Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Full heating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

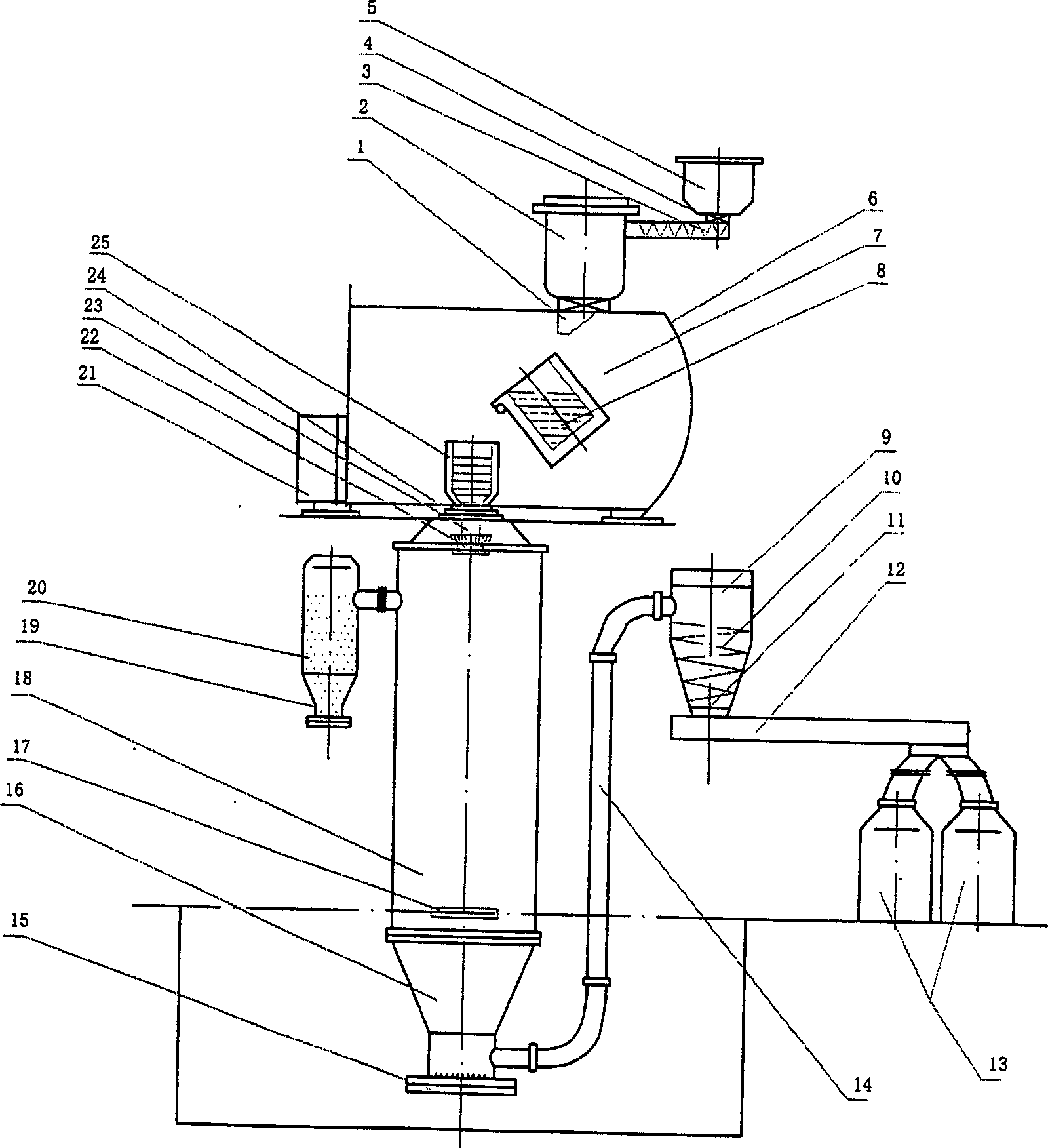

Method and apparatus for preparing rapid-solidified hydrogen-storage alloy powder material

InactiveCN1775428ASuitable for large-scale industrial productionReduce oxygen contentFuel cellsHigh pressureInduction furnace

The present invention provides a preparation method of quickly-coagulable hydrogen storage alloy powder and its equipment. Said preparation method includes four procedures of raw material preparation, smelting, making powder and hydrogenation treatment. Said invention also provides the concrete steps of the above-mentioned every procedure. Said equipment includes induction furnace or argon plasma arc furnace, atomized powder-making device and hydrogenation device, etc.

