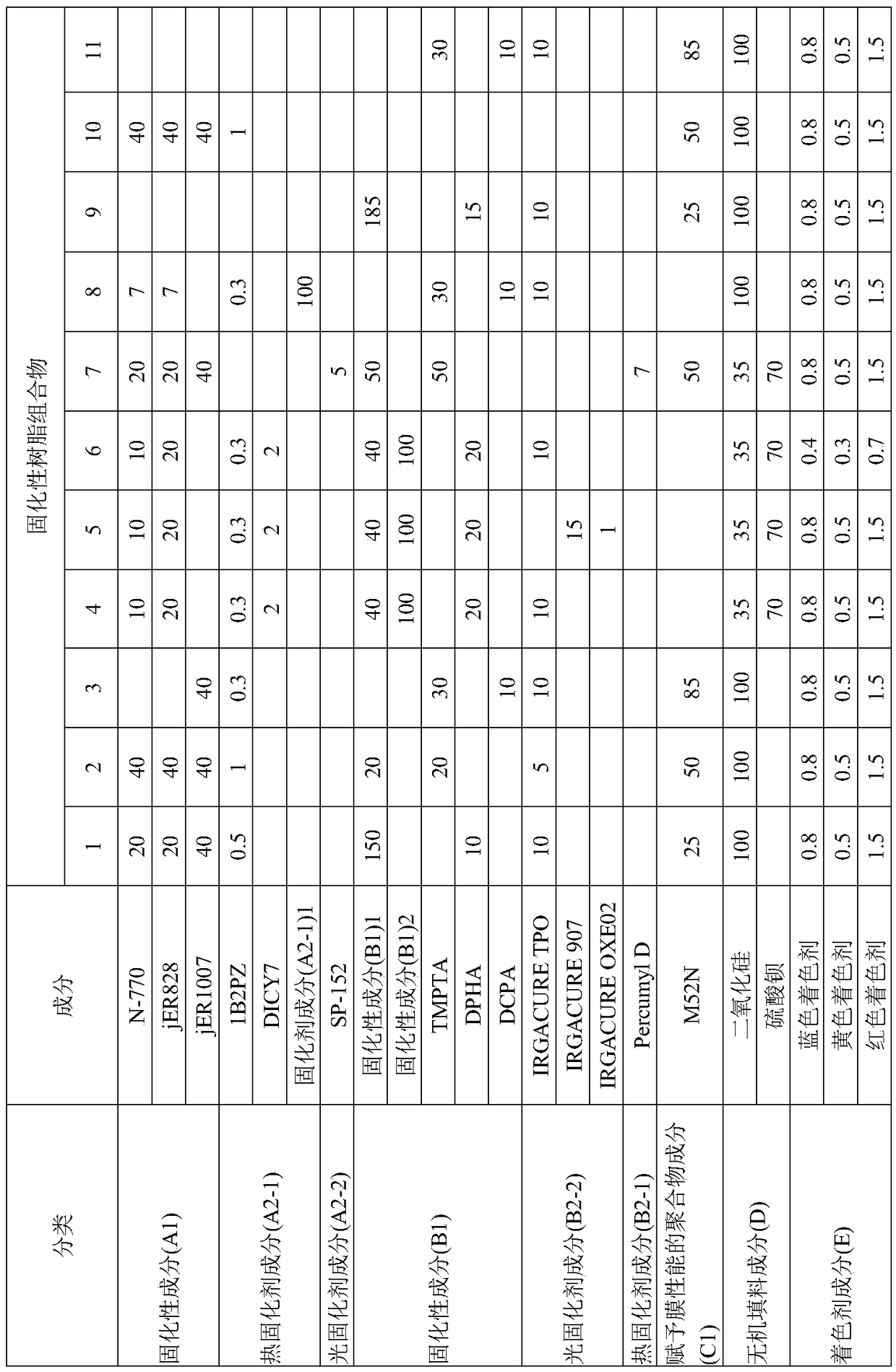

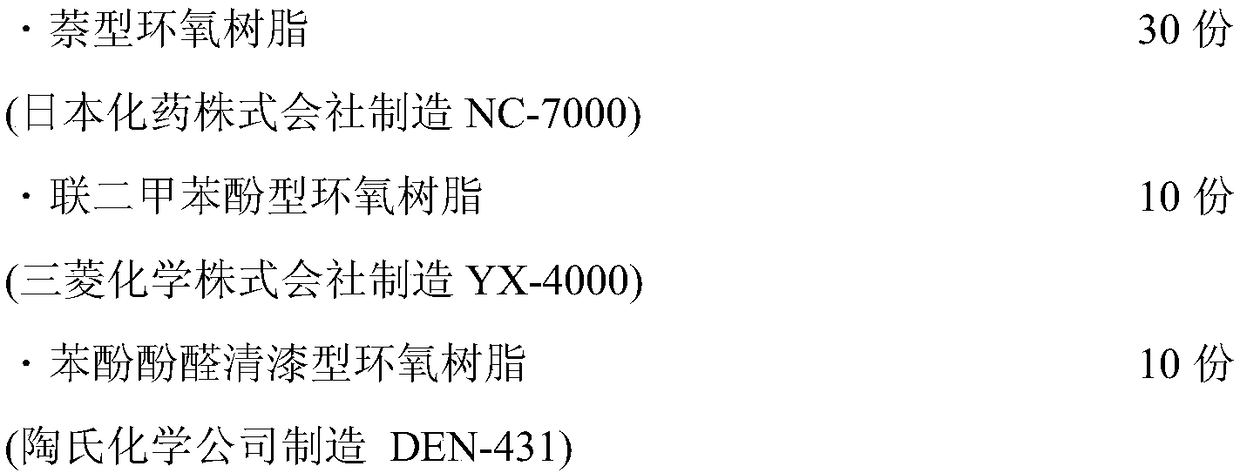

Curable resin composition and fan out type wafer level package

ActiveCN108701657AHigh quality and reliabilityReduce warpageSemiconductor/solid-state device detailsSolid-state devicesComposite materialPolymer chemistry

Provided are the following: a curable resin composition able to suppress the degree of warping at temperatures that occur when mounting semiconductor wafers and semiconductor packages, and especiallyfan out type wafer level packages (FO-WLP), and at room temperature during wafer transport and the like; and a fan out type wafer level package provided with a warpage correction layer comprising a cured product of the curable resin composition. The curable resin composition can be cured by means of at least 2 types of curing reaction and contains a curable component (A1) whose volume shrinks whenone of the curing reactions is carried out and a curable component (B1) whose volume shrinks when another curing reaction is carried out.

