Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Good cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

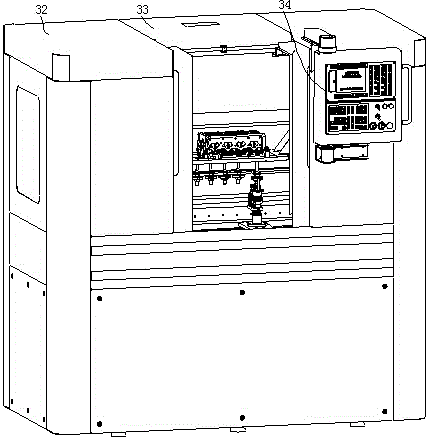

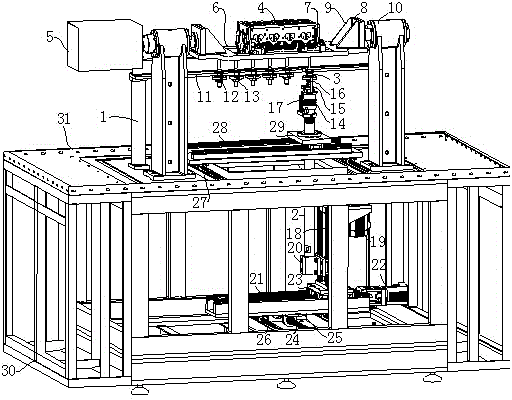

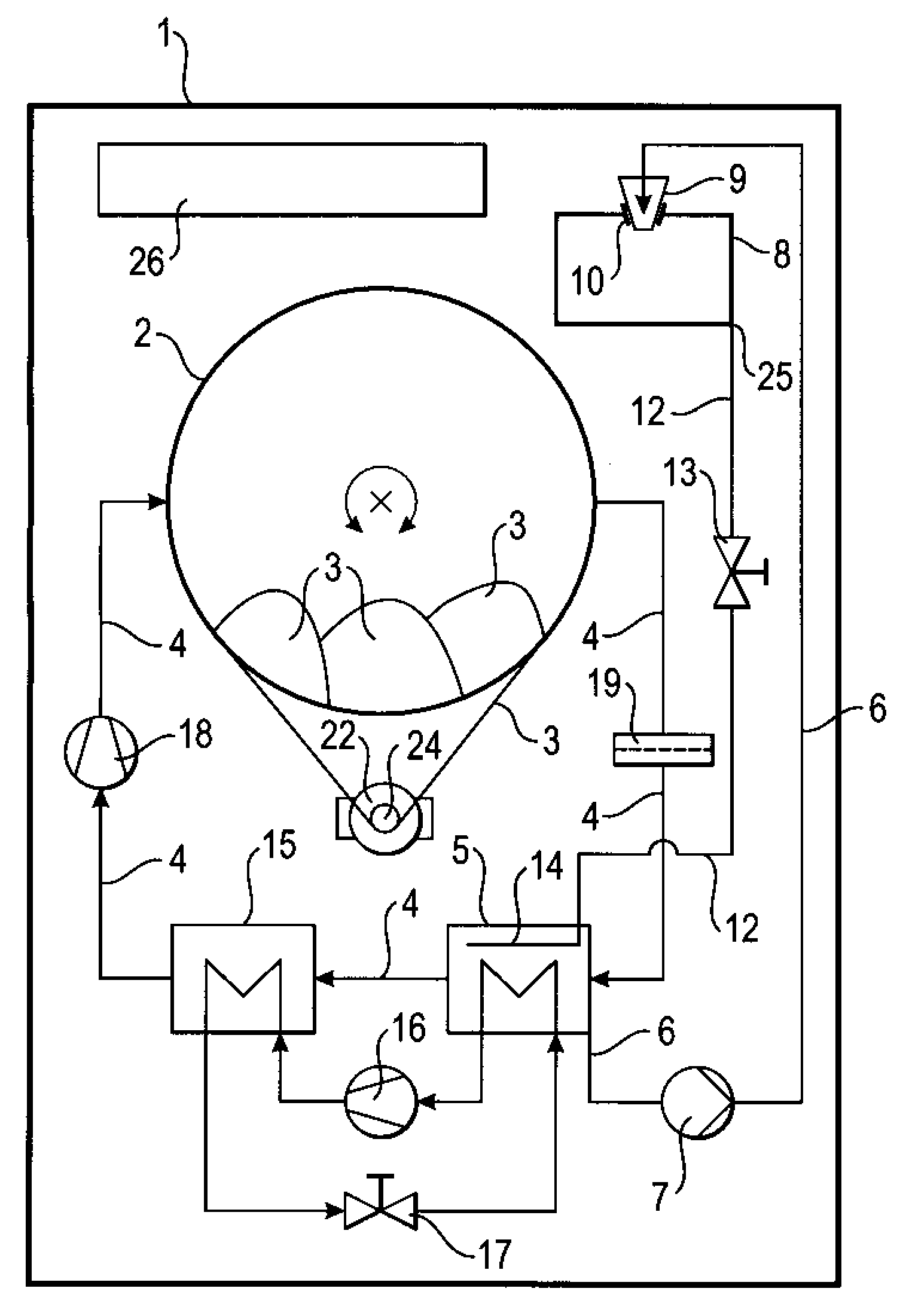

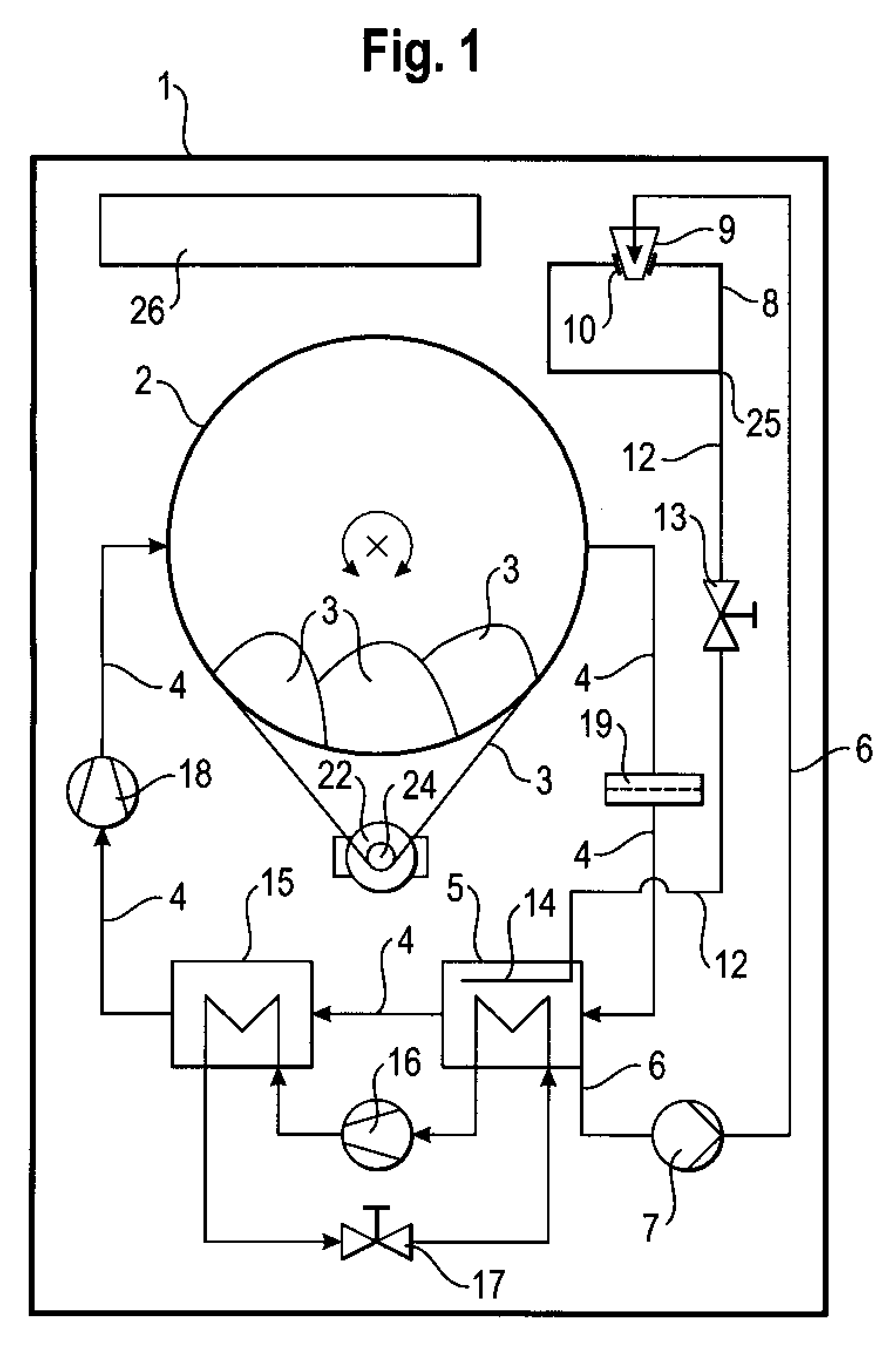

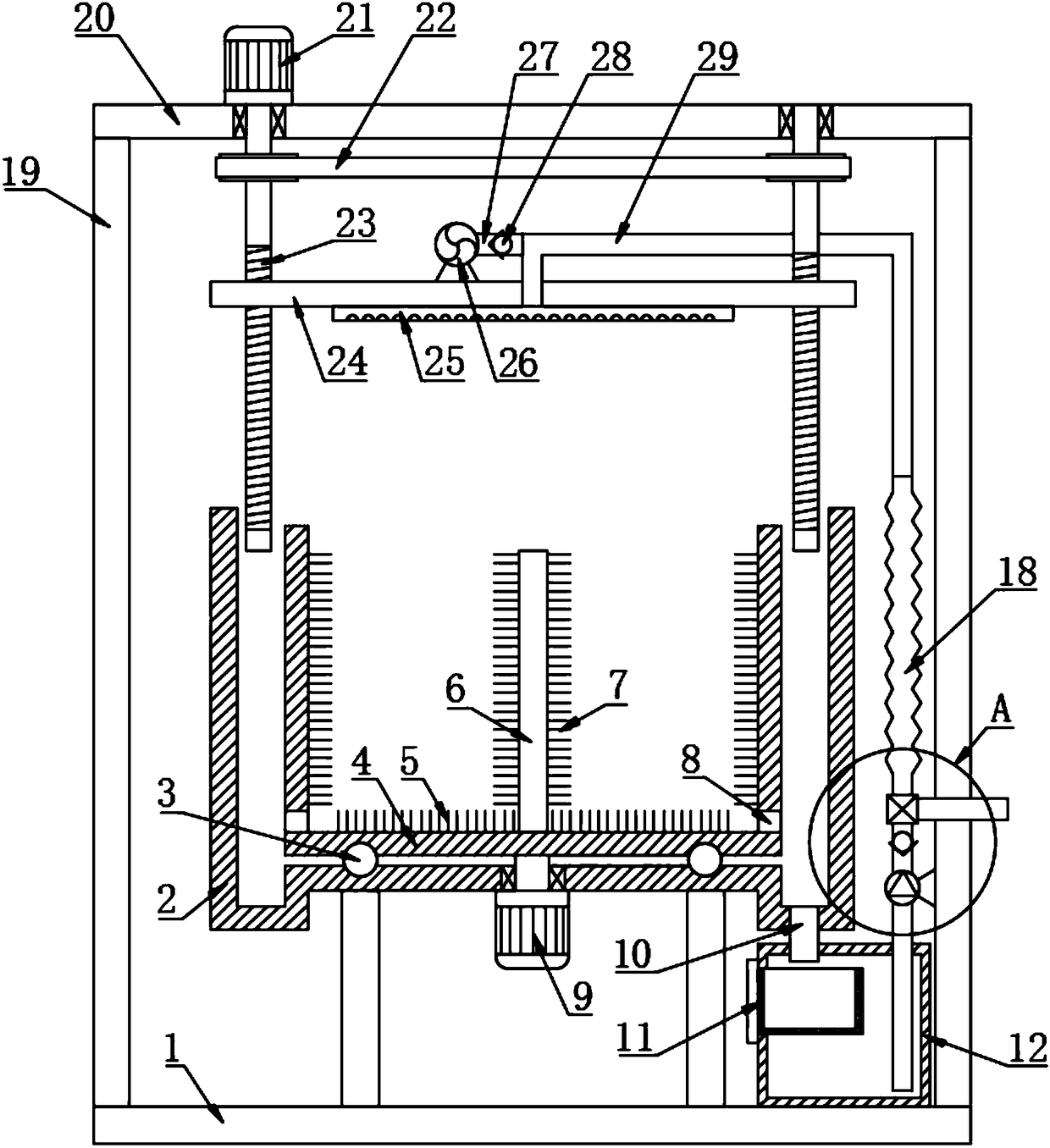

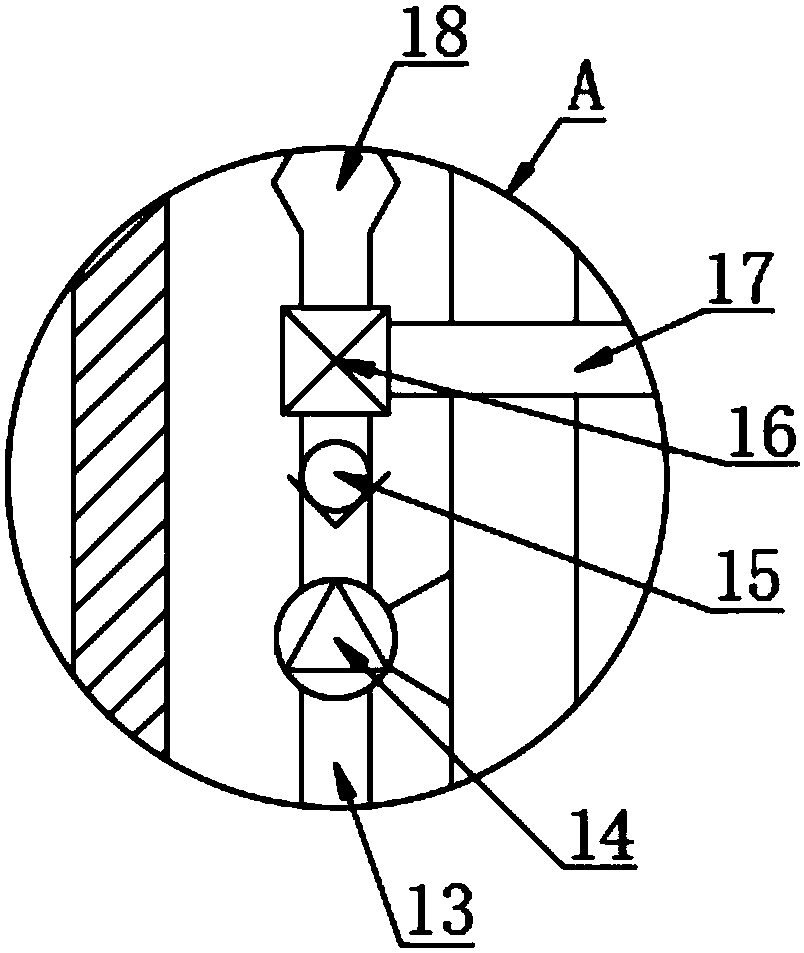

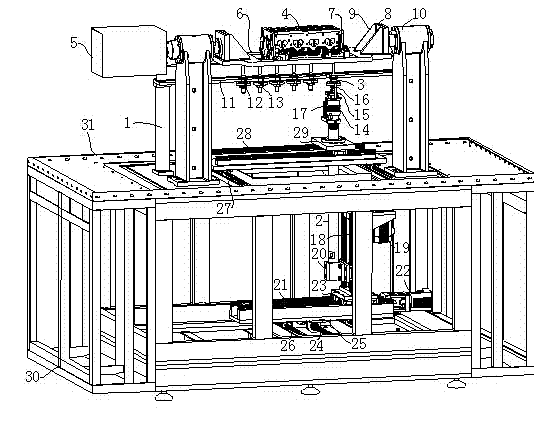

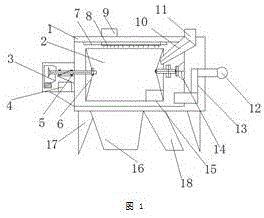

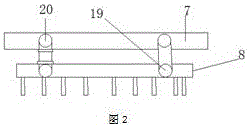

Automatic cleaning device for engine cylinder cover

InactiveCN104690025AEasy to cleanGood cleaningCleaning using gasesCleaning using liquidsEngineeringSpatial movement

The invention discloses an automatic cleaning device for an engine cylinder cover. The automatic cleaning device comprises a frame, an engine cylinder cover fixing device and a cleaning mechanism, and the engine cylinder cover fixing device and the cleaning mechanism are arranged at the upper end of the frame. The cleaning mechanism comprises a cleaning pipeline and a nozzle mounted on the cleaning pipeline, and the engine cylinder cover fixing device is positioned above the nozzle. The automatic cleaning device is characterized in that the cleaning pipeline is hard and vertically arranged below the engine cylinder cover fixing device, and the lower end of the cleaning pipeline is mounted on the frame through a three-dimensional moving device to enable the cleaning pipeline to drive the nozzle to realize three-dimensional spatial movement; the engine cylinder cover fixing device comprises a mounting frame used for fixing the engine cylinder cover, rotating shafts are outwardly arranged at two ends of the mounting frame respectively and rotatably mounted at the upper end of the frame through bearings, and the rotating shafts are in transmission connection with a rotary servo motor. The automatic cleaning device for the engine cylinder cover is as effective as manual cleaning and has the advantages high cleaning pertinence, effectiveness in cleaning, high cleaning efficiency, excellent drying effects, high drying efficiency, energy saving, consumption reduction and the like.

