Pine needle component, artware comprising pine needle component and manufacturing technology of pine needle component

A handicraft and pine needle technology, applied in decorative arts, clothing, artificial flowers, etc., can solve the problems of inability to achieve mechanized mass production, lack of employees, inconsistent structure, etc., and achieve mechanized production, ornamental balance, and processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

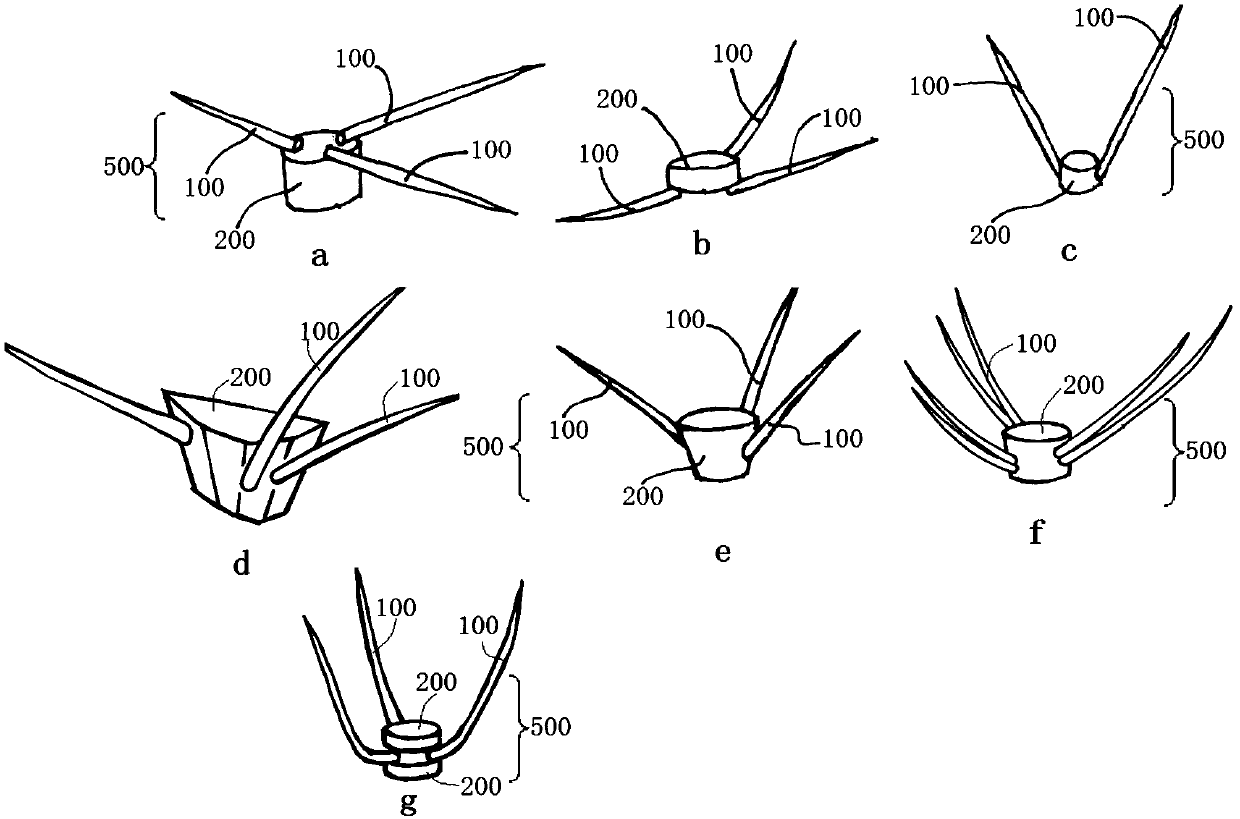

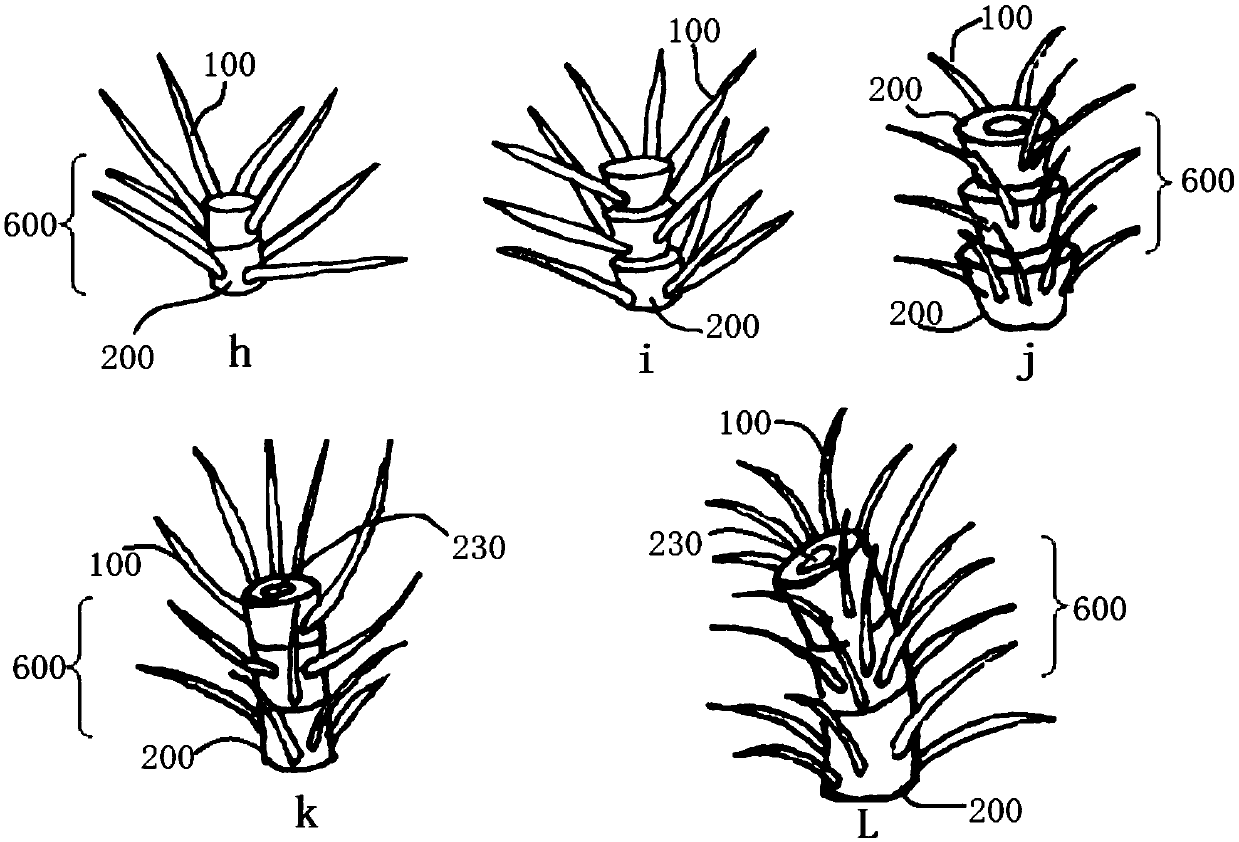

[0082] Such as Figure 1 to Figure 7 As shown, the pine needle part of the present embodiment includes a pine needle 100 and a pine needle holder 200. The bottom end of the pine needle 100 is fixedly arranged on the pine needle holder 200, and the other end of the pine needle 100 extends outward gradually away from the pine needle holder 200. The pine needle holder 200 and its The pine needles 100 arranged on the top form a pine needle assembly 500 , and a plurality of pine needle assemblies 500 are sequentially connected through the pine needle holder 200 to form a pine needle component 600 .

[0083] The pine needle part 600 of this embodiment is the most important component of the welcoming pine iron painting. The welcoming pine iron painting has always been a unique and typical representative of the iron painting industry. Pursuit is also an eternal theme that has been enduring in the industry for many years. At present, the iron paintings of Yingke pine that are widely s...

