Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Guaranteed preparation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

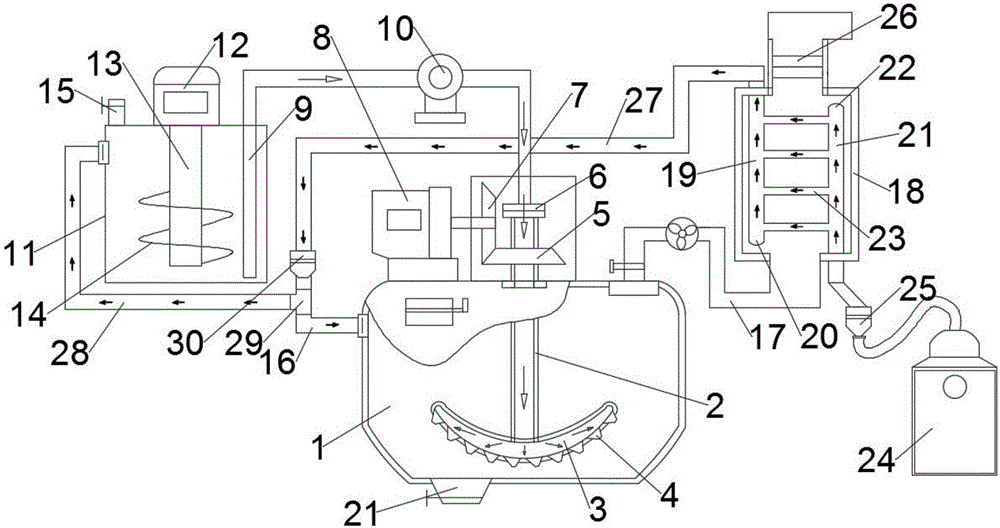

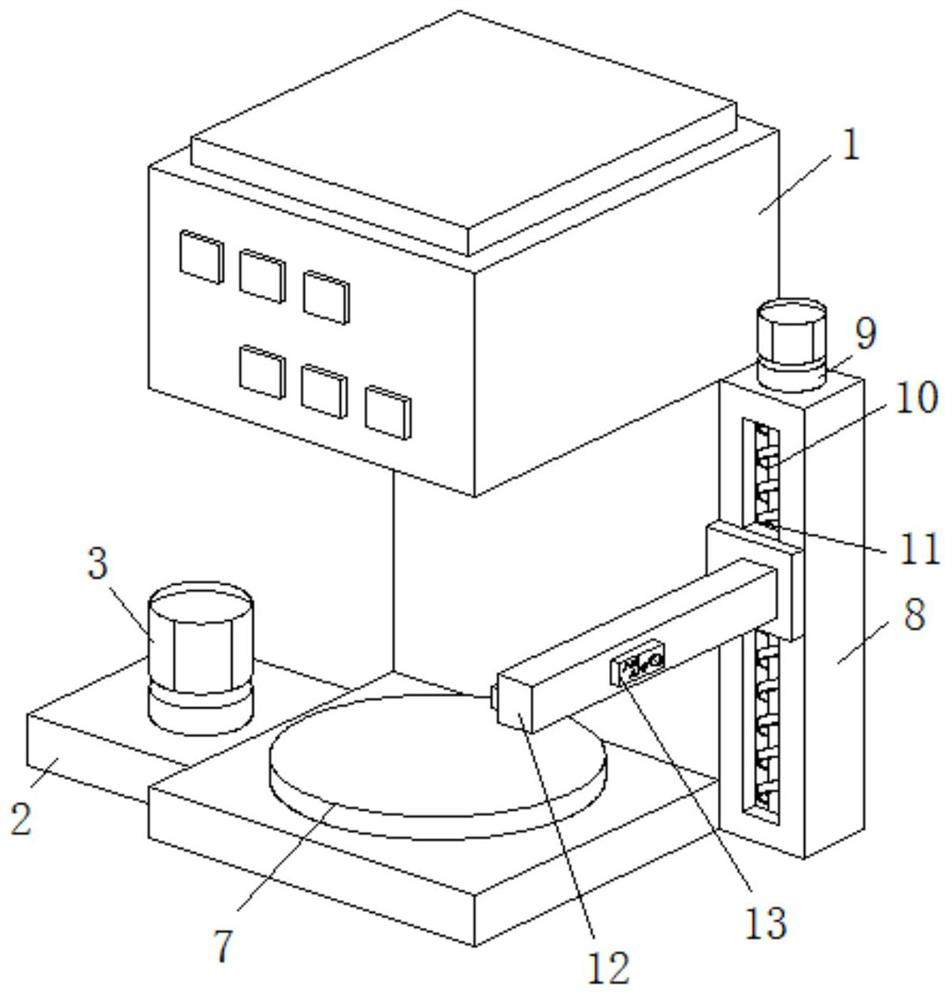

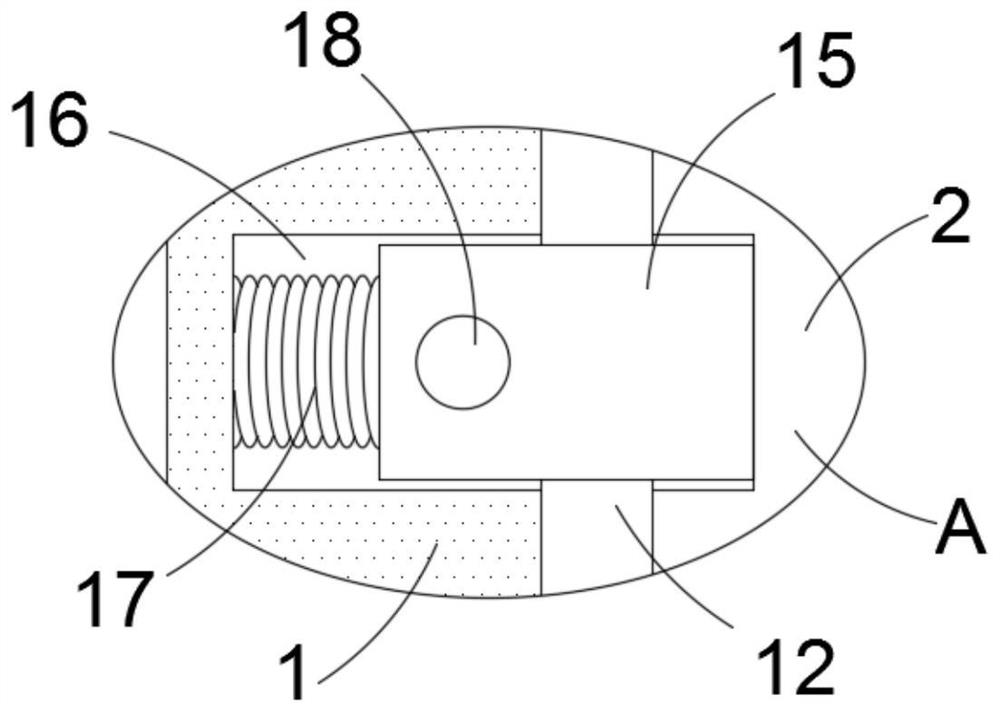

Vibration-crushing micro-pill machine

InactiveCN101574305AGood molding effectEasy to operatePharmaceutical product form changeTemperature controlGear pump

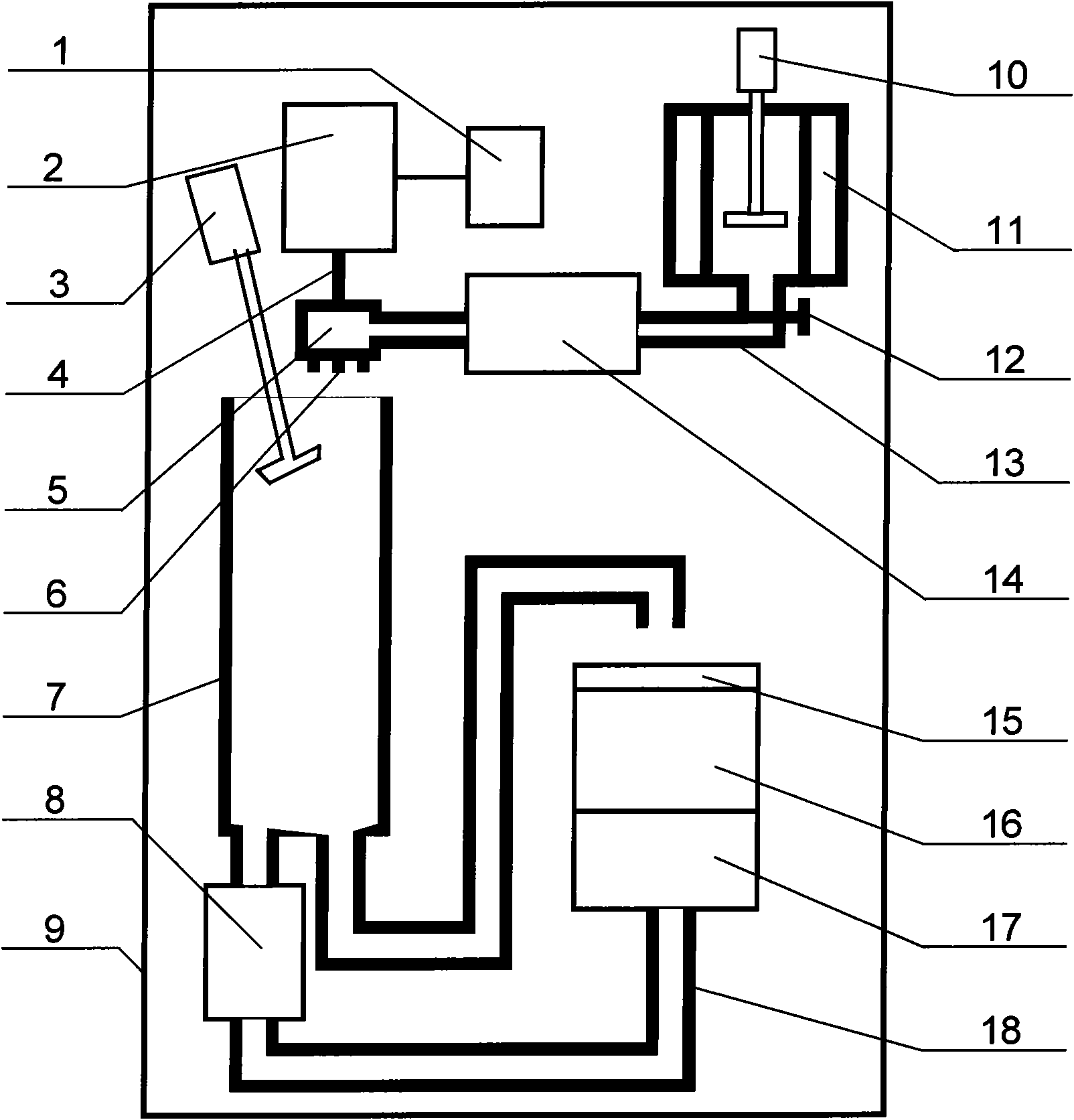

The invention pertains to the technical field of medicine preparation and relates to a vibration-crushing micro-pill machine which comprises a liquid storage pot, a pill dripping system, a cooling circulation device, a micro-pill collecting machine and a control circuit, wherein the pill dripping system comprises a dropper, a jet hole, a vibration exciter and a gear pump. The dropper is connectedwith the vibration exciter by a rigid connecting rod. The lower part of the dropper is provided with one or more jet holes, the upper part of which is a liquid inlet and the lower part thereof is a nozzle. The dropper is connected with an electric valve at the lower part of the liquid storage pot by pipes on which the gear pump is arranged. The side wall of the dropper is provided with two insertion holes in which a heater and a temperature sensor respectively connected with the control circuit are arranged. The control circuit controls the make-and-break of the heater according to the detected temperature of the temperature sensor. The cooling circulation device comprises a condensation column, a stirring device, a filter, a cooling cylinder, a cooling pump and an electromagnetic pump. The vibration-crushing micro-pill machine has the advantages of chance of batch production of micro-pills, high production efficiency, simple equipment structure and convenient control.

Owner:TIANJIN UNIV

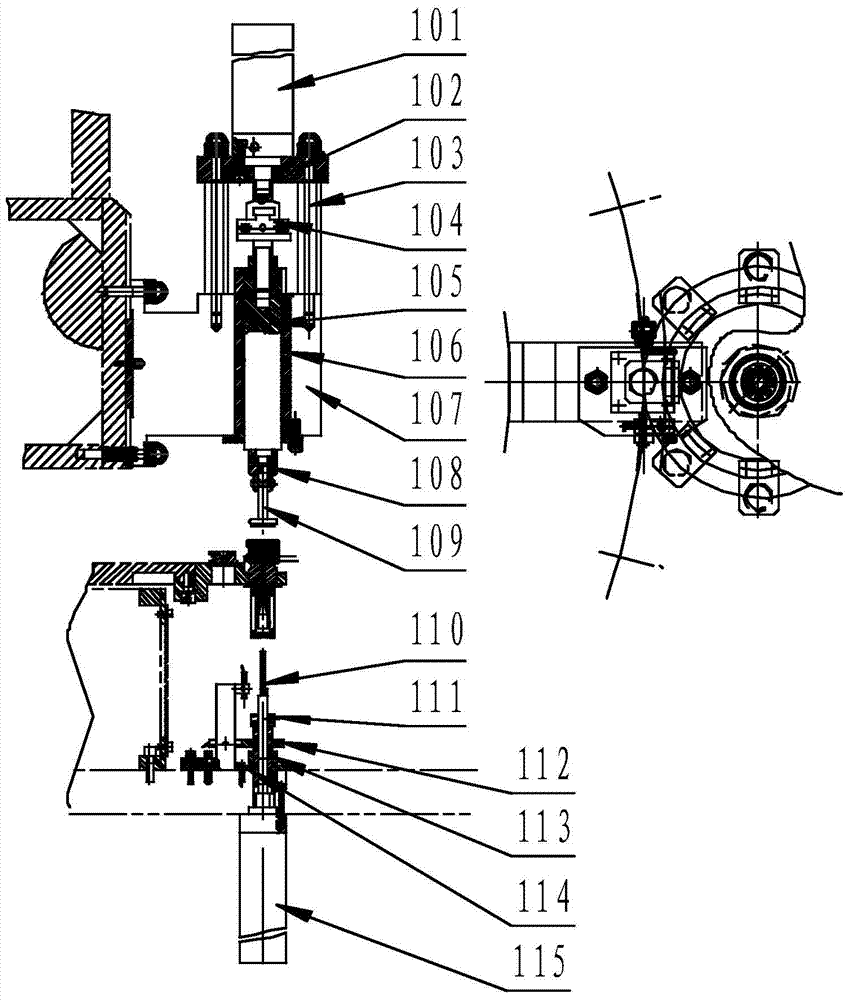

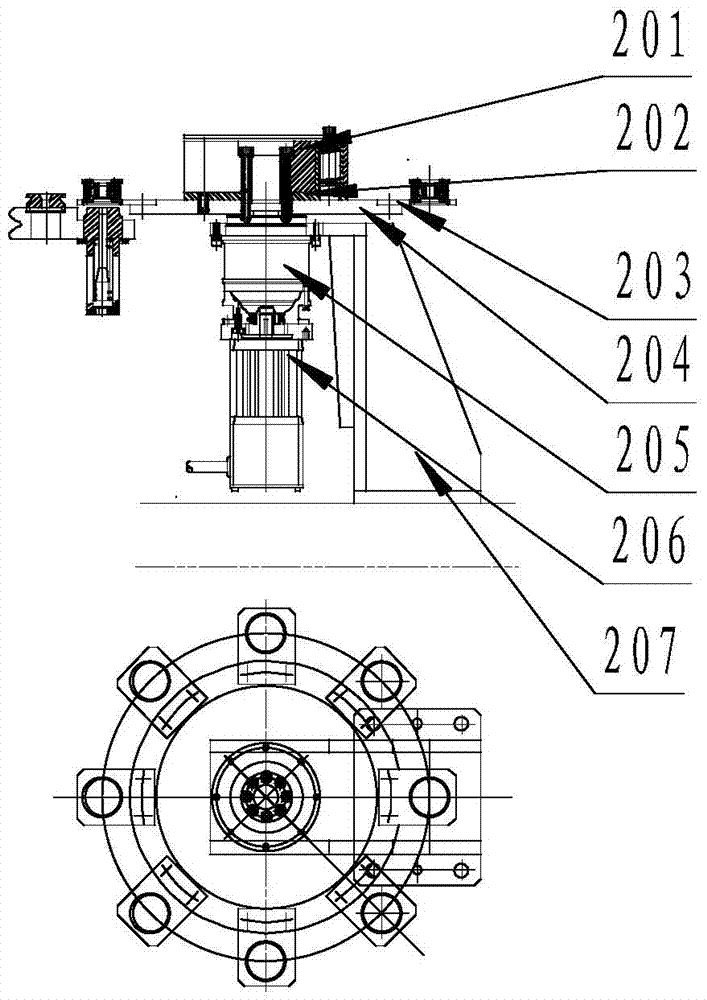

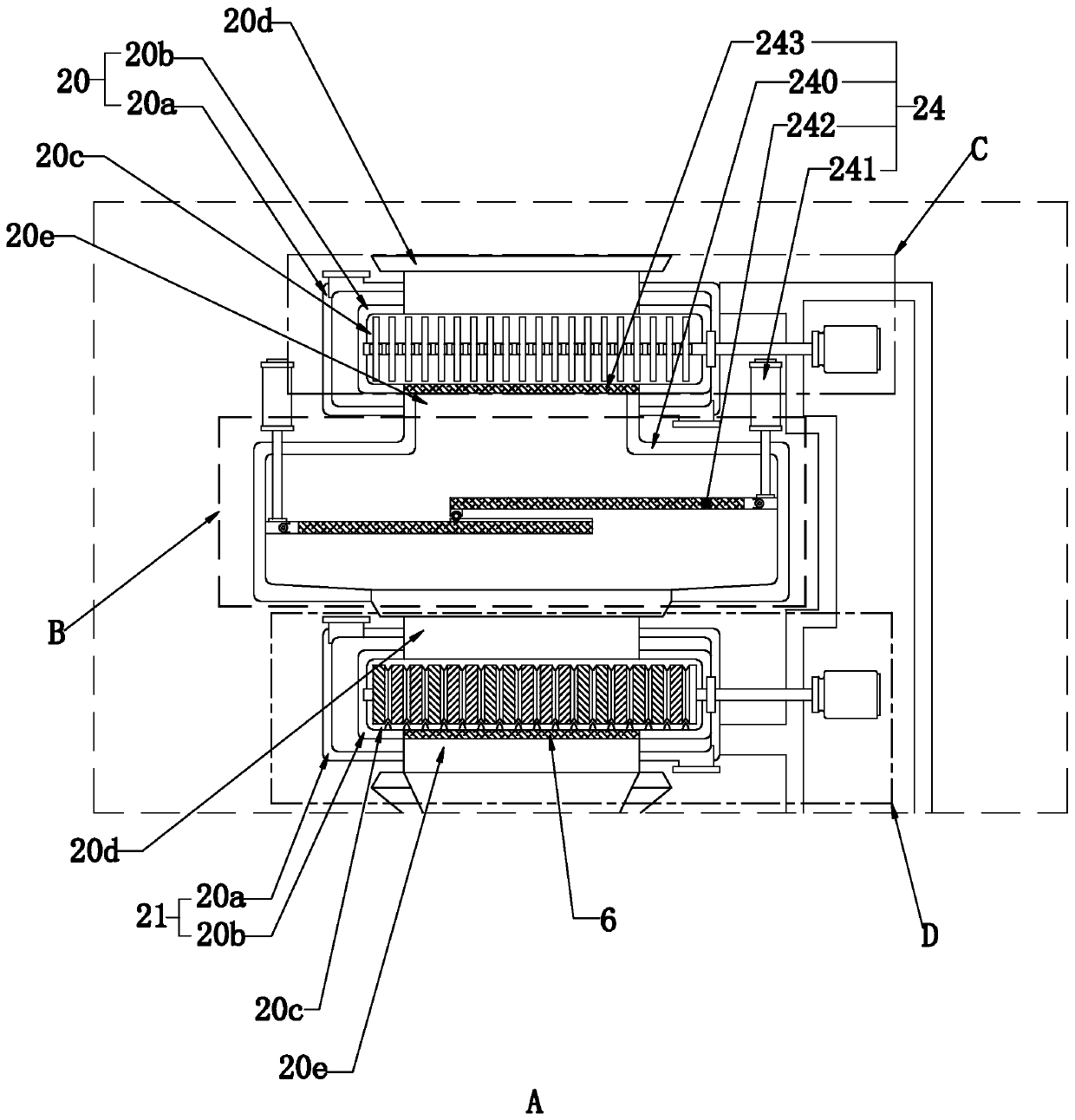

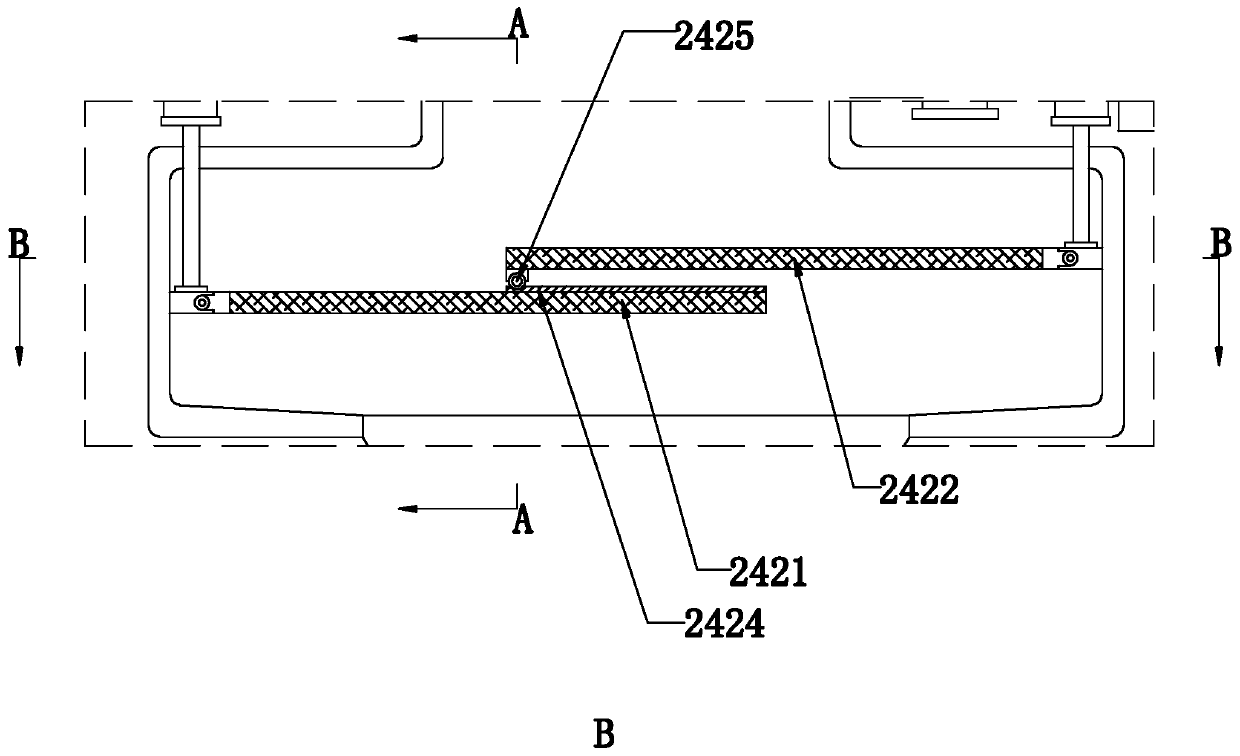

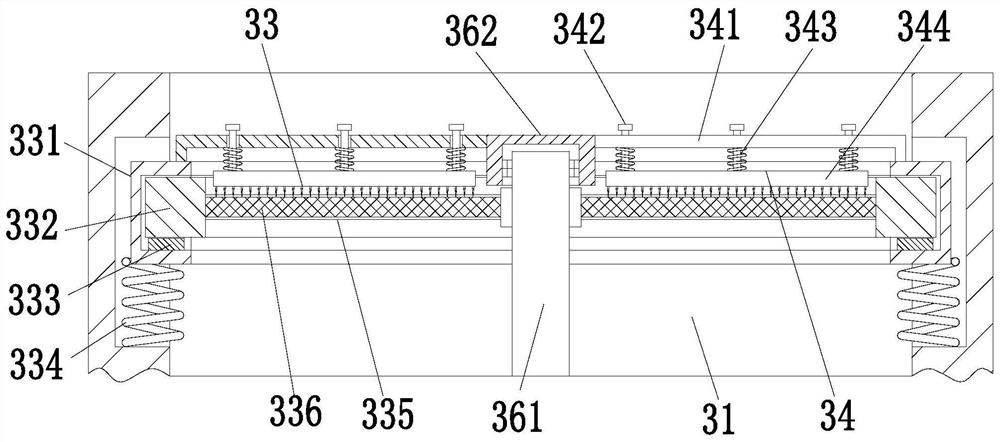

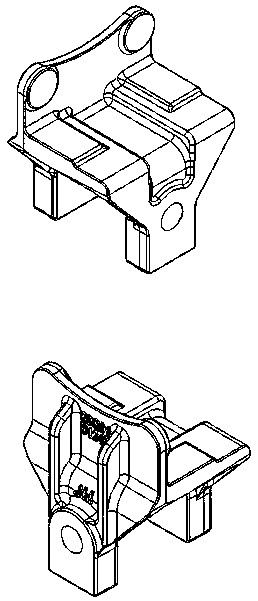

Double-disk detonator automatic assembling machine buckling assembling pressing device

