Graphite material for monocrystalline silicon growth thermal field in solar photovoltaic industry and production method thereof

An industrial monocrystalline silicon and solar photovoltaic technology, applied in the field of graphite materials, can solve problems such as small size, large gap, and insufficient volume density, and achieve the effects of improving volume density and strength, avoiding cracks, and increasing coking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

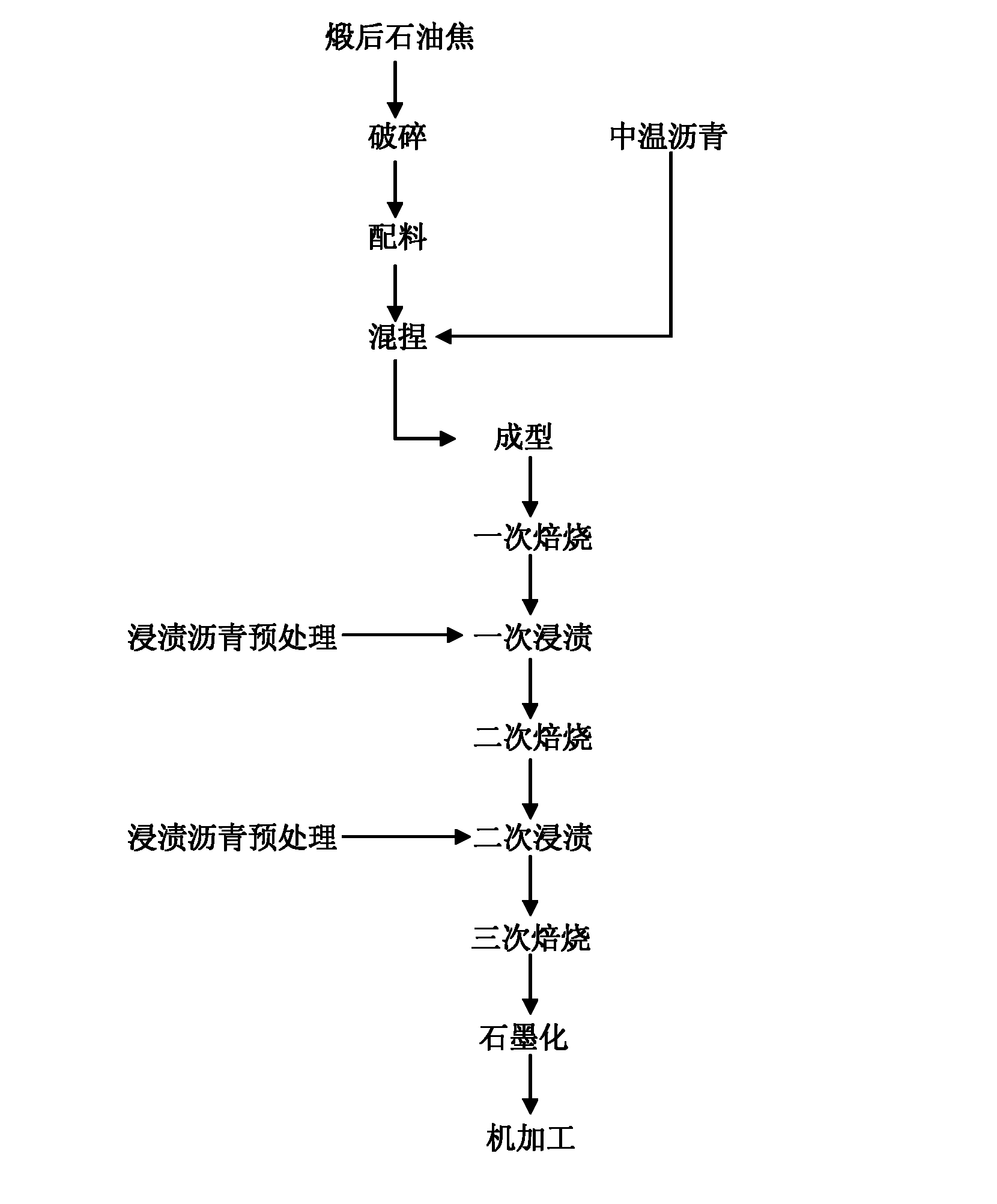

Method used

Image

Examples

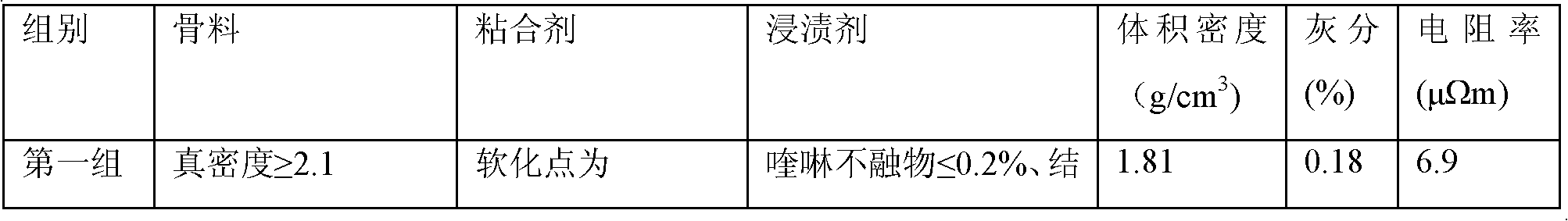

Embodiment 1

[0050] Make the true density ≥ 2.1g / cm 3 , calcined petroleum coke with ash content ≤0.3% is crushed and sieved to make 0.5mm<particle size≤0.335mm, 0.335mm<particle size≤0.15mm, 0.15mm<particle size≤0.075mm and particle size less than 0.075mm The four grades of pellets are placed in four silos respectively. Then carry out the batching, the aggregate and the binder are batched according to the weight ratio of 70:30, the binder is a medium-temperature asphalt with a softening point of 83-86°C and a coking value ≥ 49%, and the aggregate is: 0.5mm<particle size The weight of calcined petroleum coke ≤0.335mm accounts for 25% of the total calcined petroleum coke, the weight of calcined petroleum coke with 0.335mm<particle size≤0.15mm accounts for 20% of the total calcined petroleum coke, and the weight of 0.15mm<particle size The calcined petroleum coke with a particle size of ≤0.075mm accounts for 15% of the total calcined petroleum coke, and the calcined petroleum coke with a pa...

Embodiment 2