Owner:CHONGQING HONGYI MACHINERY

Emulsifiable oil for knitting

InactiveCN1995302AImprove antistatic performanceImprove cooling effectAdditivesDistilled waterAnti oxidant

The invention discloses a lubricating, anti-electrostatic, anti-rust and cooling liquid composition in the weaving manufacturing course, which consists of 85-92% mineral typed basic oil with multiple viscous basic oils and 8-15% additive, wherein the additive is composed of emulsifier, antirust agent, abrasion-proof agent, anti-oxidant, metal deactivator and distill water.

Owner:广东澳力丹润滑油有限公司

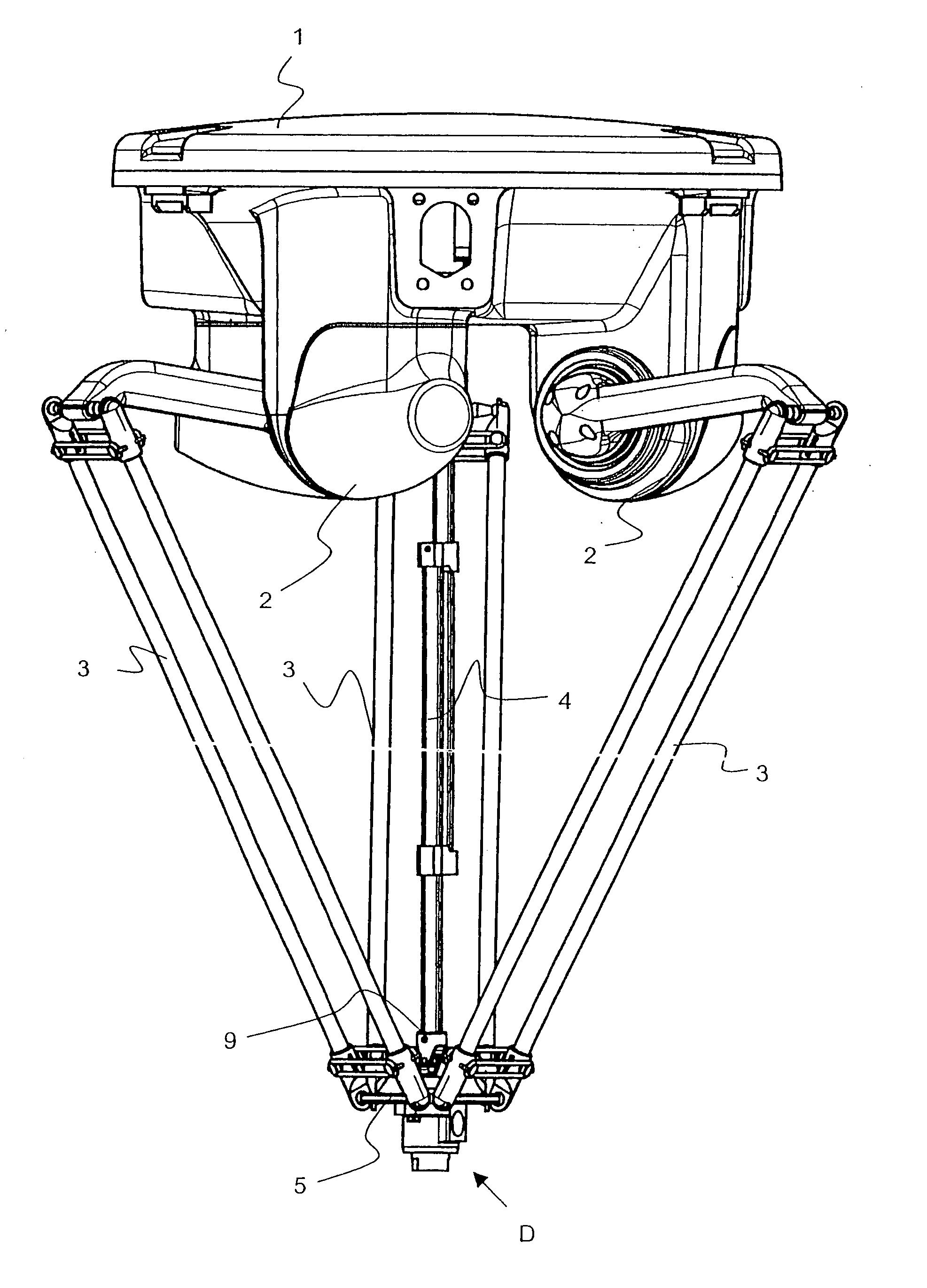

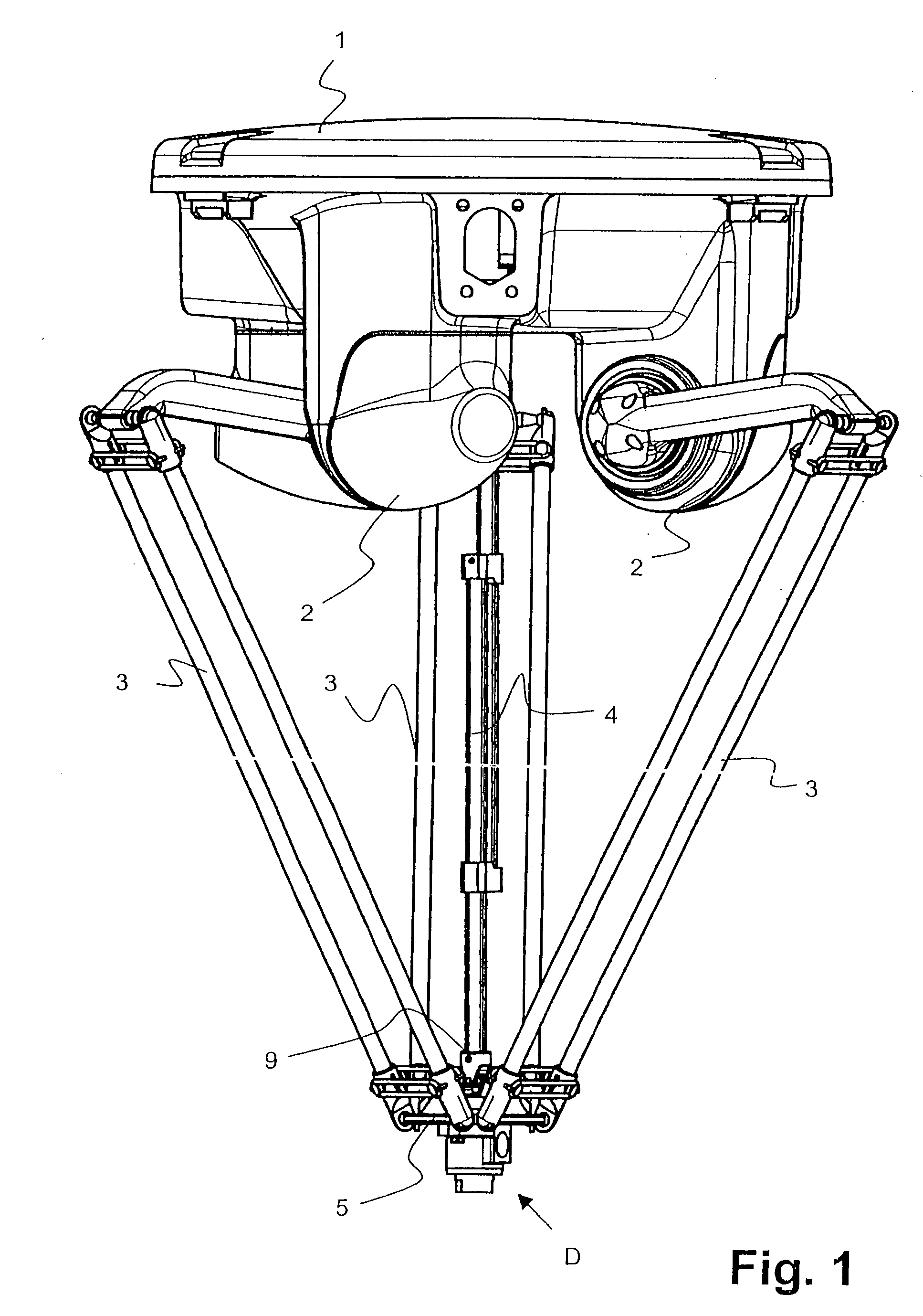

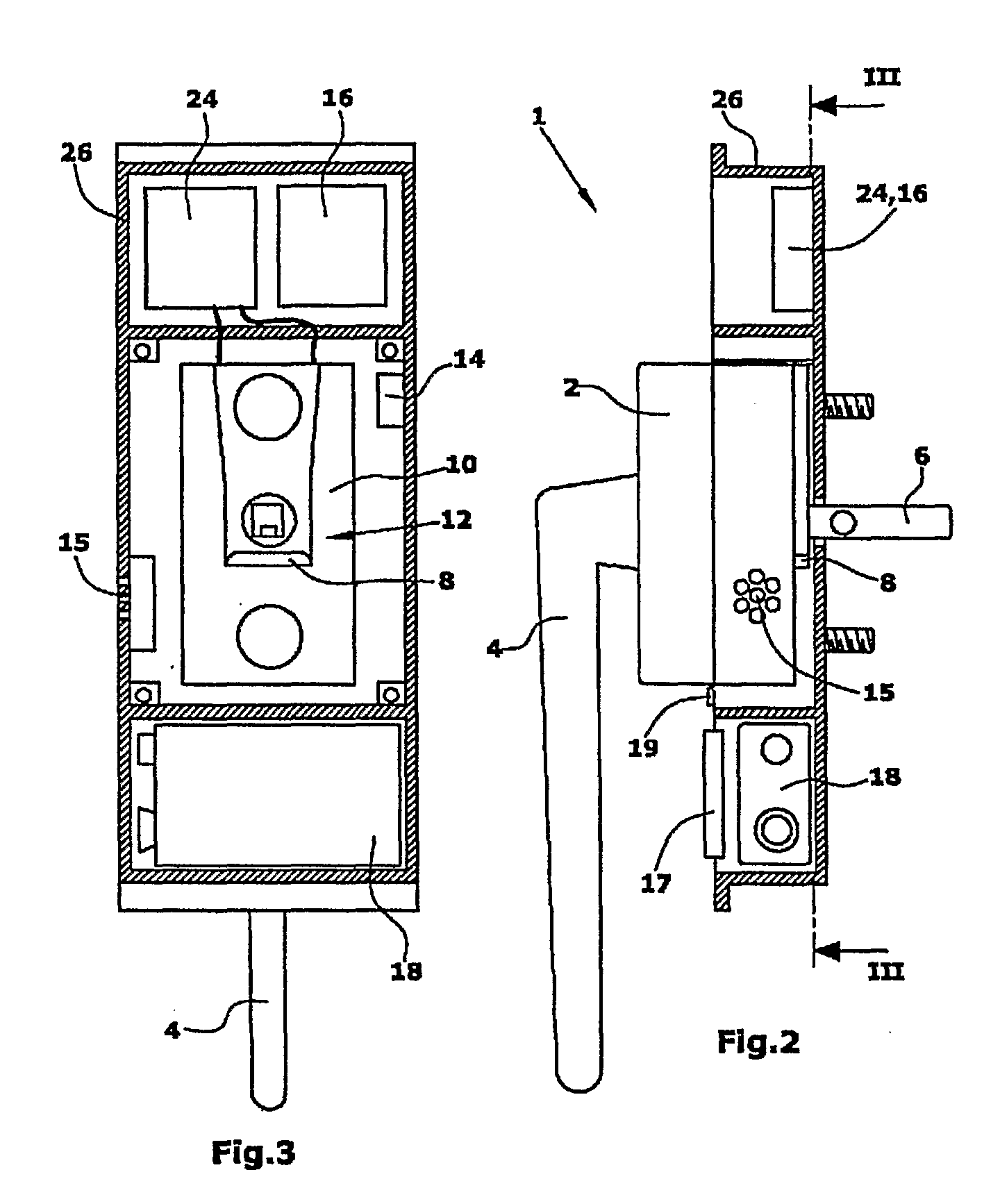

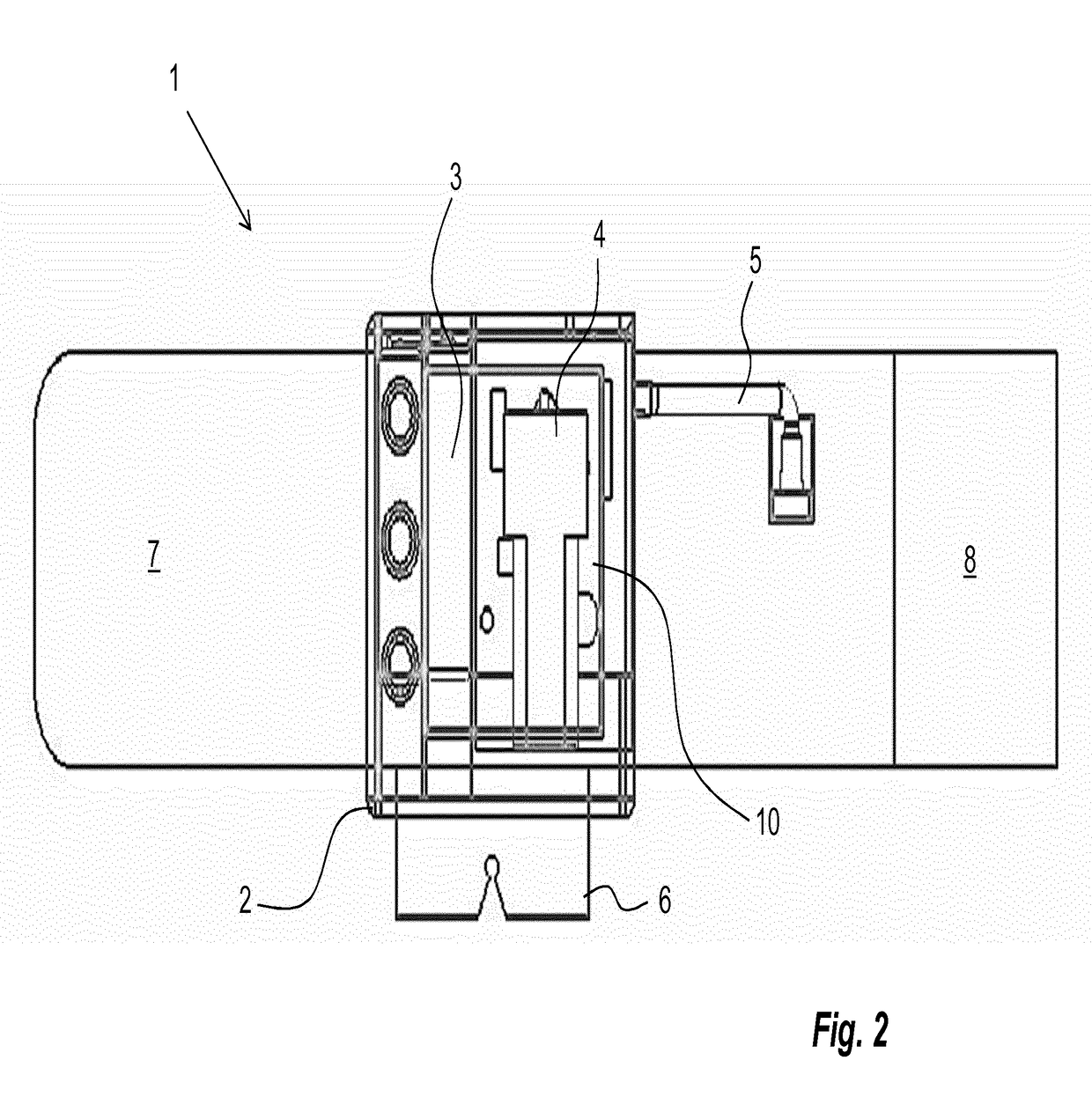

Rotary leadthrough of a robot arm

InactiveUS20070137374A1Less soilGood cleaningProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

A rotary leadthrough of a robot arm, in particular of a fourth axle of a Delta robot, has a housing and a shaft, located in an axial leadthrough of the housing and supported rotatably in this housing, for connection to the robot arm. The housing has at least two openings for cleaning the axial leadthrough. The shaft at least in a portion of its length, has a diameter which is less than the diameter of the axial leadthrough in that region, so that there is a void between the shaft and the axial leadthrough.