Embodiment 2

[0090] The pine needle part of this embodiment is basically the same as that of Embodiment 1. Furthermore, the bottom of a single pine needle 100 in this embodiment is directly fixedly connected with the pine needle holder 200, or the bottom ends of two pine needles 100 are connected to form a bunch of pine needles. The bottom ends of the bundle of pine needles are fixedly connected to the pine needle holder 200, and the fixed connection includes but not limited to welding connection. Such as figure 1 As shown in Figure f, the bottom ends of two pine needles 100 are first connected to form a bunch of pine needles, and then the bottom ends of a bunch of pine needles are fixedly connected to the pine needle holder 200 as a whole, figure 1 As shown in other drawings, the bottom end of a certain pine needle 100 is directly fixedly connected to the pine needle holder 200. According to the design and display requirements, the same pine needle holder 200 can have the situation that t...

Embodiment 3

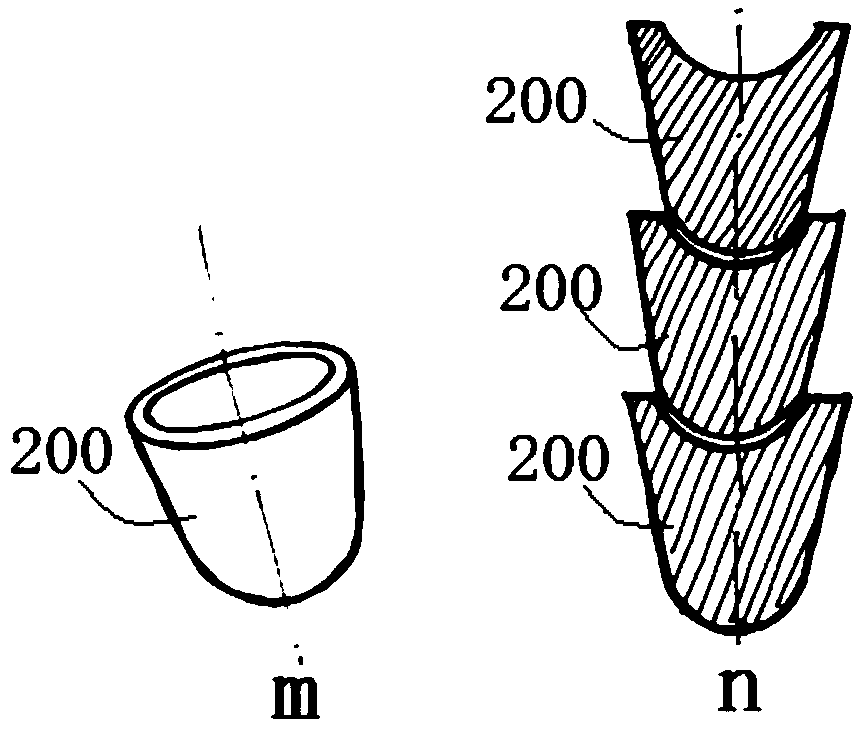

[0092] The pine needle part of the present embodiment is basically the same as the above-mentioned embodiment. Furthermore, the pine needle holder 200 in the present embodiment can be set to all solid structures, as long as the pine needle 100 can be fixedly arranged on it, and there can be a plurality of pine needle holders 200. Certain contact surfaces can be spliced sequentially. Specifically, in this embodiment, the pine needle holder 200 can adopt a polyhedron comprising a top surface, a bottom end surface and a side wall surface. The top surface of the pine needle holder 200 is parallel to the bottom surface and the cross-sectional area is the same; The seat 200 can be set as a cylinder or a prism, such as figure 1 As shown in a, b, and f, a plurality of pine needle holders 200 are sequentially connected to form a linear branch shape, such as figure 2 In h, k shown.

[0093] In this embodiment, the setting of the pine needles 100 is relatively flexible. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com