Owner:江苏申建氢能新材料有限公司

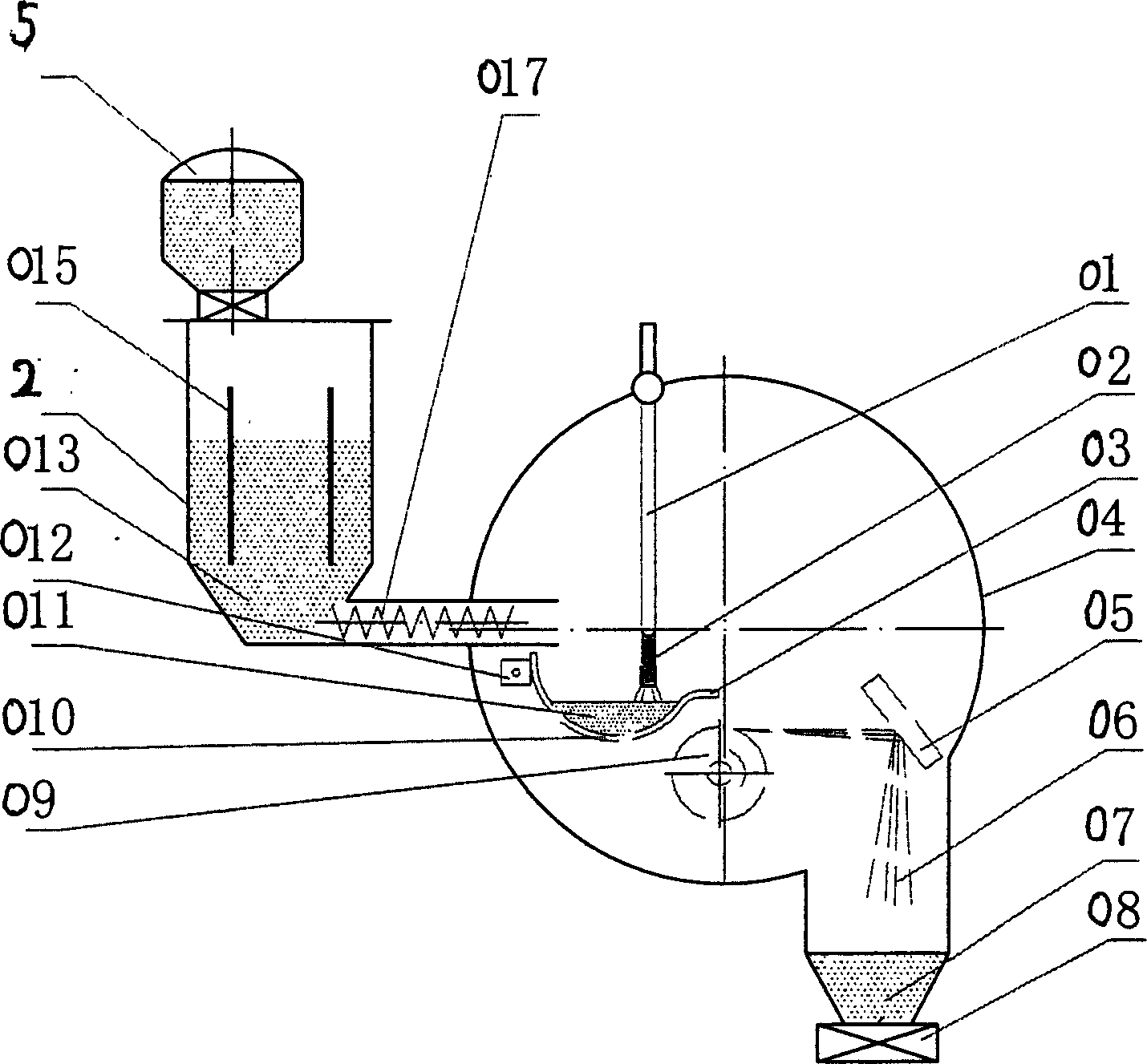

Process utilizing chemical gypsum to produce high strength alpha gypsum

ActiveCN102615694AIncrease productivityReduce energy consumptionCeramic shaping apparatusCrystal transformationMineralogy