InactiveCN103708987ALow densityReduce manufacturing and management costsDetonatorsManipulatorEngineering

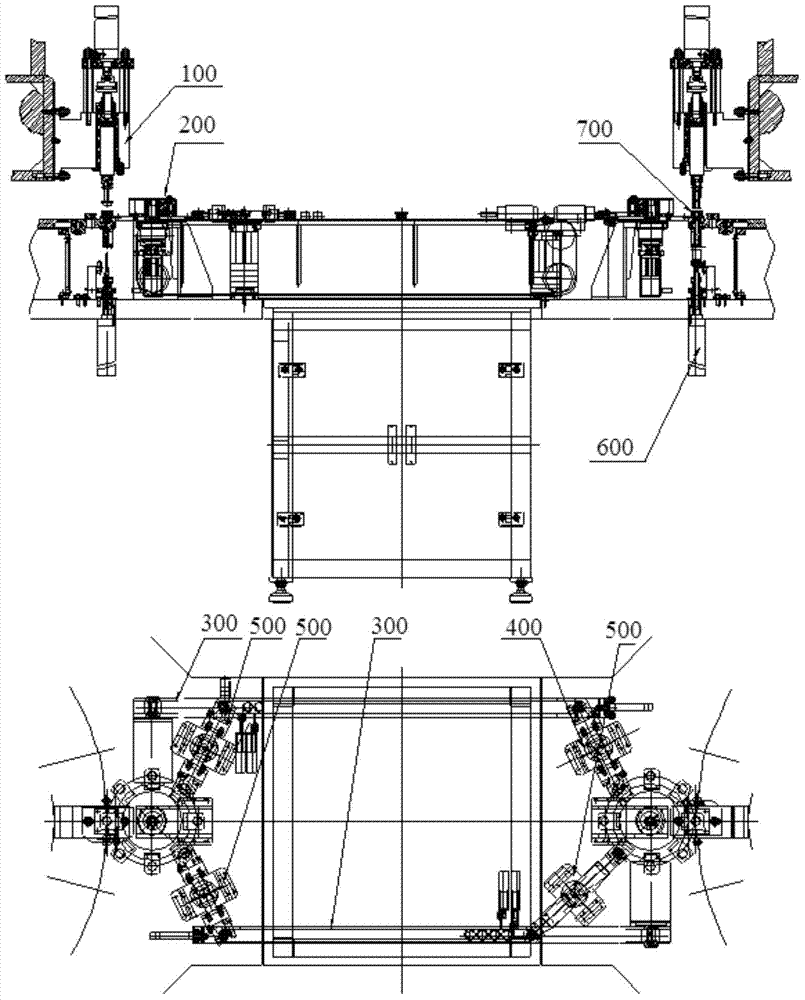

The invention discloses a double-disk detonator automatic assembling machine buckling assembling pressing device. The double-disk detonator automatic assembling machine buckling assembling pressing device is composed of two 24-position disk-type detonator automatic assembling machines and a buckling assembling pressing device. The buckling assembling pressing device is mainly assembled by a charging reinforcement cap ejecting device, a pair of a and b servo central rotating disks, two conveying devices, a overturn grabbing manipulator, three grabbing manipulators, a buckling assembling pressing device and a product turnover die which are joined and matched mutually. The buckling assembling pressing device is used for achieving ejection, grabbing, turnover, overturn and buckling with a discharging shell body of the charging reinforcement cap. The buckling assembling pressing device is arranged between the two 24-position disk-type detonator automatic assembling machines, and used for connection and coordination of product assembling of the two 24-position disk-type detonator automatic assembling machines. The double-disk detonator automatic assembling machine buckling assembling pressing device meets the multifunction requirement, and meets the high reliability requirement of the weapon system development to product assembling.

Owner:北方特种能源集团有限公司西安庆华公司

Anti-oxidation chemical industrial raw material processing and blending device

InactiveCN106823966AEnsure mixing uniformitySolve the cumbersome complexityRotary stirring mixersTransportation and packagingNitrogenProcess engineering

The invention discloses an anti-oxidation chemical industrial raw material processing and blending device. The anti-oxidation chemical industrial raw material processing and blending device comprises a raw material blending tank, a blending and stirring rotating shaft is vertically inserted in an inner cavity of a tank body of the raw material blending tank along the central axis; the inner part of an arc-shaped stirring paddle is also set into a hollow structure, and a plurality of liquid spraying through holes are uniformly formed in the bottom side surface of the arc-shaped stirring paddle; an outer cavity nitrogen induction tube is vertically arranged in a position of the right side edge of an inner cavity of a gas heating chamber; a hot gas eduction pipe is vertically arranged in a position of the left side edge of the inner cavity of the gas heating chamber; the top end of the hot gas eduction tube is guided out of the top side wall of the gas heating chamber, and the end part of a tube body is integrally connected with a cyclic hot nitrogen conveying tube. According to the anti-oxidation chemical industrial raw material processing and blending device disclosed by the invention, the mixing uniformity of a whole additive is ensured, the tedious and complicated performance of a traditional blending agent in an addition process is solved, an assistance function is provided for preparation by a filled inert gas-nitrogen, and the preparation rate of raw materials is enhanced.

Owner:六安市智奇工业设计有限公司

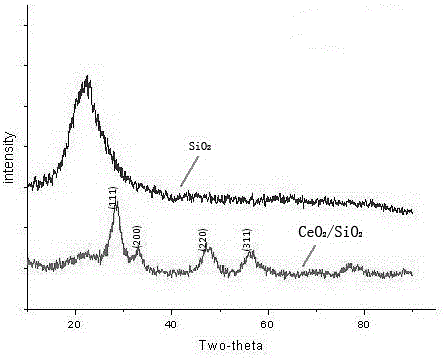

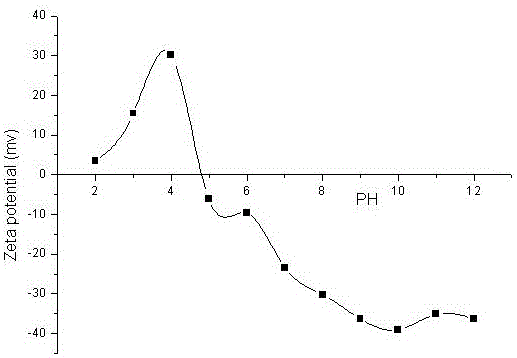

Preparation method of shell-core coated cerium oxide-silicon oxide composite abrasive grains

ActiveCN105733507AHigh degree of coatingGood dispersionOther chemical processesPolishing compositions with abrasivesLiquid layerCerium nitrate

The invention provides a preparation method of shell-core coated cerium oxide-silicon oxide composite abrasive grains. The preparation method includes the steps of (1), preparing silicon oxide suspension liquid from commercially available silicon oxide polishing slurry, and controlling a pH value of the silicon oxide suspension liquid as 10-10.5 during preparation; (2), preparing a cerium salt solution by taking cerium nitrate as a cerium salt and HMT as a precipitant; (3), slowly dropwise adding the cerium salt solution into the silicon oxide suspension liquid at a constant speed so as to obtain a mixed solution; (4), subjecting the mixed solution to oil-bath heating and heating reflux to obtain dark brown suspension liquid, cooling the dark brown suspension liquid to the room temperature and ageing until the cooled dark brown suspension liquid layers; (5), subjecting the layered dark brown suspension liquid to centrifugal separation and washing to obtain dark brown precipitate; (6), drying, grinding, roasting and comminuting the dark brown precipitate. The preparation method of the shell-core coated cerium oxide-silicon oxide composite abrasive grains solves the problems that the shell-core coated cerium oxide-silicon oxide composite abrasive grains prepared by an existing method are low in cerium oxide coating degree and unsatisfactory in coating effect.

Owner:JIANGNAN UNIV

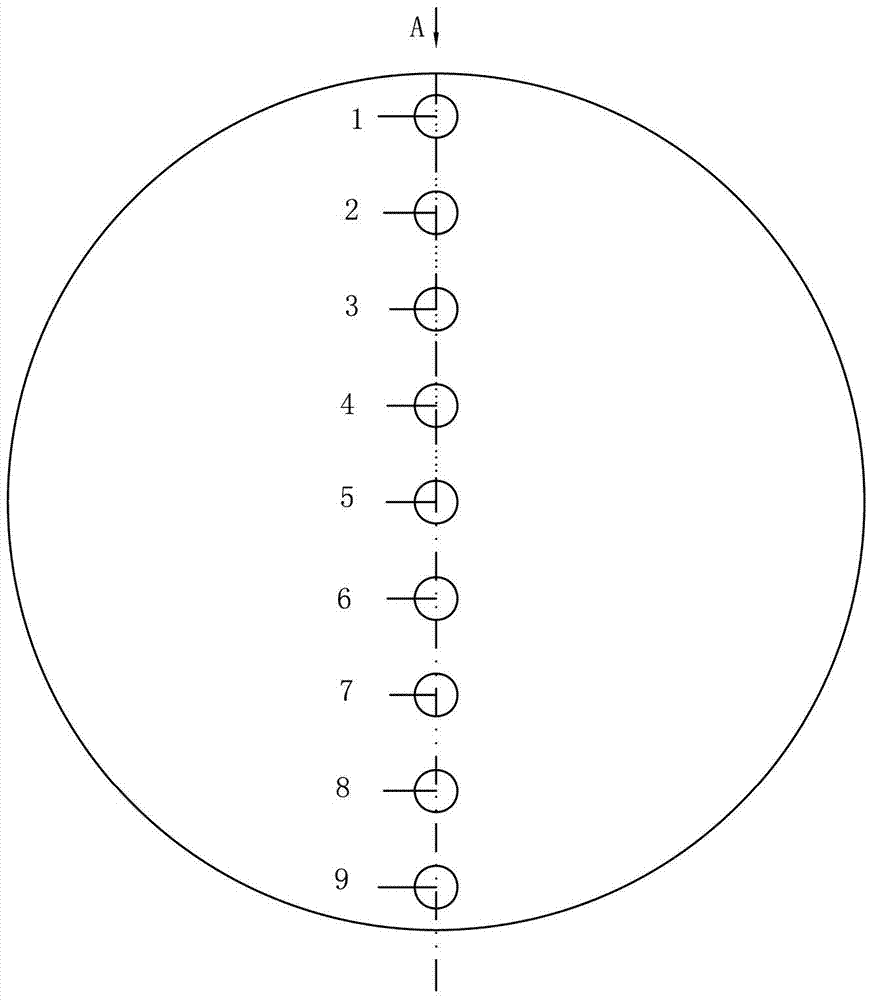

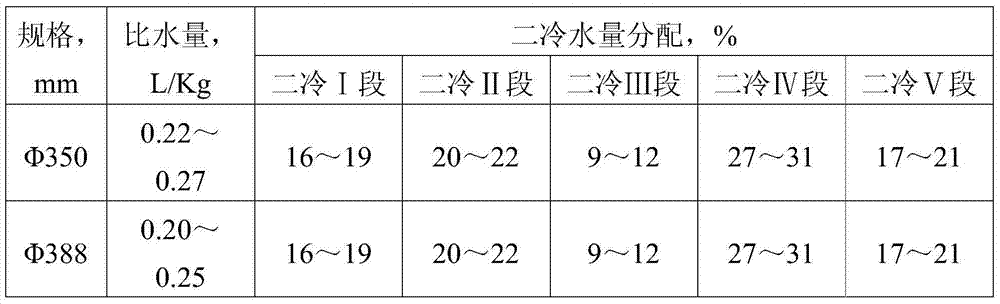

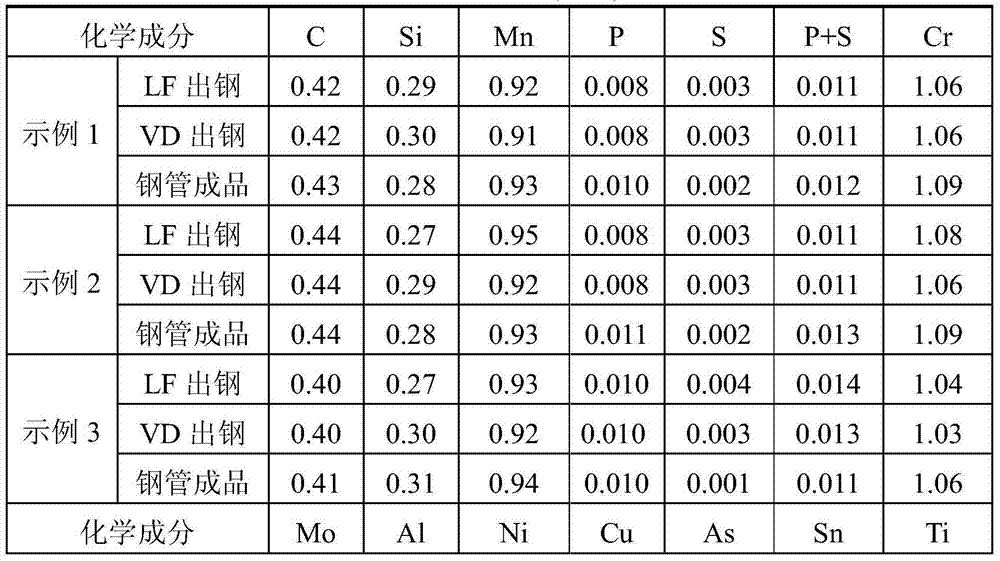

Steel for large-capacity electronic gas cylinder and manufacturing method of steel

The invention provides steel for a large-capacity electronic gas cylinder and a manufacturing method of the steel. According to the manufacturing method, by optimizing the component design, the steel quality purification and the smelting process control of the steel, the steel for the large-capacity electronic gas cylinder comprises the following chemical components in percentage by weight: 0.40-0.45% of C, 0.25-0.35% of Si, 0.85-1.00% of Mn, less than or equal to 0.013% of P, less than or equal to 0.008% of S, 1.00-1.10% of Cr, 0.20-0.25% of Mo, less than or equal to 0.015% of Ti, less than or equal to 0.18% of Ni, less than or equal to 0.18% of Cu, less than or equal to 0.010% of Sn, less than or equal to 0.025% of As, 0.015-0.040% of Al, less than or equal to 0.0002% of [H], less than or equal to 0.0070% of [N], less than or equal to 0.0020% of T[O], and the balance of iron and inevitable impurities. The steel can meet the requirements of large-capacity high-pressure gas cylinders for packaging electronic gases on application properties such as good strength and toughness.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

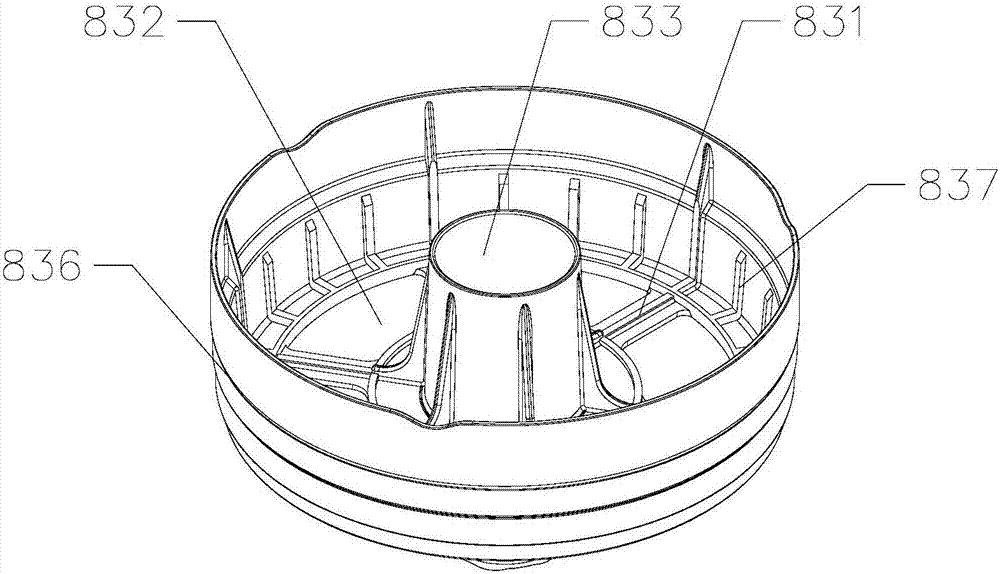

Method of making milky coffee drink with capsule drink machine

The invention provides a method of making a milky coffee drink with a capsule drink machine. The capsule drink machine comprises a base, a brewing chamber, a control panel, a brewing head, an inflow piercing needle, an extraction piercing needle, a liquid supply mechanism and a brewing cup for receiving milky coffee capsules; each milky coffee capsule includes a capsule body and a membrane and also includes a separator for liquid passage, the separator is arranged in the capsule body and divides an inner cavity of the capsule body into a first cavity and a second cavity, milk powder is arranged in the first cavity, and coffee powder is arranged in the second cavity; the method comprises the steps of emulsifying, extracting and mixing; sequentially, the milk powder is emulsified and brewed, the coffee powder is extracted and filtered, and milk and coffee liquids are mixed into a milky coffee drink; in the method, the milk and coffee liquids are mixed well, the milk liquid never floats on the surface of the coffee liquid, the taste of the milky coffee drink is enhanced, and the milky coffee drink has good color and appearance.