Owner:TAIYO INK MFG

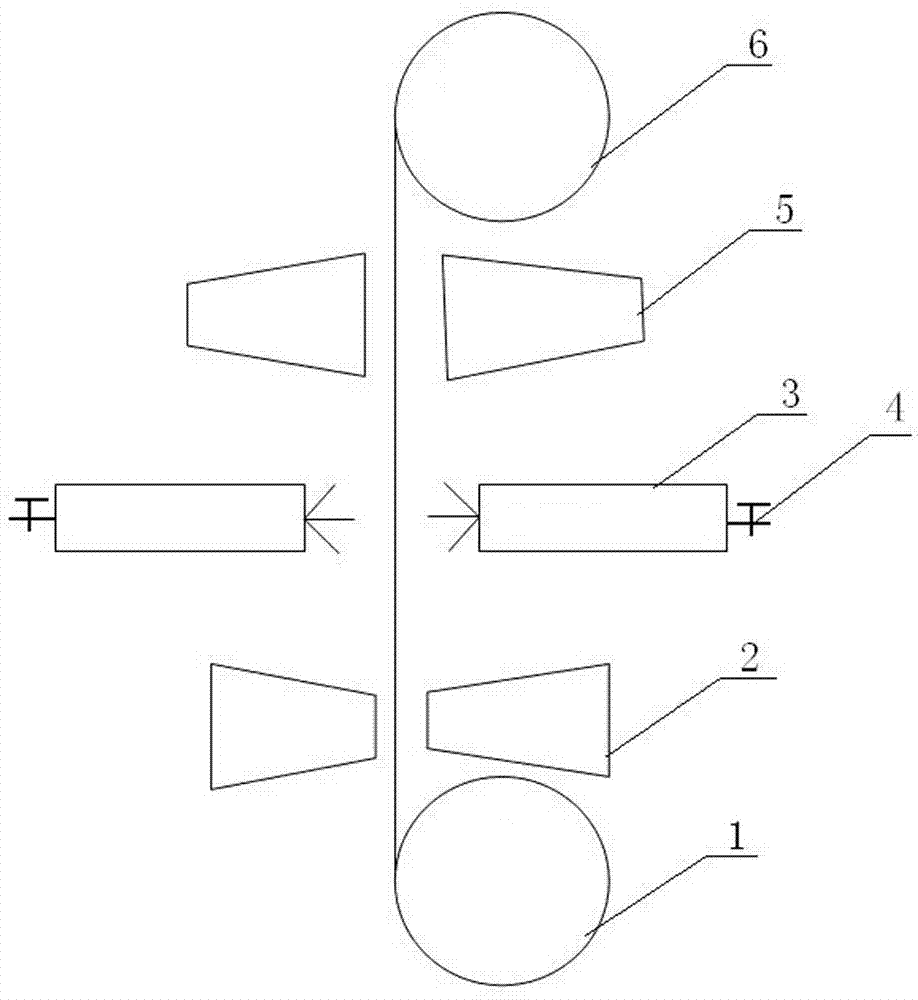

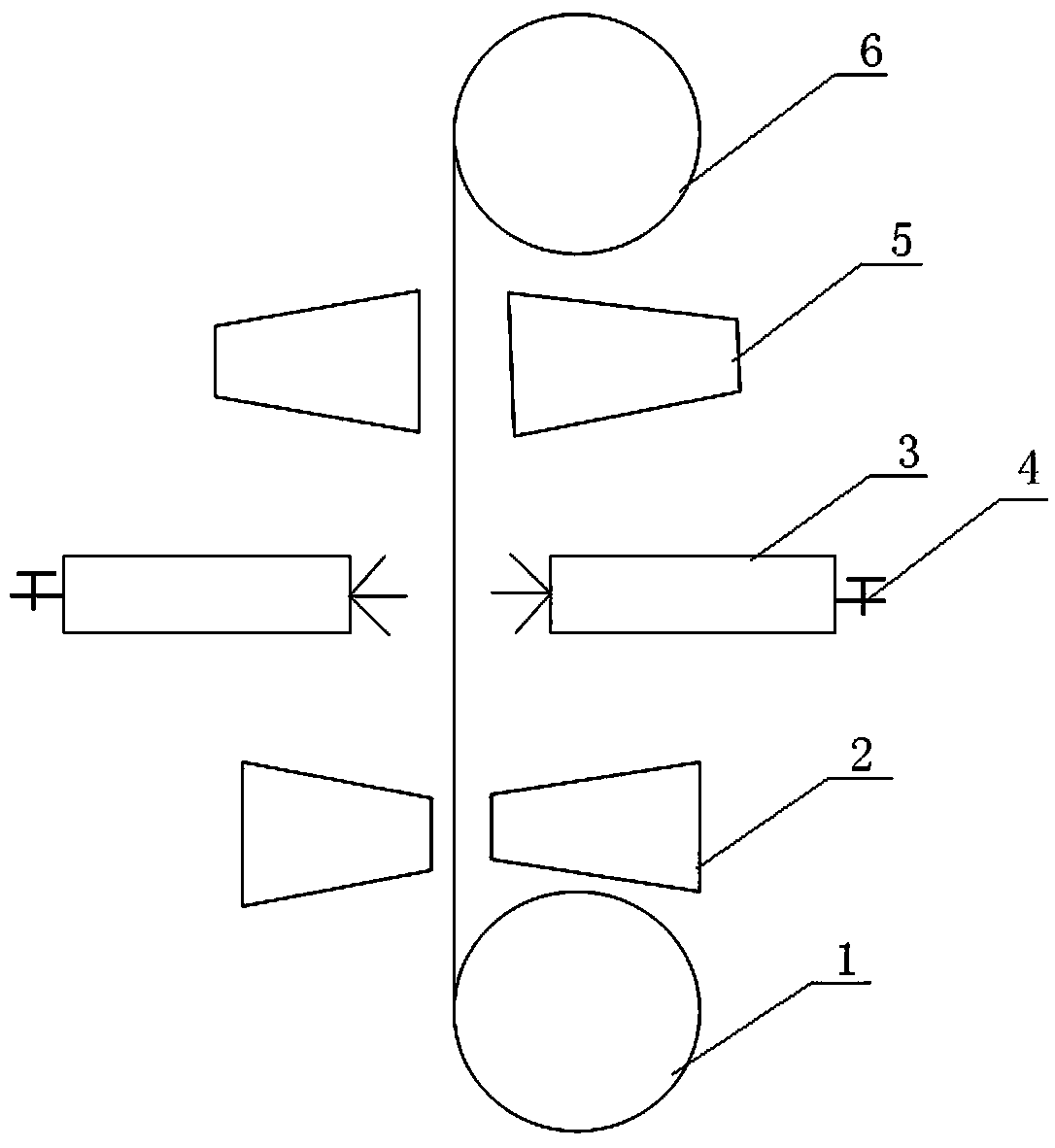

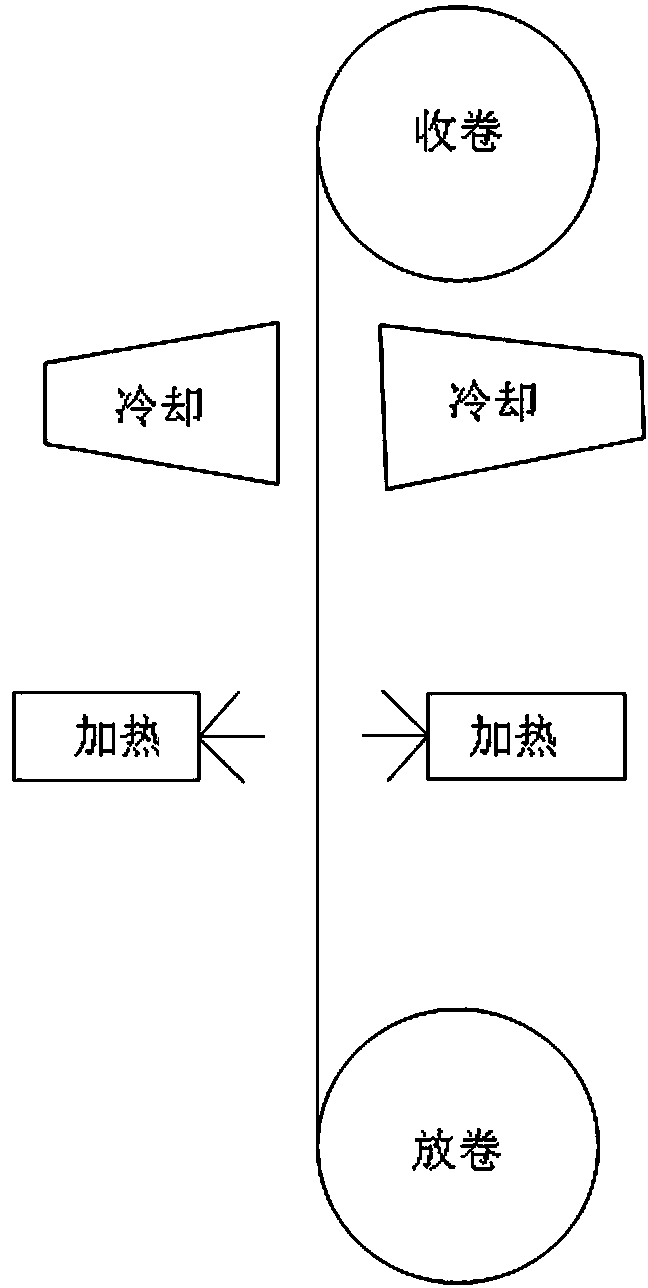

Method for preparing huge dual-side flexible aluminum foil by spraying compound solution through atomizing and powder-spraying device