The invention discloses a process continuously utilizing chemical gypsum to produce high strength alpha gypsum, which is characterized by comprising the following steps of a, fully mixing the chemical gypsum and water to form stable slurry to be reacted; b, mixing the slurry to be reacted with addictive, and performing crystal transformation after mixing; c, sending the slurry after crystal transformation to a forming machine through centrifugation, and forming a gypsum product through solidification, cutting and drying; and adopting a steam heat source to serve as the required heat source. The process utilizing the chemical gypsum to produce the high strength alpha gypsum has the advantages of being high in resource utilization rate and low in energy consumption and cost. In addition, the high strength alpha gypsum can be continuously produced.

Owner:泰安路发节能环保设备有限公司

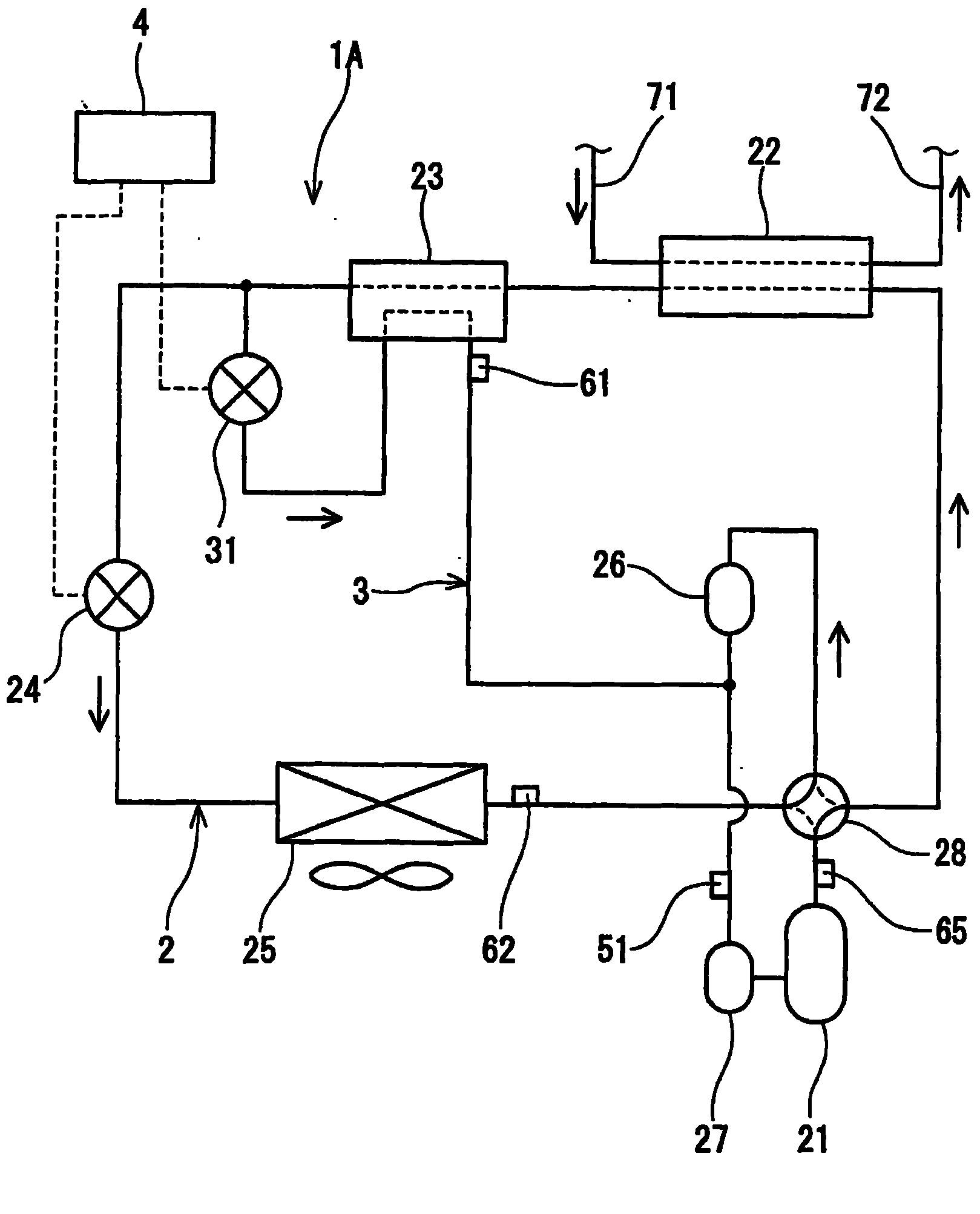

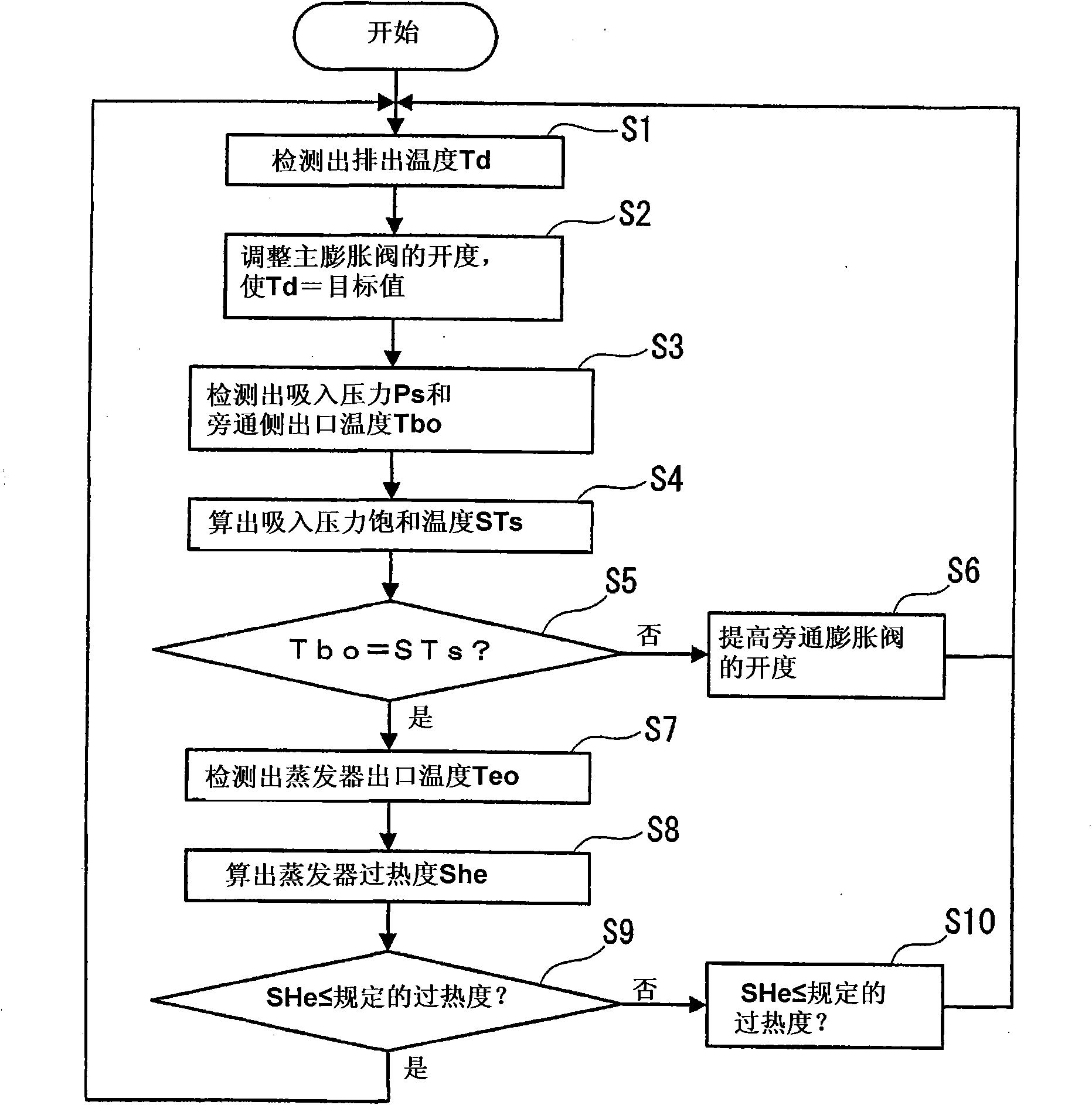

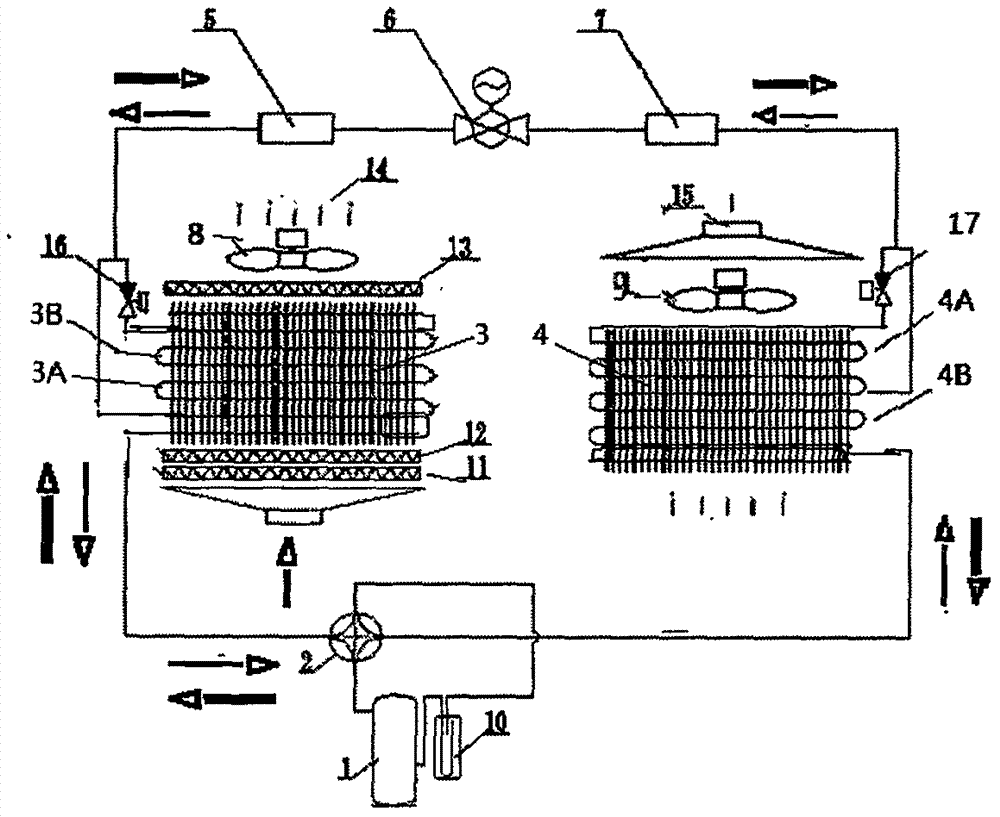

Refrigeration cycle apparatus and hot water heater

ActiveCN102032698AIncrease speedSmall pressure lossCompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigeration

A refrigeration cycle apparatus 1A includes: a refrigerant circuit 2 provided with a subcooling heat exchanger 23; a bypass passage 3 extending through the subcooling heat exchanger 23; and a controller 4 for controlling a main expansion means 24 in the refrigerant circuit 2 and a bypass expansion means 31 in the bypass passage 3. The bypass expansion means 31 is controlled so that a bypass side outlet temperature conforms to a saturation temperature at a pressure of a refrigerant to be drawn into a compressor 21, and a degree of superheat at an outlet of an evaporator 25 calculated based on an evaporator outlet temperature is equal to or lower than a predetermined degree of superheat.