Owner:HONGYANG HOME APPLIANCES

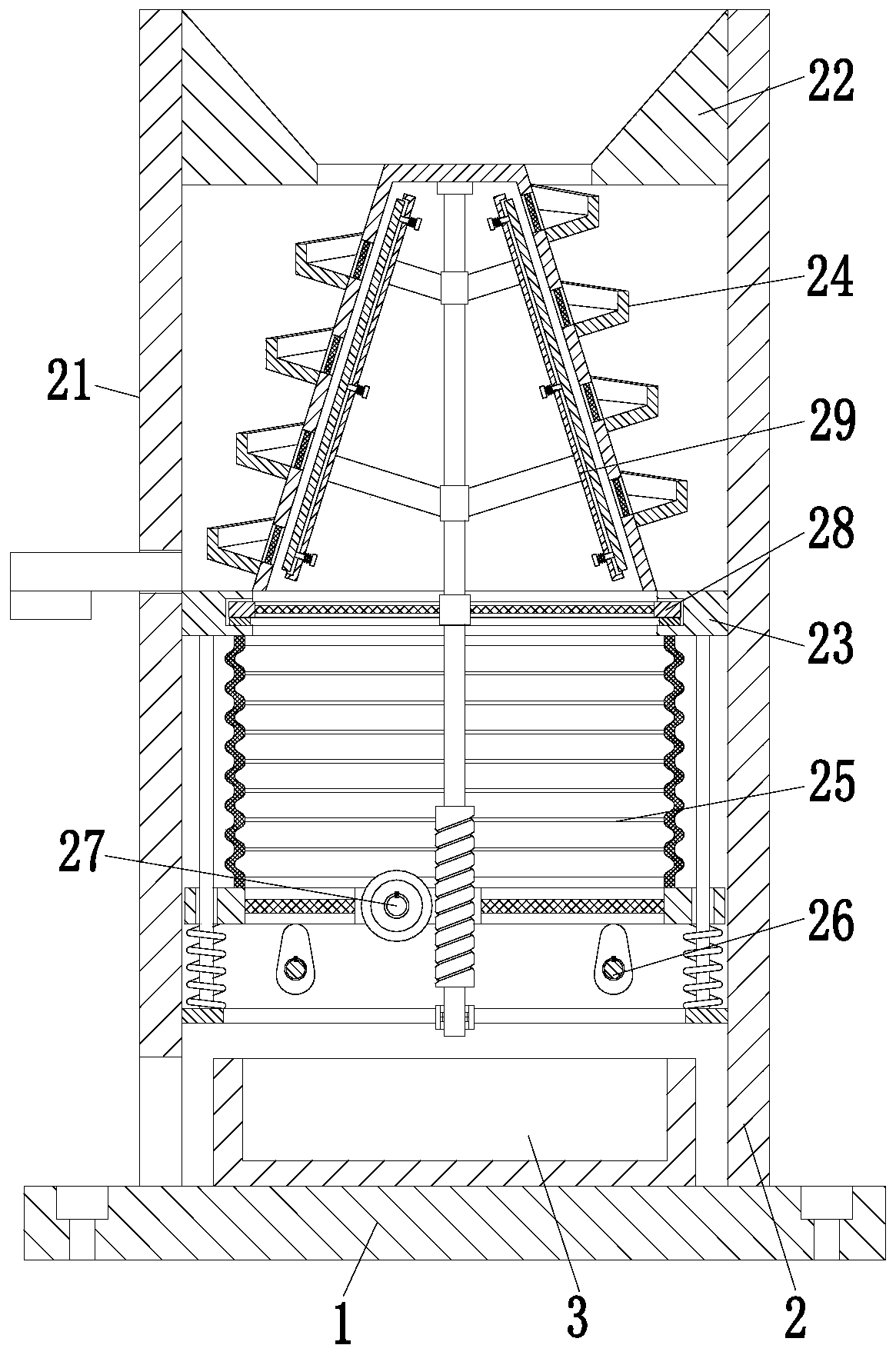

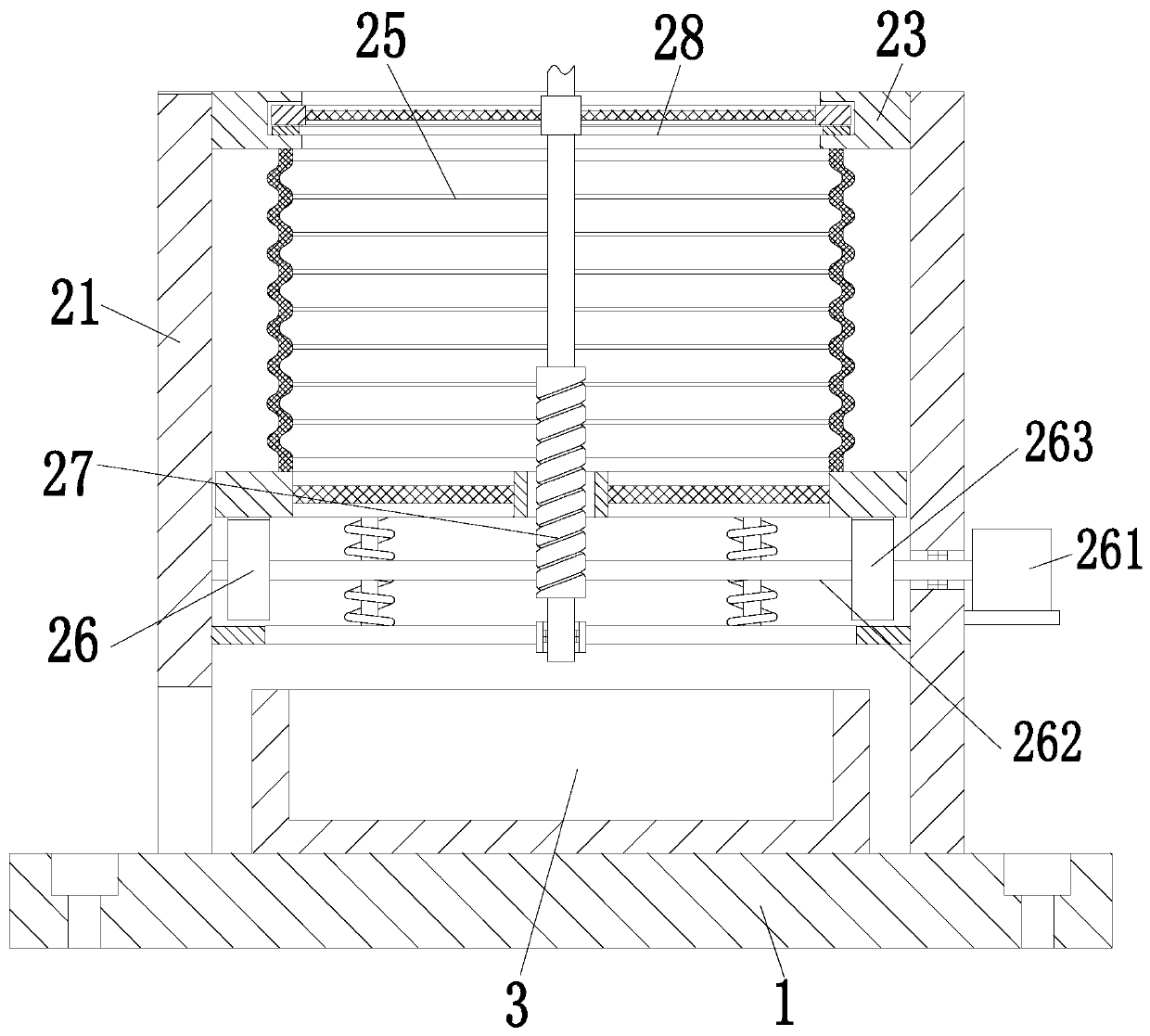

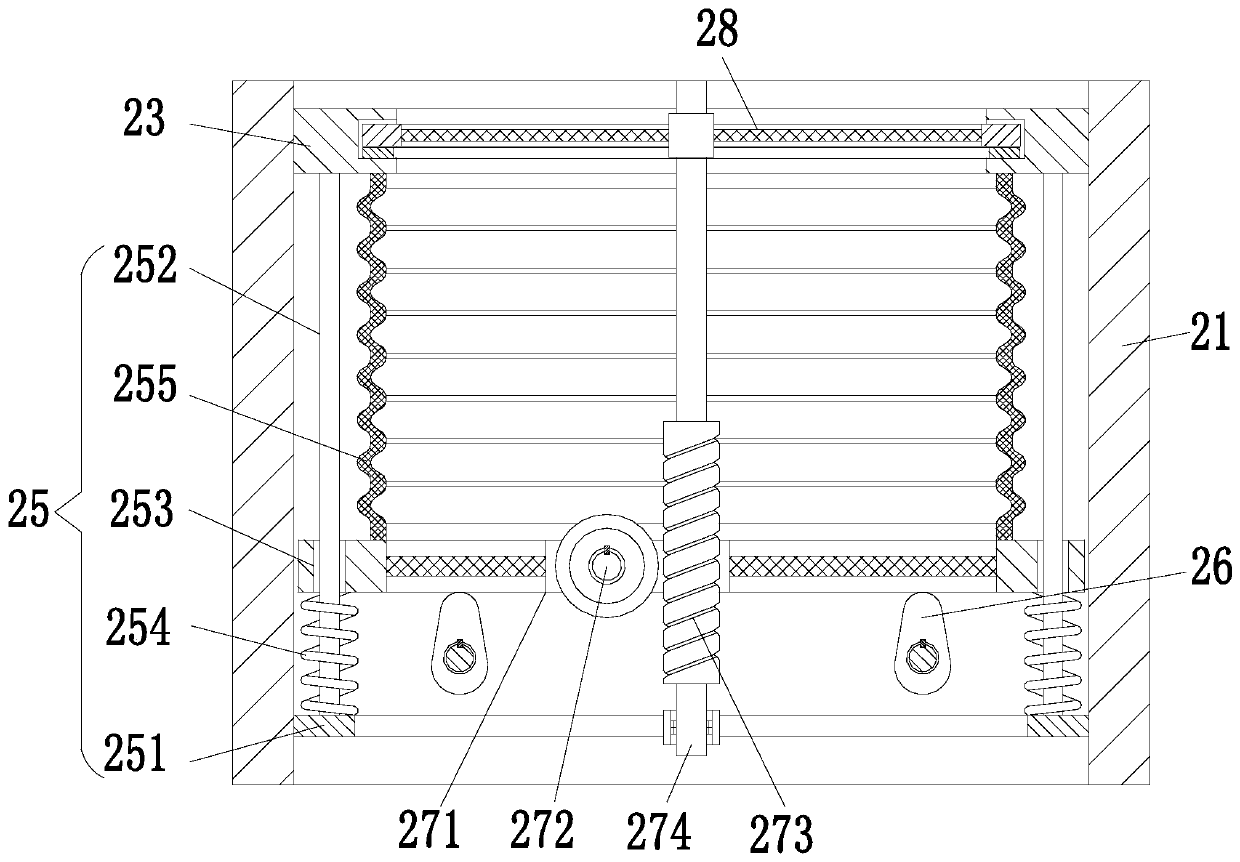

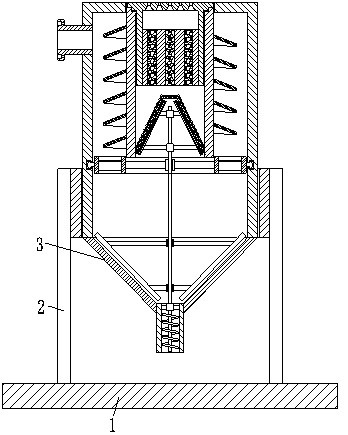

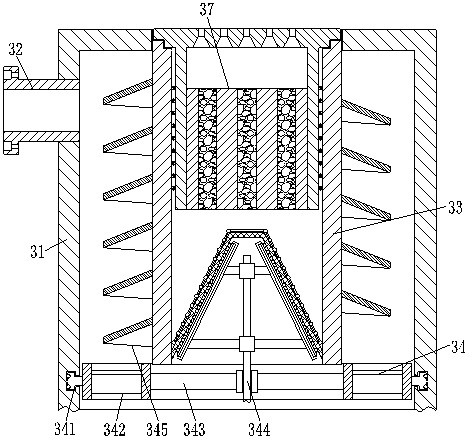

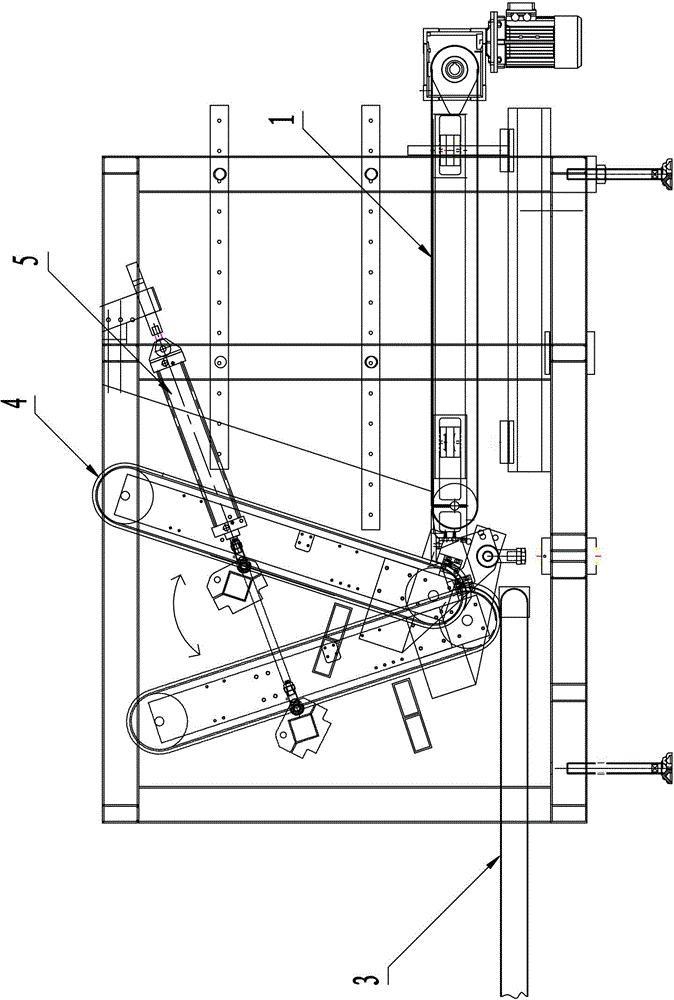

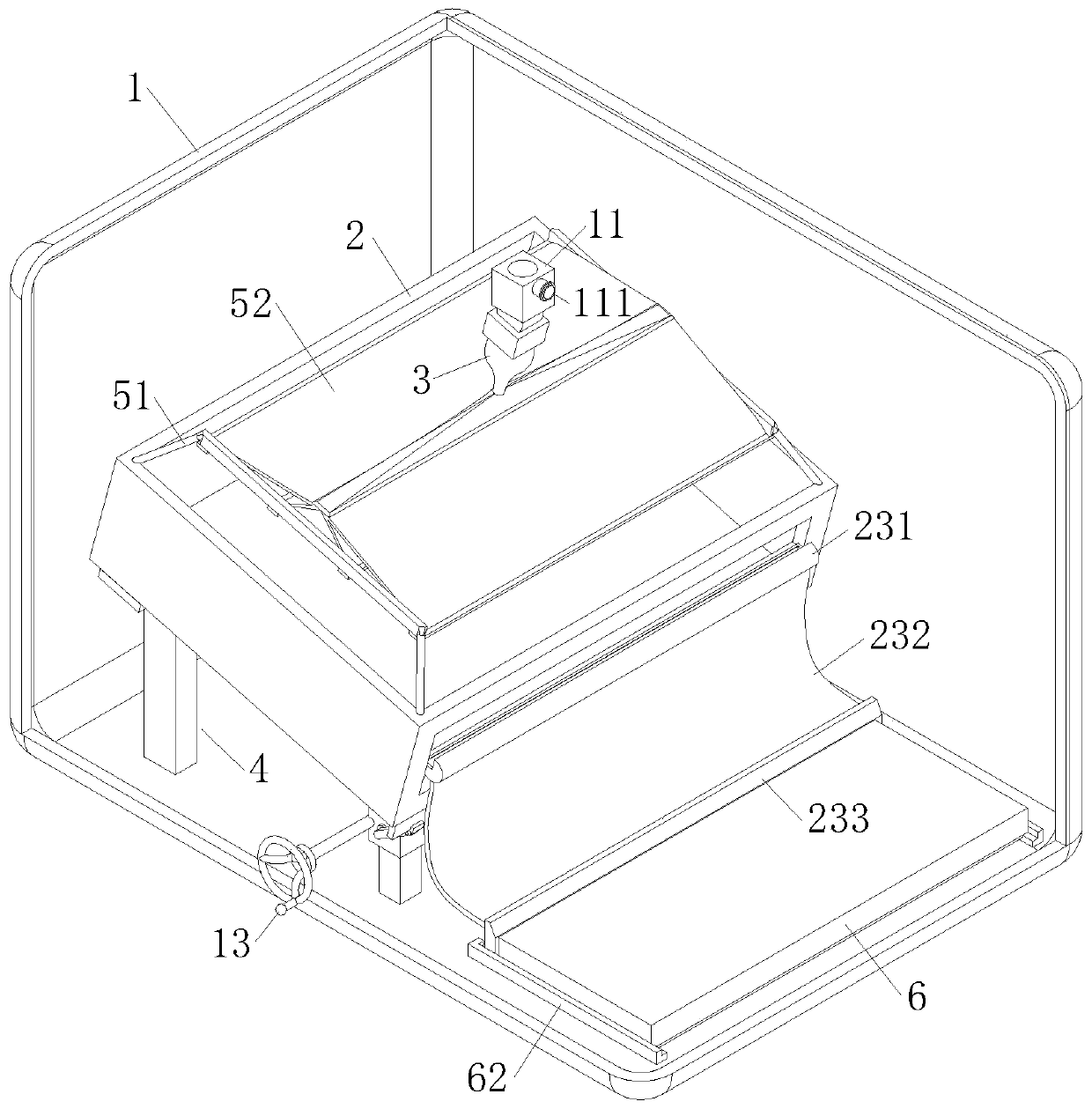

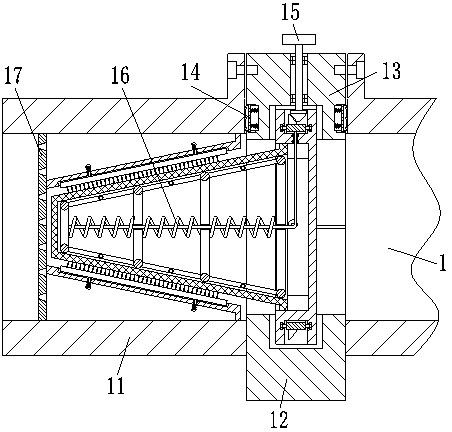

Printing ink manufacturing raw material pigment pretreatment system

ActiveCN111495751AGuaranteed preparation effectImprove processing efficiencySievingScreeningEngineeringProcess engineering

The invention relates to a printing ink manufacturing raw material pigment pretreatment system. The system comprises a bottom plate, a filtering device and a collecting box, mounting holes are evenlyformed in the bottom plate, the filtering device is mounted at the upper end of the bottom plate, a through groove is formed in the lower end of the filtering device, and the collecting box is arranged in the through groove and located in the middle of the upper end of the bottom plate. The system can solve the following problems that when existing equipment is used for filtering printing ink manufacturing raw material, the filtering effect is poor, filtering is incomplete, large-particle impurities in a raw material cannot be effectively removed, filter screen holes are easily blocked by theimpurities, and the impurities cannot be rapidly removed; when existing equipment is used for screening and processing the printing ink manufacturing raw material, the raw material cannot be vibratedto be screened, the raw material is likely to be accumulated at the upper end of a screen, the screening efficiency of the raw material is low, and subsequent processing of printing ink is affected.

Owner:英德市捷成化工有限公司

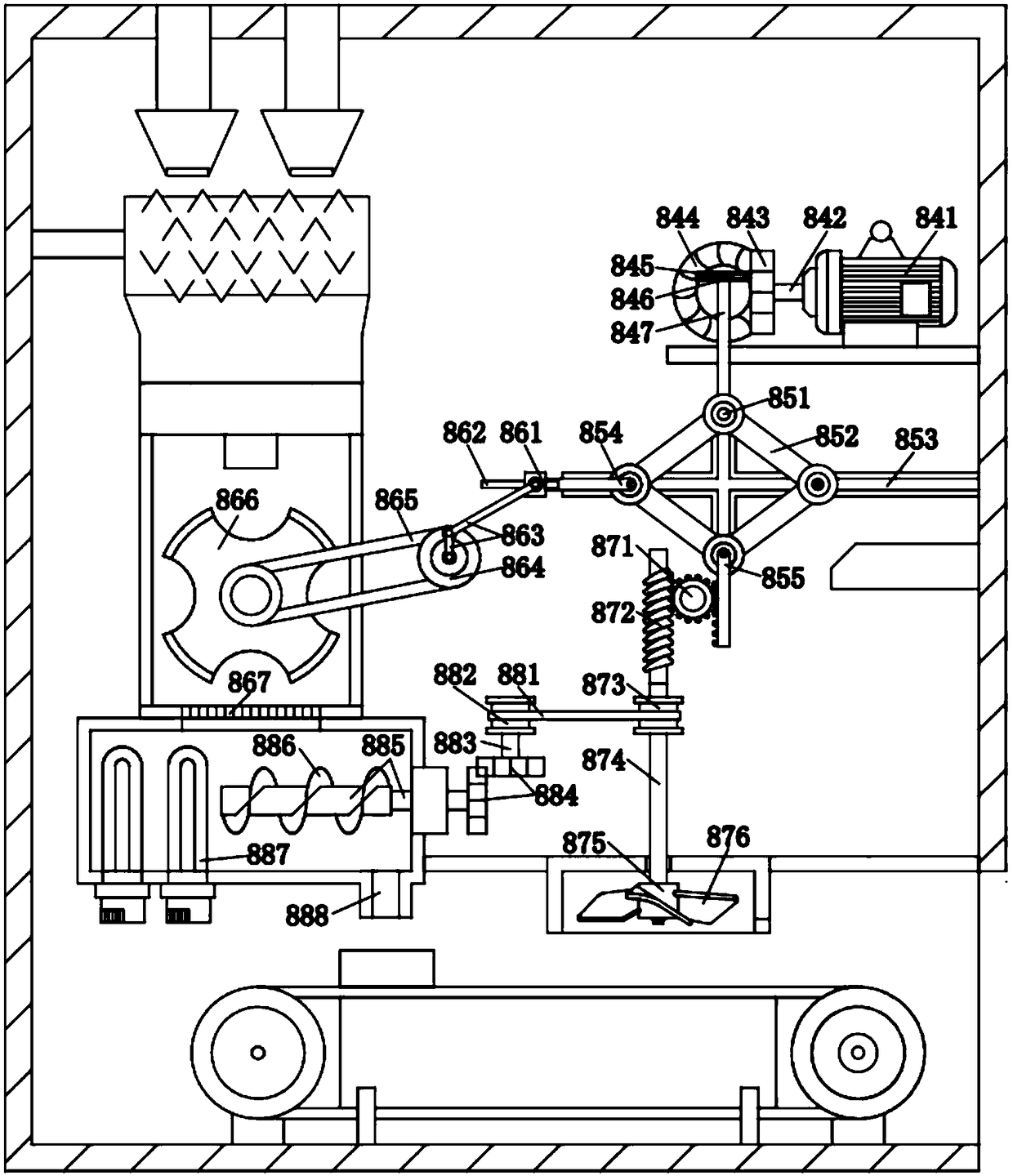

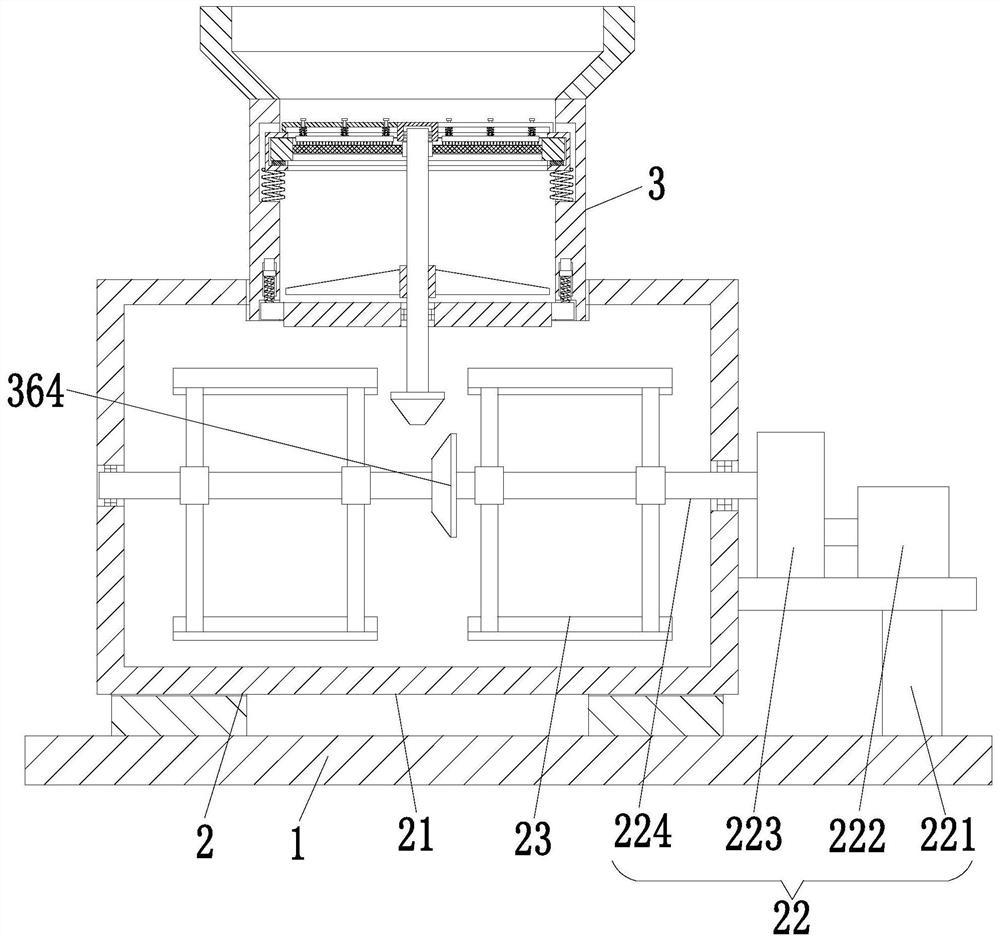

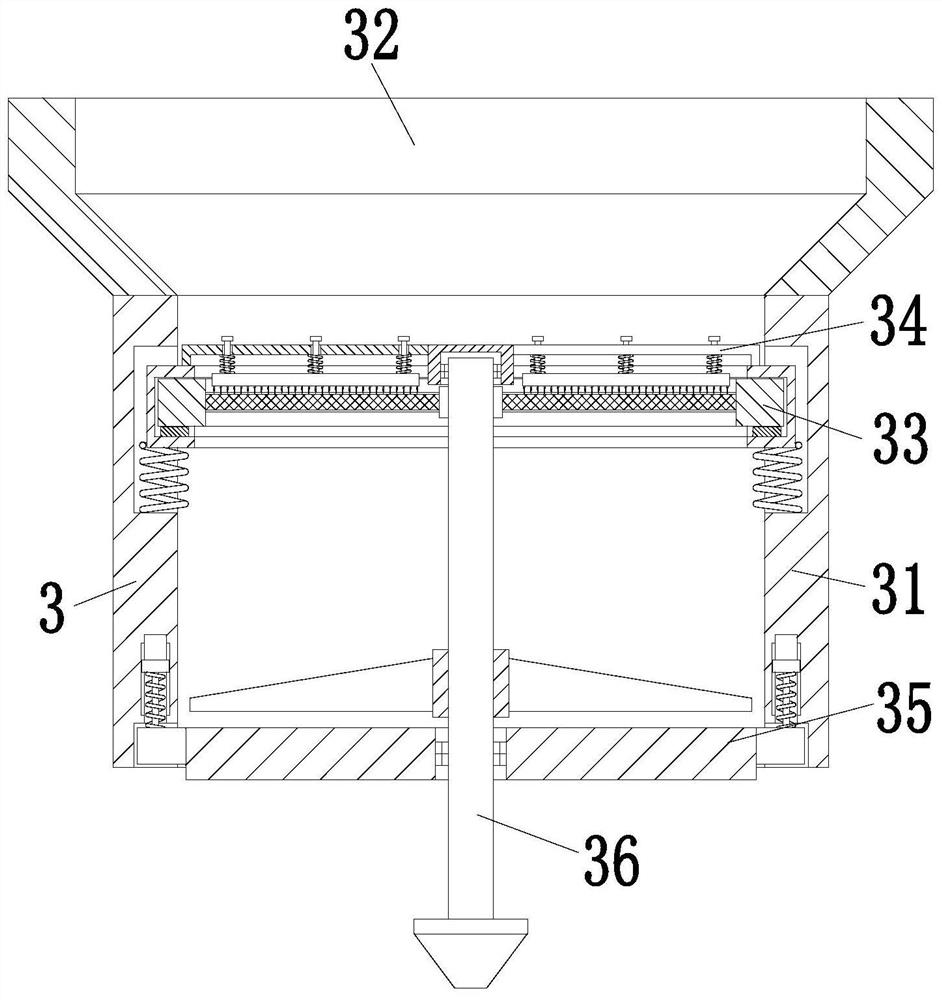

Boiler solid waste slag recycling treatment system and method

InactiveCN111185270ARealize the function of reuseEffective crushingGrain treatmentsThermodynamicsBoiler furnace

The invention relates to a boiler solid waste slag recycling treatment system and method. The boiler solid waste slag recycling treatment system comprises a bottom plate, a crushing device and a feeding device, wherein threaded holes are uniformly formed in the bottom plate, the crushing device is mounted in the middle of the upper end of the bottom plate, and the feeding device is mounted on theleft side of the crushing device. According to the boiler solid waste slag recycling treatment system and method, the problems that when existing equipment is used for conveying boiler slag, the conveying effect is poor, the occupied area is large, a large amount of manpower is needed for operation, then the conveying efficiency of the slag is low, and the subsequent processing efficiency of the slag is influenced can be solved, and the problems that when the existing equipment is used for crushing the slag, the crushing effect is poor, the crushing is not uniform, the diameter of the crushedslag cannot be adjusted, meanwhile, the crushed slag cannot be screened, and the manufacturing effect of a subsequent light partition plate is influenced can be solved.

Owner:张汀仁

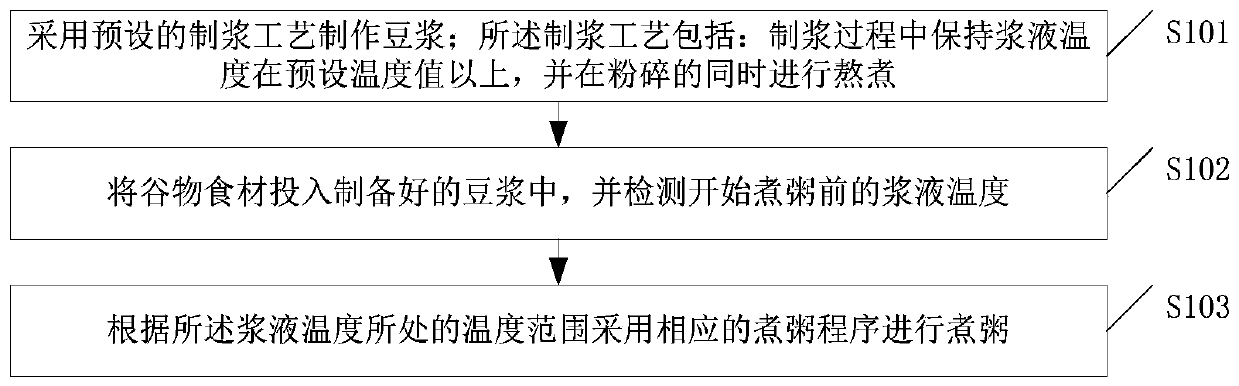

Method for preparing soybean milk porridge

InactiveCN110463768AContinuous operationShorten the timeMilk substitutesFood scienceSlurryCooking process

The embodiment of the invention discloses a method for preparing soybean milk porridge, wherein the method comprises the steps: preparing soybean milk by a preset soybean milk preparing process, wherein the soybean milk preparing process comprises the steps of keeping the slurry temperature above the preset temperature value in the soybean milk preparing process, and cooking while crushing; putting cereal food into the prepared soybean milk, and detecting the slurry temperature before starting to cook porridge; and according to the temperature range of the slurry temperature, adopting a corresponding porridge cooking procedure to cook porridge. Through the method, soybean milk preparation and cooking of the soybean milk porridge are carried out successively by one food processing machine,continuous operation is carried out, the problem that other methods need two or more appliances is solved, and the time and resources are greatly saved; and moreover, the influence of the difference between high and low starting temperatures on the whole porridge cooking process is solved, so that the consistent porridge cooking effect and taste are ensured.

