seat belt tensioner

A safety belt and pre-tensioning technology, which is applied in the direction of safety belts, belt tighteners, transportation and packaging, etc. in the car, and can solve the problems of high cost of permanent magnet actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

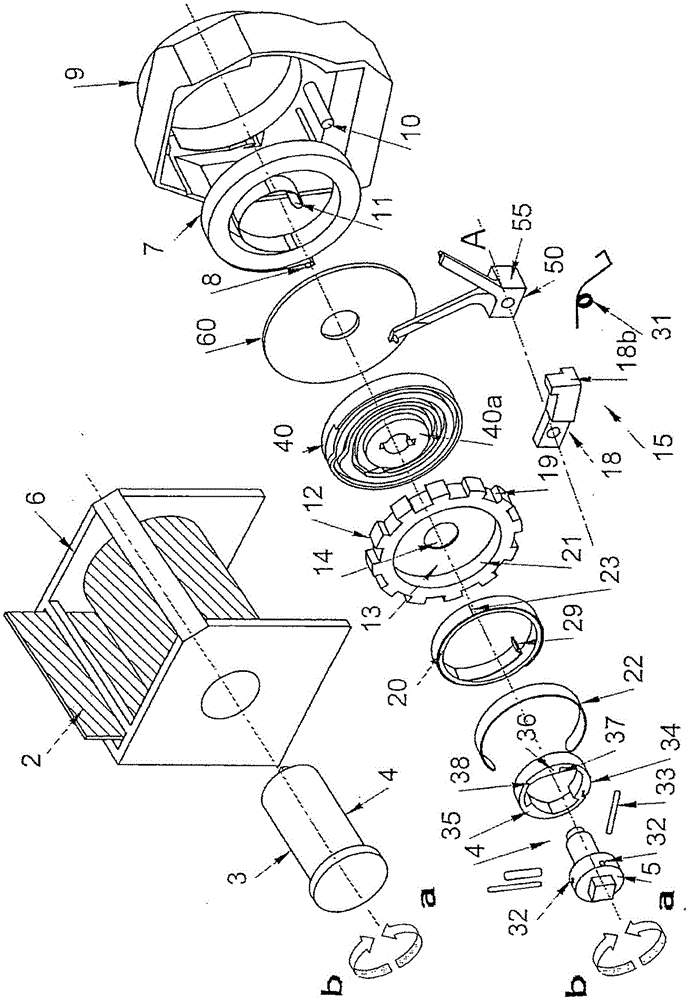

[0042] figure 1 The seat belt retractor 1 is shown. The belt take-up device 1 can wind a belt 2 onto a belt take-up section 3 of a mandrel 4 . The mandrel 4 has a two-section structure, and is composed of a seat belt tightening section 3 and a driving section 5 . The mandrel is rotatable in the safety belt casing 6 .

[0043] Furthermore, the belt tensioner 1 has a drive spring 7 whose outer end 8 is fixedly connected to a plastic housing 9 . The plastic shell 9 uses three pins 10 to be connected and fixed with the safety belt casing 6 at the side.

[0044] The main drive spring 7 is connected with its inner end 11 in a rotationally fixed manner to the drive section 5 of the spindle 4 . Therefore, when rotating in the unwinding direction b, that is, when the safety belt 2 is unrolled, the mandrel 4 is tensioned by the main drive spring 7 in the winding direction.

[0045] In addition, the seat belt tightening device 1 also includes a ratchet 12 that is adjacent to the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com