Owner:PANASONIC CORP

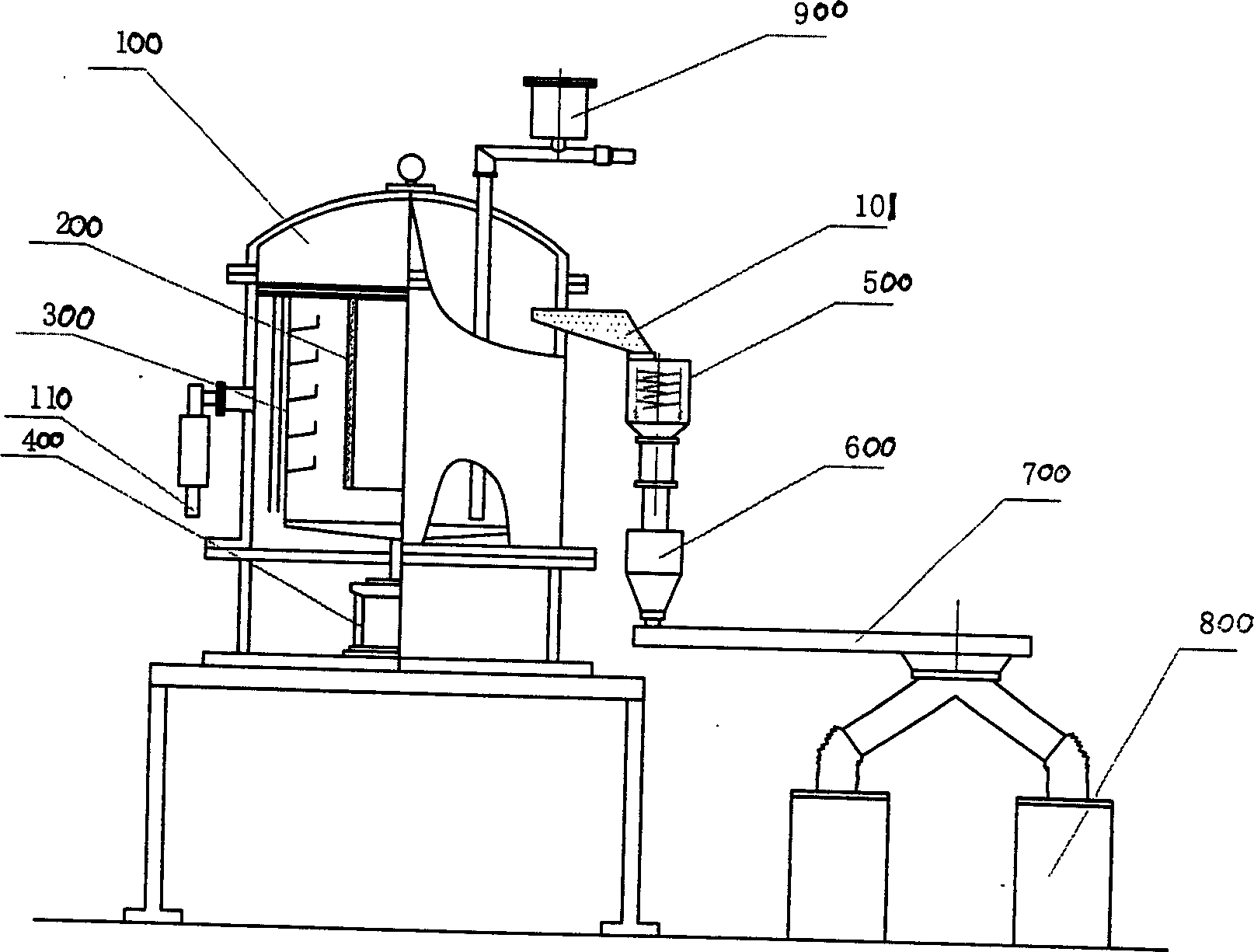