Owner:JOYOUNG CO LTD

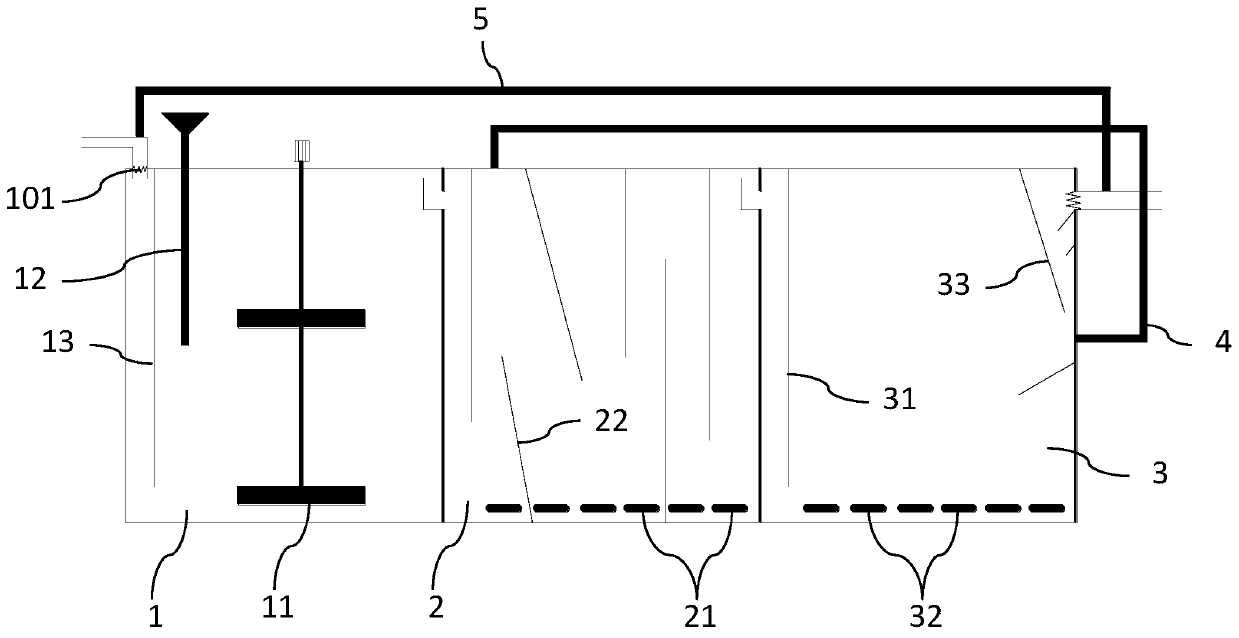

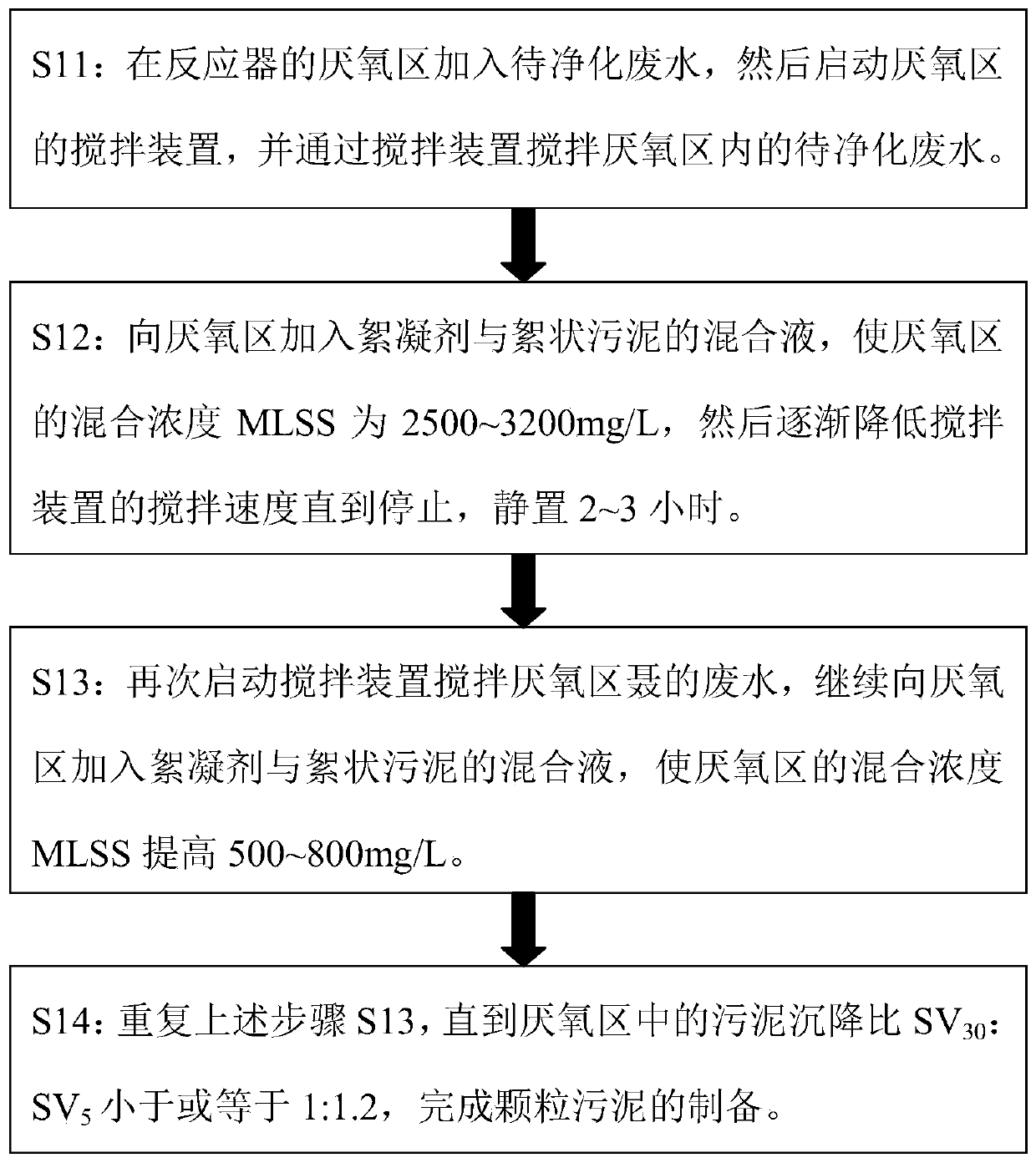

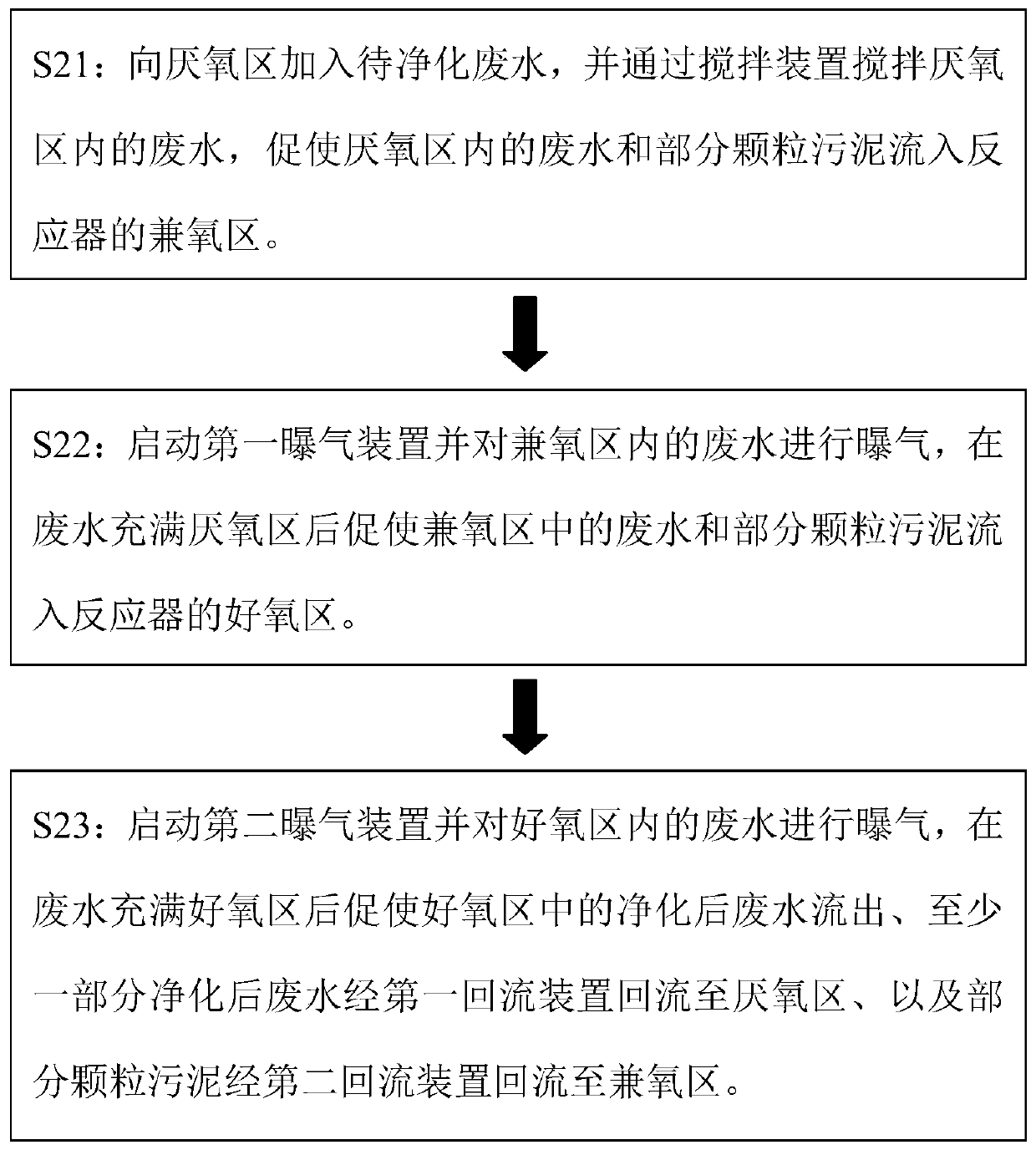

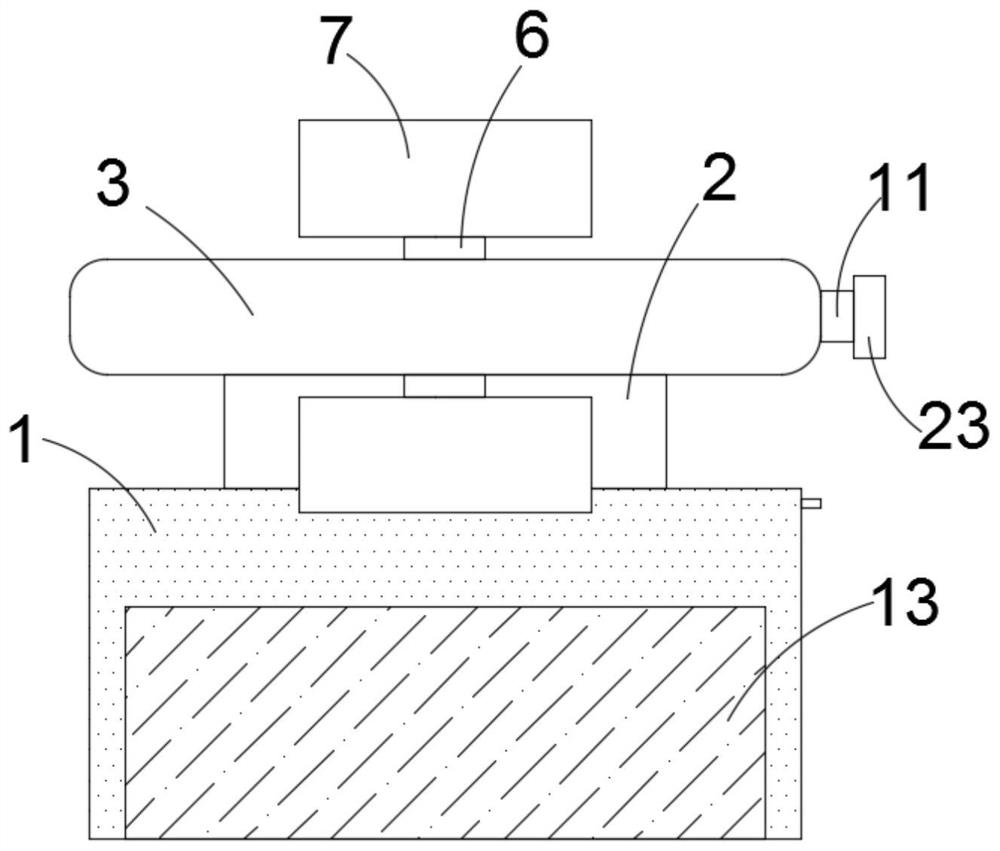

Granular sludge preparation method and reactor

ActiveCN110550737AGood flocculation effectGuaranteed preparation effectSpecific water treatment objectivesWater contaminantsFlocculationSludge

The invention provides a granular sludge preparation method and a reactor. The granular sludge preparation method comprises the steps that to-be-purified waste water is added into an anaerobic zone ofthe reactor, and the anaerobic zone is stirred through a stirring device; mixed liquid of a flocculating agent and flocculent sludge is added into the anaerobic zone, thus the mixing concentration MLSS of the anaerobic zone is 2500-3200 mg / L, and the stirring speed of the stirring device is decreased gradually till the stirring device stops; in the mixed liquid of the flocculating agent and the flocculent sludge, the mass ratio of the flocculating agent to the flocculent sludge is (1:0.8) to (0.3:1); the anaerobic zone is stirred again through the stirring device, the mixed liquid of the flocculating agent and the flocculent sludge is added again, and thus the mixing concentration MLSS of the anaerobic zone is increased by 500-800 mg / L; and the previous step is repeated till the sludge settling ratio SV30:SV5 in the anaerobic zone is less than or equal to 1:1.2, and the granular sludge is prepared. According to the preparation method, by adding the mixed liquid of the flocculating agent and the flocculent sludge, the flocculation ability of the waste water can be reinforced, the sludge granulation process is accelerated, and the preparation forming efficiency is improved.

Owner:万创青绿(北京)环境科技有限公司 +2

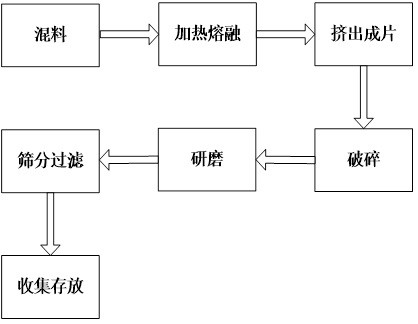

Mineral powder coating production and preparation process

ActiveCN112246403AAvoid inclusionsAvoid cloggingGas current separationPowdery paintsPowder coatingCeramic materials

The invention relates to a mineral powder coating production and preparation process. A bottom plate, supporting frames and a screening device are included, wherein the supporting frames are symmetrically installed at the upper end of the bottom plate, and the screening device is installed between the upper ends of the supporting frames. According to the process, the problem that the preparation effect of coatings is affected because the screening effect is poor, screening is uneven, and ultrafine powder particles in the powder coatings cannot be effectively removed when the powder coatings are screened through existing equipment, and the problem that the air environment is prone to being affected as the ultrafine powder particles in the airflow are prone to diffusing into the air becauseultrafine powder in airflow usually cannot be effectively collected or filtered when the powder coatings are processed through the existing equipment can be solved.