InactiveCN103789755AHigh quality and reliabilityFast thermal responseSolid/suspension decomposition chemical coatingImideAluminum foil

The invention discloses a method for preparing a huge dual-side flexible aluminum foil by spraying a compound solution through an atomizing and powder-spraying device. The method comprises the following steps: (1) preparing a compound liquid: dissolving a monomer of polyimide resin to obtain a polyimide resin solution, adding PTC (Positive Temperature Coefficient) powder into the polyimide resin solution, and mixing uniformly; (2) heating the aluminum foil to 100-400 DEG C through a heating device, and spraying the compound solution prepared in the step (1) onto the aluminum foil by using the atomizing and powder-spraying device to form a coating of polyimide resin compound PTC liquid; (3) baking the aluminum foil onto which the polyimide resin compound PTC liquid coating is sprayed in the step (2), and performing a cross-linking reaction to obtain the huge dual-side flexible aluminum foil. Compared with the prior art, the method has the advantages that the machining process is simple and convenient, the production efficiency and yield are increased, the thickness consistence of a product is high, and the prepared huge dual-side flexible aluminum foil is high in reliability, quick and accurate in the thermosensitive reaction, and convenient for adjusting the volume.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for preparing double-faced flexible aluminum foil by electrostatic coating of polymer composite PTC (positive temperature coefficient) powder

InactiveCN103811096AHigh quality and reliabilityFast thermal responseNon-metal conductorsLiquid spraying plantsPolymer compositesMachining process

The invention discloses a method for preparing a double-faced flexible aluminum foil by electrostatic coating of polymer composite PTC (positive temperature coefficient) powder. The method includes the steps: (1) preparing the polymer composite PTC powder; (2) heating the aluminum foil to reach the temperature of 250-400 DEG C by the aid of a heating device, coating the polymer composite PTC powder manufactured in the step (1) on the aluminum foil by the aid of an electrostatic coating device, and forming a polymer composite PTC powder coating on the aluminum foil; (3) baking the aluminum foil coated with the polymer composite PTC powder coating in the step (2) to obtain the double-faced flexible aluminum foil by the aid of a recrystallization process. Compared with the prior art, the machining process of the method is simple and convenient, production efficiency and yield can be improved, consistency of product thicknesses is high, the quality reliability of the manufactured double-faced flexible PTC aluminum foil is high, thermal sensitive reaction is fast and accurate, and volume is conveniently adjusted.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Warpage correction material and method for manufacturing fan out-type wafer level package

PendingCN110447097AHigh quality and reliabilityAdjust the amount of warpingSemiconductor/solid-state device detailsSolid-state devicesElastic modulusEngineering

Provided is a warpage correction material which can adjust the amount of warpage even at the temperature at which a fan out-type wafer level package (FO-WLP) is mounted, and at room temperature at which, for example, wafer transportation is performed, and thereby reduce the warpage of the WLP. This warpage correction material for a fan out-type wafer level package is characterized by comprising acurable resin composition including a component that is curable by means of an active energy ray and heat, wherein when the warpage correction material is formed into a flat film-shaped cured productby curing the warpage correction material by means of the active energy ray and heat, and the linear expansion coefficient alpha (ppm / DEG C) at 25 DEG C, the elastic modulus beta (GPa) at 25 DEG C, and the thickness gamma ([mu]m) of the cured product satisfy the following relational expression: 2000<=alpha*beta*gamma<=10000.

Owner:TAIYO INK MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com