Owner:ROBERT BOSCH GMBH

Dryer comprising a heat sink and a condensate container

ActiveUS20090320312A1Alleviate problemGood cleaningDrying machines with non-progressive movementsTextiles and paperEngineeringHeat spreader

A dryer includes a drying chamber, a process air guide that guides process air along the articles to pick up humidity from them, a heat sink in the process air guide that precipitates humidity from the process air as a condensate, and a condensate collector with a condensate container having an insert that is permeable to the condensate and that projects through an opening into the condensate container for transferring the condensate to and from the condensate container. The insert includes a first filter that filters particles from the condensate prior to storing the condensate in the condensate container.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Window or Door Handle

InactiveUS20080284595A1Good cleaningSimple to installBurglar alarm by openingBurglar alarm by glass breakingElectrical and Electronics engineeringDoor handle

An olive-shaped window or door fitting includes a handle housed in a handle fitting, an autonomous monitoring and alarm module arranged in a module housing with several sensors, and an evaluation unit, which receives alarm signals and detection signals. The monitoring and alarm module has at least one handling noise sensors integrated into the module housing, which is directed towards a pane of glass and selectively records acoustic frequencies which occur when glass is broken and which in the event of glass being broken transmits an alarm signal to the evaluation device.

Owner:WERU GMBH & CO KG

Environment-friendly clean burner

The invention discloses an environment-friendly clean burner, which comprises a copper core, a flame distributor, a furnace plate, a nozzle and a burner bottom cup in sequence from top to bottom, wherein the burner bottom cup is assembled and combined with the furnace plate, and the burner bottom cup and the furnace plate are limited and fixed through a temperature detection sensor which is fixed on the burner bottom cup and a positioning boss which is arranged on the burner bottom cup; the copper core is arranged in the center of the furnace plate; and the flame distributor is arranged on the outer ring of the furnace plate. The environment-friendly clean burner has the advantages that the requirement of one-step air supply for the burner is met, and holes do not need to be formed on other components; the air supply of the burner is realized independently without opening air inlet holes, so that an inner cavity of a cooking utensil can be kept clean, and the cleanliness of the clean burner is high; and a flame thrower is divided into a plurality of small units for sectional combustion, big and small flame outlet holes are concentrated in the different gradient surfaces of the small units, and are alternately and uniformly distributed in rows to ensure that secondary air supplementary amount is sufficient, the radiating area is enlarged, the temperature and the oxygen concentration in a high-temperature area are reduced, the generation of harmful NO is inhibited, and the heat efficiency is improved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Preparation method of environment-friendly emulsified releasing agent

The invention discloses a preparation method of an environment-friendly emulsified releasing agent. The environment-friendly emulsified releasing agent comprises the following raw materials by mass, 15-25 parts of simethicone, 5-8 parts of polyvinyl alcohol, 6-9 parts of ricinoleic acid, 3-6 parts of dimer fatty acid, 5-7 parts of assistant emulsifiers, 6-10 parts of hydroxyalkyl ammonium, 0.6-1.0 part of organic dicarboxylic acid, 0.05-0.1 part of bactericide and 45-60 parts of deionized water. By adopting the film forming mode that a primary emulsifier and an antirust agent are synthesized by organic acid and hydroxyalkyl ammonium, in company with the assistant emulsifiers, simethicone is emulsified in the deionized water and polyvinyl alcohol, the external-use emulsified releasing agent is mainly used for epoxy resin and unsaturated polyester material forming dies, and is sprayed to the surfaces of the dies for use, so that the effects that epoxy resin and unsaturated polyester products are easy to form, do not corrode the dies, and are not bonded with the dies are reached; and the environment-friendly emulsified releasing agent has the characteristics that no decomposition residues exist, the colors and performances and the products are not affected, the cleaning property is good and no pollution to environment is caused.

Owner:刘方旭

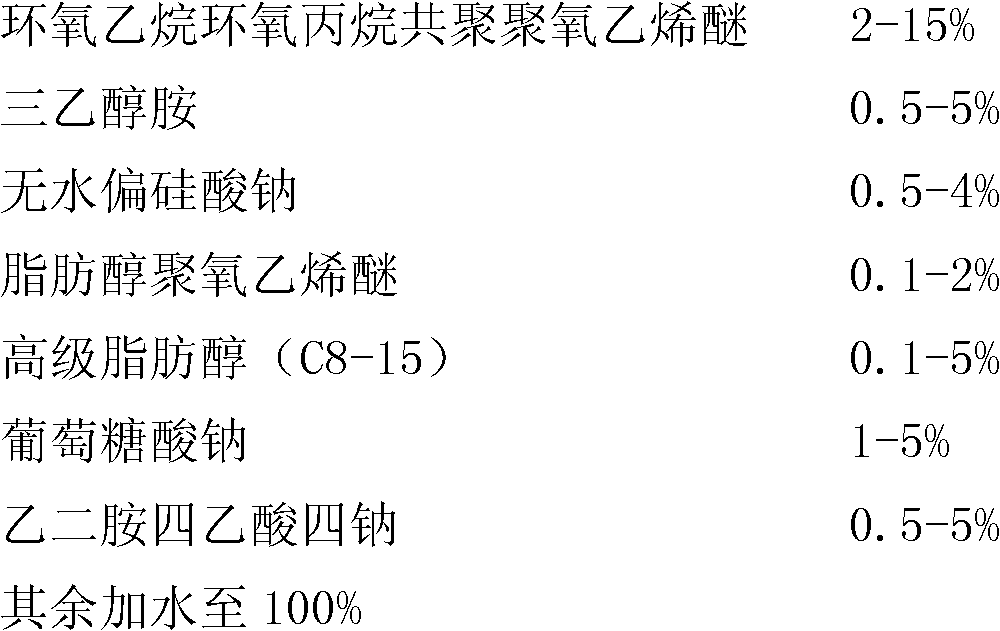

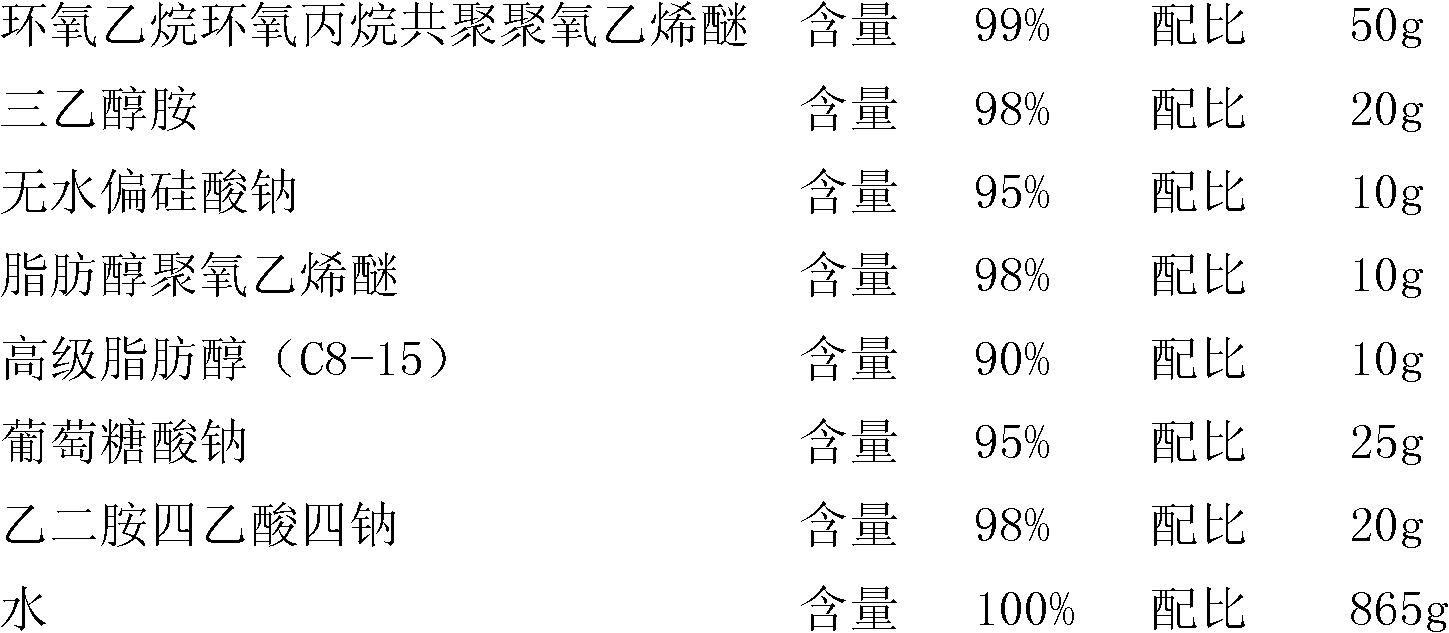

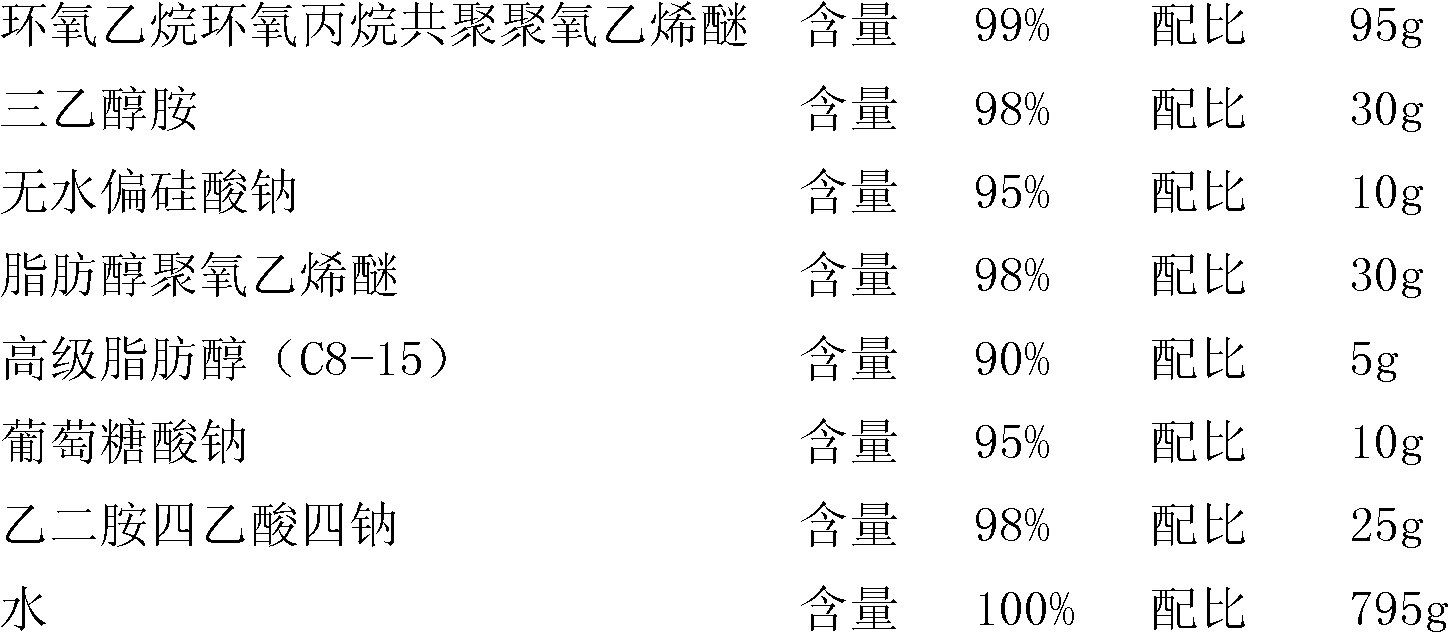

Water-based industrial detergent capable of self-defoaminng at normal temperature and preparation method thereof

InactiveCN102161939AReduce intensityThe principle of achieving self-defoamingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSodium metasilicate

The invention relates to a water-based industrial detergent capable of self-defoaming at normal temperature and a preparation method thereof. The detergent comprises the following components in percentage by weight: 2-15% of ethylene oxide epoxypropane copolymerized polyoxyethylene, 0.5-5% of triethanolamine, 0.5-4% of sodium metasilicate anhydride, 0.1-2% of fatty alcohol-polyxyethylene ether, 0.1-5% of advanced fatty alcohol (C8-15), 1-5% of sodium gluconate, 0.5-5% of ethylene diamine tetraacetic acid and the balance of water. The preparation method mainly comprises the following steps: dissolving the sodium metasilicate anhydride, the sodium gluconate and the ethylene diamine tetraacetic acid in the water; and then adding the ethylene oxide epoxypropane copolymerized polyoxyethylene, the triethanolamine, the fatty alcohol-polyxyethylene ether, the advanced fatty alcohol (C8-15) and the like in sequence, and mixing to finally obtain the industrial detergent. In the invention, based on the combined action of lipophilic group epoxypropane in the ethylene oxide epoxypropane copolymerized polyoxyethylene and lipophilic group in the system as well as industrial oil stain, the intensity of foam generated in the process of cleaning is reduced so as to realize the self-defoaming effect; through the synergistic effect of various components, optimal cleaning and antirust effects are achieved; simultaneously, through the synergistic effect of various surfactants, the defect that inorganic salts always form white spots on the surface of a workpiece is obviously improved.

Owner:华阳新兴科技(天津)集团有限公司

Water-resource-saving traditional Chinese medicinal material cleaning device

InactiveCN108526058APrevent splashResidue reductionDrying gas arrangementsCleaning using toolsWater resourcesEngineering

The invention discloses a water-resource-saving traditional Chinese medicinal material cleaning device which comprises a base. A working box is fixedly arranged at the top of the base through a support, a cleaning box is rotatably arranged at the inner bottom of the cleaning box through roll balls, a first speed reduction motor is fixedly arranged at the bottom center of the working box, a top motor shaft of the first speed reduction motor is fixedly connected with the bottoms of the working box and the cleaning box in a penetrating manner, a plurality of water drainage ports are uniformly formed in the bottom of the side wall of the cleaning box, a water drainage pipe is connected at the right lower corner of the working box, a water tank is arranged at the top of the base, the water drainage pipe penetrates the top of the water tank and is connected in the water tank, the water tank is provided with a filtering drawer, the filtering drawer is positioned below the water drainage pipe,and an opening for penetrating the filtering drawer is formed in the side wall of the water tank. According to the cleaning device, cleaned water directly shook off under the rolling action, water stain residue is decreased, subsequent processing is facilitated, sewage is filtered, water is recycled, and water resources are effectively saved.

Owner:苏清凉

Automatic cleaning method for engine cylinder cover

ActiveCN104722522AGood cleaningKeep dryDrying solid materials without heatDrying machines with non-progressive movementsAutomatic controlControl system

The invention discloses an automatic cleaning method for an engine cylinder cover. According to the automatic cleaning method, automatic control is achieved through an automatic control system in the cleaning process, and spray nozzles are driven by a three-dimensional moving device to move below the engine cylinder cover and spray cleaning fluid or compressed air, so that the engine cylinder cover is washed. The automatic cleaning method is characterized in that in the cleaning process, the two ends of the engine cylinder cover are installed on a machine frame through a horizontal rotating shaft, the engine cylinder cover is driven by a servo motor to rotate, the dimension that the cleaned workpiece rotates is added on the basis of three-dimensional movement cleaning, so that the effect of simulating manual cleaning is achieved, and therefore the cleaning efficiency is improved. By the adoption of the automatic cleaning method, the effect of simulating manual cleaning can be achieved. The automatic cleaning method has the advantages that the cleaning pertinency is good, the cleaning effect and the drying effect are good, the cleaning efficiency and the drying efficiency are high, energy is saved, and consumption is reduced.