Owner:贵州贵毅宏祥环保材料有限公司

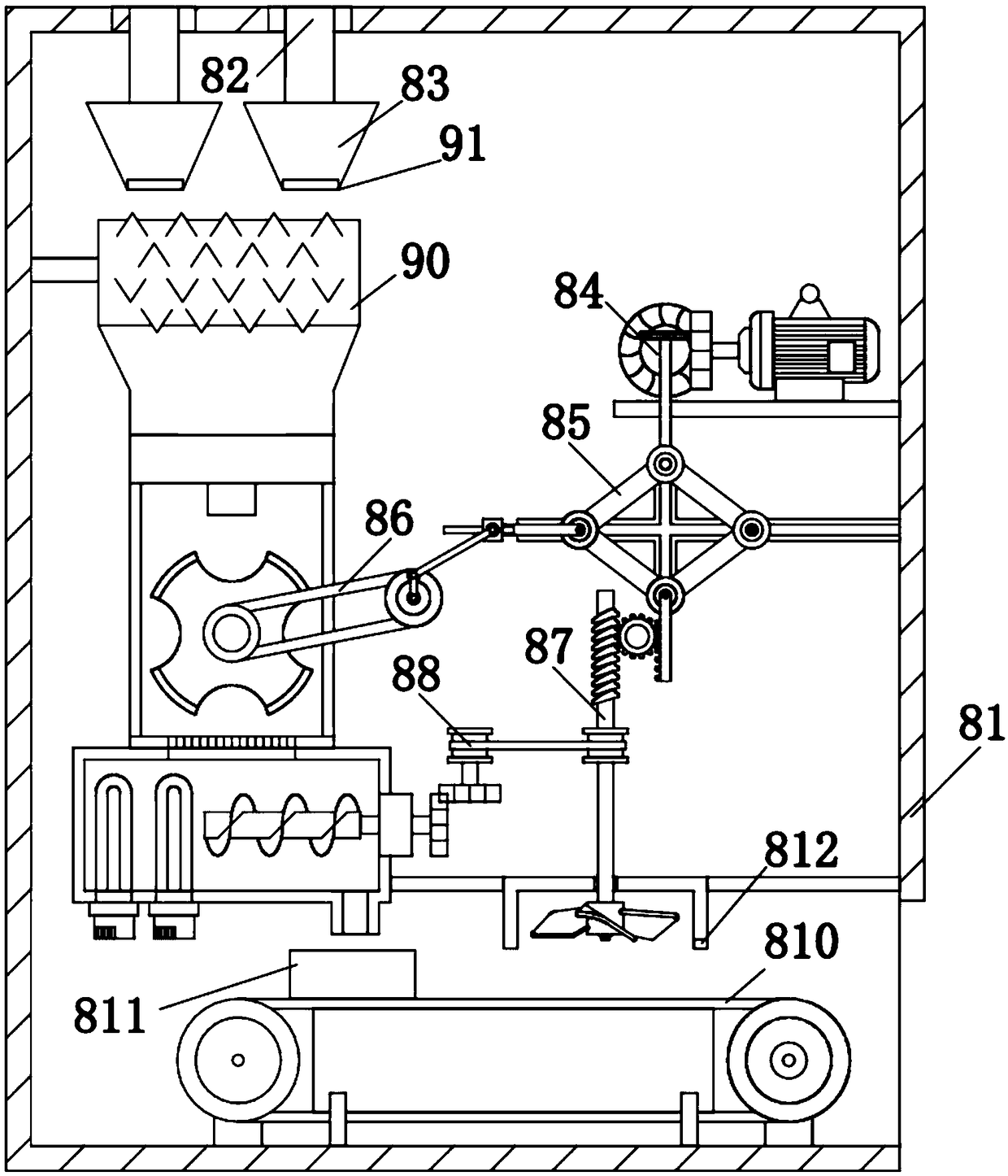

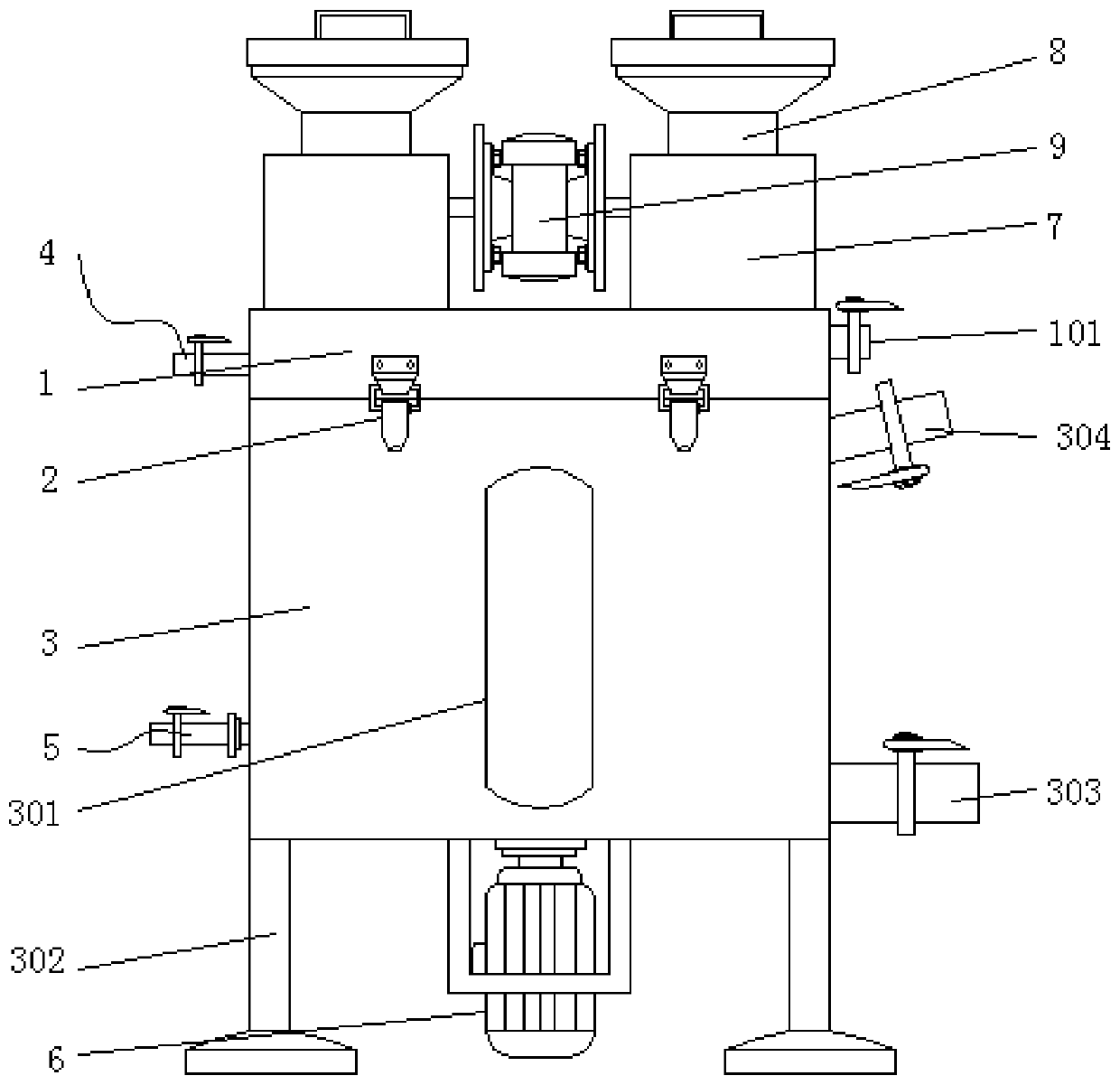

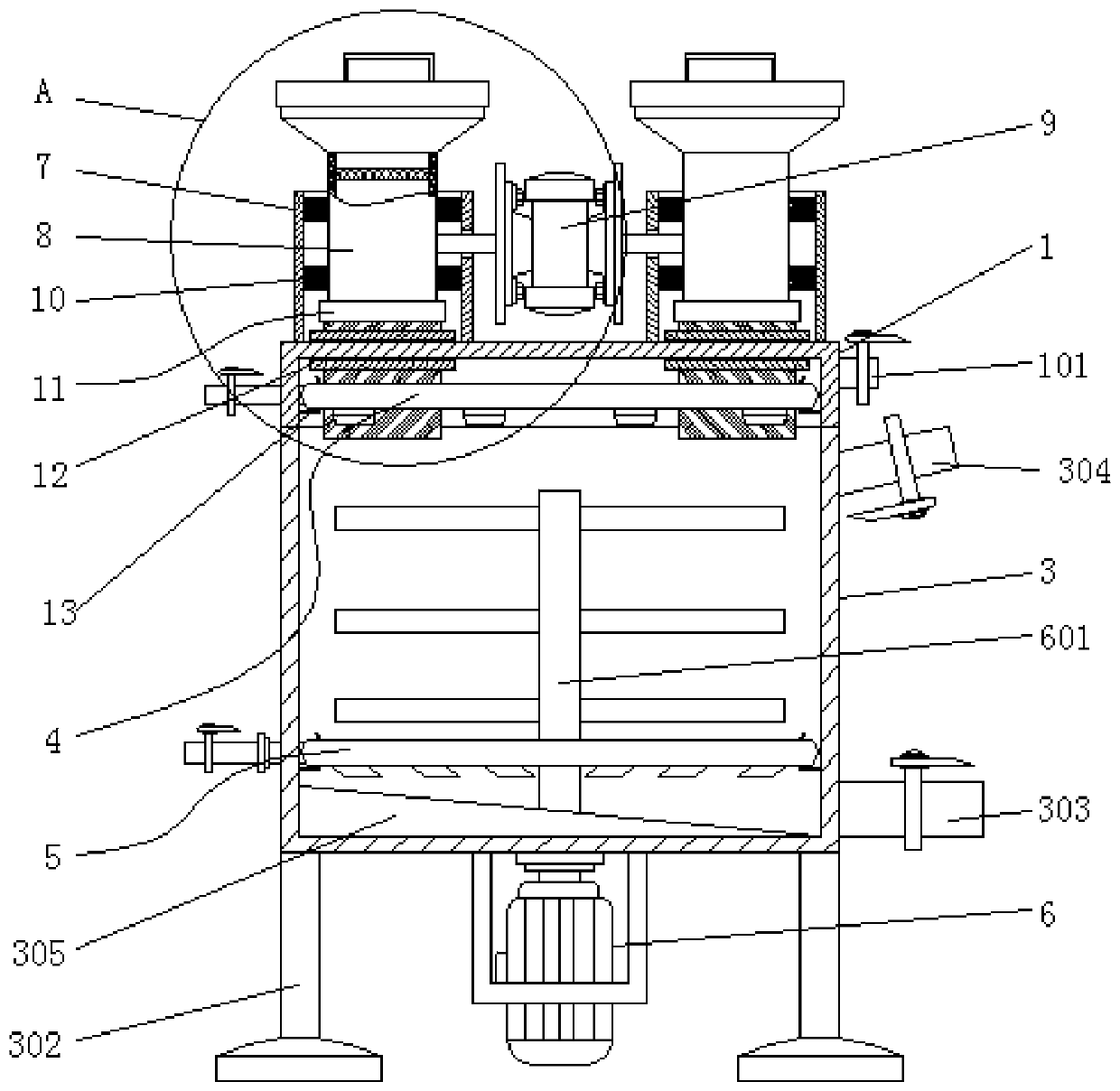

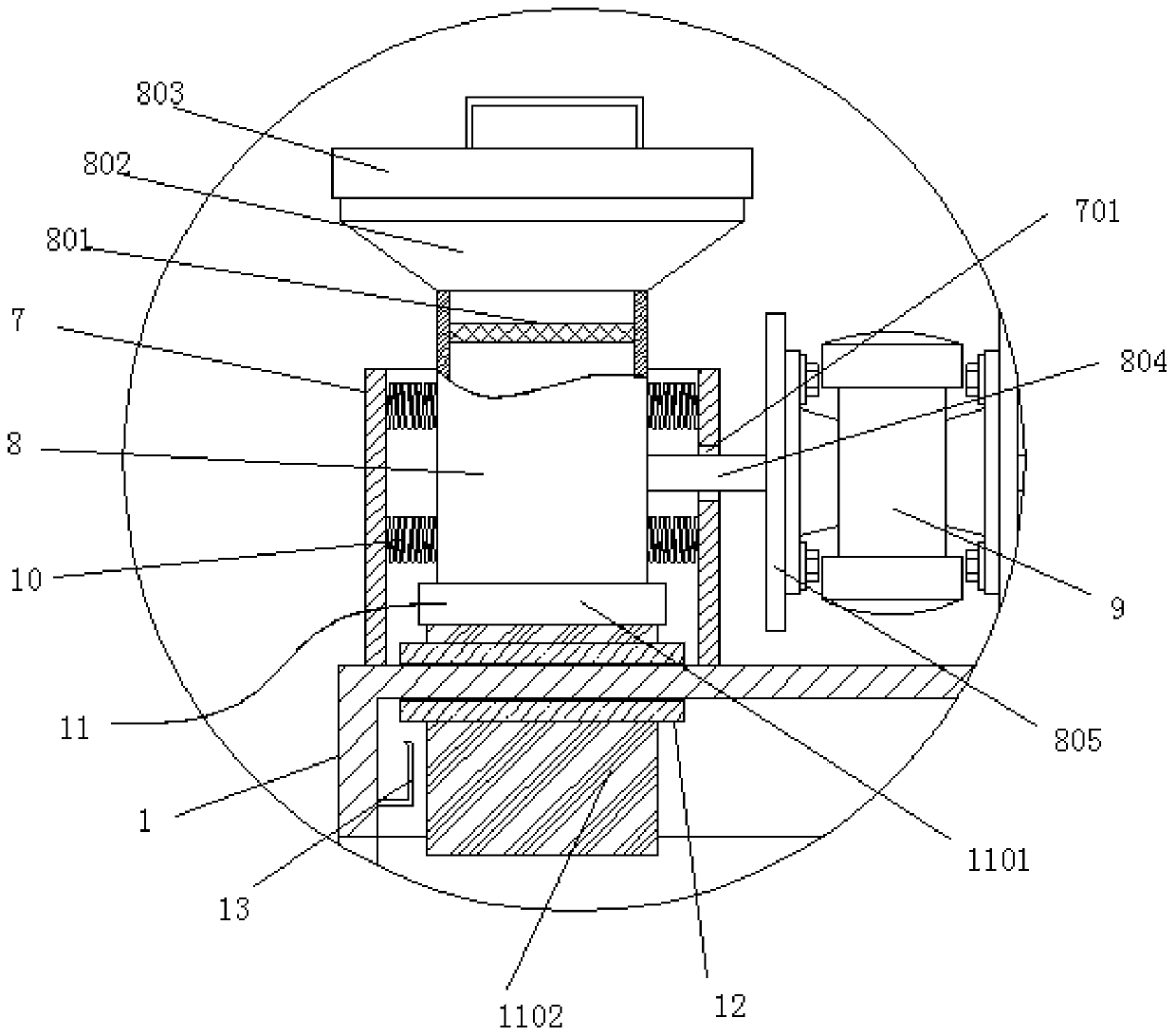

Traditional Chinese herbal medicine preparation device

InactiveCN108854806AControl injection weightGuaranteed preparation effectTransportation and packagingMixer accessoriesImpellerMedicine

The invention discloses a traditional Chinese herbal medicine preparation device. The preparation device is provided with a raw material box, an injection valve and a weight sensor, so that the injection weight of varieties of raw materials can be accurately controlled; the preparation device is provided with a smashing rotating shaft, a smashing motor and a smashing roller, so that the raw materials can be smashed; the raw materials which are not completely smashed can be filtered out by work of a screening mechanism, so that a preparation effect is ensured; the screened materials are stirredby a stirring fan blade, the stirred materials can fall into a medicine container from a discharging opening, and the stirred materials can be conveyed under a stirring impeller by a conveying belt after falling is finished; by means of an elongated electric telescopic rod, medicine can be secondarily stirred and mixed by the rotating stirring impeller; thus, a mixing effect is better.

Owner:利辛县众善医药科技有限公司

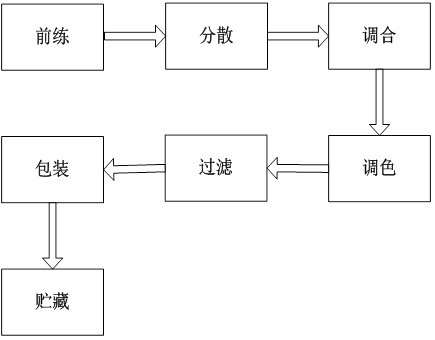

Paint preparation process and preparation device

ActiveCN110628328AGuaranteed preparation efficiencyImprove efficiencyTransportation and packagingMixersEngineeringSolvent

The invention relates to a paint preparation process, which comprises the steps of raw material preparation, solid grinding, raw material mixing and remaining material adding. The preparation device comprises a rack, and a grinding apparatus, a solid feeding assembly and a dispersing apparatus that are respectively mounted on the rack from top to bottom. The invention has the beneficial effects that: the solvent and solute are respectively filtered and crushed before mixing so as to improve the subsequent paint preparation efficiency and effect.

Owner:浙江富思丽涂料有限公司

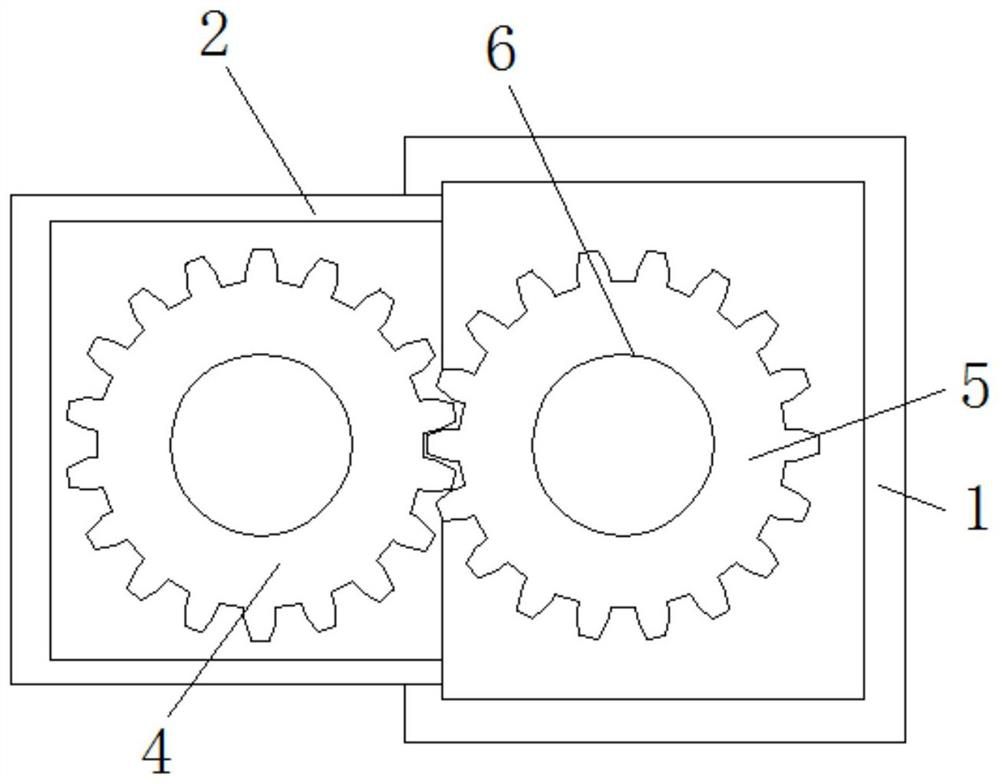

Automatic rotary type material extrusion forming device

ActiveCN110588231AAchieve extrusionVariety of extrusionOrnamental structuresSpecial ornamental structuresElectric machineryEngineering

The invention discloses an automatic rotary type material extrusion forming device. The device comprises a base and a controller, wherein the base is provided with a first electric extendable rod, thefirst electric extendable rod is provided with a transverse block, and one end of the transverse block towards the middle of the base is fixedly connected with one side of a vertical cylinder body with an opening downward; and the cylinder body is provided with a vertical rotating shaft, a first gear is arranged on the periphery of the upper portion of the rotating shaft, a first motor is fixedlyarranged on one side of the inner wall of the top of the cylinder body, and a second gear is fixed arranged on an output shaft of the first motor. According to the automatic rotary type material extrusion forming device, full-automatic operation is adopted to extrude the surface of a raw material to prepare a pattern, and a plurality of first balls are manufactured at the same time, so that the manufacturing effect is ensured, and meanwhile, the manufacturing cycle is shortened; and compared with traditional manual manufacturing, the full-automatic operation is adopted, the time and the laborare saved, the amount of each use is accurately calculated, the waste of the raw material or the difference existing in two articles with the same pattern caused by subjective consciousness of a producer cannot occur, requirements of people on the private customization can be met, and the cost can be effectively reduced.

Owner:BOHAI UNIV

Preparation method of apatite resin sheet for external detector method

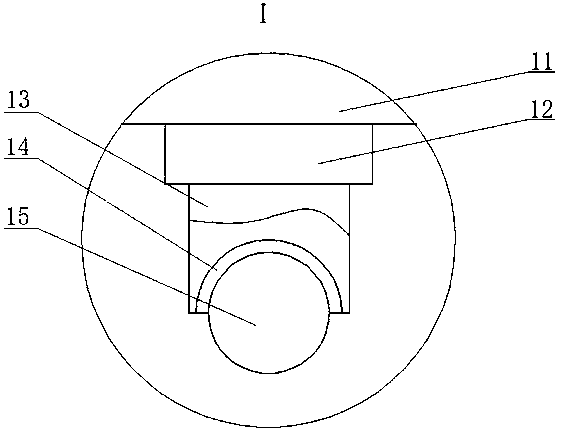

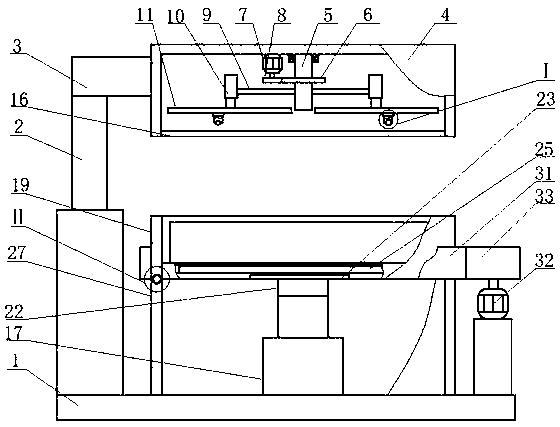

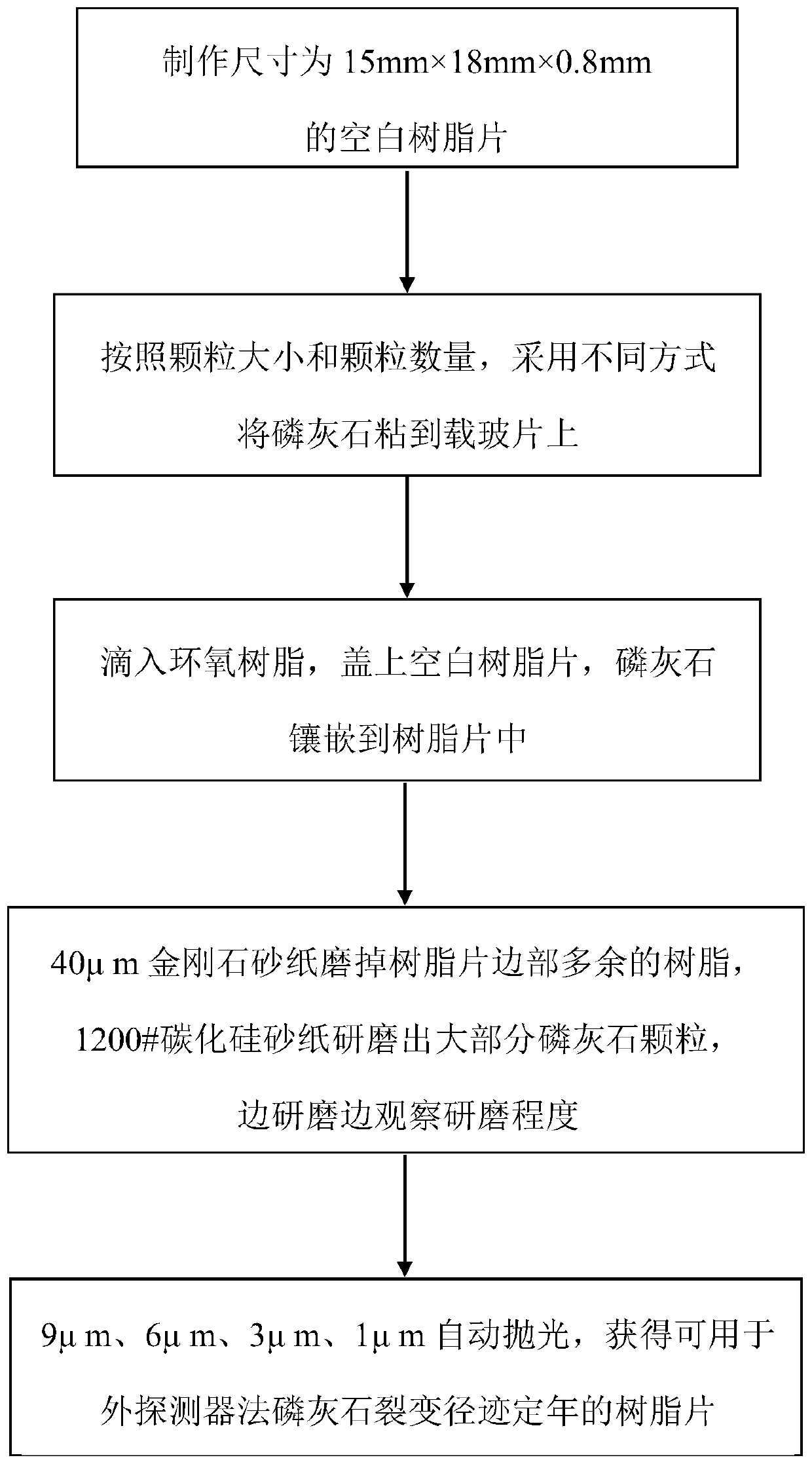

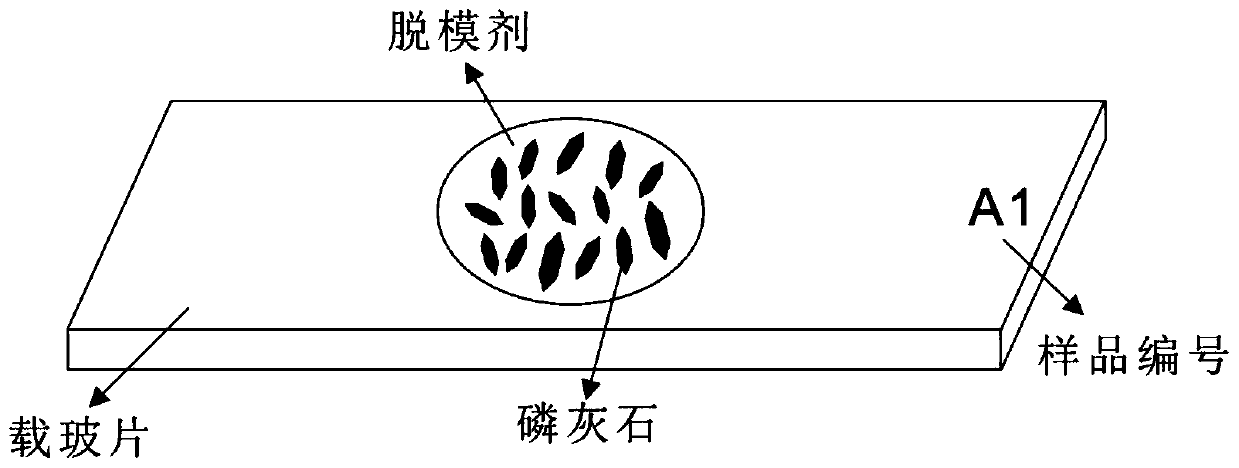

PendingCN110553897AGuaranteed preparation effectHigh precisionPreparing sample for investigationParticle numberFission track dating

The invention provides a preparation method of an apatite resin sheet for an external detector method. The preparation method mainly comprises the following steps: preparing a blank resin sheet with the size of 15mm*18mm*0.8 mm; according to the particle size and the particle number, bonding apatite to a glass slide in different modes; dropwise adding epoxy resin, covering with the blank resin sheet, and embedding the apatite into the resin sheet; grinding off redundant resin at the edge part of the resin sheet by using 40-micron diamond abrasive paper; grinding out most apatite particles by using 1200 # silicon carbide abrasive paper, and observing the grinding degree while grinding; and performing automatic polishing with cloth having sizes of 9 [mu]m, 6 [mu]m, 3 [mu]m and 1 [mu]m to finally obtain the resin sheet which can be used for apatite fission track dating by an external detector method. Compared with the existing preparation method, the preparation method provided by the invention can ensure the preparation effect of the apatite fission track dating resin sheet, and effectively improves the precision of the fission track method.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

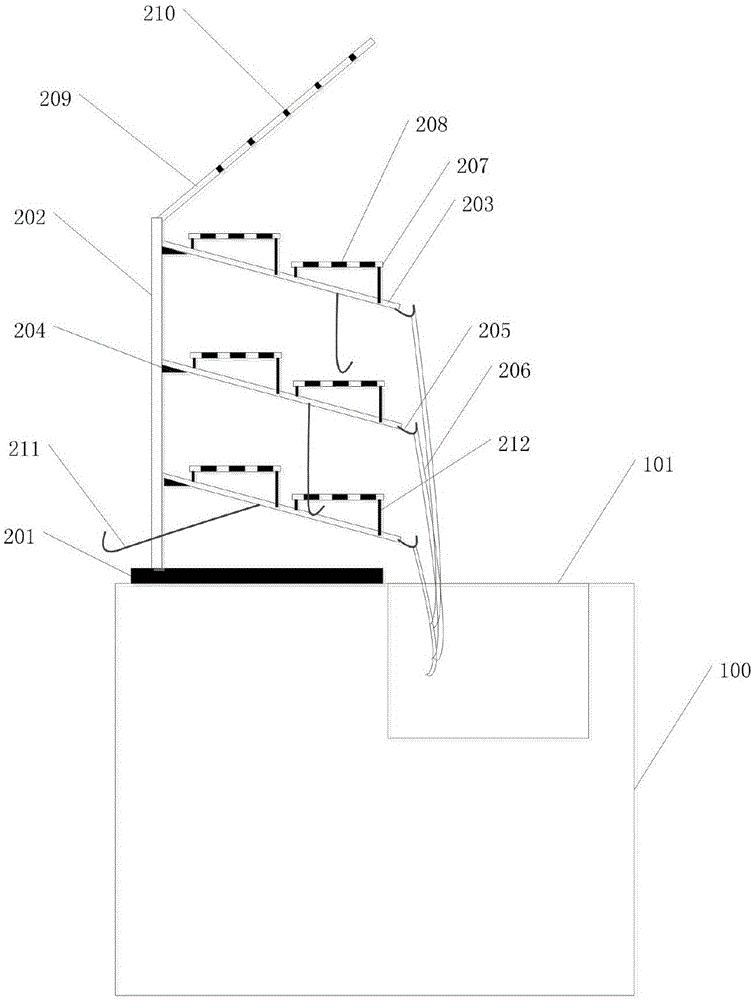

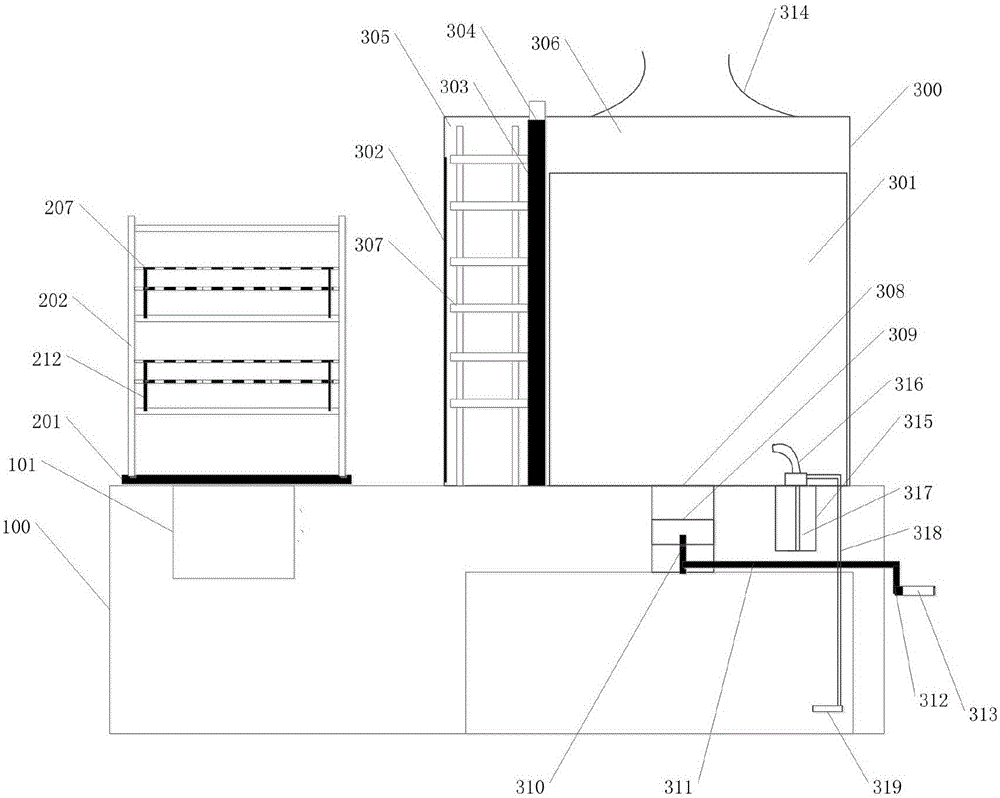

Combined biologic experiment table

InactiveCN106345556AEasy to placeFacilitate layer-by-layer placementLaboratory benches/tablesEngineeringWorkbench

The invention discloses a combined biologic experiment table which comprises a vessel loading frame and an ultraclean workbench, wherein the vessel loading frame is arranged on one side of a water pool of the experiment table and is used for airing the cleaned test tubes and culture dishes; the ultraclean workbench is arranged on one side of the water pool of the experiment table; the ultraclean workbench is used for performing the experiment operations, including manufacturing for a culture dish flat plate or a test tube slope, strain separation and purification, animal and plant tissue culture, and the like. The combined biologic experiment table can assist an experimenter in more efficiently finishing the early cleaning of the culture dishes or the test tubes and the later experiment operations, including manufacturing for a culture dish flat plate or a test tube slope, strain separation and purification, animal and plant tissue culture, and the like. The structure is compact but not limited; the experiment table space is reasonably utilized; the experimenter can more conveniently and safely operate.

