Printing ink manufacturing raw material pigment pretreatment system

A pretreatment, raw material technology, applied in sustainable manufacturing/processing, solid separation, climate sustainability, etc., can solve the problems of incomplete filtration, poor filtration effect, affecting ink processing, etc., to improve filtration efficiency, improve sieve The effect of dividing the area and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

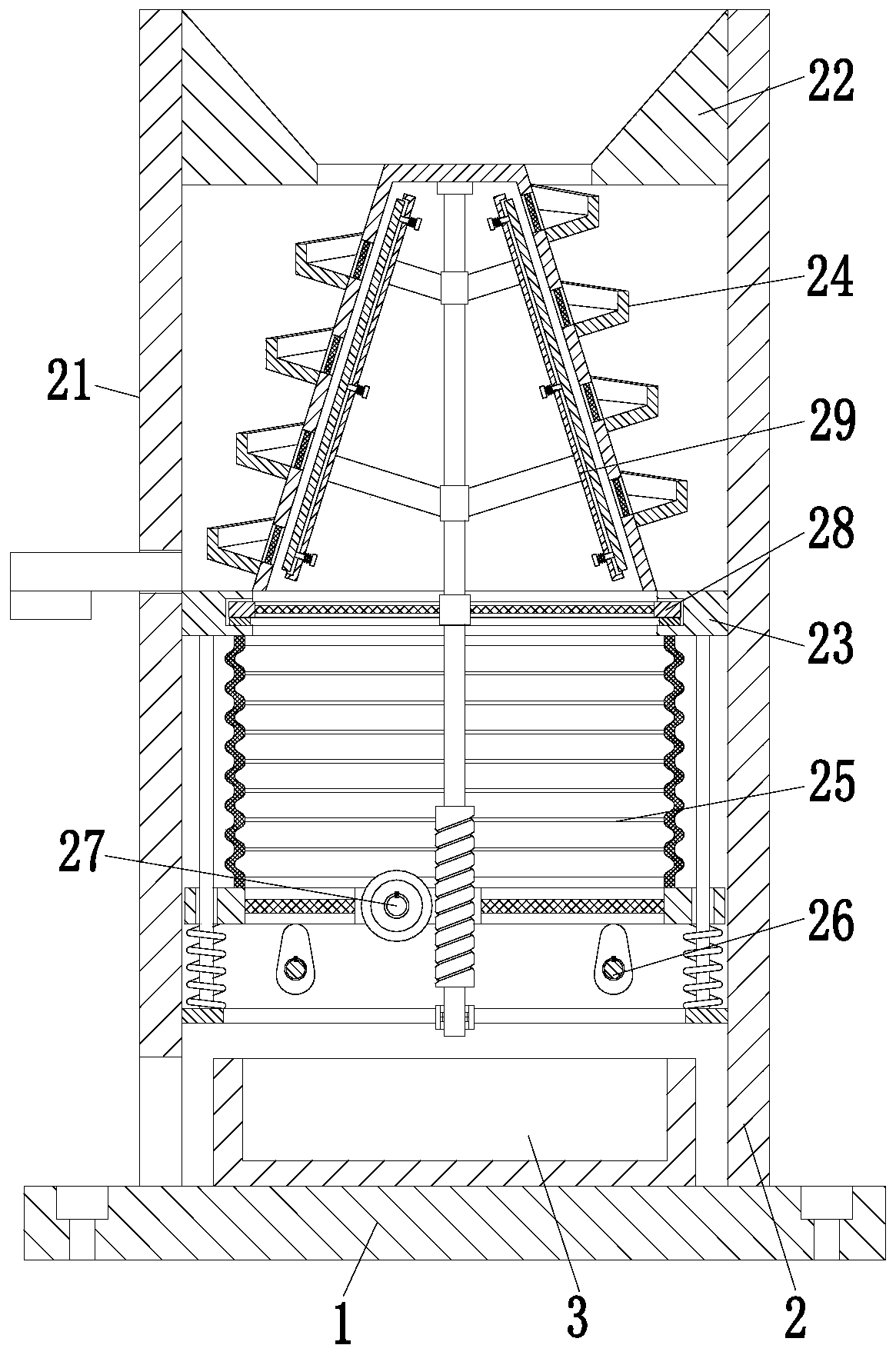

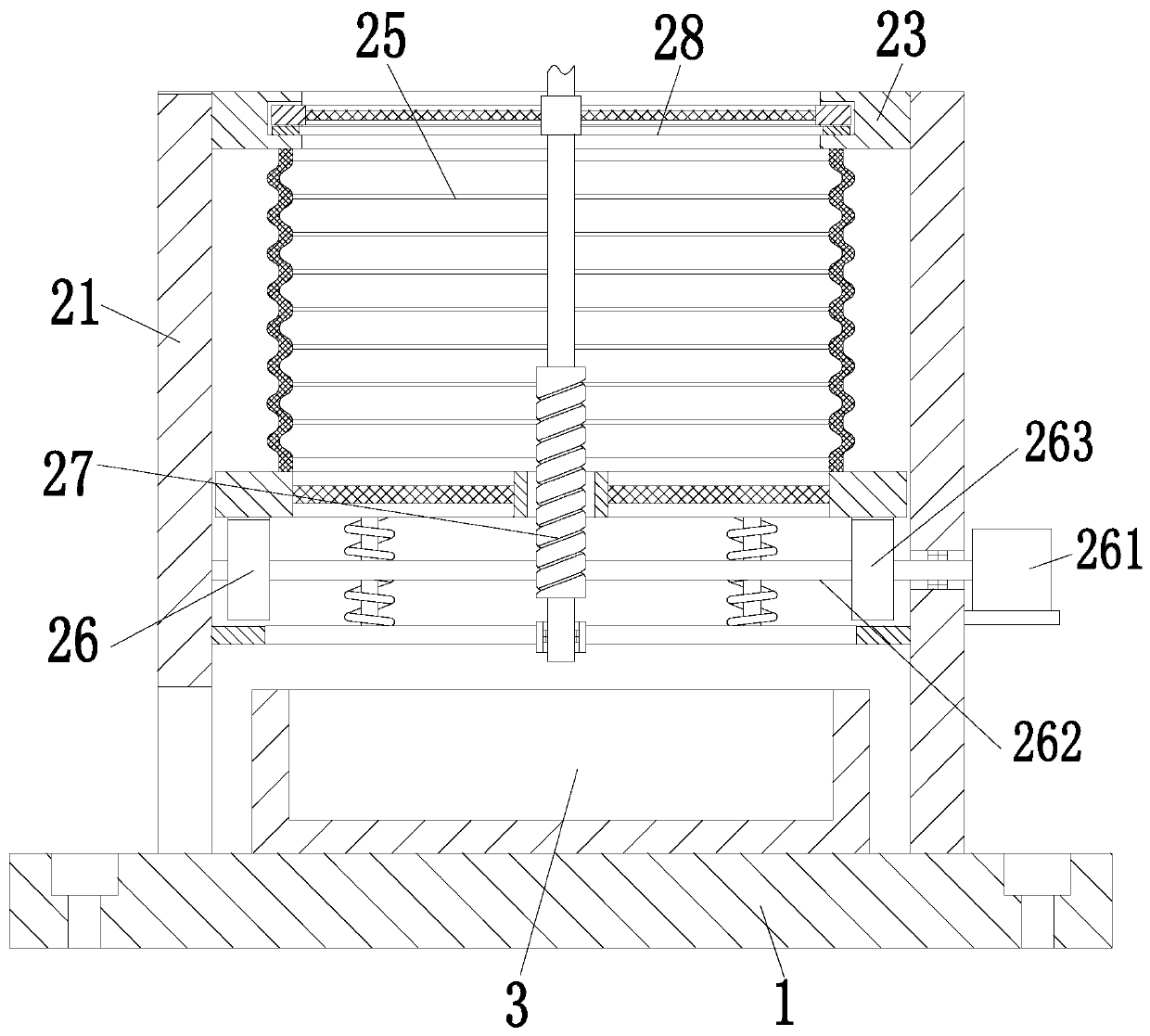

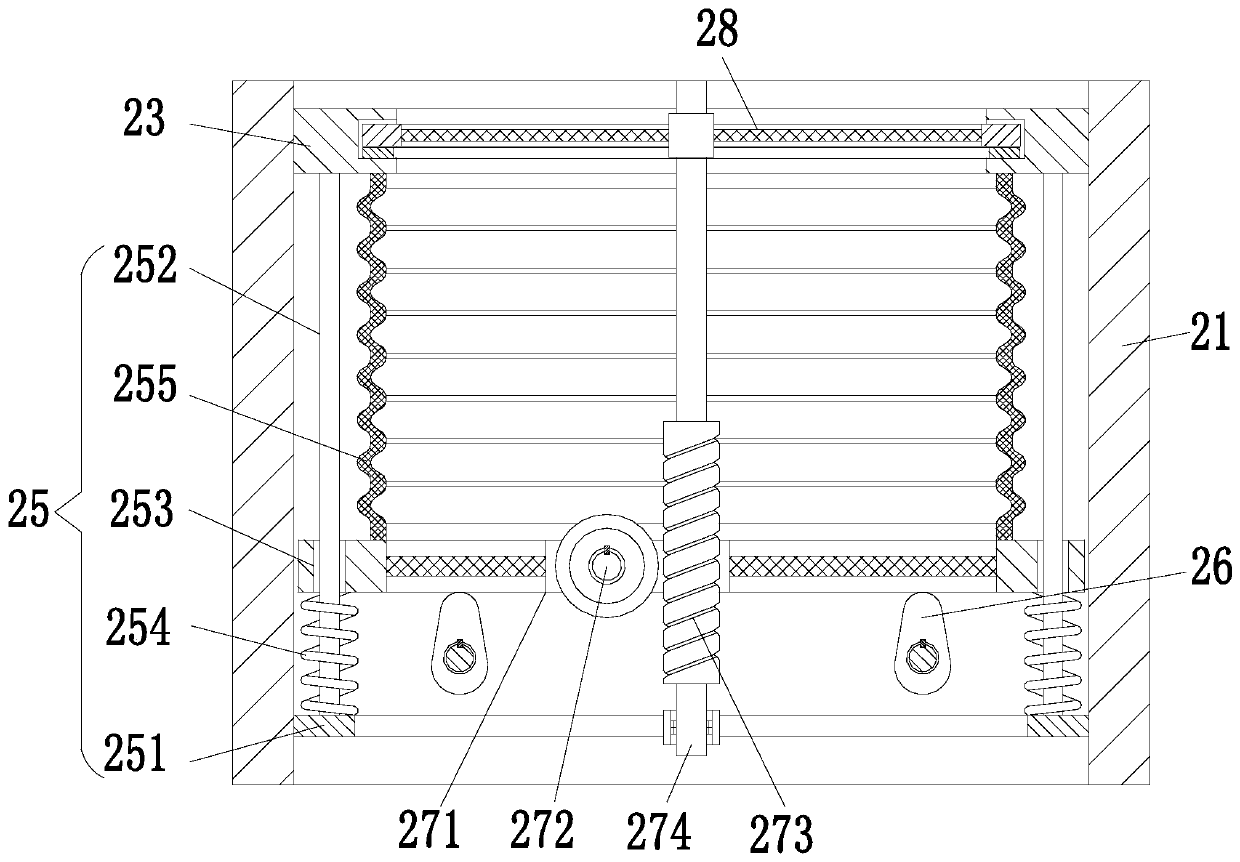

[0027] Such as Figure 1 to Figure 5 As shown, a raw material pigment pretreatment system for ink manufacturing includes a base plate 1, a filter device 2 and a collection box 3, the base plate 1 is uniformly provided with installation holes, the upper end of the base plate 1 is equipped with a filter device 2, and the lower end of the filter device 2 A through groove is provided, and a collecting box 3 is arranged in the through groove, and the collecting box 3 is located in the middle of the upper end of the bottom plate 1 .

[0028] Described filtering device 2 comprises housing frame 21, feeding frame 22, dividing plate 23, filtering mechanism 24, screening mechanism 25, driving mechanism 26, rotating mechanism 27, screen mesh mechanism 28 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com