Servo controller for spot welding gun

A technology of servo control device and spot welding gun, applied in the direction of torque/mechanical power control, digital control, electrical program control, etc., can solve the problems of unable to speed up the responsiveness of the control system, unstable control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

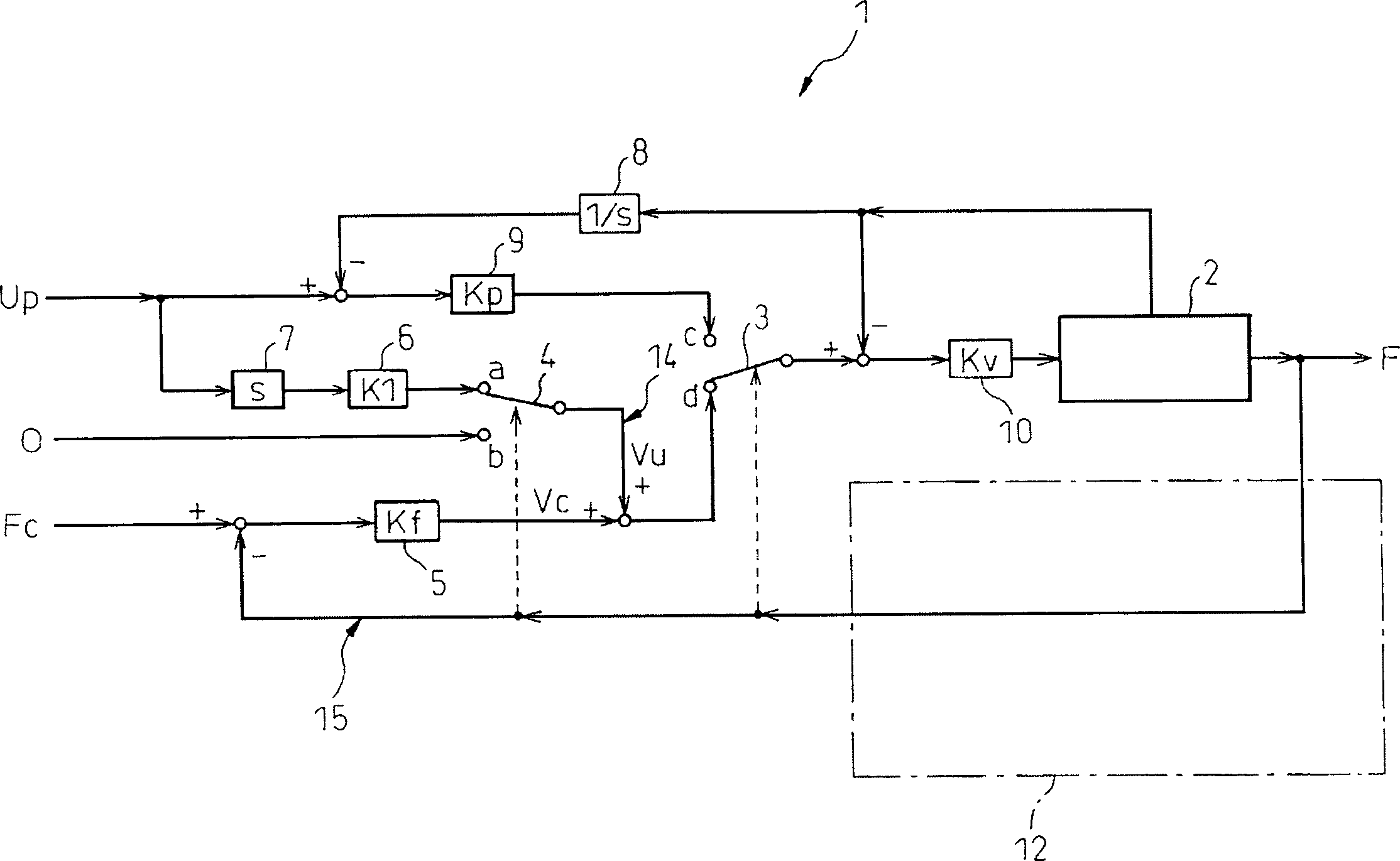

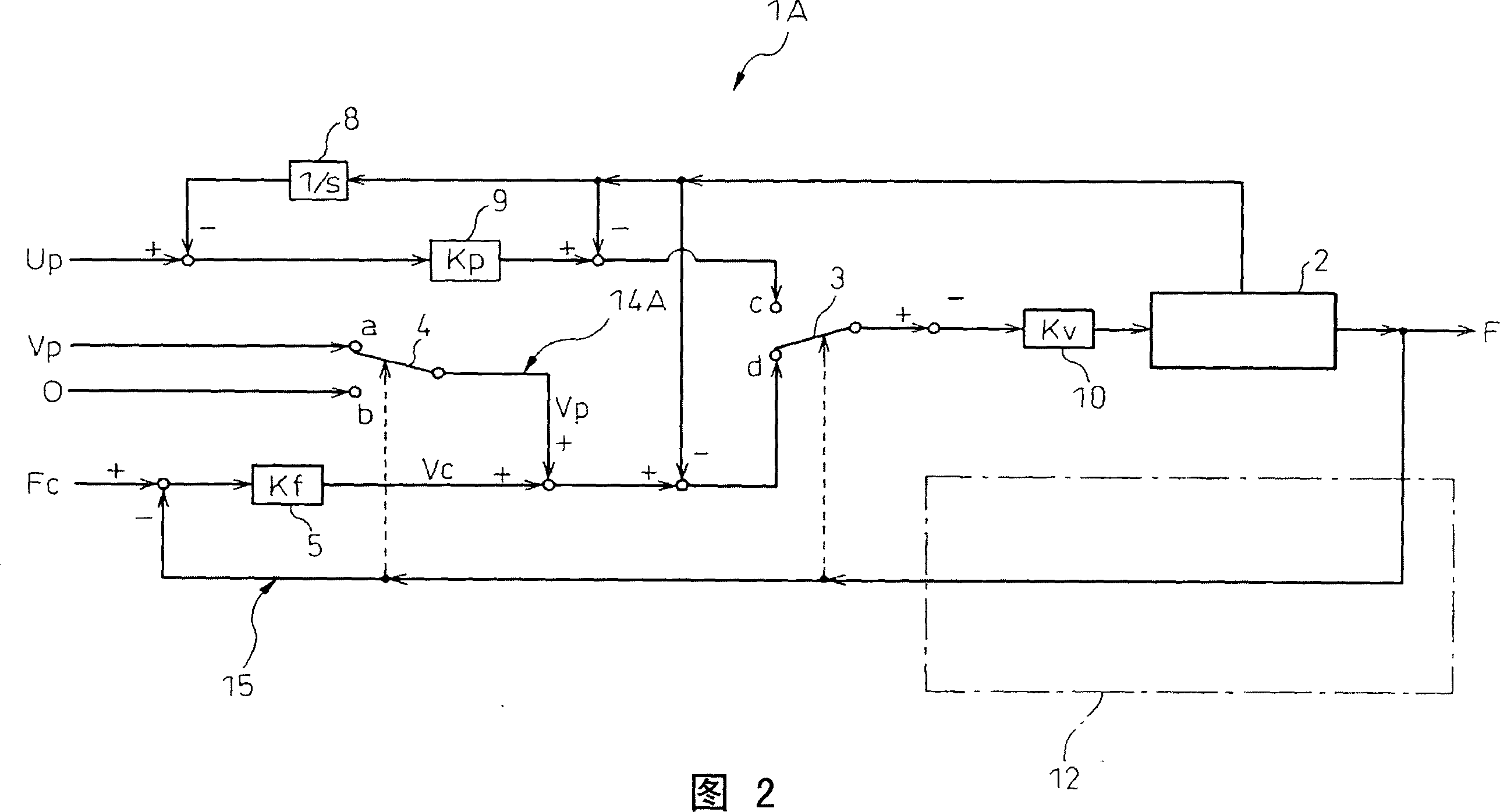

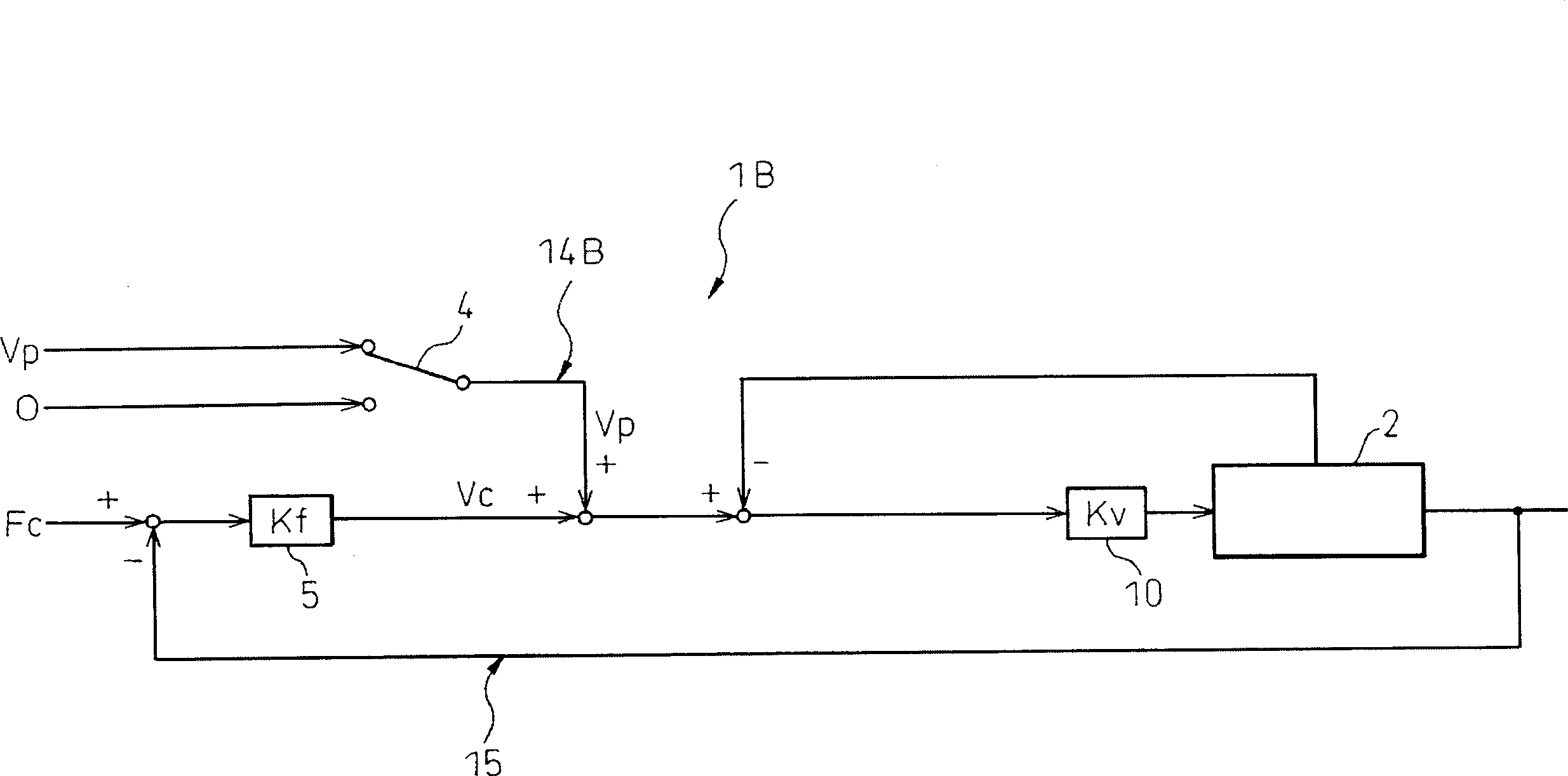

[0017] Embodiments of the present invention will be described in detail below using the drawings. figure 1 The first embodiment of the servo control device of the spot welding gun according to the present invention is shown.

[0018] The servo control device of this embodiment is to drive one of the movable welding torch nozzles in the opposite direction through a servo motor (control object) among a pair of welding torch nozzles that are not shown in the figure, and control The servo control device of the spot welding gun for the welding pressure of the object to be welded held between the nozzles is bus-connected to a high-level control device of a welding robot (not shown) via a common memory.

[0019] A not-shown host control device is composed of a CPU, an input / output interface, a ROM, a RAM, a nonvolatile RAM, and the like. The teaching operation panel used to teach various actions to the robot or set various setting values and parameters is connected to the input a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com