Owner:HEBEI UNIV OF ENG

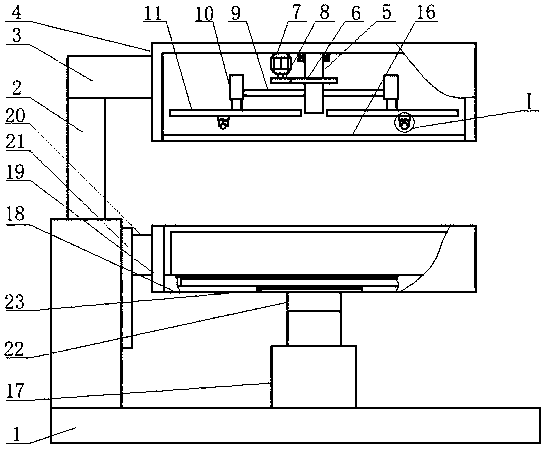

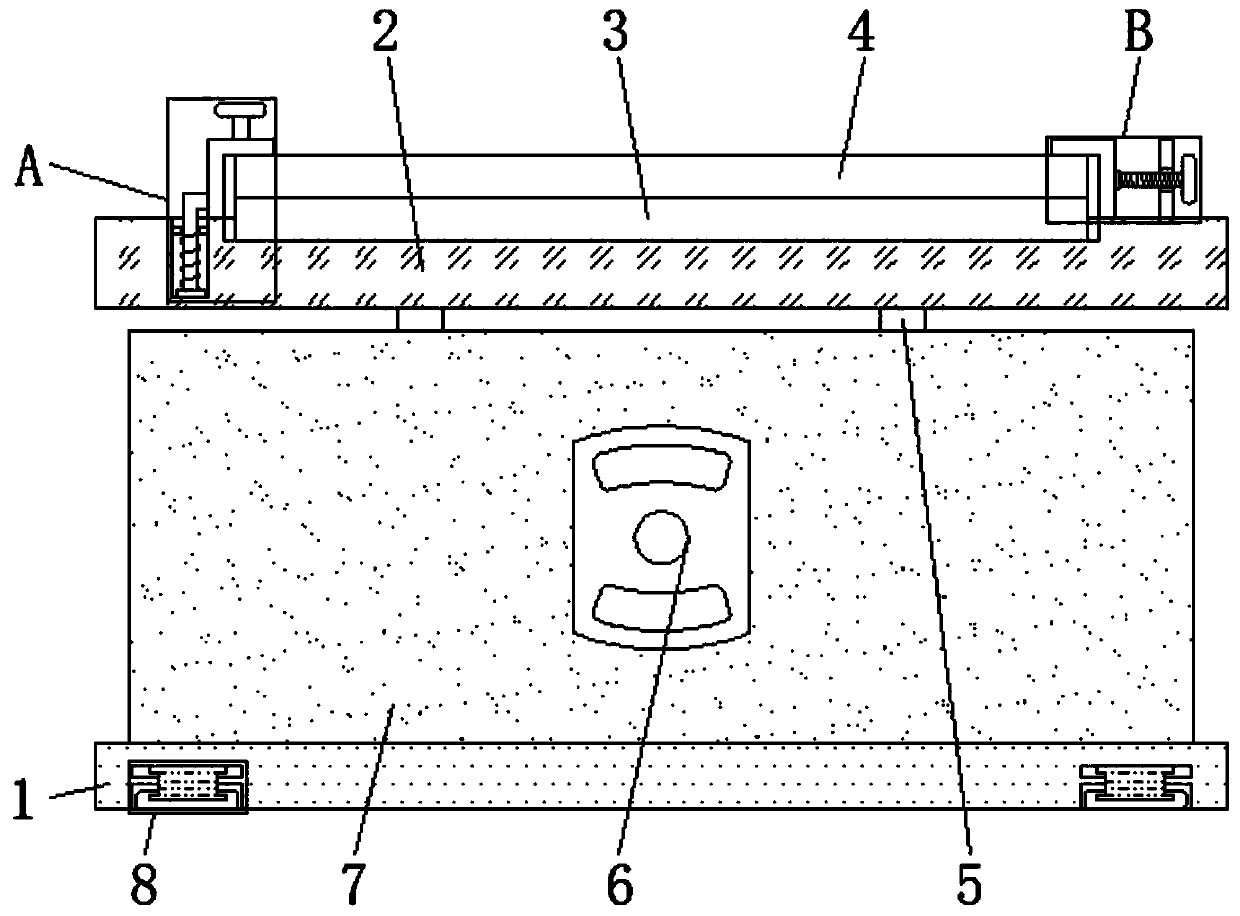

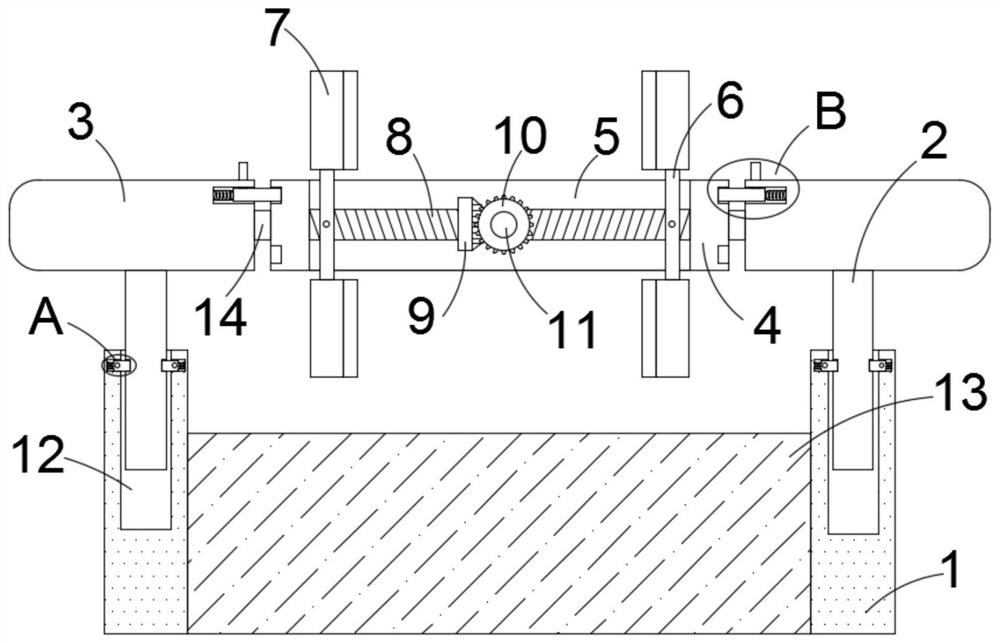

Smear manufacturing device for medical examination

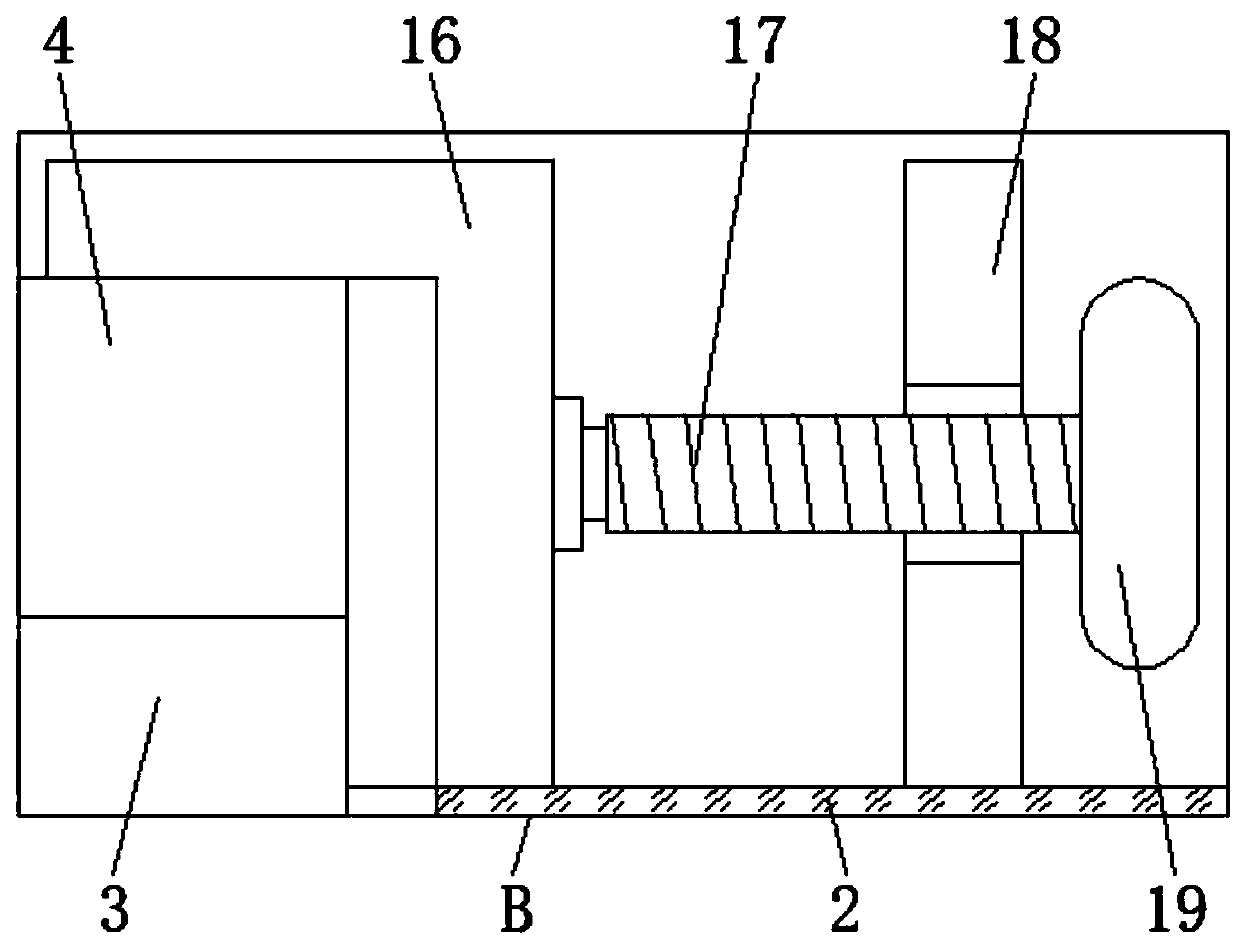

InactiveCN110864951AGuaranteed preparation effectImprove stabilityPreparing sample for investigationScrew threadThreaded rod

The invention discloses a smear manufacturing device for medical examination. The device comprises a base, an inspection table, a lower slide, an upper slide and a lifting cavity, the lifting cavity is fixed to the center of the top end of the base, the inspection table is arranged above the lifting cavity, the lower slide is placed in the center of the top of the inspection table, the upper slideis placed at the top end of the lower slide, and a positioning plate is fixed at the top end of the inspection table on one side of the upper slide; and a second clamping seat is arranged above the inspection table on the side, close to the positioning plate, of the upper slide, a threaded rod is in threaded connection with the outer wall of the side, away from the second clamping seat, of the positioning plate, one end of the threaded rod extends out of the positioning plate and is hinged to the outer wall of the second clamping seat, and a rotary handle is fixed to the end, away from the second clamping seat, of the threaded rod. The manufacturing effect of the manufacturing device in use is ensured, the stability of the manufacturing device in use is improved, and the convenience of the manufacturing device in use is improved.

Owner:张素华

Dyeing assistant proportioning device for textile printing and dyeing

InactiveCN110947321APrevent backflowAvoid clumpingRotary stirring mixersTransportation and packagingTextile printerElectric machinery

The invention discloses a dyeing assistant proportioning device for textile printing and dyeing. The device comprises a proportioning cylinder cover, the lower part of the proportioning cylinder coveris fixedly connected to a proportioning cylinder body through an industrial hasp, two discharging outer pipes are symmetrically distributed on a cover body on the top end surface of the proportioningcylinder cover, the interior of the discharging outer pipe is fixedly connected to a discharging inner pipe through a vibration spring, during use, powdery raw materials are added to a storage hopperon the discharging inner pipe, a vibration motor is matched with the vibration spring so that left-right vibration of the discharging inner pipe in the transverse direction is achieved, uniform discharge of powdery raw materials can be realized through a discharging screen plate, caked raw materials in the powdery raw materials can be screened out through vibration screening of the discharging screen plate, the interior of the device can be rapidly washed in an all-around mode through a spraying cleaning assembly, external hot air is conveyed to the bottom in the device through a hot air drying assembly, and drying operation on the interior of the device is achieved.

Owner:王灼义

Method for manufacturing dental full-crown prosthesis with optimized material elasticity modulus distribution

ActiveCN112932707AReduce undesirable stress distributionEasy to observeArtificial teeth3D printingFinite element analysis softwareProsthesis

The invention discloses a method for manufacturing a dental full-crown prosthesis with optimized material elastic modulus distribution, which comprises the following steps of: A, constructing a model: after the tooth of a patient is prepared, scanning in the mouth to obtain digital impression data, according to related anatomical sizes, constructing a three-dimensional model with a tooth preparation body and 4-8 layers of layered full-crown prostheses for jaw teeth and occlusion relations; b, further importing the layered full-crown prosthesis and tooth preparation model into finite element analysis software, setting corresponding parameters, and optimizing and establishing elastic modulus distribution of 4-8 layers of full-crown models; c, according to the elasticity modulus distribution data, obtained through optimization, of the 4-8-layer full-crown model, preparing the dental full-crown prosthesis with individualized and optimized elasticity modulus distribution by 3D printing. The service life of the full-crown restoration can be effectively prolonged, clinical complications such as ceramic cracking and fracture are reduced, and the elasticity modulus distribution of the full-crown restoration is simpler than that of a full-layer gradual-change functionally graded material in the aspect of manufacturing.

Owner:赵克

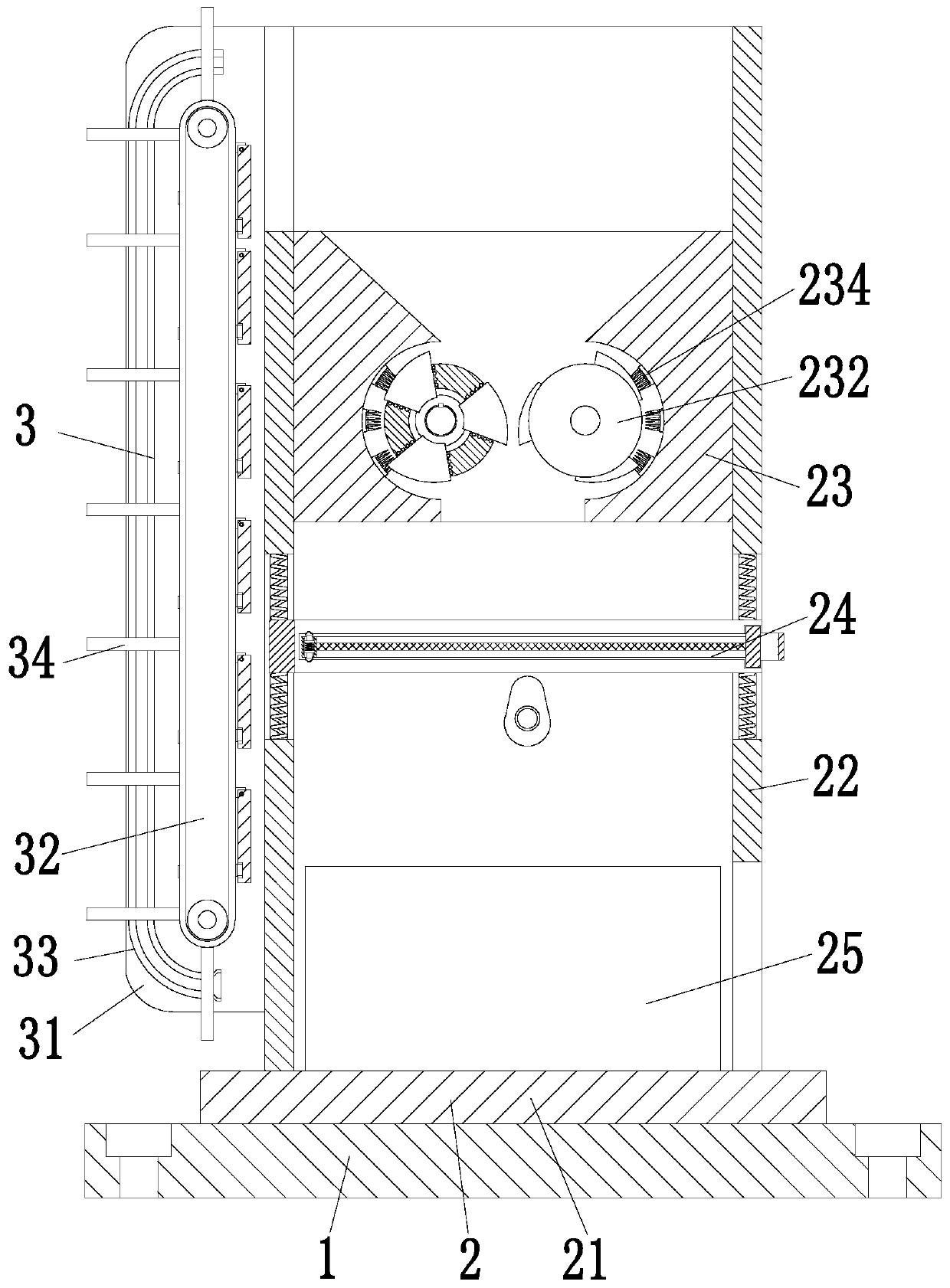

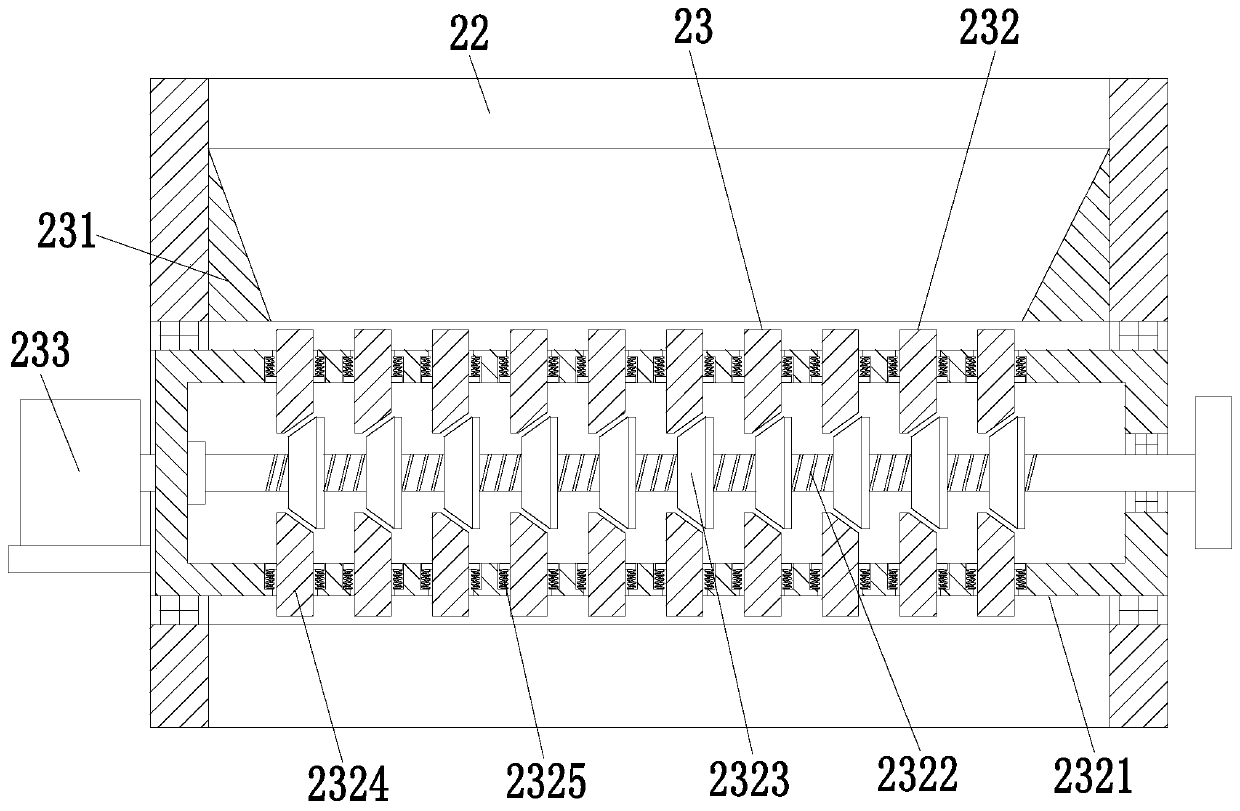

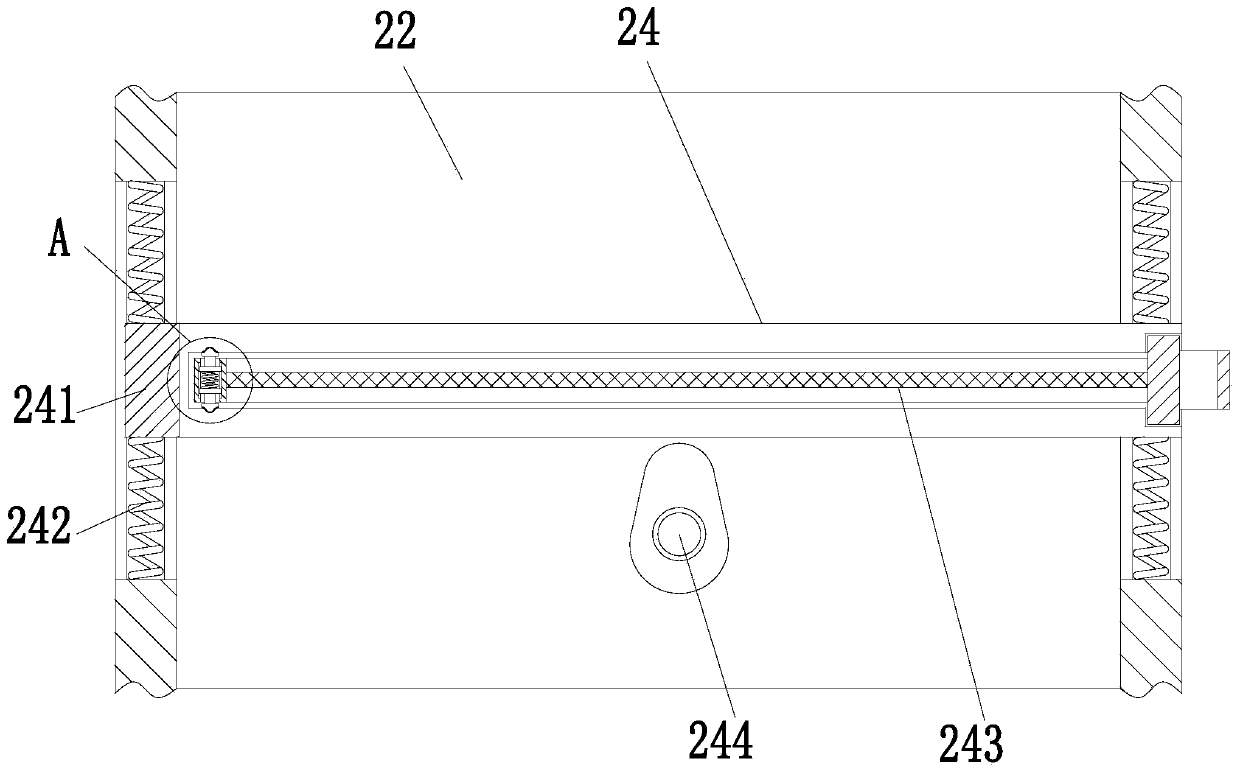

A kind of asphalt concrete production and processing equipment

ActiveCN111472235BEasy to cleanAffect the use effectRoads maintainenceArchitectural engineeringCrushed stone

The invention relates to an asphalt concrete production and processing equipment, comprising a base plate, a stirring device and a feeding device. The base plate is uniformly provided with installation holes, the upper middle part of the base plate is equipped with a stirring device, and the upper end of the stirring device is provided with a through groove. A feeding device is installed inside. The present invention can solve the problem that the existing equipment cannot effectively screen gravel materials when preparing and processing asphalt concrete, which leads to the fact that large crushed stones are easily mixed in the finished material after mixing, which affects the subsequent processing of the finished material use, and when the existing equipment is preparing and processing asphalt concrete, gravel usually easily blocks the mesh of the screen, and the screen cannot be cleaned in time, resulting in low filtration efficiency of the screen and affecting the preparation efficiency of asphalt concrete. Wait for the problem.

Owner:浦江县沥青拌和有限公司

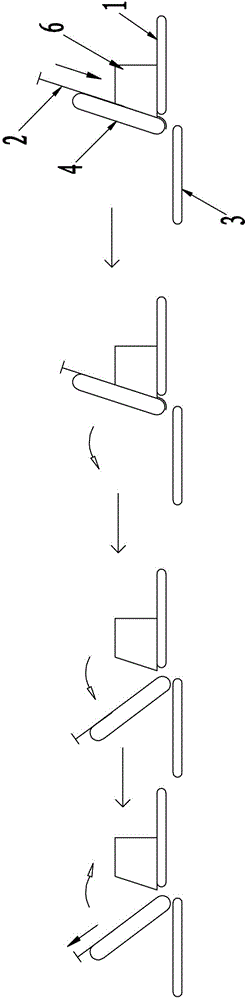

Method for distributing ceramic tiles and brick transferring mechanism applied to method

ActiveCN104526866AGuaranteed preparation effectImprove product qualityDischarging arrangementFeeding arrangmentsBrickEngineering

The invention provides a method for distributing ceramic tiles. The method comprises the steps that firstly, surface materials are scattered on a conveying belt to form a surface material pile, and then a plurality of layers of strip materials are added on the surface material pile; when the surface material pile runs to the cutting station, one side, in the running advancing direction, of the surface material pile is attached to a transferring conveying belt, wherein, at least one groove for forming a brick with the required cutting thickness is formed in the surface of the transferring conveying belt at an interval, and the grooves are attached to the surface material pile so as to enable the groove to be filled with the surface materials with the required cutting thickness; in the cutting process, a cutter unit for cutting the surface material pile carries out cutting in the direction attached to the surface of the transferring conveying belt; and after the cutting motion is completed, the cutting unit swings to the discharging station along with the transferring conveying belt, and the cut brick surface materials in the grooves are conveyed to the next station through a plane conveying belt to be pressed and formed. According to the scheme, the cutting effect of the surface materials of the brick can be ensured, and it can be ensured that the cut and formed brick surface materials are discharged in the certain suitable angle direction.