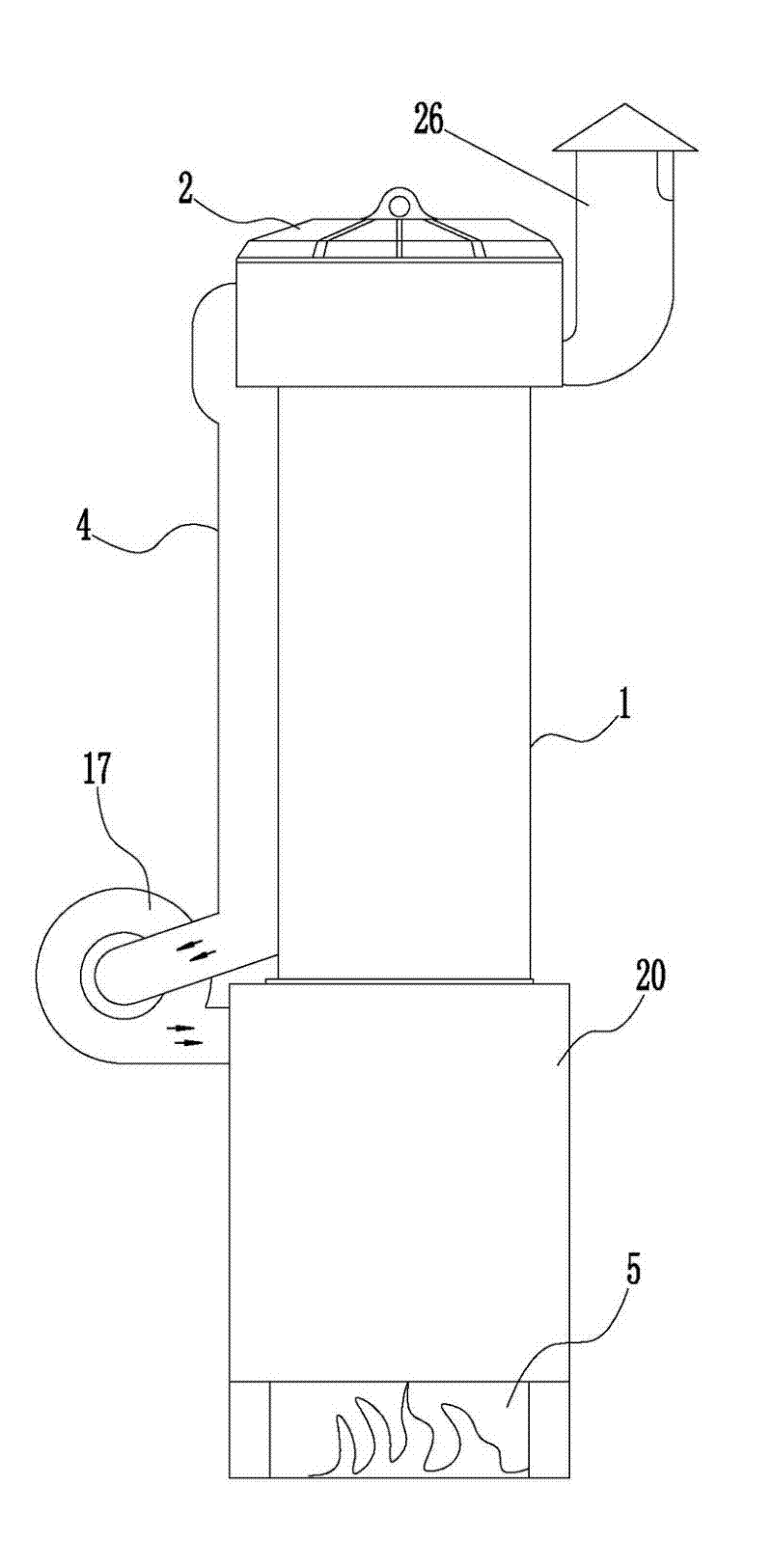