[0057] Make the true density ≥ 2.1g / cm 3 , calcined petroleum coke with ash content ≤0.3% is crushed and sieved to make 0.5mm<particle size≤0.335mm, 0.335mm<particle size≤0.15mm, 0.15mm<particle size≤0.075mm and particle size less than 0.075mm The four grades of pellets are placed in four silos respectively. Then carry out the batching, the aggregate and the binder are batched according to the weight ratio of 70:30, the binder is a medium-temperature asphalt with a softening point of 83-86°C and a coking value ≥ 49%, and the aggregate is: 0.5mm<particle size The weight of calcined petroleum coke ≤0.335mm accounts for 15% of the total calcined petroleum coke, the weight of calcined petroleum coke with 0.335mm<particle size≤0.15mm accounts for 22% of the total calcined petroleum coke, and the weight of 0.15mm<particle size The calcined petroleum coke with a particle size of ≤0.075mm accounts for 18% of the total calcined petroleum coke, and the calcined petroleum coke with a pa...

Embodiment 3

[0064] Make the true density ≥ 2.1g / cm 3 , calcined petroleum coke with ash content ≤0.3% is crushed and sieved to make 0.5mm<particle size≤0.335mm, 0.335mm<particle size≤0.15mm, 0.15mm<particle size≤0.075mm and particle size less than 0.075mm The four grades of pellets are placed in four silos respectively. Then carry out batching, the aggregate and the binder are batched according to the weight ratio of 75:25, the binder is a medium-temperature asphalt with a softening point of 83-86°C and a coking value ≥ 49%, and the aggregate is: 0.5mm<particle size The weight of calcined petroleum coke ≤0.335mm accounts for 10% of the total calcined petroleum coke, the weight of calcined petroleum coke with 0.335mm<particle size≤0.15mm accounts for 25% of the total calcined petroleum coke, and the weight of 0.15mm<particle size The calcined petroleum coke with a particle size of ≤0.075mm accounts for 20% of the total calcined petroleum coke, and the calcined petroleum coke with a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com