Owner:CHONGQING HONGYI MACHINERY

Cylinder cleaning screen for vacuum low-temperature grain drying tower

The invention discloses a cylinder cleaning screen for a vacuum low-temperature grain drying tower. The cylinder cleaning screen comprises a cleaning screen shell and a screen drum. A feeding port and an air suction port are formed in the top of the cleaning screen shell. The bottom of the feeding port is connected with a feeding shedding plate which can be connected with the screen drum. A variable-frequency motor is arranged on one side of the cleaning screen shell. Rotation rods are arranged on the two sides of the screen drum and are connected with the cleaning screen shell through bearing blocks. An output shaft of the variable-frequency motor is connected with the rotation rods. A brush is arranged at the top end of the screen drum, and the brush is connected with the cleaning screen shell through a fixing rod. An induced draft fan is arranged at the bottom end of the cleaning screen shell. The induced draught fan is located on one side of the screen drum. The cylinder screening screen is simple in overall structure and novel in design and has very good popularization value.

Owner:安徽富通环保节能科技股份有限公司

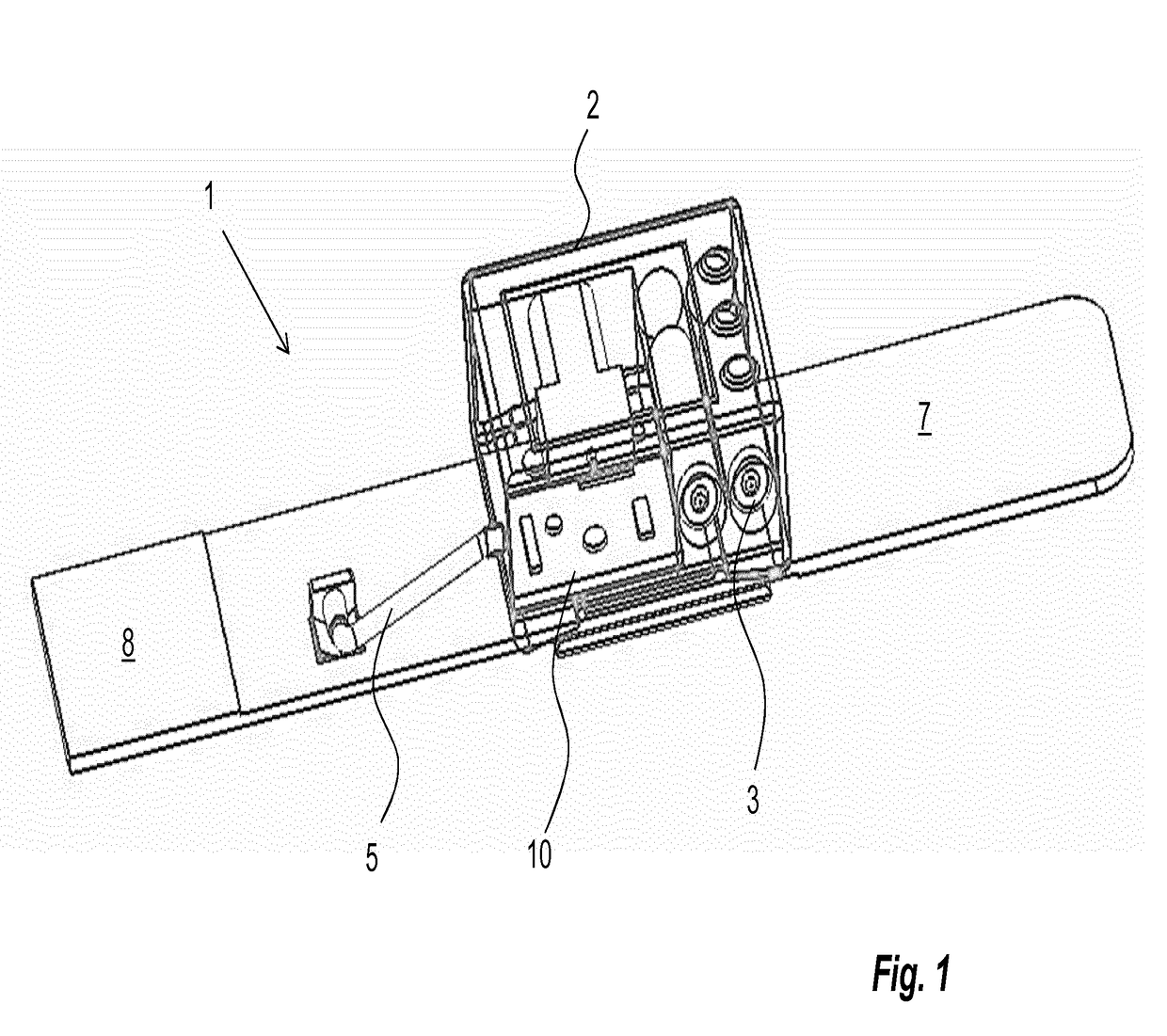

Smart Tourniquet

InactiveUS20170325825A1Good cleaningVisual indicationEndoscopesSurgical instrument detailsTourniquetVein

A smart tourniquet includes a casing having a control unit; a contact area arranged to the casing, configured to contact a patient's skin, and connected to the control unit; a cuff arranged to the casing with an inflatable bladder; an adjustable strap arranged to the cuff for securing the cuff and casing to the patient; a pump contained in the casing, connected to the bladder, and controlled by the control unit; a thermoelectric module contained in the casing, controlled by the control unit, and connected to the contact area; and at least one sensor contained in the casing for detecting blood pulse and controlled by the control unit. The control unit is configured to inflate and deflate the bladder in response to blood pulse for changing a pressure around an arm or leg and to heat the contact area for vasodilating a vein under the patient's skin for visual detection.

Owner:CAREBAY EURO LTD

Solvent composition, cleaning method, coating film formation method, heat transfer medium, and heat cycle system

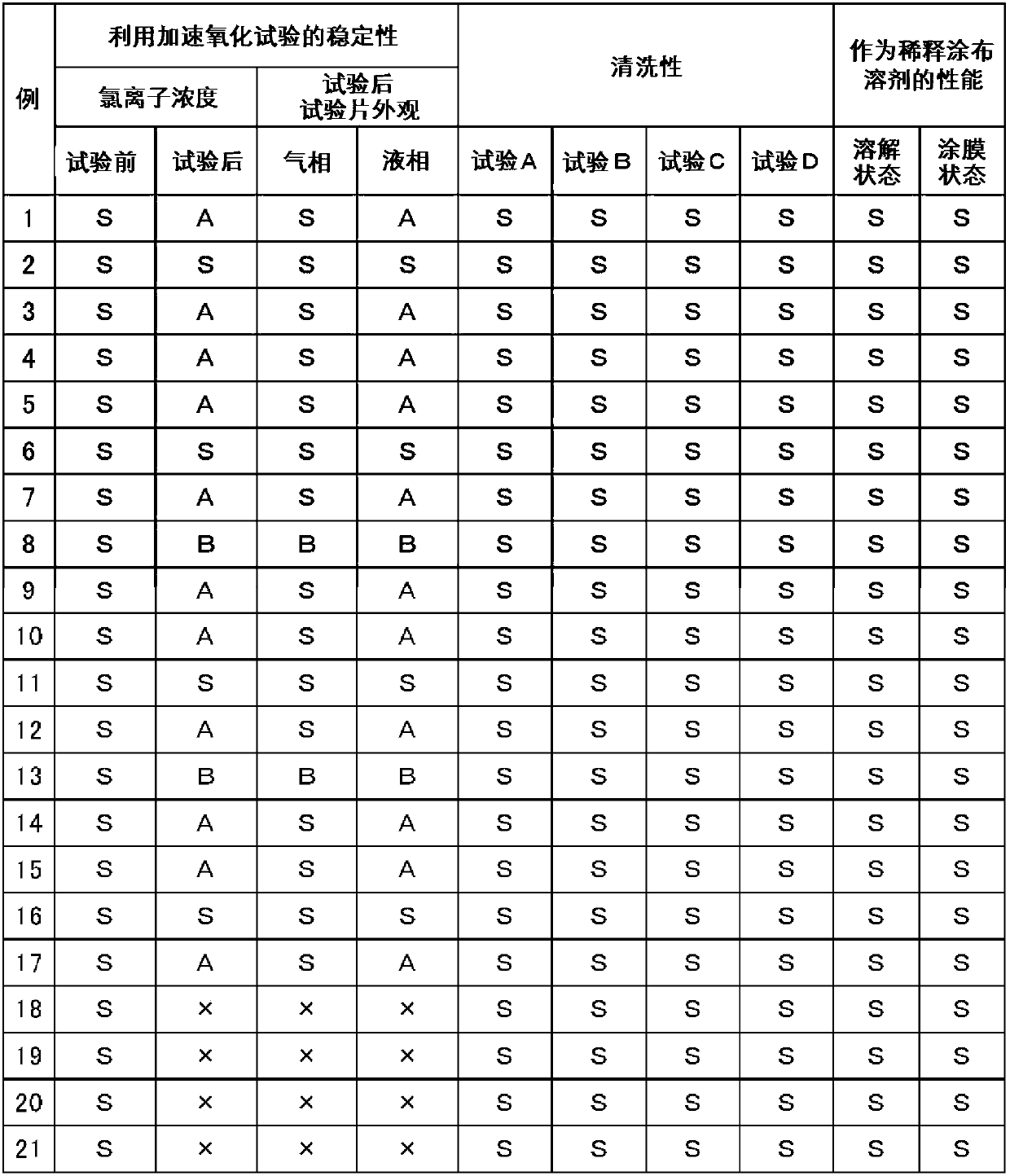

ActiveCN107849500AGood solubilityGood cleaningOrganic chemistryNon-surface-active detergent compositionsVolatile organic compoundSolubility

Provided are: a solvent composition that has an excellent ability to dissolve various organic substances, has excellent cleaning performance and drying properties, does not cause detrimental effects to the global environment, and has superior stability; a cleaning method using the solvent composition; a coating film formation method; a heat transfer medium that includes the solvent composition; and a heat cycle system using the heat transfer medium. A solvent composition that includes 1-chloro-2,3,3-trifluoro-1-propene and 1-chloro-3,3-difluoro-1-propene; a cleaning method in which the solventcomposition is brought into contact with an article to be cleaned; a method in which a non-volatile organic compound is dissolved in the solvent composition to prepare a coating film-forming composition, the coating film-forming composition is applied upon an object to be coated, and thereafter the solvent composition is evaporated to form a coating film comprising the non-volatile organic compound; a heat transfer medium that includes the solvent composition; and a heat cycle system using the heat transfer medium.

Owner:ASAHI GLASS CO LTD

Water-soluble bicomponent metal processing fluid

InactiveCN109735389ADoes not affect functional stabilityWill not affect system stabilityLubricant compositionSurface-active agentsCleansing Agents

The invention discloses a water-soluble bicomponent metal processing fluid which comprises a lubricating fluid and a rustproof cleaning fluid; the lubricating fluid comprises the following raw materials in parts by weight: 30-50 parts of lubricant, 4-10 parts of pH stabilizer, 0.05-0.25 part of de-foaming agent and 30-60 parts of deionized water; the rustproof cleaning fluid comprises the following raw materials in parts by weight: 6-15 parts of rustproof agent, 10-20 parts of pH stabilizer, 3-10 parts of surface active agent, 3-10 parts of dispersant, 0.05-0.25 part of de-foaming agent and 30-60 parts of deionized water; the lubricating fluid and the rustproof cleaning fluid can be mixed at any ratio, without influence on the original function and system stability thereof; the rustproof cleaning fluid can be used for replacing a cleaning agent for cleaning workpieces and can be reused, the cleaning agent can be saved, the discharging processing cost is reduced, and environmental protection and benefit can be both achieved; the metal processing fluid has high lubricity, excellent anti-microbial effect, rust protection, cleaning property and anti-foaming property.

Owner:SHENZHEN FRANCOOL TECH

Method for making wet wipes with natural plant cleaning agent

InactiveCN102293604ANo damageImprove solubilityNon-ionic surface-active compoundsOrganic detergent compounding agentsEnvironmental resistanceAlkylphenol

A method for fabricating wet tissues by using a natural plant cleaning agent, characterized by comprising the following steps: first, by weight parts, taking 5 to 50 parts of limonene, 3 to 7 parts of an alkylaryl ether sulfate, 10 to 15 parts of an alkylphenol ether, 0.5 to 1 part of an associative thickener, 27 to 81.5 parts of deionized water, and at room temperature, stirring for 20 to 30 min by a high-speed dispersion machine at a speed of 1,500 to 2,000 rpm for emulsification, so as to obtain a natural plant cleaning agent, wherein the alkylaryl ether sulfate is Disponil AES48, the alkylphenol ether is Dispersant 130, the associative thickener is Thickener 3820; and then, subjecting a non-woven fabric material to UV sterilization for 20 to 30 min on a wet tissue machine, cutting the non-woven fabric into strips having a size of 16 x 20 cm, and immersing the strips in the natural plant cleaning agent, wherein the immersion amount is 800 to 1,000 g / m2; and finally, folding and packaging in a routine manner into wet tissues. The wet tissues can be used to clean range hoods, kitchen stoves, film of appliances, glass, tiles and steel products without any damage, the use is convenient, and the cleaning effect is excellent; moreover, the wet tissues have the advantages of being safe and environmental protective, having strong detergency, requiring a simple production process and a low cost, thereby having wide applications.

