Method and an apparatus in a ventilation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

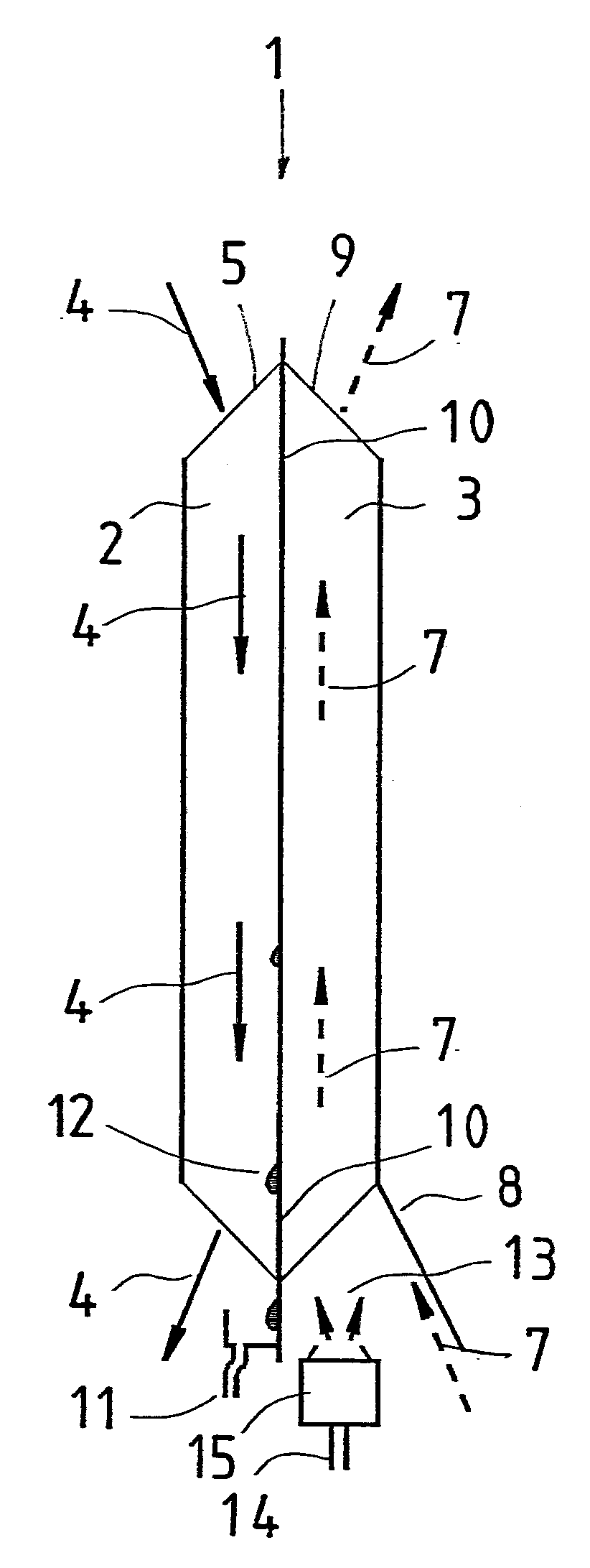

[0016]In FIG. 1, reference numeral 1 relates to a heat exchanger which operates in counter flow and which has an exhaust air side 2 and a supply air side 3. The exhaust air side may also be entitled the warm side of the heat exchanger and the supply air side be entitled its cold side. The exhaust air 4 flows in accordance with the arrows from above and downwards in the Figure from an exhaust air inlet 5 to an exhaust air outlet 6.

[0017]Correspondingly, the supply air 7 flows according to the broken line arrows in a direction from beneath from a supply air inlet 8 in an upward direction to a supply air outlet 9. The partition 10 between the exhaust air side 2 and the supply air side 3 consists of or comprises a thermally conductive material, which is gas-tight and impermeable to water, such as copper, aluminium or certain plastics qualities. The wall thickness of the partition is so slight that the wall may be designated a foil.

[0018]If it is assumed that the incoming supply air 7 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com