Owner:清远市升华建陶有限公司

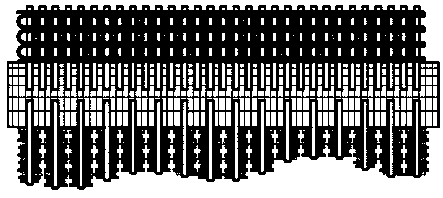

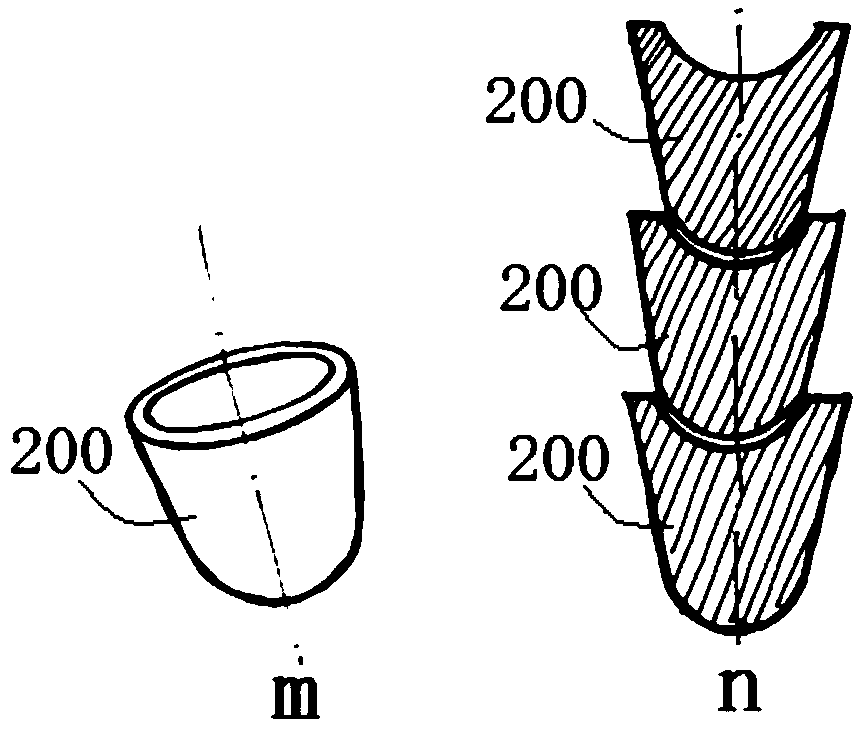

Composite forming method of multifunctional integrated composite material

ActiveCN110588013AAvoid multiple connectionsImprove performanceAdditive manufacturing apparatus3D object support structuresEngineeringFunctional requirement

The invention relates to a composite forming method of a multifunctional integrated composite material. The composite forming method is characterized in that a plurality of functional areas and corresponding transition areas are obtained by partitioning according to different functional requirements of parts; the transition areas are manufactured by adopting a 3D printing or a flexible guide three-dimensional weaving forming process according to the shape requirements of the functional areas, and the transition areas with adjacent functional area guide template information on two sides are obtained; Z-direction reinforcement arrays of the adjacent functional areas are respectively formed on two sides of the transition areas; all functional areas are woven and formed, and a multifunctionalintegrated composite material prefabricated body is obtained; and single matrix material or multiple matrix materials are synchronously impregnated and cured, so that composite forming of the multifunctional integrated composite material is achieved. According to the composite forming method, different quantities and varieties of the reinforcing bodies, the matrix materials and the appropriate forming processes are adopted for the different functional areas to carry out synchronous weaving forming; and meanwhile, the preformed transition areas can isolate the two functional areas on the two sides, the various matrix materials can be simultaneously impregnated, and on the basis of achieving the integral forming of the multifunctional integrated composite material, the respective forming quality, functionality and performance characteristics of the different functional areas are effectively guaranteed.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Preparation process of nano thermal insulation coating

InactiveCN111607328AImprove insulation effectStrong insulationFireproof paintsAntimony oxides/hydroxides/oxyacidsThermal insulationPhysical chemistry

The invention discloses a preparation process of a nano thermal insulation coating. The method comprises the following steps: preparation of nano antimony pentoxide: adding 14-15 parts of antimonous oxide and 19-20 parts of deionized water into a stirring reaction kettle to be stirred, so that the antimonous oxide and the deionized water are fully mixed into a slurry; then heating the slurry to raise the temperature to 90-95 DEG C, after the heating is finished, adding inlet water into the kettle and stirring for 5 to 7 minutes; slowly dropwise adding 11-12 parts of hydrogen peroxide into a mixture after stirring; after hydrogen peroxide is added completely, continuing to stir for 2-4 minutes to fully mix a slurry with hydrogen peroxide; after mixing, heating and refluxing an obtained mixture for 43 to 48 minutes to prepare a white thick paste, slightly cooling the white thick paste, filtering the white thick paste to remove aggregates or block particles in the white thick paste, and drying the obtained white thick paste in an oven at 80-90 DEG C to obtain the nano antimony pentoxide.

Owner:JIANGSU BAOPING ANTI THEFT TECH CO LTD

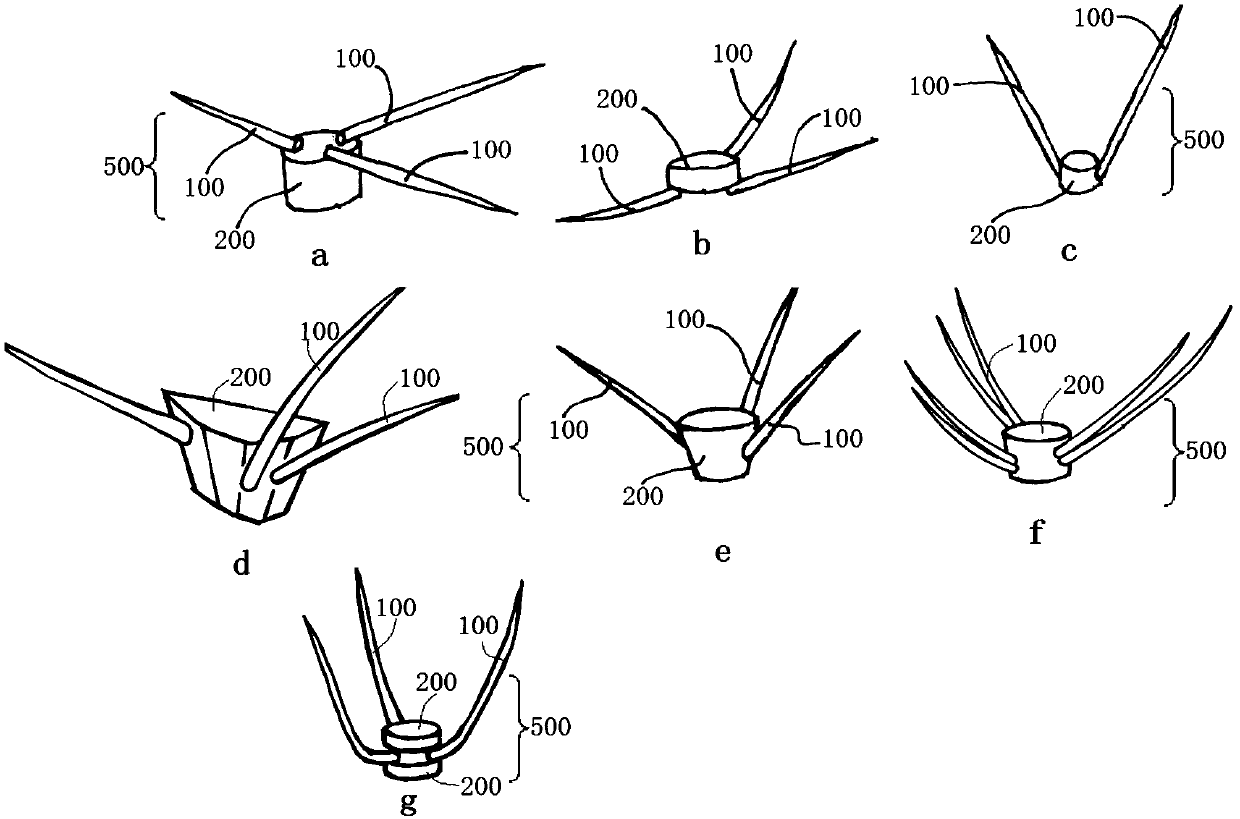

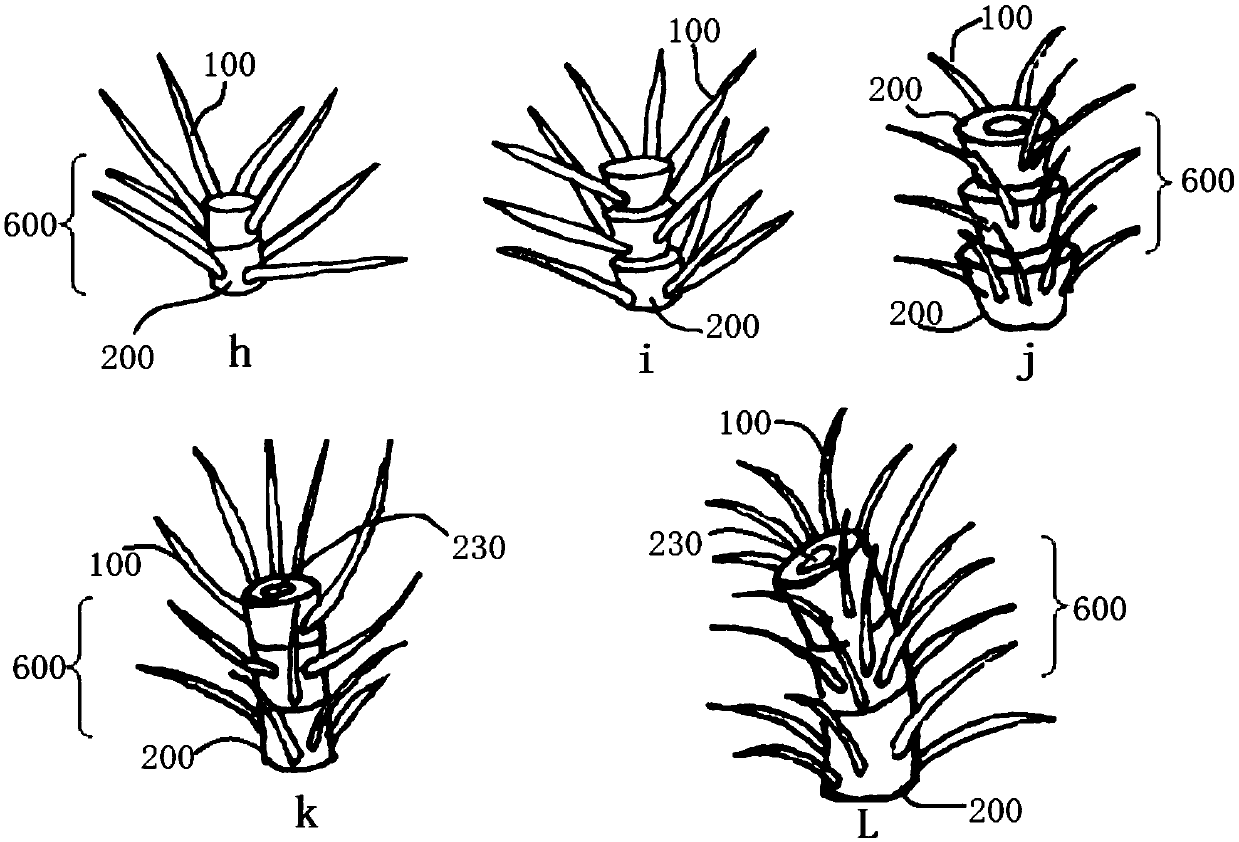

Pine needle component, artware comprising pine needle component and manufacturing technology of pine needle component

PendingCN109677186AReduce technical difficultyLower skill requirementsArtificial flowers and garlandsSpecial ornamental structuresState of artManufacturing technology

The invention discloses a pine needle component, artware comprising the pine needle component and a manufacturing technology of the pine needle component, and belongs to the field of artware manufacturing. The pine needle component comprises pine needles and pine needle seats; the bottom ends of the pine needles are fixedly arranged on the pine needle seats; each pine needle seat and the pine needles arranged on the pine needle seat form one pine needle assembly; and the multiple pine needle assemblies are connected sequentially through contact of the pine needle seats to form the pine needlecomponent. By the aid of the pine needle component, the artware and the manufacturing technology, the defects that the manufacturing difficulty of iron picture artware is large and mechanical production cannot be realized in the prior art are overcome; and by the aid of the pine needle component, the pine needle structures of existing Guest-Greeting Pine iron picture artware are improved technically, and extremely-difficult artistic creation is changed into technical operations which can be completed by ordinary technicians.

Owner:芜湖江南工业设计有限公司

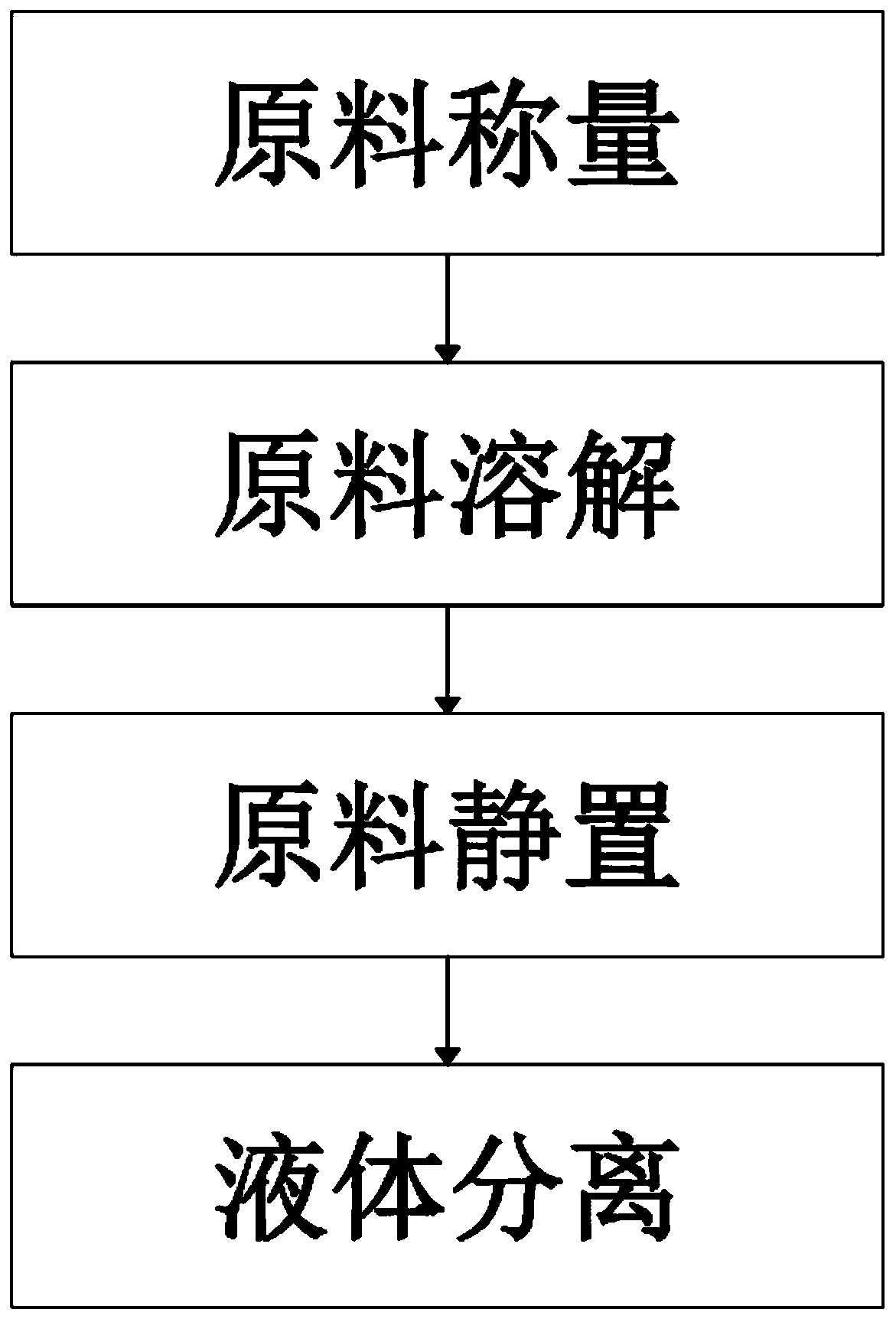

Preparation method and application of caustic soda

InactiveCN111170334AGuaranteed manufacturingIncrease concentrationCalcium/strontium/barium carbonatesAlkali metal oxides/hydroxidesCalcium hydroxideSalt water

The invention belongs to the technical field of sodium hydroxide preparation, and particularly relates to a preparation method and application of caustic soda. The preparation method and application of caustic soda comprise the following steps of: S1, weighing raw materials, S2, dissolving the raw materials, namely dissolving the refined edible salt in distilled water to prepare saturated edible salt water, adding ammonium bicarbonate to prepare fresh sodium bicarbonate when edible salt crystals are separated out from the bottom, filtering out sodium bicarbonate, and adding quick lime into water to generate fresh calcium hydroxide, S3, standing the raw materials, and S4, liquid separation. Calcium hydroxide and sodium bicarbonate are mixed to generate sodium hydroxide; while production andpreparation of sodium hydroxide are guaranteed, auxiliary products and ammonium chloride can be used for chemical fertilizer production and artificial stone preparation of calcium carbonate, and whenfreshness and deterioration prevention of the raw materials are guaranteed, the preparation concentration and the purity of sodium hydroxide are improved, residual impurities of other solutions are avoided, and the preparation effect is guaranteed.