Owner:TIANJIN LIUHONG TECH DEV

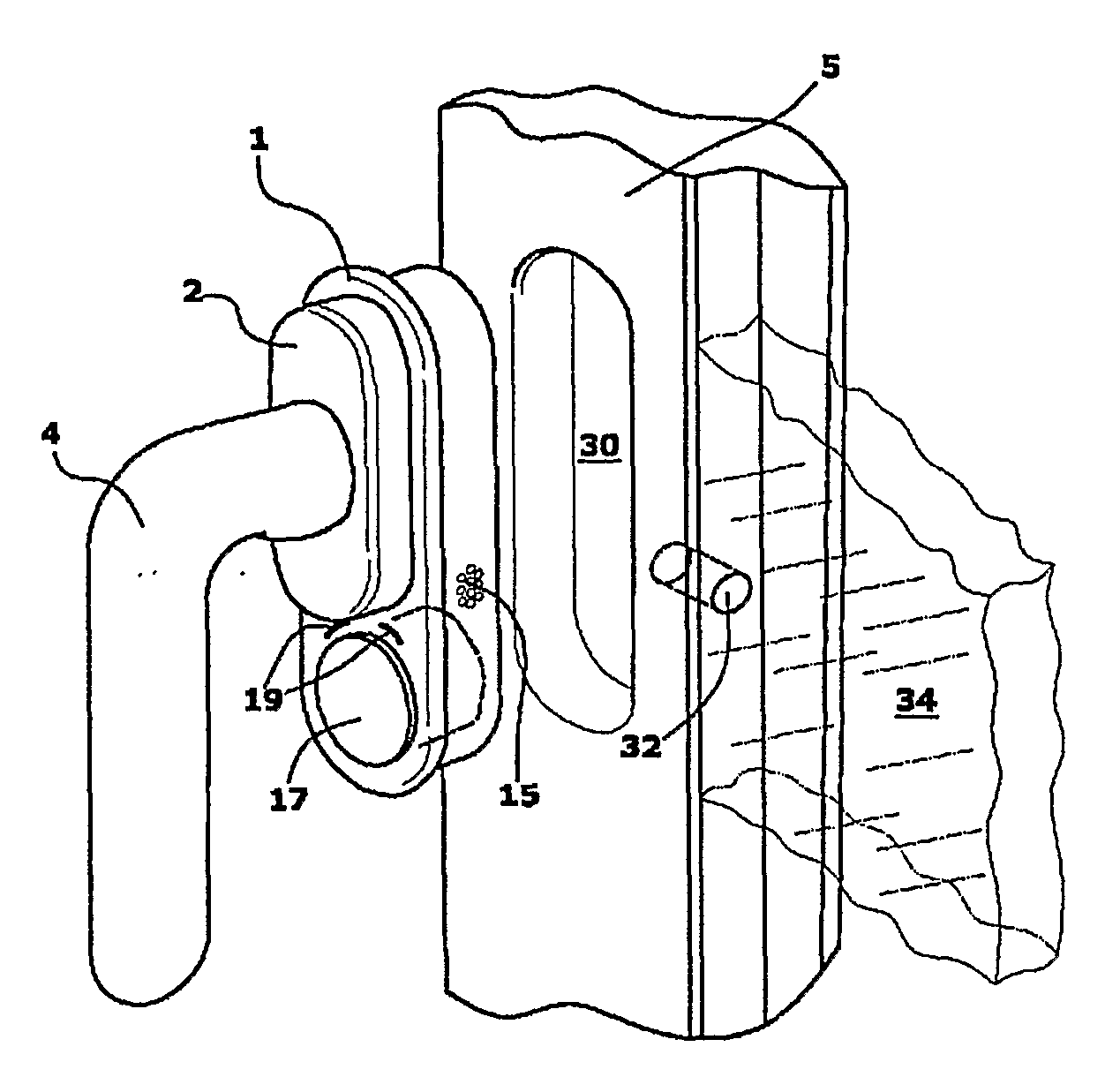

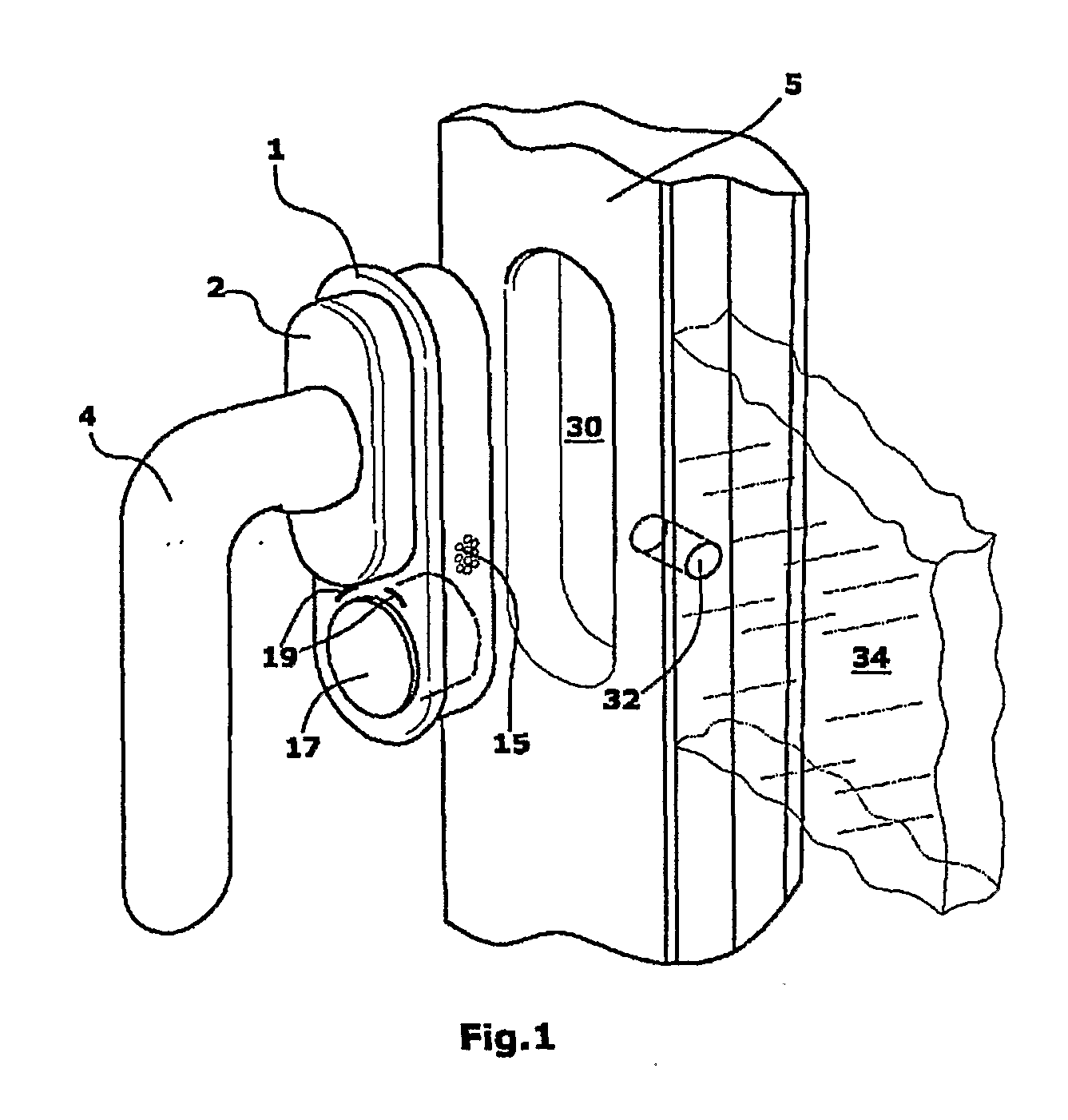

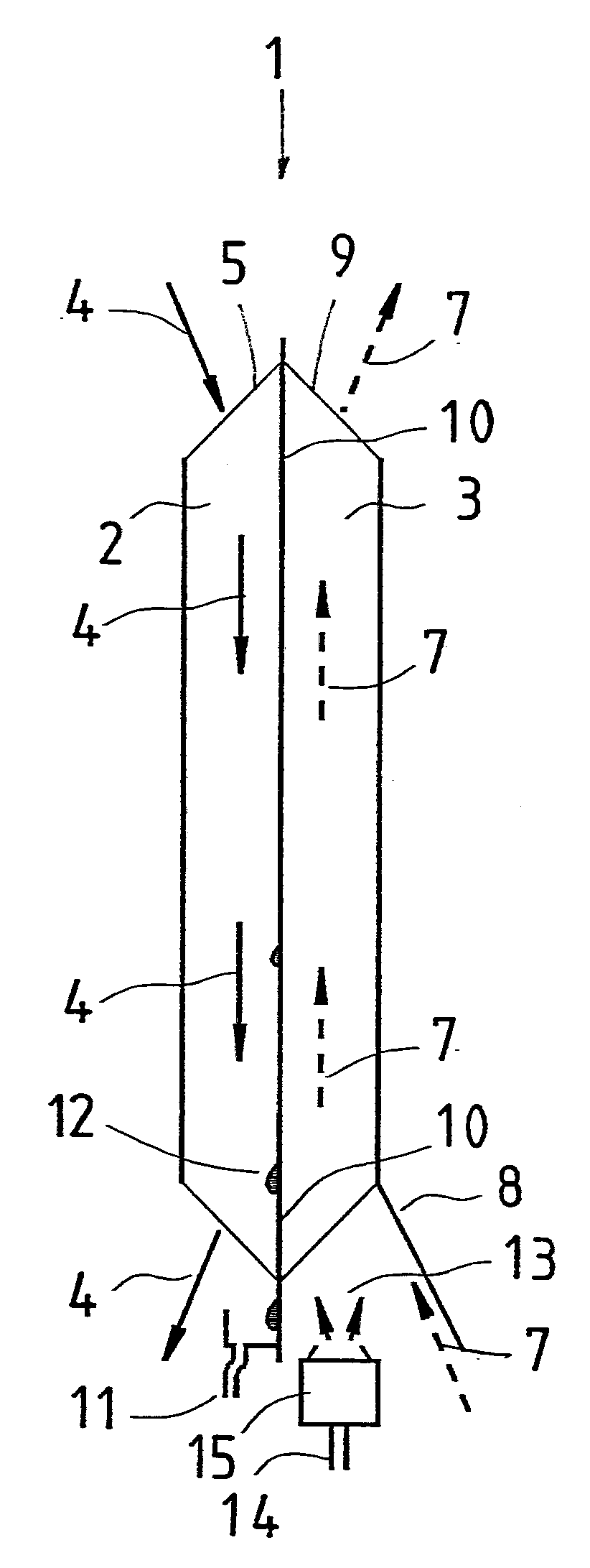

Method and an apparatus in a ventilation system

InactiveUS20120255705A1Good cleaningGood possibilityEnergy recovery in ventilation and heatingAir-treating devicesElectricityEngineering

A method for recovering heat and humidity in a ventilation system includes cooling warm and humid exhaust air at a condensation surface in a heat exchanger and collecting the condensate as formed, heating dry and cold supply air at the opposite side of the condensation surface and atomizing the condensate and supplying the atomized condensate to the supply air at the supply air inlet of the heat exchanger. The atomizing is generated b a piezoelectric atomizer. A device for recovering heat and humidity in a heat exchanger in a ventilation system includes a condensation surface at the exhaust air side of the heat exchanger and a collection device for condensate. At the inlet of the supply air side of the heat exchanger there is provided a piezoelectric atomizer that is fed with the condensate for supplying atomized condensate to the inlet.

Owner:R VENT GRP BV

Oil-removing antibacterial multifunctional cleaning agent and preparation method thereof

ActiveCN112175745AImprove permeabilityEasy to separateInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentWater rinsing

The invention relates to the technical field of oil stain cleaning agents, in particular to an oil-removing antibacterial multifunctional cleaning agent and a preparation method thereof. The oil-removing antibacterial multifunctional cleaning agent is prepared from the following raw materials in parts by weight: 0.8-2.3 parts of anionic surfactant, 0.2-0.3 part of bactericide, 3-4 parts of organicsolvent, 0.2-0.3 part of inorganic base, 0.25-0.35 part of essence and the balance of water, totaling 100 parts; and the oil-removing antibacterial multifunctional cleaning agent also comprises a cleaning builder. By controlling the use amounts and types of the anionic surfactant, the alkylol amine, the bactericide, the alcohol ether and the like, secondary dirt is prevented from being generated,a small amount of cleaning agent components with high lipophilicity are prevented from remaining on the surfaces of stains in the water rinsing process, the quick rinsing performance is improved, andthe stability of a cleaning agent system is improved.

Owner:ZHEJIANG KANGMANJIA DAILY NECESSITIES CO LTD

Automatic dishwashing cleaning composition

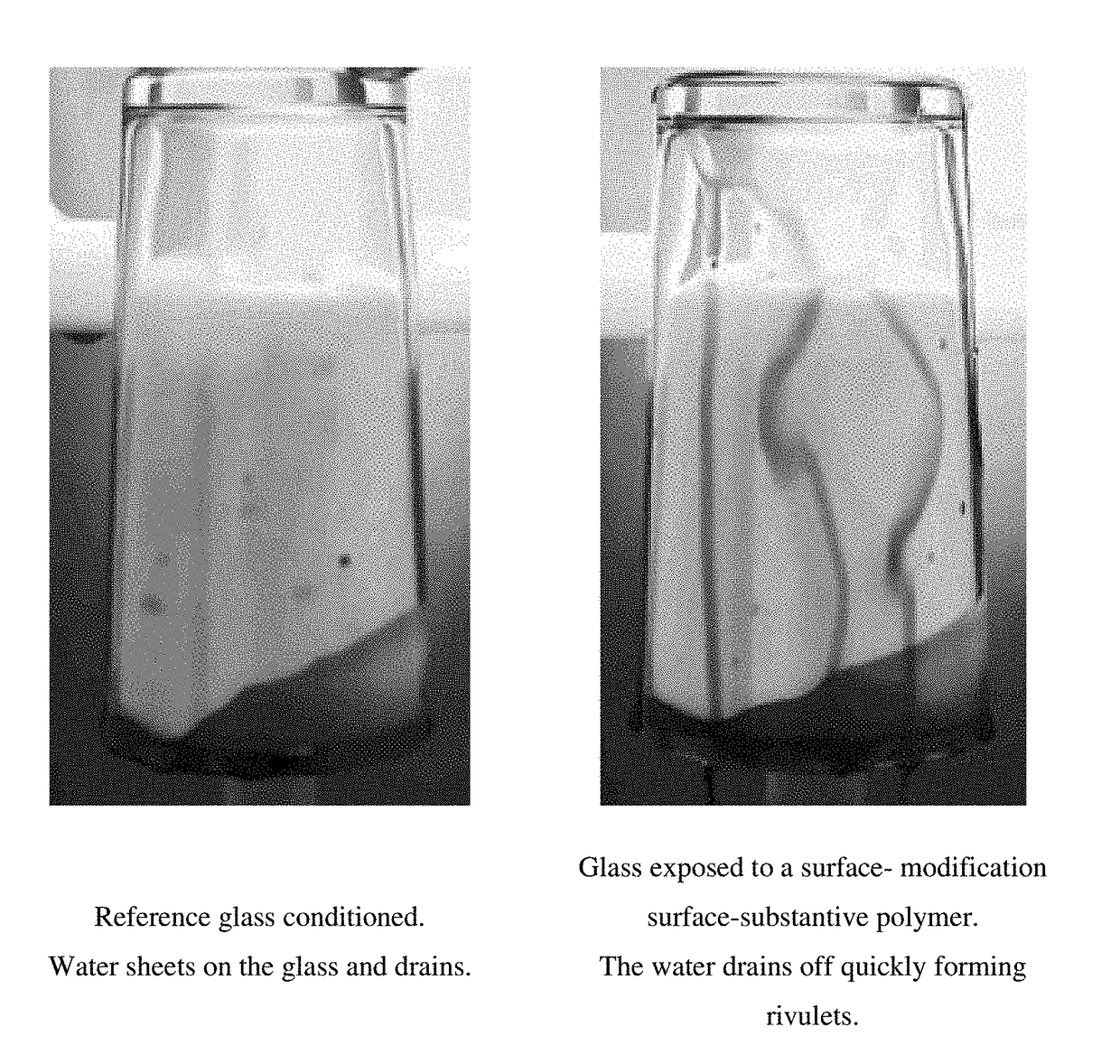

ActiveUS20170355929A1Reduction of formationGood cleaningOrganic detergent compounding agentsDetergent mixture composition preparationSurface modificationPolymer chemistry

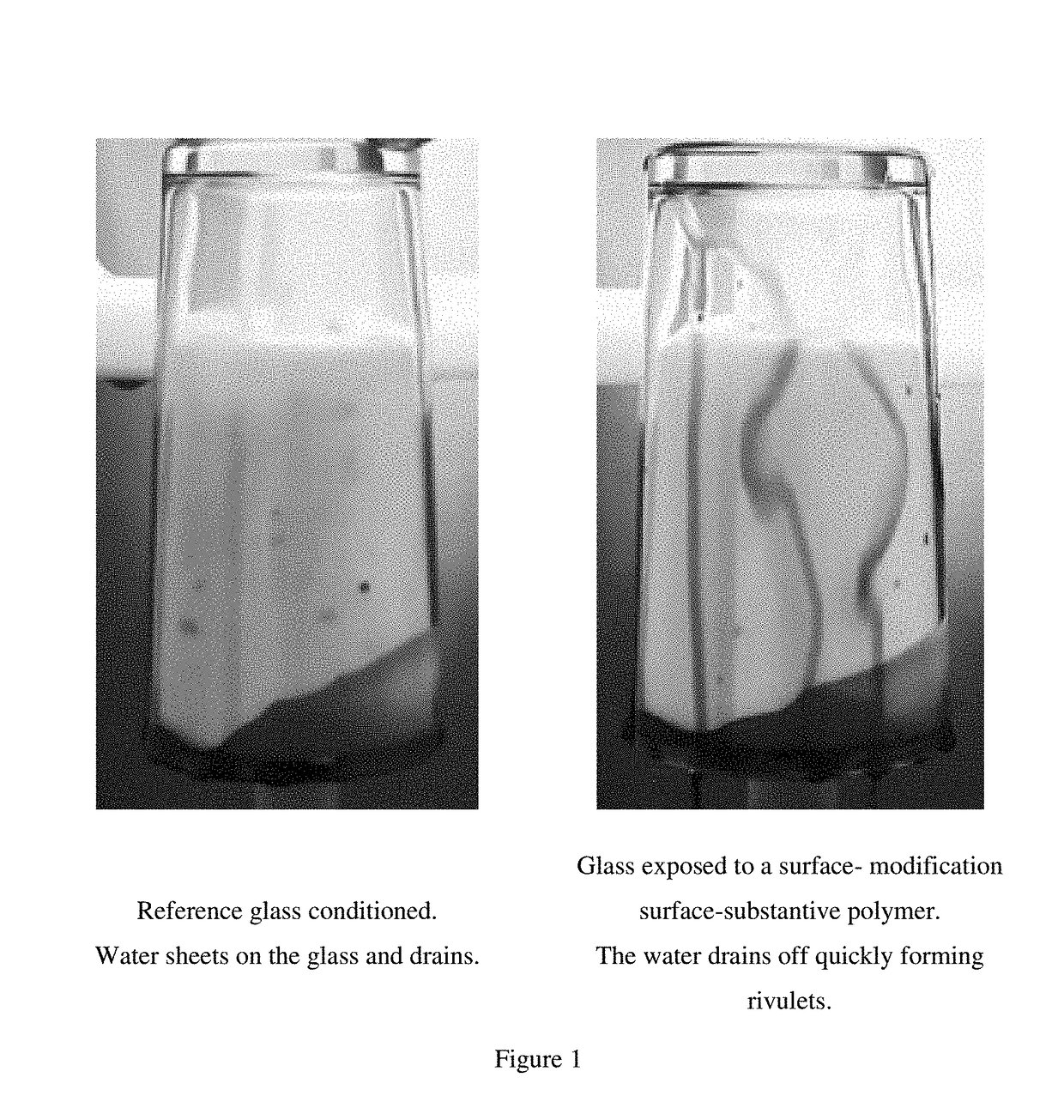

An automatic dishwashing cleaning composition including a dispersant polymer and a surface-modification surface-substantive polymer wherein the composition leaves glass after being washed with the composition in an automatic dishwasher with a contact angle with deionised water of less than about 50° and wherein the surface-modification surface-substantive polymer has a rivulet forming effect on water drainage from glass.

