Method for manufacturing metal circuit

A metal circuit and aluminum alloy technology, which is applied to the coating process of metal materials, antennas, circuits, etc., can solve the problems of difficult electroplating of die-casting magnesium and aluminum alloys, long time for grinding and finishing, and the electroless plating process cannot be carried out smoothly. Avoid the reaction, the effect is stable, and the effect of the production effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

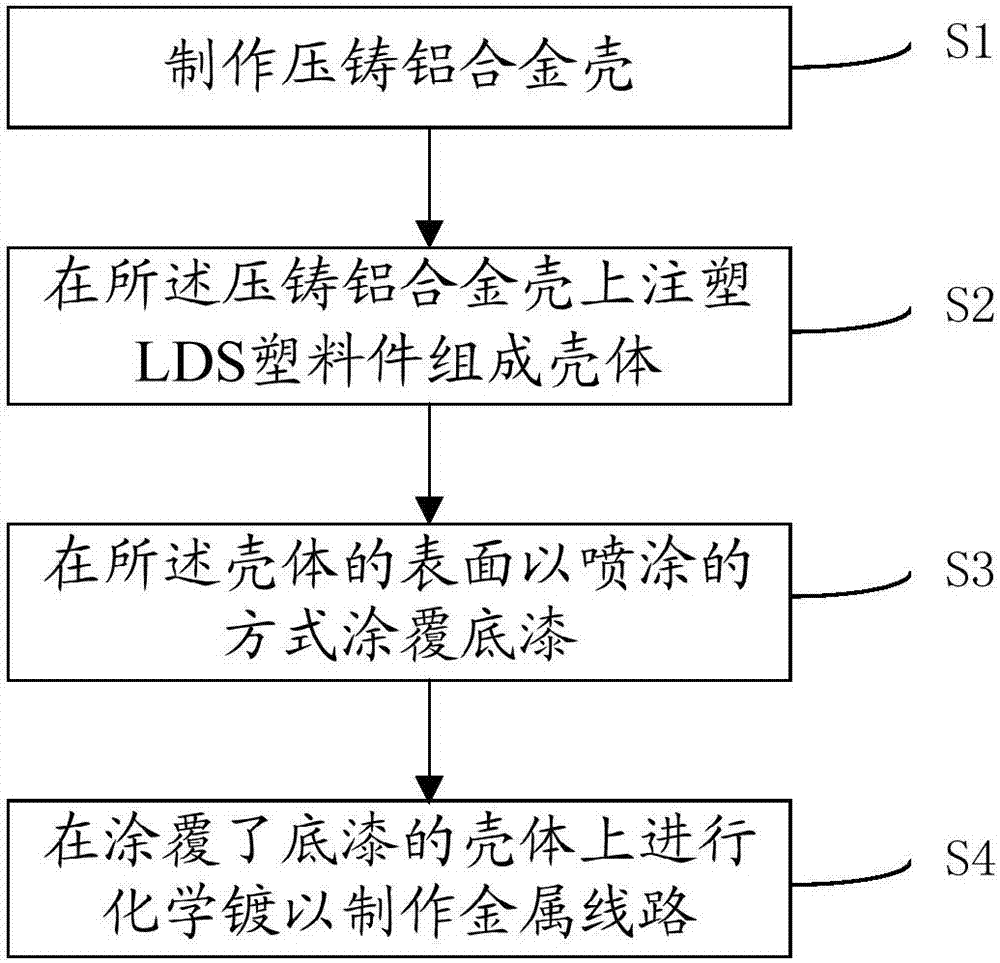

[0042] In order to better illustrate the present invention, the present invention is described in detail with the following preferred embodiments and in conjunction with the accompanying drawings, specifically as follows:

[0043] Such as figure 1 As shown, a method for electroless plating of a die-casting magnesium-aluminum alloy and a nano-injection molded part of LDS plastic provided in this embodiment includes the following steps:

