Cleaning process of alkali liquor desalter

A desalination device and process technology, which is applied in the field of lye desalination device cleaning process, can solve the problems of high labor intensity, complex cleaning process, low membrane flux recovery, etc., to reduce labor intensity, simple cleaning process, and improve cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

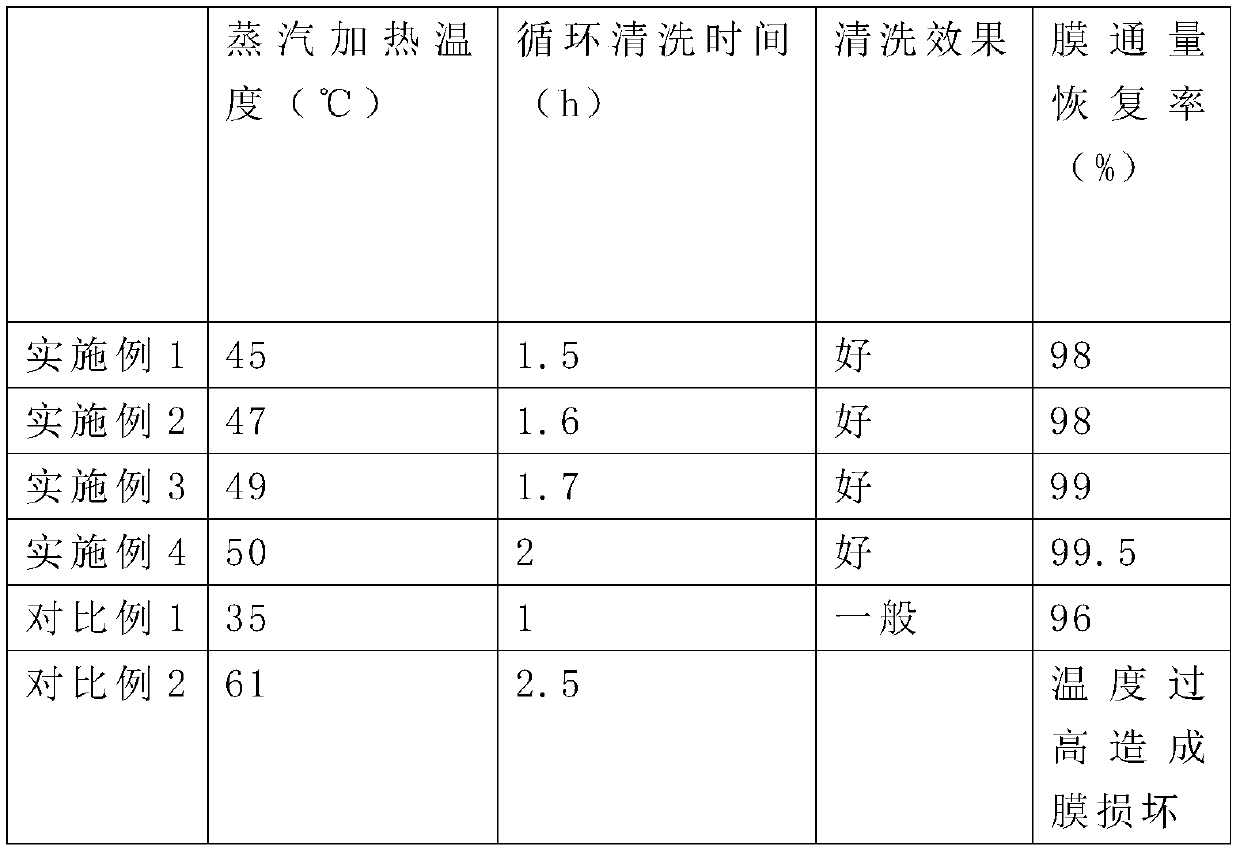

Embodiment 1

[0033] A cleaning process for an alkali desalination device, comprising the following steps:

[0034] a. After the desalination device is in operation, when the pressure rises to the set value of the cleaning process, it starts to stop for cleaning;

[0035] b. Fill the cleaning tank with demineralized water first, and eject the residual materials in the desalination device after parking;

[0036] c. Then fill the cleaning tank with demineralized water, heat it up to 45°C by passing in steam, and carry out circular cleaning for 1.5 hours.

Embodiment 2

[0038] A cleaning process for an alkali desalination device, comprising the following steps:

[0039] a. After the desalination device is in operation, when the pressure rises to the set value of the cleaning process, it starts to stop for cleaning;

[0040] b. Fill the cleaning tank with demineralized water first, and eject the residual materials in the desalination device after parking;

[0041] c. Then fill the cleaning tank with demineralized water, heat it up to 47°C by passing in steam, and carry out circular cleaning for 1.6 hours.

Embodiment 3

[0043] A cleaning process for an alkali desalination device, comprising the following steps:

[0044] a. After the desalination device is in operation, when the pressure rises to the set value of the cleaning process, it starts to stop for cleaning;

[0045] b. Fill the cleaning tank with demineralized water first, and eject the residual materials in the desalination device after parking;

[0046] c. Then fill the cleaning tank with demineralized water, heat it up to 49°C with steam, and carry out circular cleaning for 1.7 hours.

[0047] In step c, the desalinated water temperature of the circular cleaning is 49° C., and the circular cleaning time is 1.7 h. Specifically, at this temperature and the circular cleaning time, the cleaning effect and the membrane flux recovery rate are excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com