Owner:THE PROCTER & GAMBNE CO

Substrate cleaning machine and substrate cleaning method

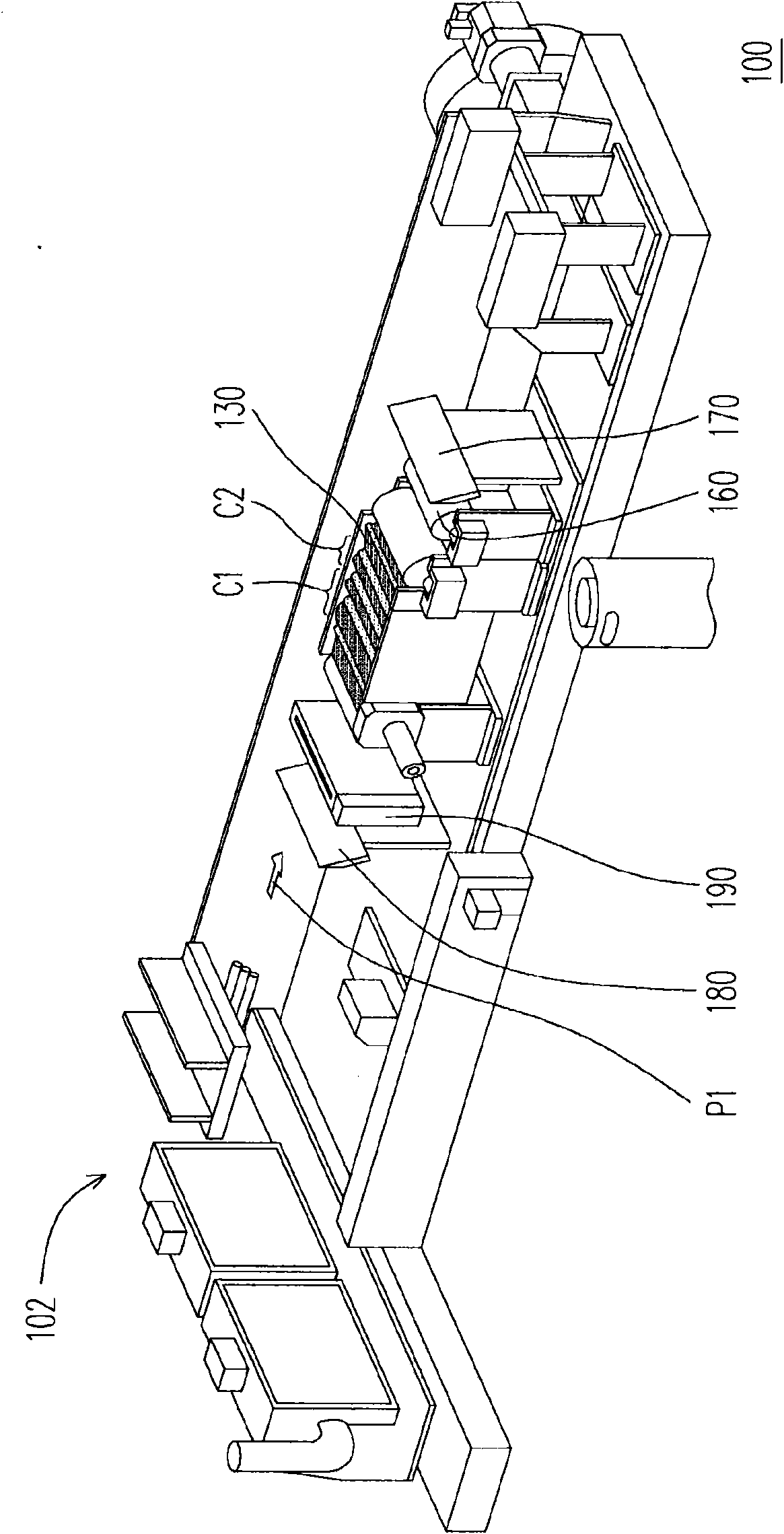

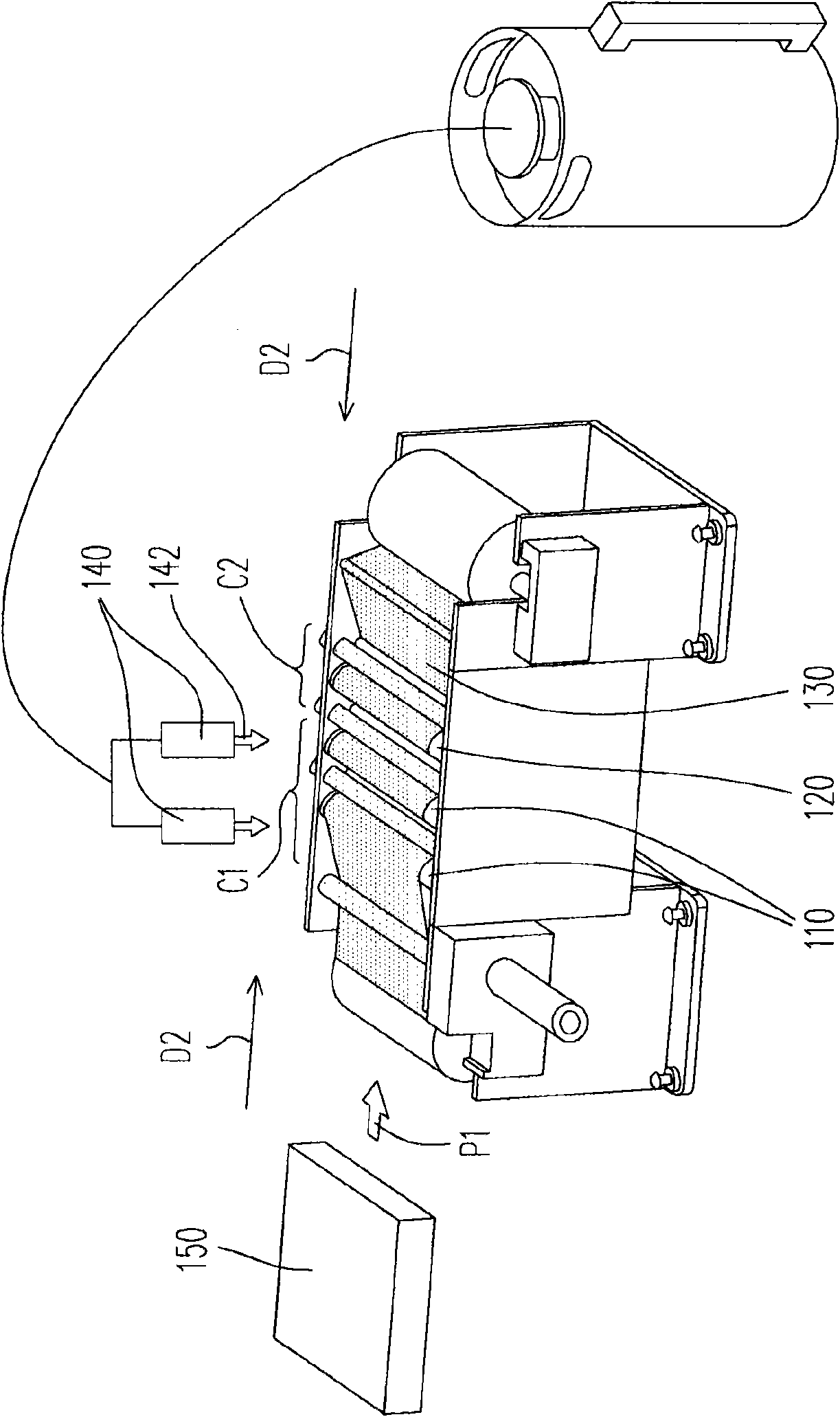

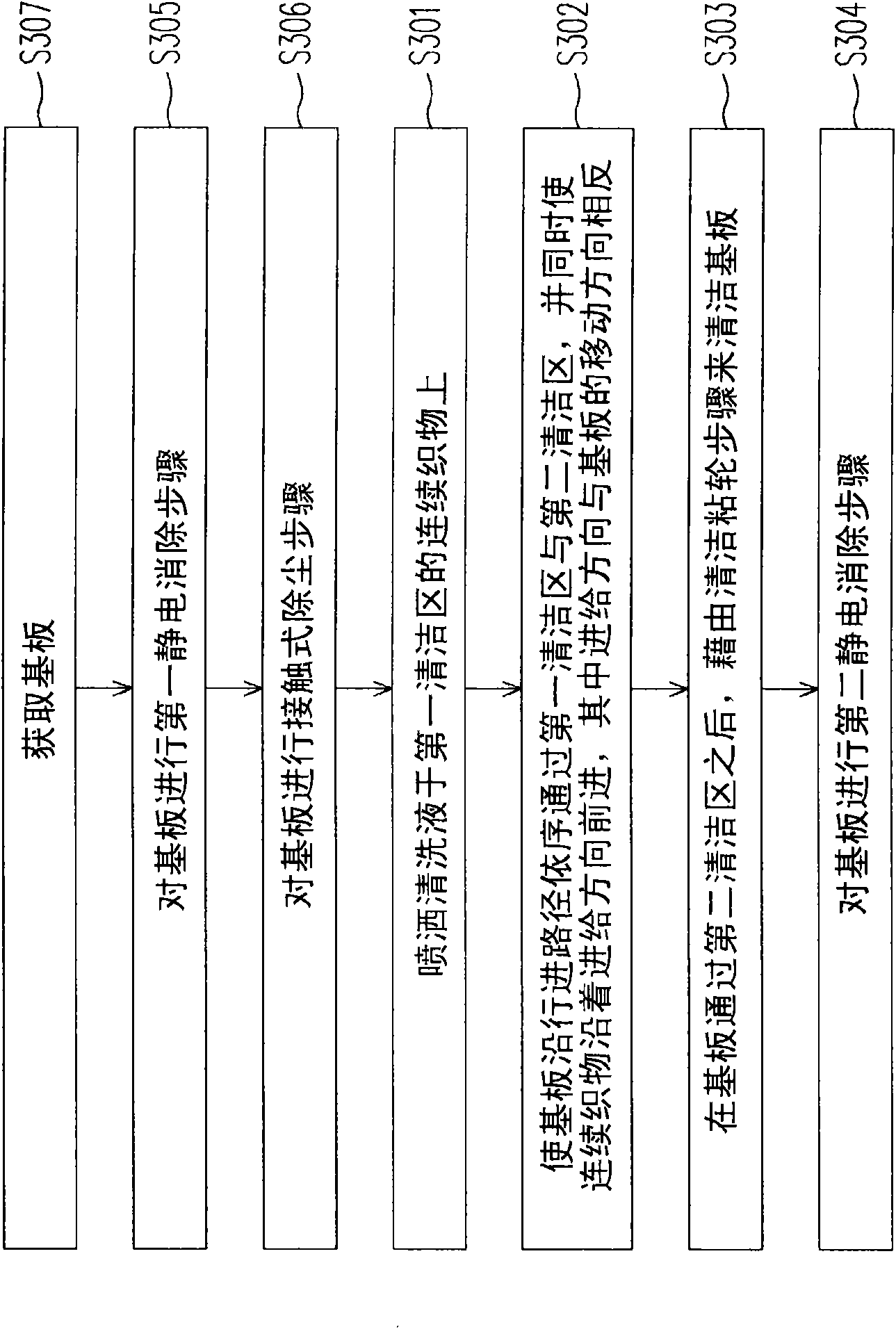

InactiveCN101969022AEasy to cleanGood dust removalSemiconductor/solid-state device manufacturingSpray nozzleMechanical engineering

The invention relates to a substrate cleaning machine which comprises a first support part, a second support part, continuous fabric and a spray nozzle. The first support part and the second support part are respectively arranged on a traveling path of a substrate, and the substrate is applicable to sequentially pass above the first support part and the second support part along the traveling path. The continuous fabric is applicable to go forward along a feed direction, and the feed direction is reverse to a movement direction of the substrate. The first support part and the second support part are used for bearing the continuous fabric, thereby respectively forming a first cleaning area and a second cleaning area on the traveling path. The spray nozzle is applicable to spraying cleaningliquid on the continuous fabric in the first cleaning area. The invention also provides a substrate cleaning method.

Owner:AU OPTRONICS CORP

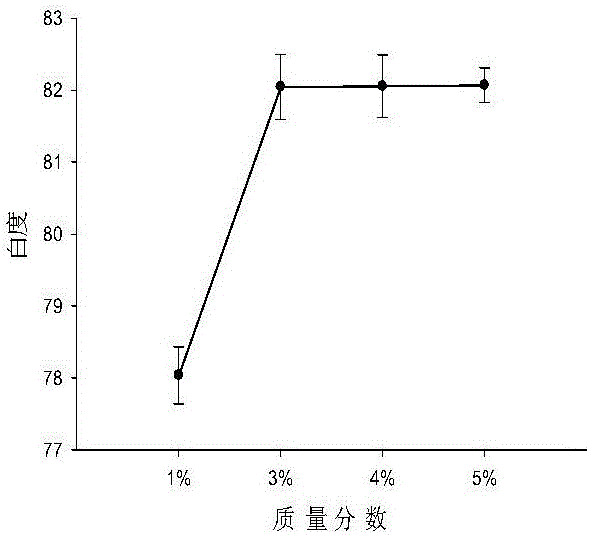

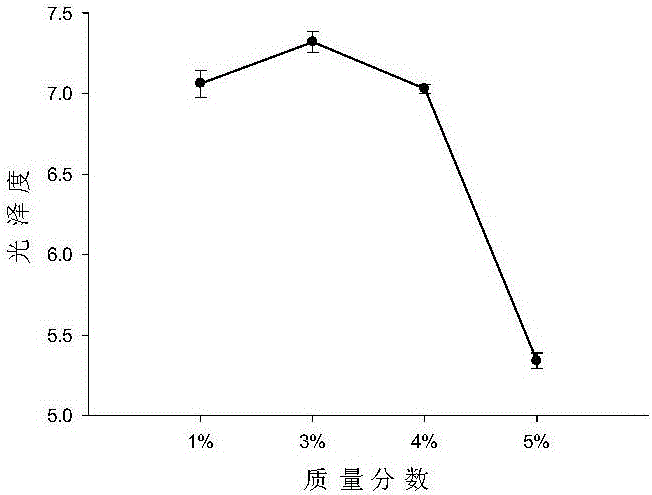

Method for cleaning mildew on paper relics

ActiveCN105755900AImprove cleanlinessImprove cleaning conditionsSurface-active detergent compositionsDetergent compounding agentsSiphonDistilled water

The invention relates to a method for cleaning mildew on paper relics. A technical scheme is as below: fixing a paper sample with mildew between two pieces of glass, soaking the sample in a mildew enzyme cleaner for paper relics at 20-40 DEG C for 15-90 min, then removing the residual cleaner by a siphon method, and naturally drying. The method has good cleaning effect on paper sample with mildew; the treated paper has whiteness improved by 5.58, glossiness improved by 0.33, and pH value increased to 6.82, and the tensile strength decrease has no significant change compared with the index in traditional distilled water cleaning.

Owner:LIAONING UNIVERSITY

Preparation method of industrial water-base detergent for metals

The invention provides a preparation method of an industrial water-base detergent for metals. The epoxyethane-epoxypropane copolymerized polyethenoxy ether lowers the strength of foam generated in the cleaning process, thereby achieving the goal of automatic defoaming without additionally adding any defoaming agent. Under the synergistic actions of all the components, the detergent has optimal cleaning and antirust effects, can form a hydrophobic protective film on the cleaned metal surface to maintain the cleaned metal. The preparation method comprises the following steps: stirring and filtering several times to obtain a mixed solution B, and distilling the mixed solution B. The detergent is clean and impurity-free, has higher quality, is safe to use, and can effectively ensure the metal luster.