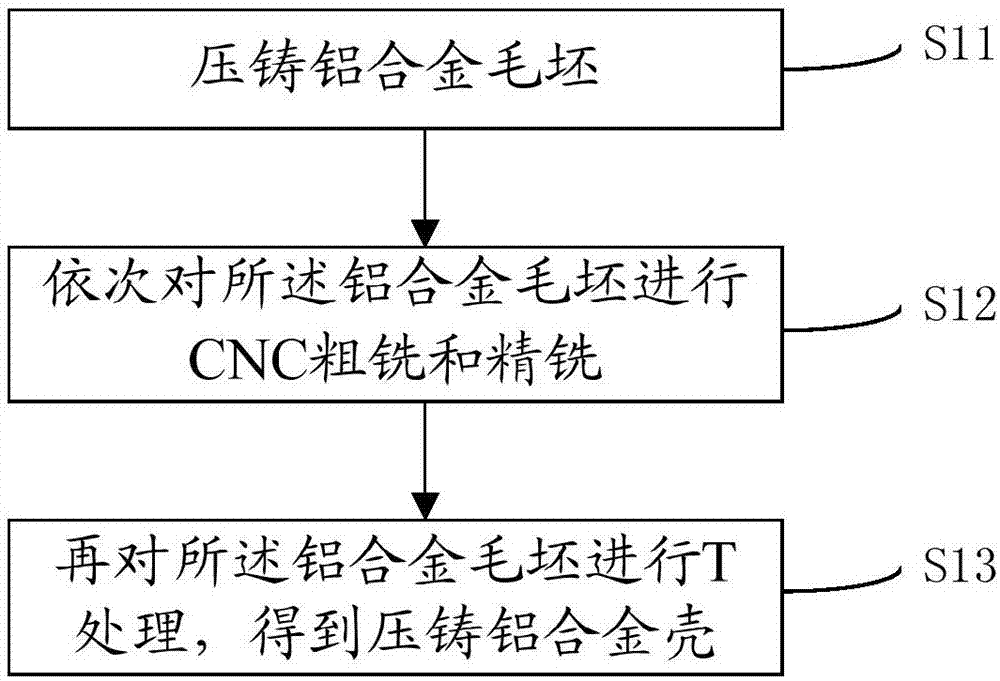

[0044] S1: Making a die-cast magnesium-aluminum alloy shell;

[0045] S2: Injecting LDS plastic parts on the die-cast magnesium-aluminum alloy shell to form the shell;

[0046] S3: spraying a primer on the surface of the housing;

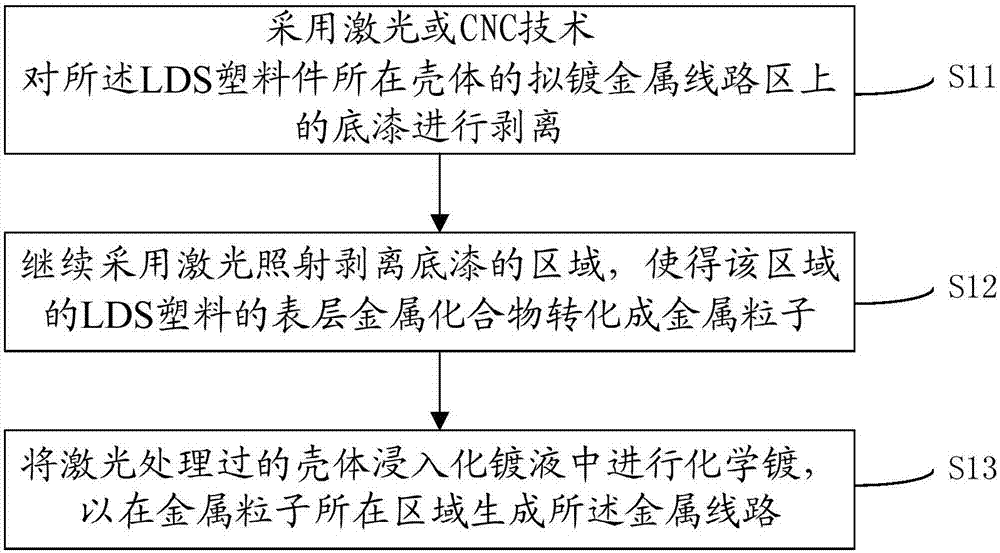

[0047] S4: Electroless plating is performed on the primer-coated casing to make metal circuits.

[0048] In step S2 of this embodiment, the primer for resisting electroless plating is sprayed on the entire surface of the casing composed of LDS plastic parts. This method of spraying the primer is easy to operate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com