Owner:苏州慧伯凯化工有限公司

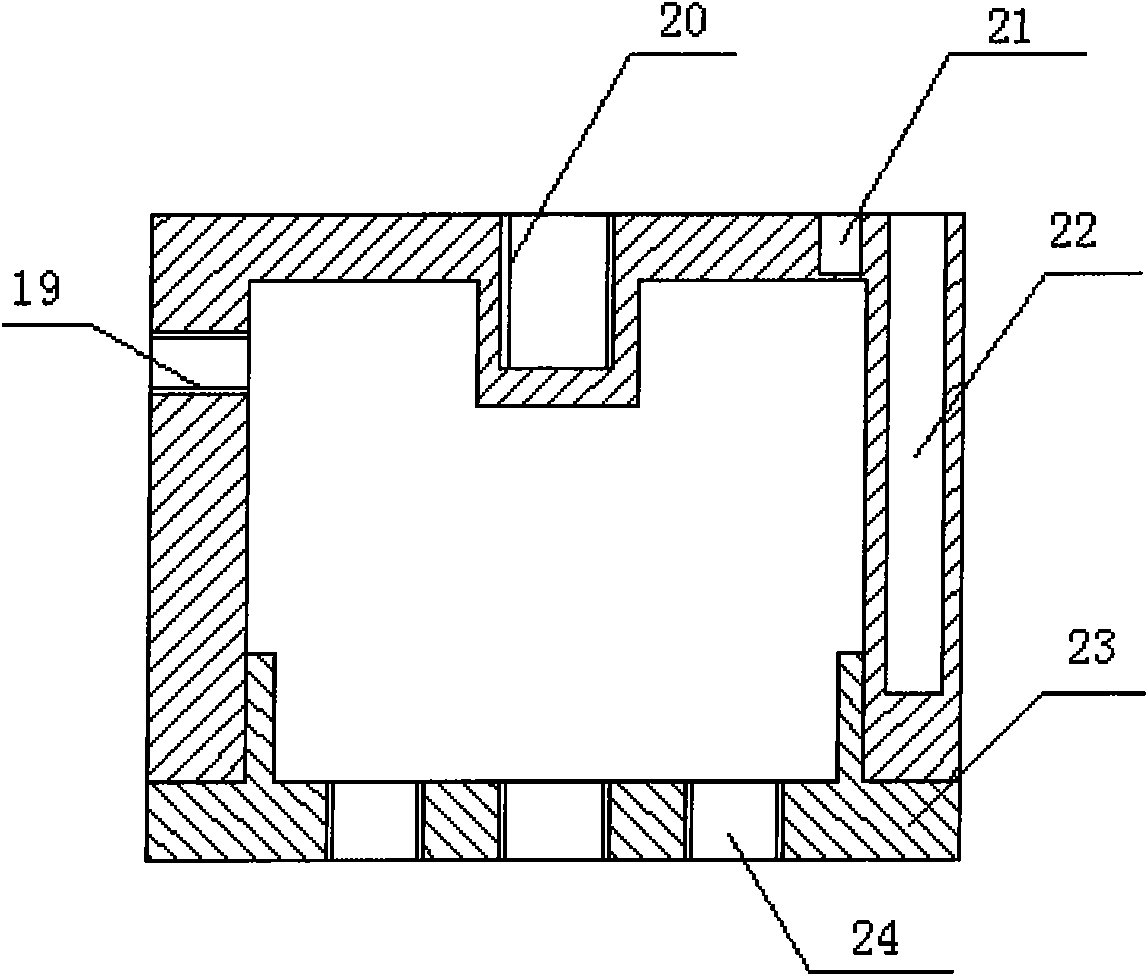

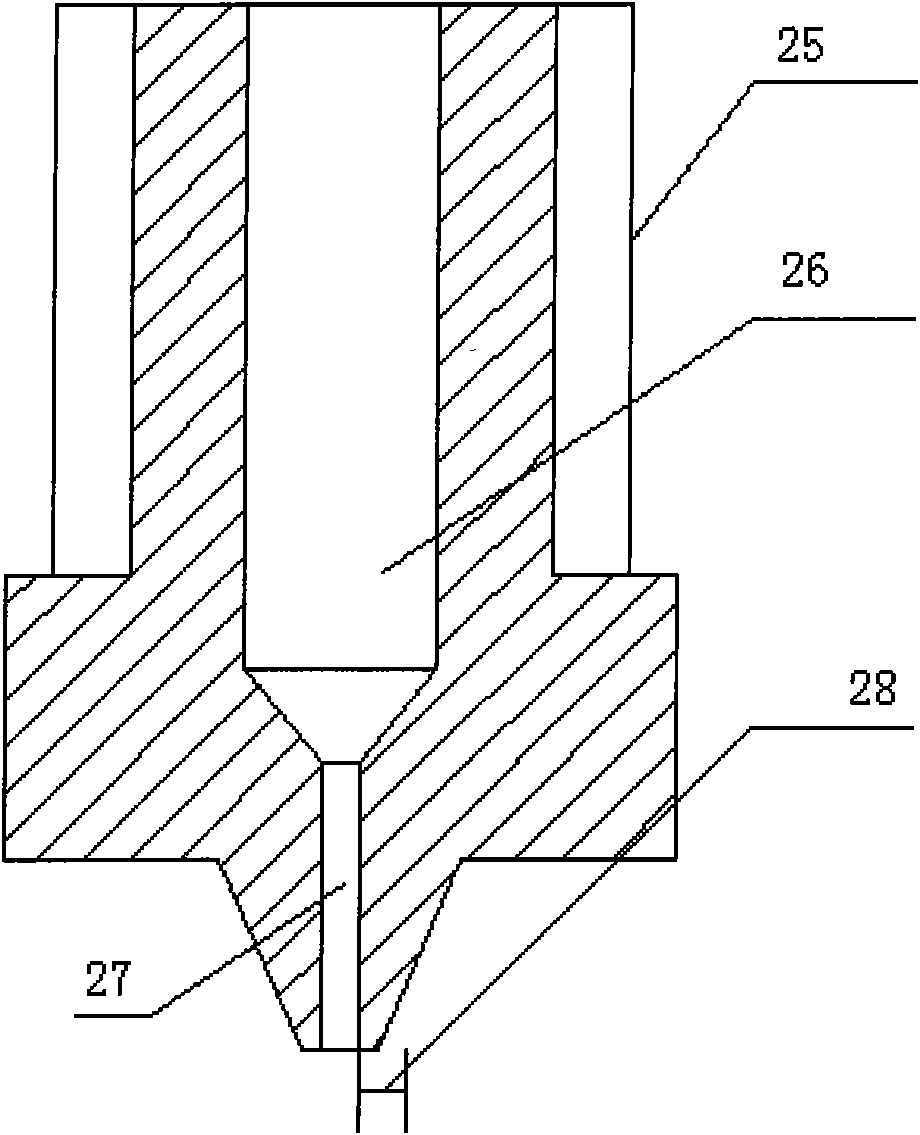

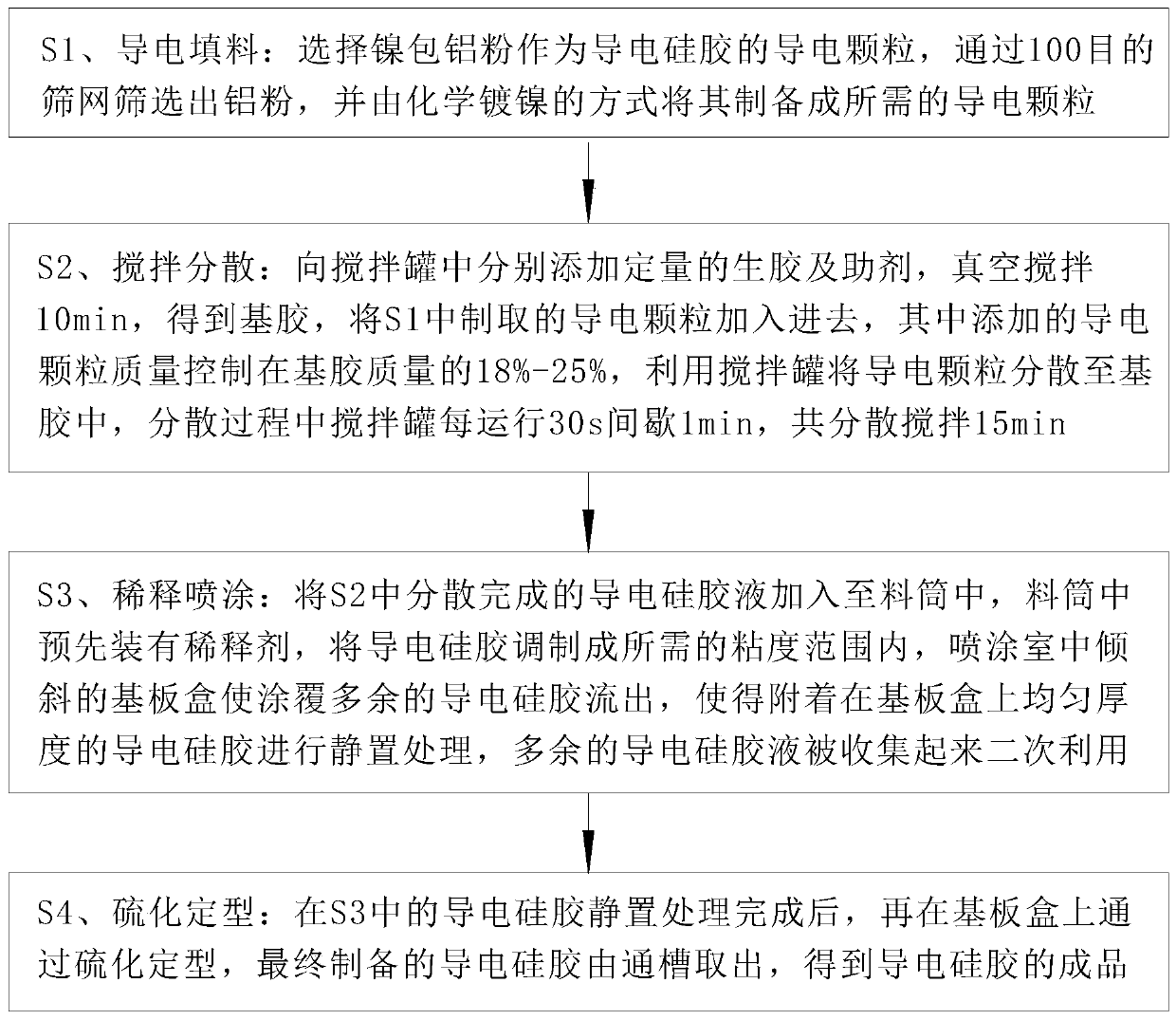

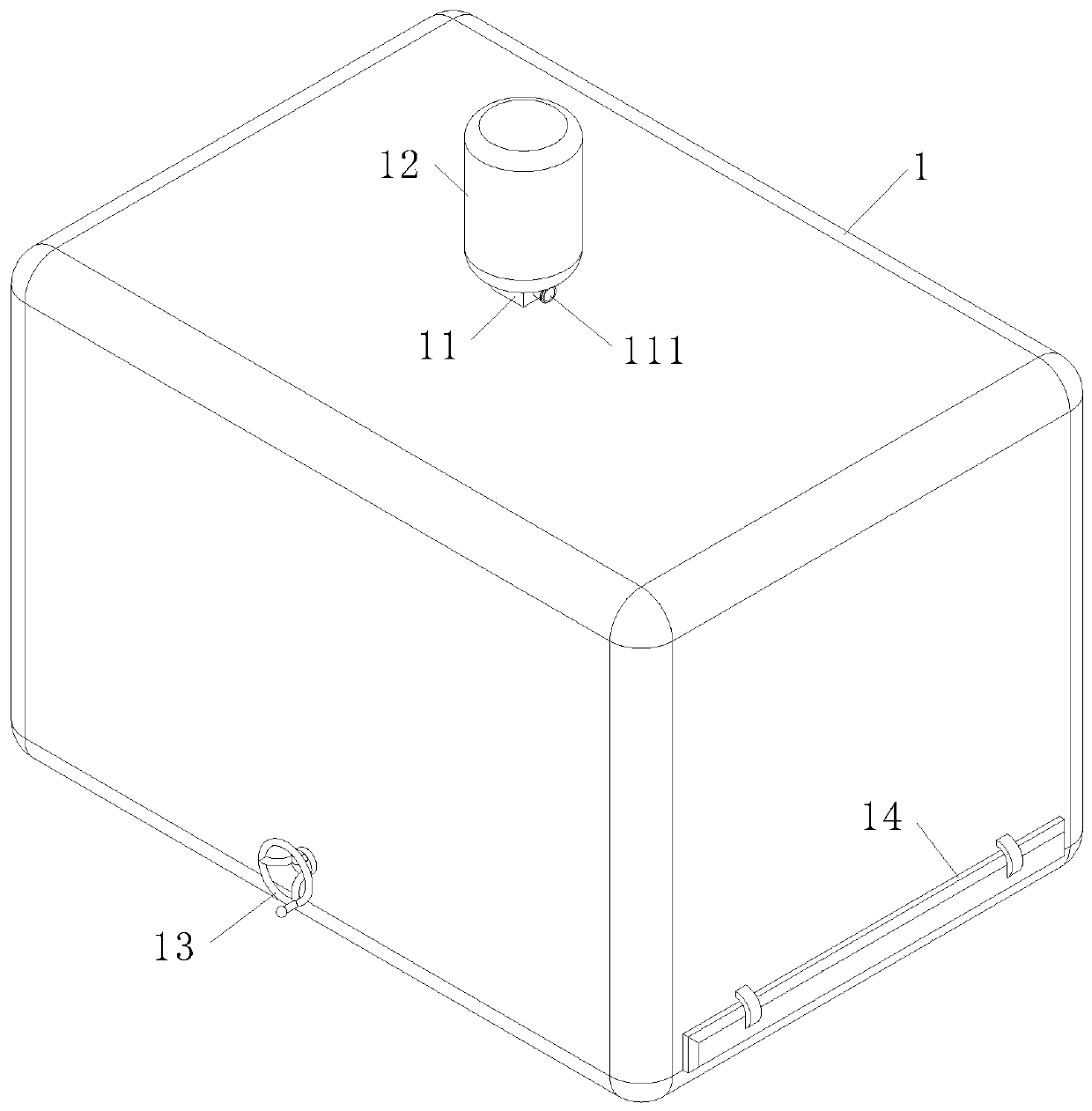

Preparation method of single-component vulcanized electric conduction silica gel

The invention relates to the technical field of electromagnetic shielding materials, in particular to a preparation method of single-component vulcanized electric conduction silica gel. The preparation method comprises the steps of electric conduction filling, stirring and dispersing, dilution spraying and vulcanization shaping. A spray chamber adopted in dilution spraying comprises a shell, a substrate case and a spray head. Struts are arranged below the substrate case and enable the substrate case to be inclined by an angle. Due to the fact that in the spray forming process, the uniform thickness of electric conduction silica gel liquid attached to the substrate case cannot be controlled, areas with insufficient standing forming and vulcanization degrees exist on electric conduction silica gel, stability of the overall performance of the electric conduction silica gel is destroyed, and the use effect of the electric conduction silica gel is reduced, the inclined substrate case is arranged in the spray chamber, a through groove at one end of the substrate case is used in cooperation, much electric conduction silica gel liquid sprayed to the substrate case flows out under the gravity action, then the uniform thickness of an electric conduction silica gel coating is kept, and therefore the preparation effect of the single-component vulcanized electric conduction silica gel is improved.

Owner:宿州迅驰电子科技有限公司

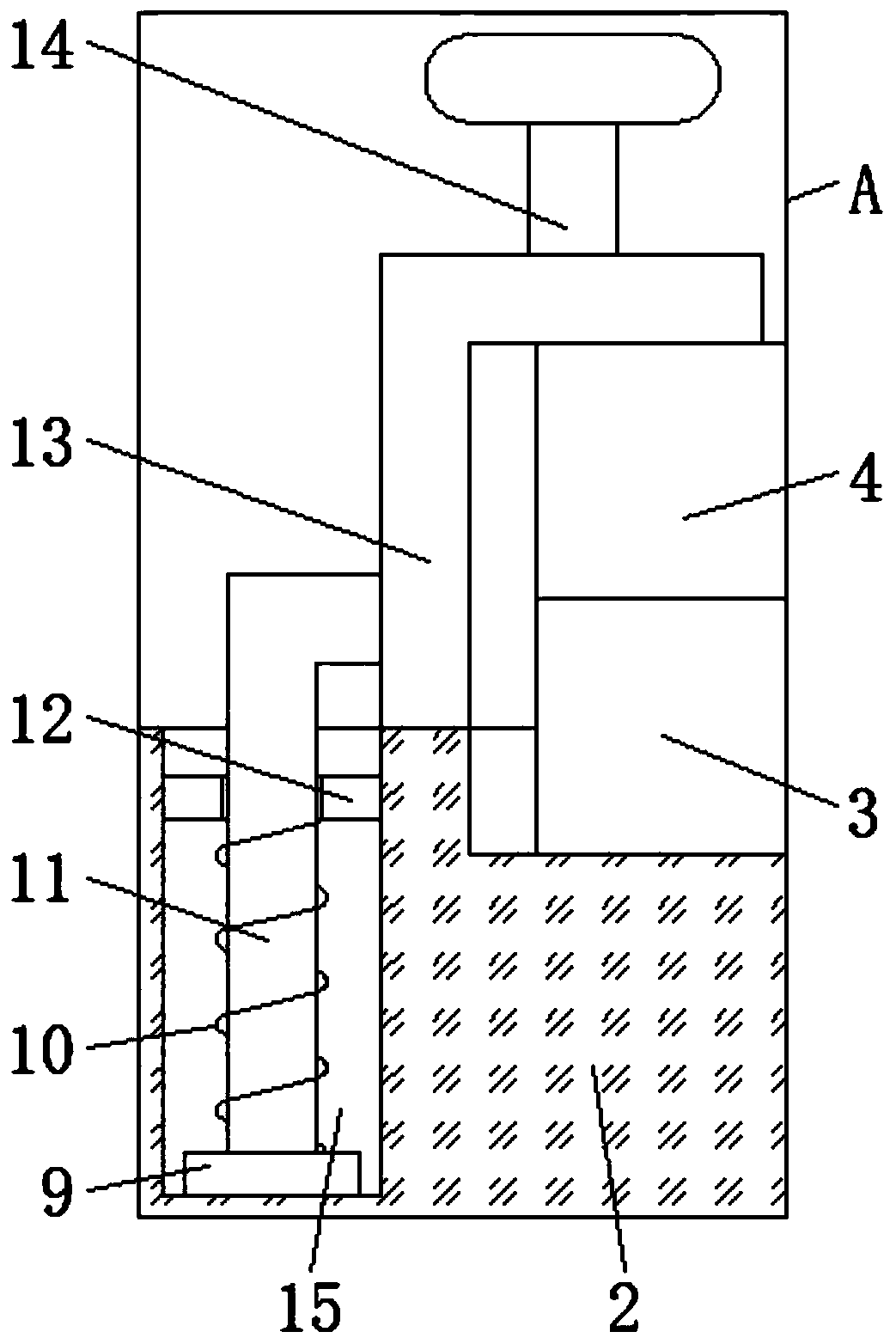

Design platform structure based on artistic design

InactiveCN114633578AEasy to controlRelease of controlHand artistic toolsWork holdersStructural engineeringMechanical engineering

The invention discloses a design platform structure based on artistic design, which comprises two bottom plates, telescopic plates are slidably arranged on the two bottom plates, telescopic grooves corresponding to the telescopic plates are formed in the two bottom plates, and limiting mechanisms corresponding to the telescopic plates are arranged in the two telescopic grooves. Top plates are fixedly arranged at the ends, away from the bottom plate, of the two telescopic plates, a rotating plate is rotationally arranged between the two top plates, the rotating plate is rotationally arranged on the two top plates through two rotating shafts, and an artwork clamping mechanism is arranged on the rotating plate. The height can be adjusted according to needs, adaptability is high, artworks can be rapidly clamped and fixed, creation of the artworks is facilitated, the design platform can be rapidly used for turning over, disintegrating slag on the platform is poured into a waste box, rapid cleaning and collecting of the disintegrating slag are achieved, and the working efficiency is improved. The situation that disintegrating slag is accumulated on the design platform to affect artwork manufacturing is avoided, and the artwork manufacturing effect is improved.

Owner:JIUJIANG UNIVERSITY

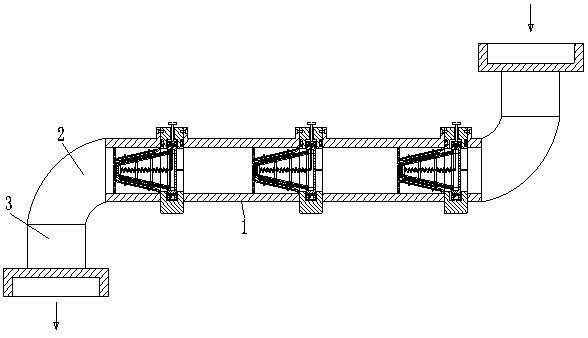

Paint coating production processing treatment method

ActiveCN111659172AGuaranteed preparation effectConvenience for subsequent useGravity filtersStationary filtering element filtersStructural engineeringMechanical engineering

The invention relates to a paint coating production processing treatment method. Equipment adopted by the method comprises a filtering device, connecting pipes and mounting flanges, the filtering device is of a cylindrical hollow structure, the connecting pipes are symmetrically mounted on the outer side of the filtering device, the mounting s are mounted on the outer sides of the connecting pipes, and the filtering device, the connecting pipes and the mounting flanges are arranged in a Z shape. The method can solve the problems that when existing equipment is used for filtering and processinga paint coating, the filtering effect is poor, the filtering is incomplete, large-particle impurities in the paint coating cannot be effectively filtered out and affect the preparation effect of thecoating, and when the paint coating is filtered and processed by the existing equipment, the mounting and dismounting effects of a filter screen are poor, the filter screen cannot be quickly replacedand cleaned, meanwhile, the surface of the filter screen cannot be cleaned, impurities are prone to blocking filter screen holes, and the using effect of the filter screen is affected.

Owner:湖南鑫湘钰新材料科技有限公司

Front suspension precoated sand mold

The invention belongs to the field of core shooting machine tooling, and relates to a front suspension precoated sand mold which comprises a concave mold, a convex mold and a pouring gate, wherein theconcave mold is combined with the convex mold; the two are superposed to form an overall square mold; the pouring gate is placed in a pouring gate cavity; mounting holes and tooling holes are arranged at four corners of the convex mold and the convex mold; the mounting holes of the two are correspondingly arranged; the concave mold and the convex mold are further provided with ejector pin holes and heating channels, wherein the ejector pin holes are arranged in a manner of penetrating fronts and backs, while the heating channels are arranged to penetrate upper ends and lower ends; a sand shooting channel is formed in the concave mold and leads to the outside to form a sand shooting opening. The front suspension precoated sand mold can reduce dosage of precoated sand through combination ofthe concave mold and the convex mold, can also ensure a good molding structure, can reduce the weight of the concave mold by an underlaying cavity designed in the back of the concave mold, can effectively improve product molding precision and efficiency, and ensures high quality and low rejection rate of products.

Owner:YUZHOU KUNLUN MOLD CO LTD

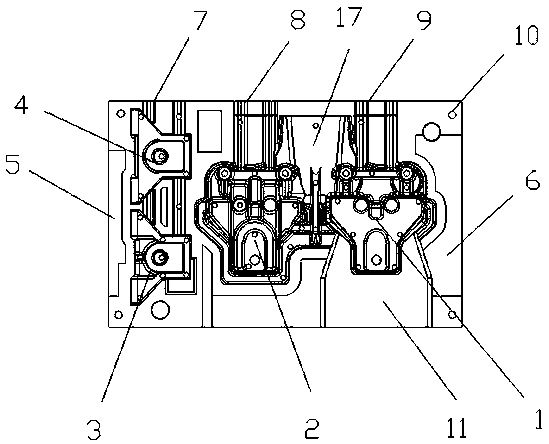

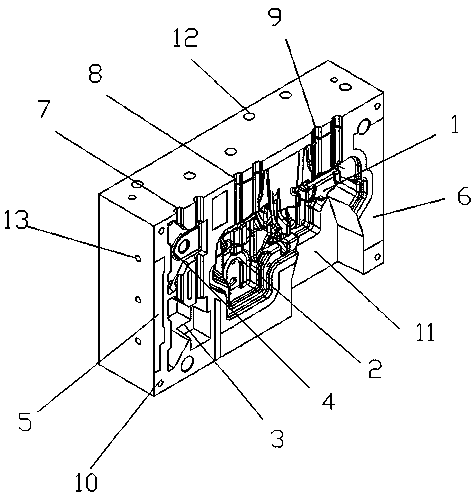

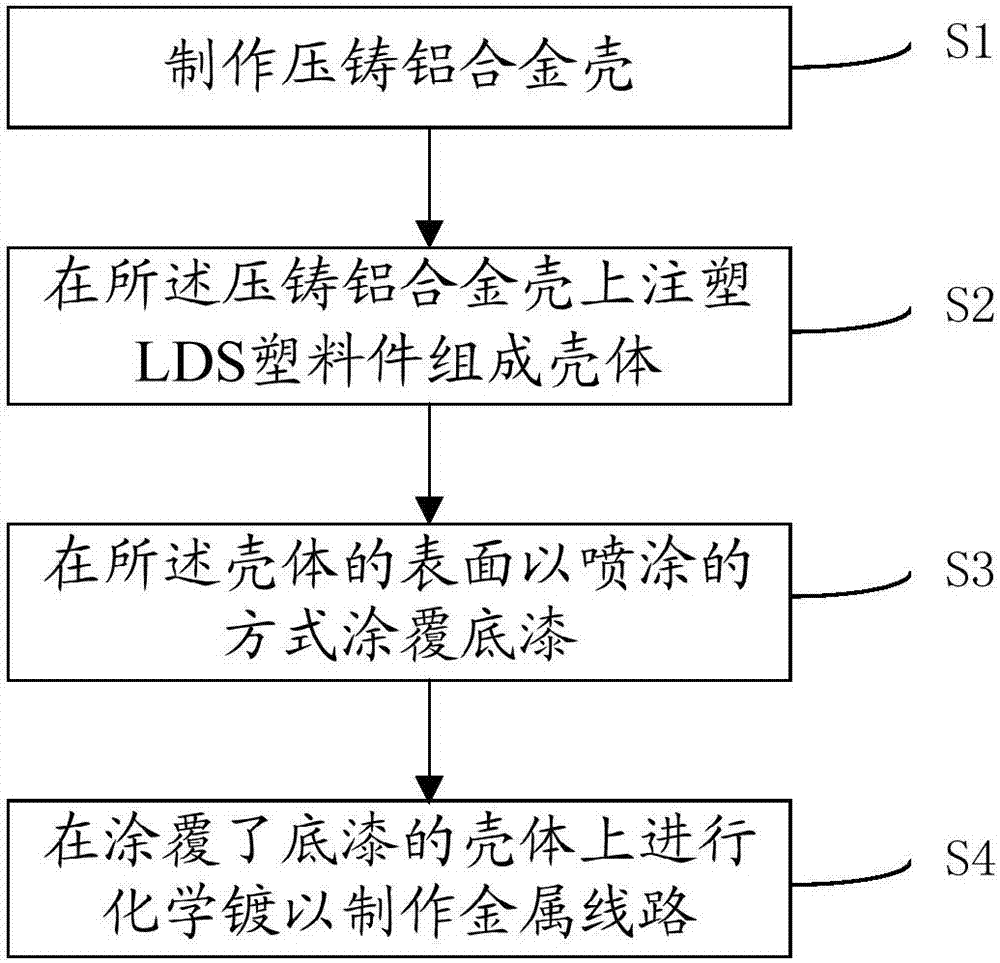

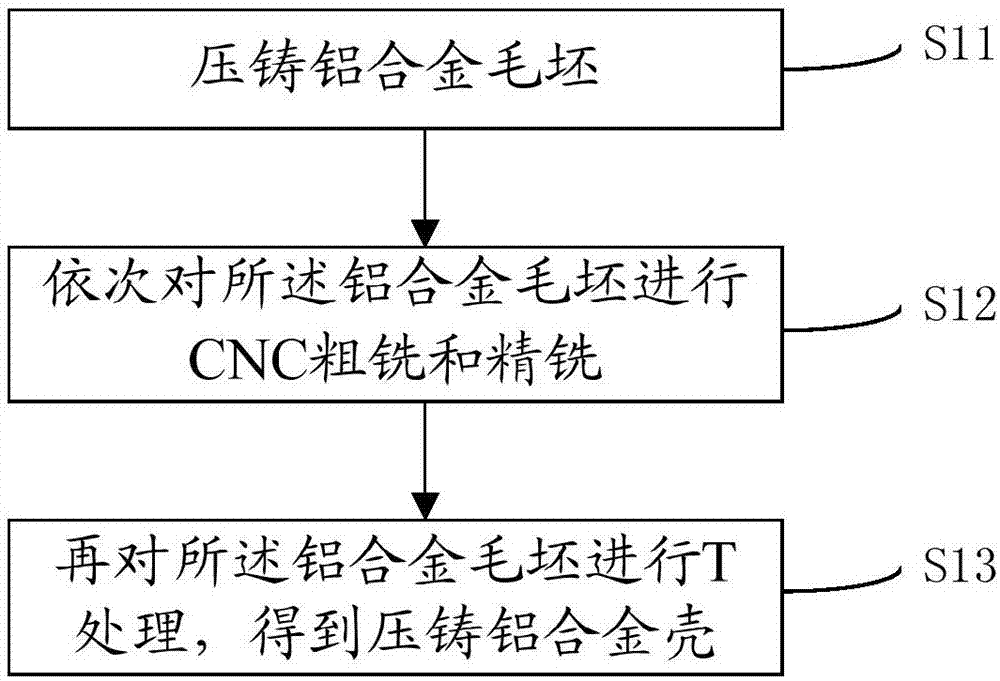

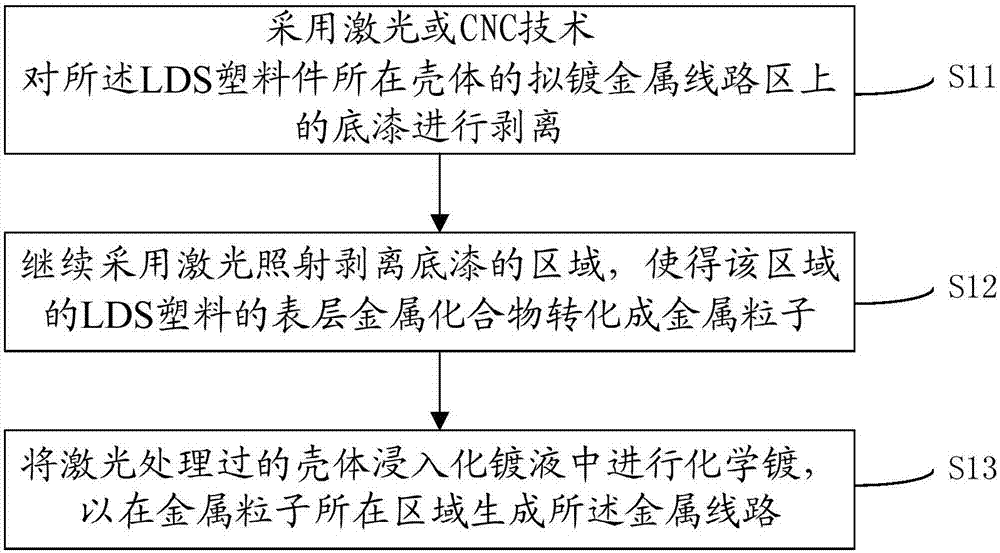

Method for manufacturing metal circuit

ActiveCN106894004AStable effectAvoid reactionAntenna supports/mountingsRadiating elements structural formsChemical platingPressure casting

The invention provides a method for manufacturing a metal circuit. The method comprises the following steps: manufacturing a pressure-casting magnesium aluminum alloy shell; injection-molding an LDS plastic part on the pressure-casting magnesium aluminum alloy shell to form a shell; coating the surface of the shell with primer in a spraying manner; performing chemical plating on the shell coated with the primer to manufacture the metal circuit, wherein the primer can be a PU material, or acrylic acid or oxirene ester primer. A thickness of the primer is 10-30 mu m. The layer of primer is coated on a nano-injection-molding part of the pressure-casting magnesium aluminum alloy and the LDS plastic, such that effective protection on the pressure-casting magnesium aluminum alloy shell is realized in a manufacturing process of the metal circuit through chemical plating, reaction between the pressure-casting magnesium aluminum alloy and chemical plating liquid agent in the chemical plating process is avoided, and the manufacturing effect of the metal circuit is ensured.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com