Owner:ZHENJIANG RUIDE ENERGY SAVING TECH

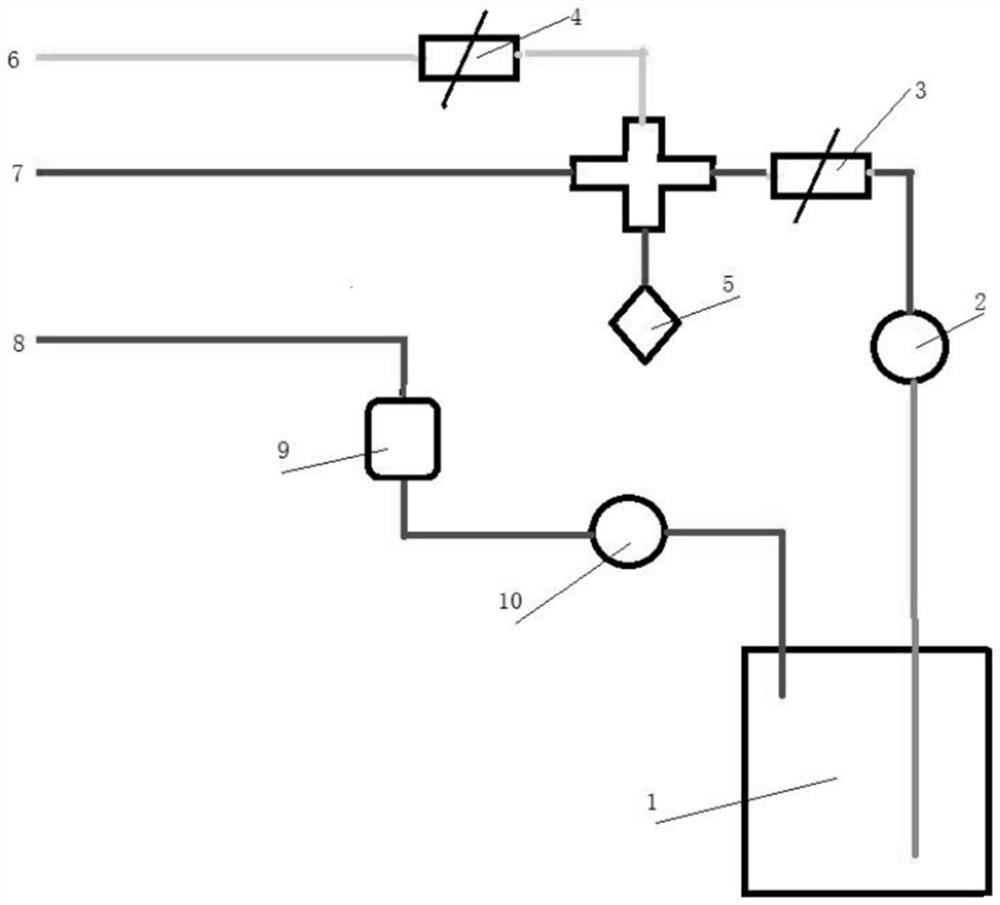

Engine cleaning system and method

PendingCN111852651AGood cleaning efficiencyGood cleaningMachines/enginesLubricant filling/drainingProcess engineeringWaste management

The invention discloses an engine cleaning system. The engine cleaning system comprises a cleaning pump, a recovery pump and a cleaning liquid barrel, one end of the cleaning pump communicates with the cleaning liquid barrel through a cleaning pipeline, and the other end of the cleaning pump sequentially communicates with a cleaning valve, a multi-way communicating vessel and an engine oil filterconnector through the cleaning pipeline; and one end of the recovery pump communicates with the cleaning fluid barrel through a recovery pipeline, and the other end of the recovery pump sequentially communicates with a filter and an engine oil sump pan oil outlet through the recovery pipeline. The multi-way communicating vessel further sequentially communicates with a pressure regulating air valveand a compressed air source through air pipes.

Owner:SHANGHAI METRONIC ROTTWEIL ELECTRONICS MACHINERY TECH CO LTD

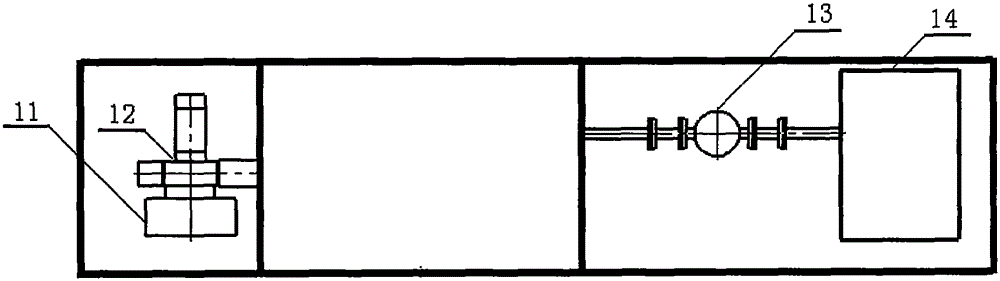

Automatic cleaning and drying integrated machine for rain boots

The invention provides an automatic cleaning and drying integrated machine for rain boots, for solving the problem that an inner cleaning machine, an outer cleaning machine and a drying machine of the rain boots are independently arranged. The automatic cleaning and drying integrated machine comprises a rain boot cleaning part and a rain boot drying part, and is characterized in that inner and outer cleaning and drying chambers are arranged, in the inner and outer cleaning and drying chambers, an inner cleaning mechanism of the rain boot cleaning part and an inner drying mechanism of the rain boot drying part are arranged in parallel and are combined with a rain boot support mechanism, and an outer cleaning mechanism is additionally arranged above the inner and outer cleaning and drying chambers. The automatic cleaning and drying integrated machine is of a movable closed box structure, is complete in function and attractive in appearance, is environmentally friendly and sanitary, is small in floor area, and is convenient to use; the features of compact structure and reasonable design are fully exerted. With the automatic cleaning and drying integrated machine, the inner and outer cleaning as well as the drying processes of the rain boots are carried out once on one station of one machine. The automatic cleaning and drying integrated machine has the advantages that multiple purposes are realized, the functions are complete, the working procedure is simple, the work efficiency is high, the floor area and manpower and material resources are saved, water resource and electricity resource are saved, etc.

Owner:张勤

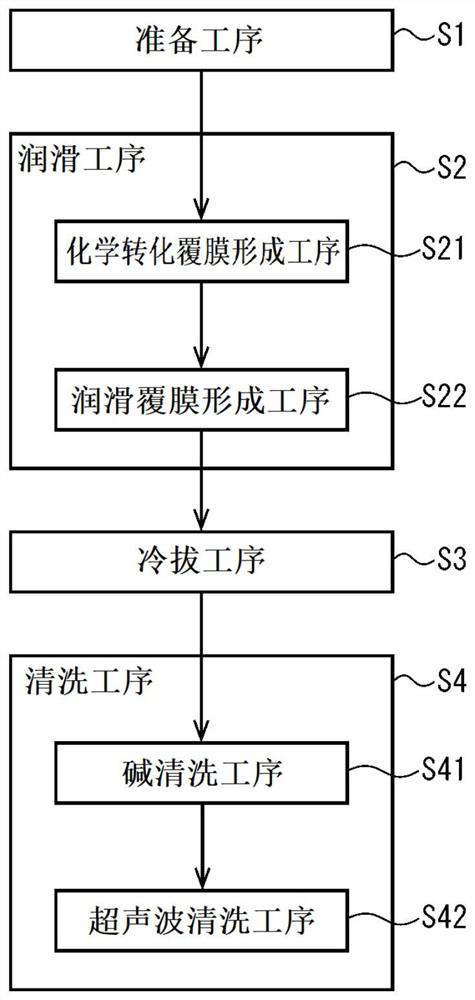

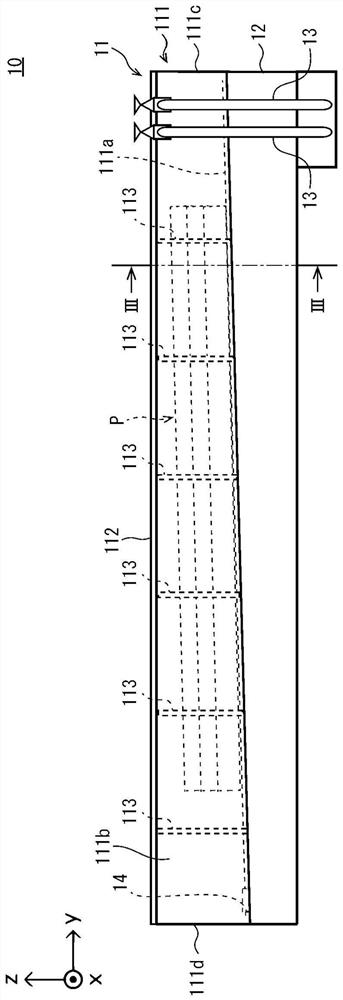

Method for manufacturing metallic pipe, and method for washing metallic pipe

PendingCN112805409AGood cleaningLow costHollow article cleaningMetallic material coating processesMegasonic cleaningChemical conversion

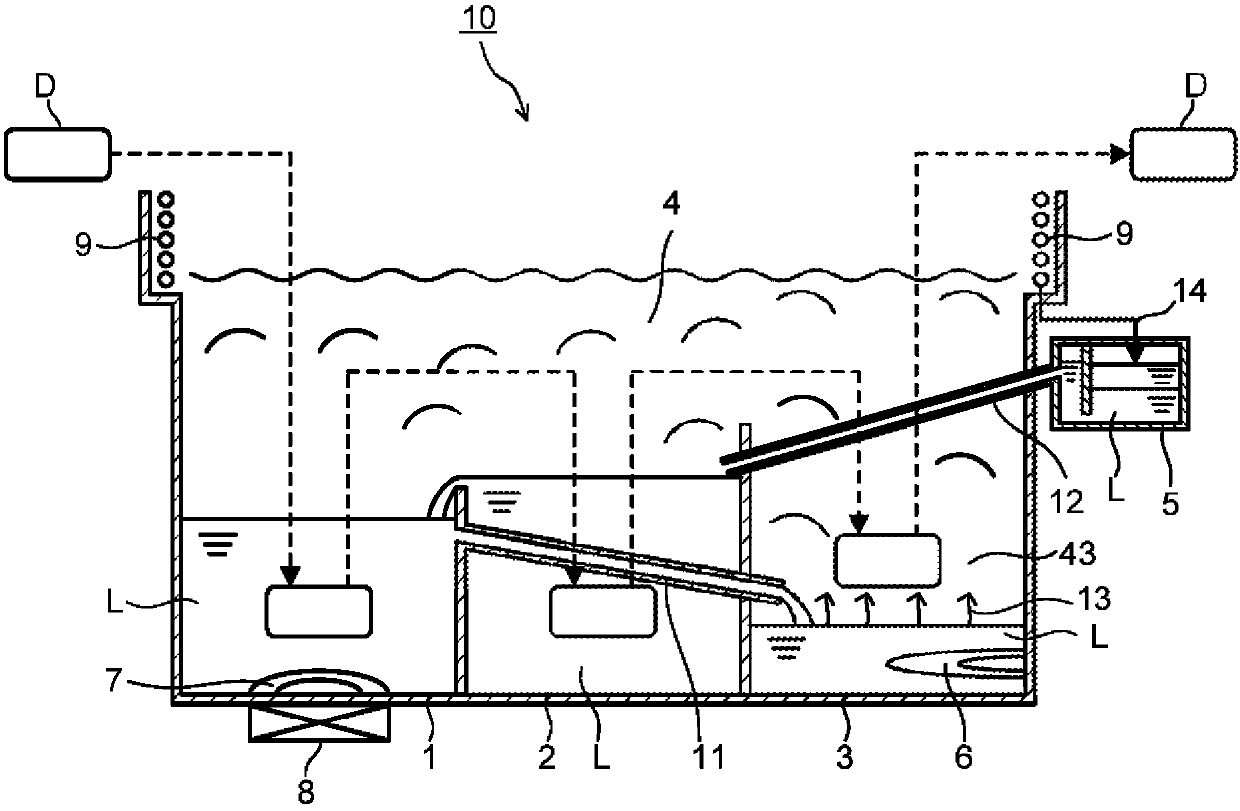

In the washing of a metallic pipe having a chemical conversion coating film and a lubricant coating film both formed on the surface thereof, it is aimed to achieve both of energy saving (cost reduction) and good washability. A method for manufacturing a metallic pipe (P) comprises: a provision step (S1) of providing an original pipe made from a metal; a lubrication step (S2) of forming a chemical conversion coating film on the surface of the original pipe and then forming a lubricant coating film on the chemical conversion coating film; a cold drawing step (S3) of subjecting the original pipe having the chemical conversion coating film and the lubricant coating film formed thereon to a cold drawing work to form a metallic pipe (P) having a desired size; and a washing step (S4) of washing the metallic pipe (P) to remove the chemical conversion coating film and the lubricant coating film. The washing step (S4) comprises: a step (S41) of immersing the metallic pipe (P) in an alkaline defatted solution which is placed in an alkali washing vessel (11) and is not heated to a high temperature; and a step (S42) of irradiating a wash solution in an ultrasonic washing vessel (21) with ultrasonic waves and immersing the metallic pipe (P) that has been immersed in the alkaline defatted solution in the wash solution while generating fine bubbles in the wash solution.

Owner:NIPPON STEEL CORP

Micro-emulsion cutting fluid and preparation method thereof

The invention discloses micro-emulsion cutting fluid and a preparation method thereof. The micro-emulsion cutting fluid is prepared from the following raw material components in percentage by mass: 20to 50 percent of a compound anti-rust agent, 6 to 20 percent of lanolin, 5 to 15 percent of polyethylene glycol 400, 10 to 26 percent of fatty alcohol-polyoxyethylene ether AEO-9, 8 to 35 percent oflubricating oil, 2 to 10 percent of sorbitan fatty acid ester and the balance of water. The preparation method of the micro-emulsion cutting fluid comprises the following steps: firstly, adding deionized water into an agitator, and sequentially and slowly adding polyethylene glycol 400, fatty alcohol-polyoxyethylene ether AEO-9 and sorbitan fatty acid ester in a low rotating speed state; stirringat normal temperature until a system is uniform and transparent; secondly, adding triethanolamine borate, triethanolamine oleic soap, the lanolin and refined lubricating oil into the system obtained in the first step and stirring to obtain the micro-emulsion cutting fluid. The cutting fluid disclosed by the invention has the advantages of good biodegradability, extreme pressure lubricity, rust resistance, cooling and cleaning properties, and has no harm to a human body.

Owner:苏州市神顺新晨生物科技有限公司

A kind of environment-friendly emulsifying release agent and preparation method thereof

PendingCN106065354ADoes not corrode the moldGood cleaningLubricant compositionChemistryDecomposition

The invention discloses an environmentally friendly emulsified release agent, which comprises the following raw materials in parts by mass: 15-25 parts of dimethyl silicone oil, 5-8 parts of polyvinyl alcohol, 6-9 parts of ricinoleic acid, and 3-6 parts of dimer fatty acid 5-7 parts of co-emulsifier, 6-10 parts of hydroxyalkylamine, 0.6-1.0 part of organic dicarboxylic acid, 0.05-0.1 part of fungicide, 45-60 parts of deionized water; Synthetic main emulsifier and antirust agent with base amine, supplemented by co-emulsifier to emulsify simethicone oil in deionized water and polyvinyl alcohol to form a film, providing a method mainly used for epoxy resin and unsaturated polyester materials Emulsified mold release agent for external use of forming molds, sprayed on the surface of molds, to achieve the effect of easy molding of epoxy resin and unsaturated polyester products, no corrosion of molds, no bonding with molds, no residual decomposition products, and no influence on products Color and performance, good cleaning, no pollution to the environment and so on.

Owner:刘方旭

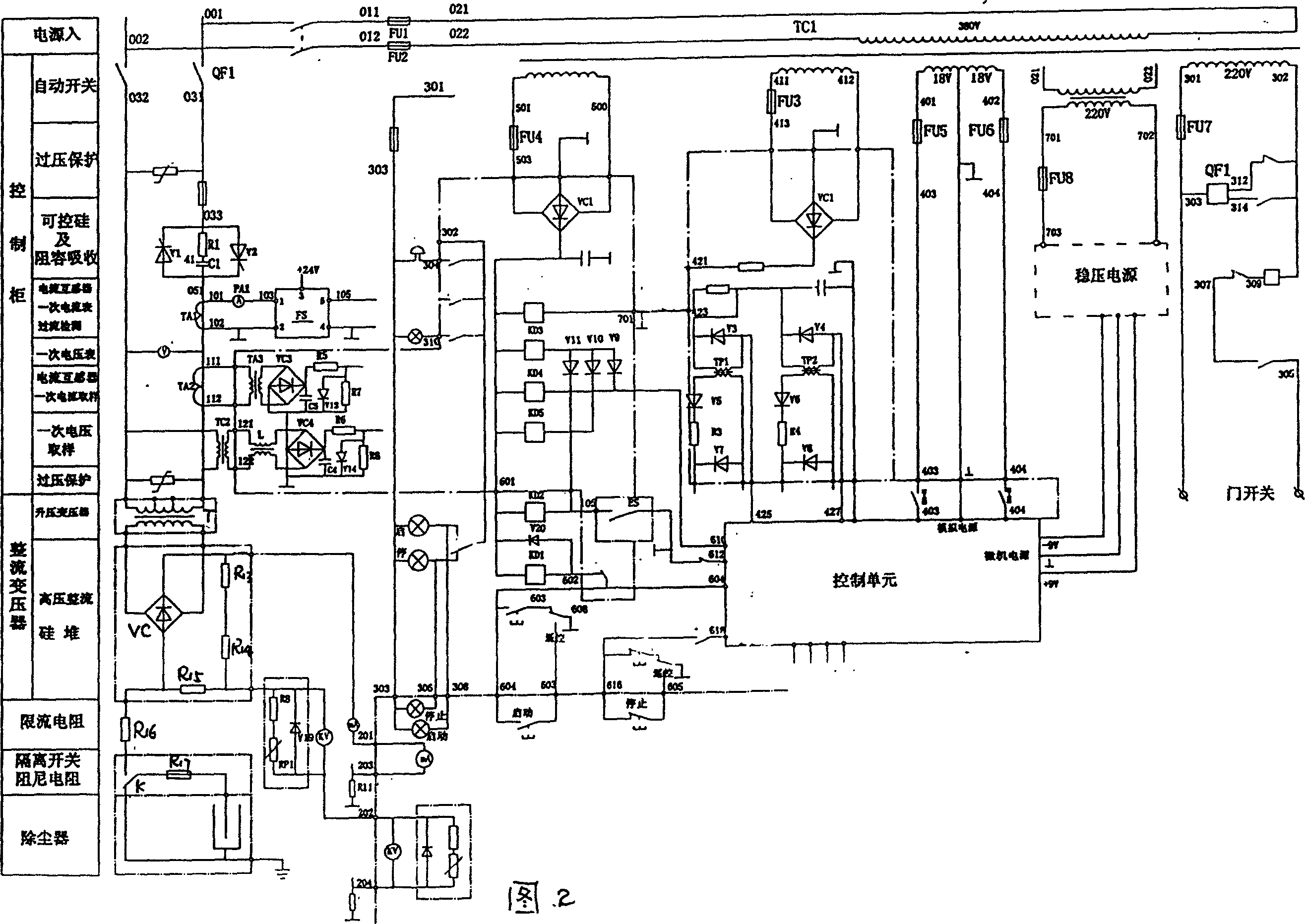

Industrial electric dust removing device purifying system

ActiveCN1291794CReasonable structureImprove dust removal effectExternal electric electrostatic seperatorElectric supply techniquesLow voltageEngineering

The present invention relates to industrial electrically dusting purification system comprising electric duster, high voltage DC power supply and low voltage PLC control system. The purification system is provided with high voltage SCR power supply, upper computer communication interface for communication with upper computer, and low voltage control system with programmable PLC controller to control the pulse shaker, heater and discharge unit of the electric duster. The present invention adopts live showing clean technology to spray atomized water to clean dust collecting electrode and discharge electrode for optimized electric field cleaning effect and lowered operation cost; and has also electromagnetic shaker. The present invention has reasonable structure, high dusting effect and low cost.

Owner:高国纯

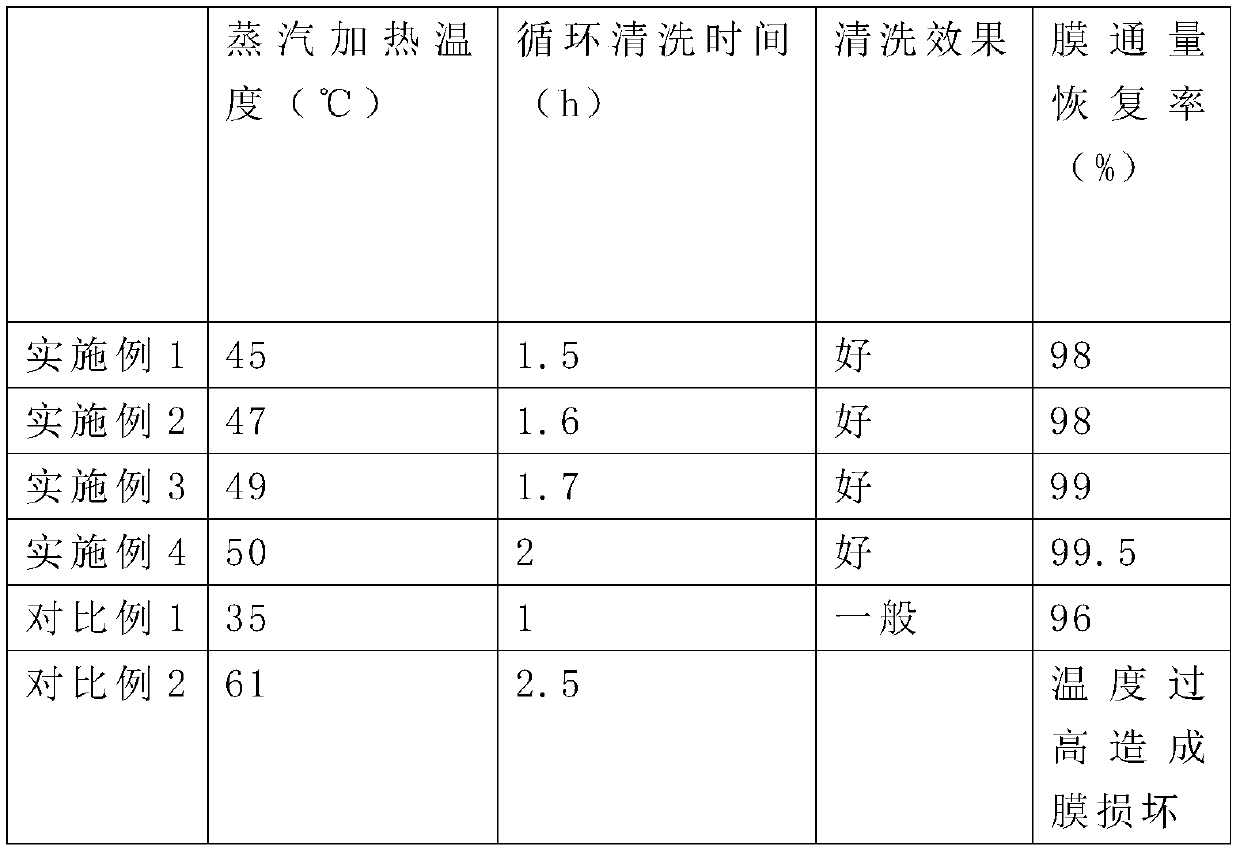

Cleaning process of alkali liquor desalter

InactiveCN110975632AReduce labor intensityImprove recovery rateGeneral water supply conservationAlkali metal sulfite/sulfate purificationProcess engineeringEnvironmental engineering

The invention discloses a cleaning process of an alkali liquor desalter and belongs to the technical field of chemical separation. The process is characterized by comprising the following steps of: a,after the desalter runs, the pressure rises to a set value of the cleaning process, a machine is stopped for cleaning; b, firstly, a cleaning tank is filled with desalted water, and residual materials in the desalting device are ejected out after the machine is stopped; and c, the cleaning tank is filled with desalted water, steam is introduced to raise the temperature to 45-50 DEG C, and cycliccleaning is conducted for 1.5-2 h. The cleaning process is simple, the labor intensity of personnel is greatly reduced, the cleaning efficiency and the cleaning effect are improved, the cleaning watercost is saved, and the membrane flux recovery rate is increased.

Owner:YIBIN HIEST FIBER +1

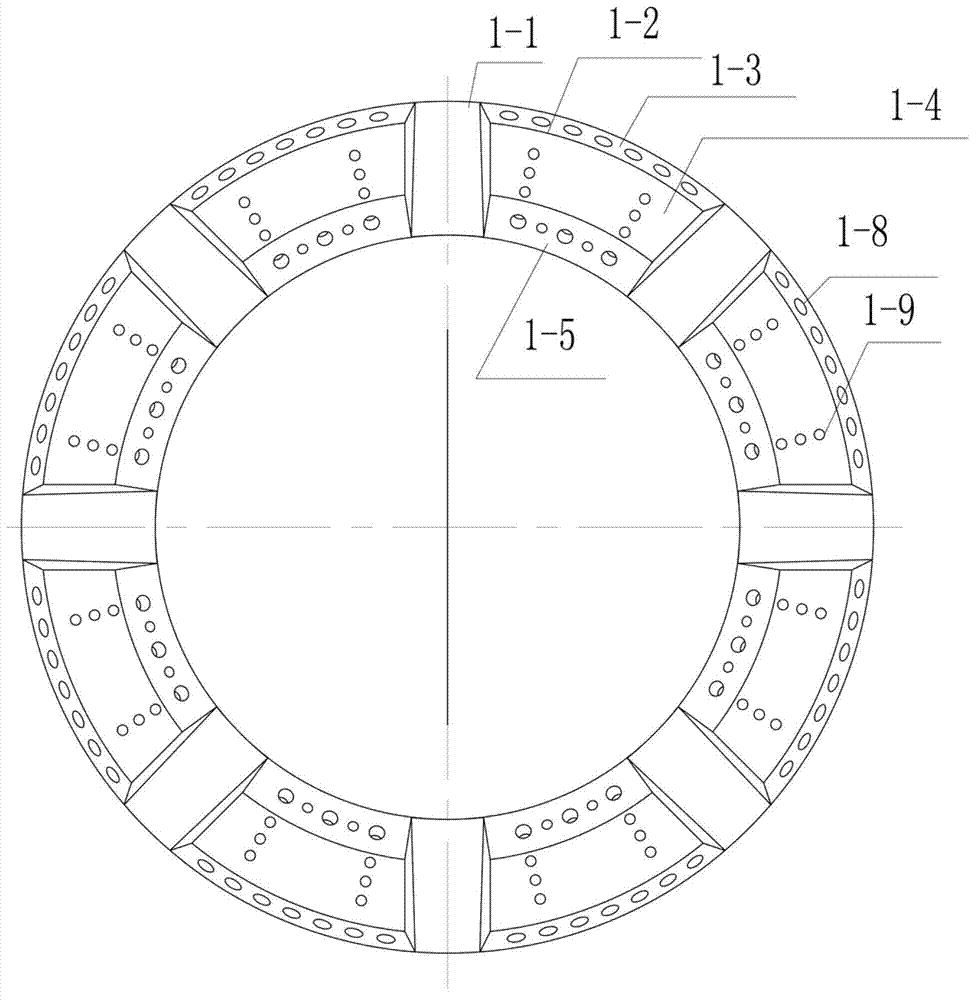

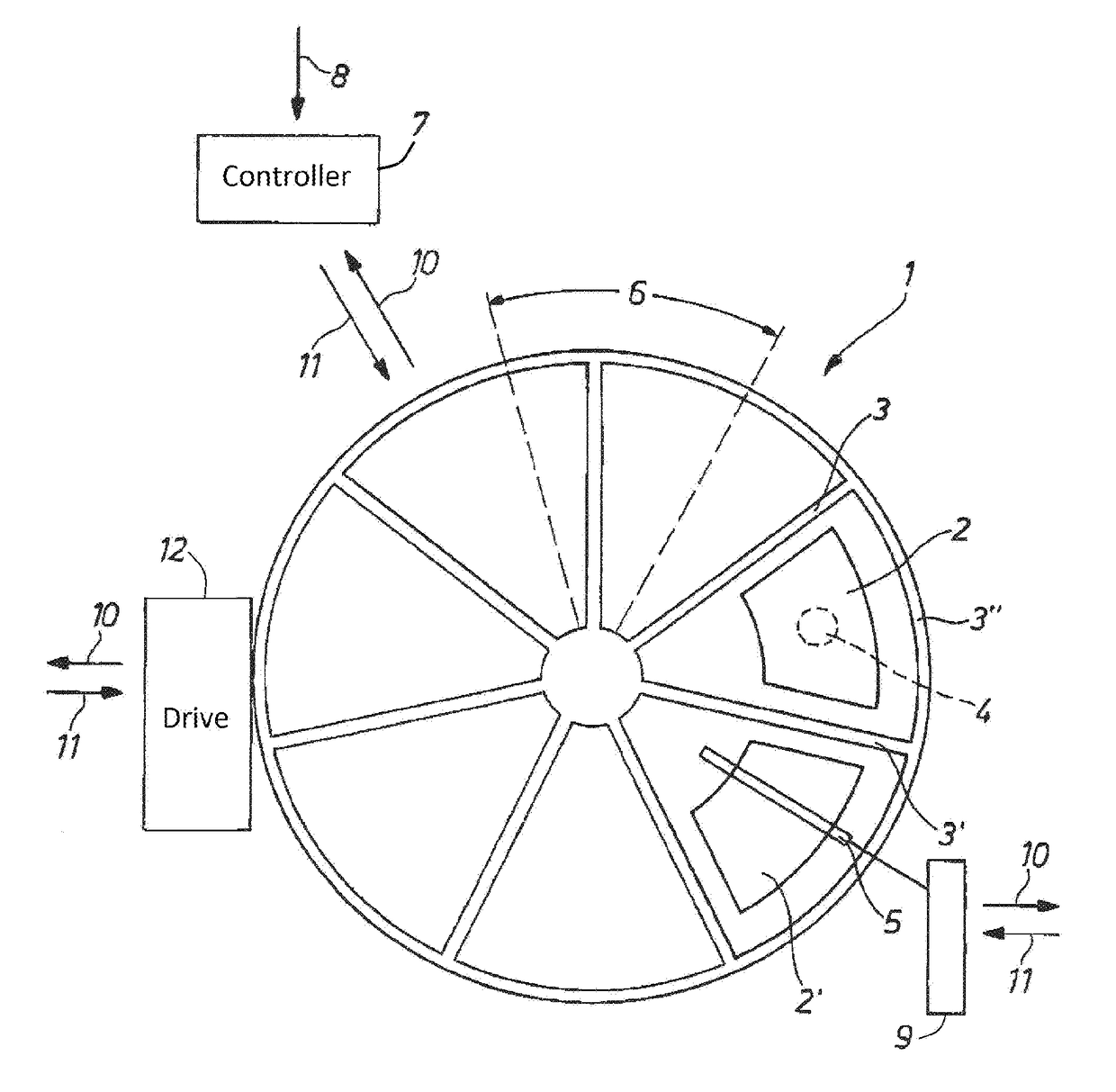

Method and apparatus for operating a screening wheel filter

A method and an apparatus for operating a screening wheel filter for high-viscosity melts with pressures of >10 bar and temperatures of >90° C., wherein a screening wheel (1) is rotationally driven step by step, and screening inserts (2) arranged in the screening wheel (1) are successively subjected to a stream of cleaning agent produced by a cleaning agent drive (9) in a backflushing cleaning station, are to be optimized in such a way that less cleaning agent is used, better cleaning of the screening inserts takes place and a saving of energy is ensured. For this purpose it is proposed that the cleaning backflushing in the backflushing cleaning station takes place during the rotation of the screening wheel (1), wherein an open-loop or closed-loop control device (7) assigned to the cleaning agent drive (9) is used to set the amount of cleaning agent and / or the pressure of the cleaning agent and / or the flow rate of the cleaning agent in dependence on the rotational speed of the screening wheel (1) and / or in dependence on a differential pressure prevailing at the screening inserts (2) located in the melt channel (4) and the effective opening of the slot die normal to the radial is less than the distance covered by the screening wheel (1) during a driving step.

Owner:GNEUSS GMBH

Efficient industrial metal cleaning agent

The invention provides an efficient industrial metal cleaning agent. The cleaning agent is formed by the following components, by weight, 25-36 parts of a metal corrosion inhibitor, 15-17 parts of a cleaning aid, 13-15 parts of a metal rust inhibitor, 8-12 parts of triethanolamine, 5-7 parts of sodium metasilicate, 10-15 parts of sodium gluconate, 7-12 parts of alkylphenol polyoxyethylene and 3-4 parts of hydrochloric acid. The synergistic effect of the components makes the cleaning agent have best cleaning and rust inhibiting effects and form a hydrophobic protection film on the surface of a cleaned metal to main the cleaned metal, so the cleaned metal has a rust inhibition property within a period of time; the cooperation with the rust inhibitor improves the rust inhibition performance of the metal; and the cleaning agent is clean and has no impurities, so the quality of the cleaning agent is improved, and the cleaning agent is safe to use, and effectively guarantees the glossiness of the metal.

Owner:ZHENJIANG RUIDE ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com