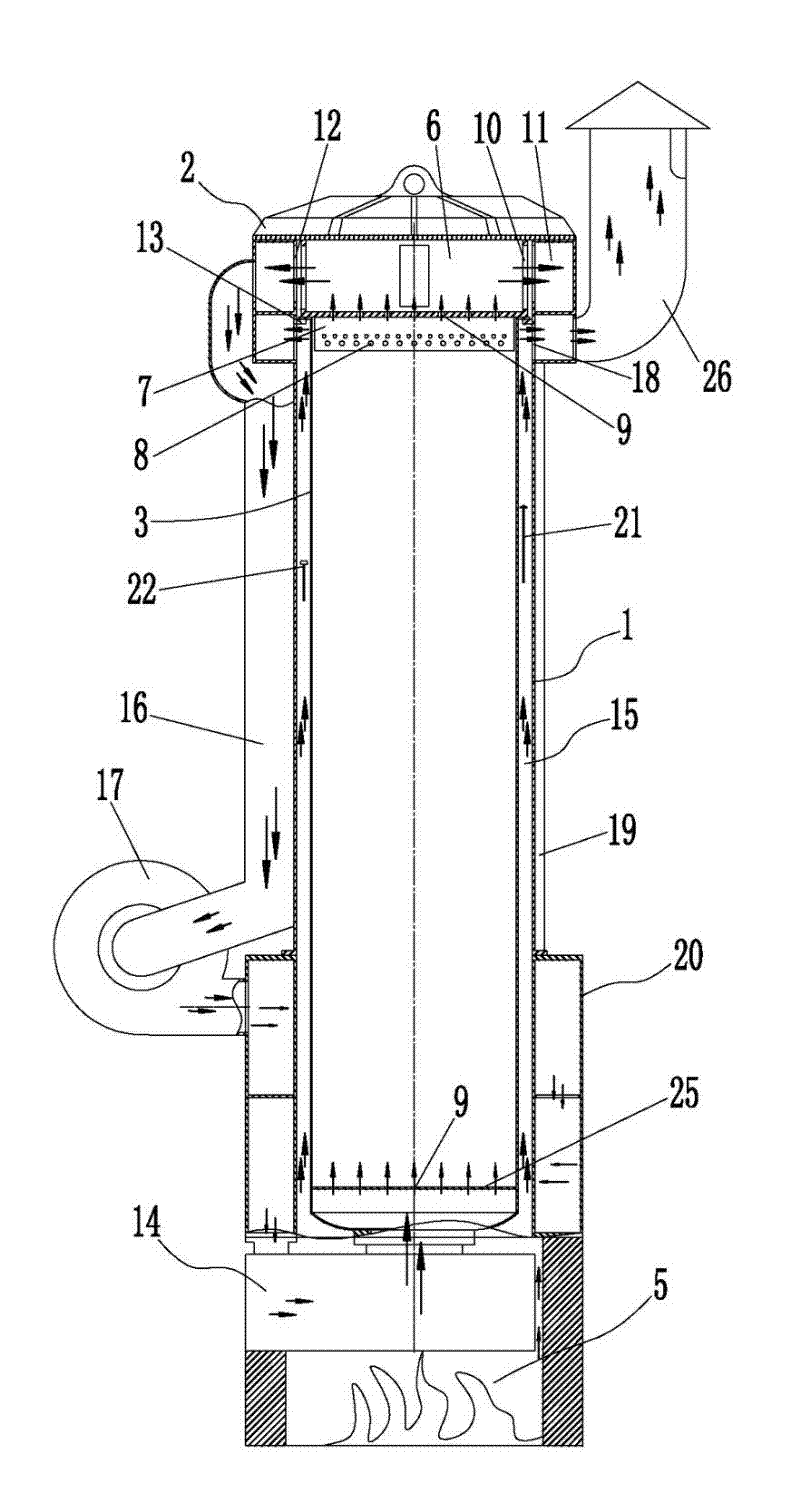

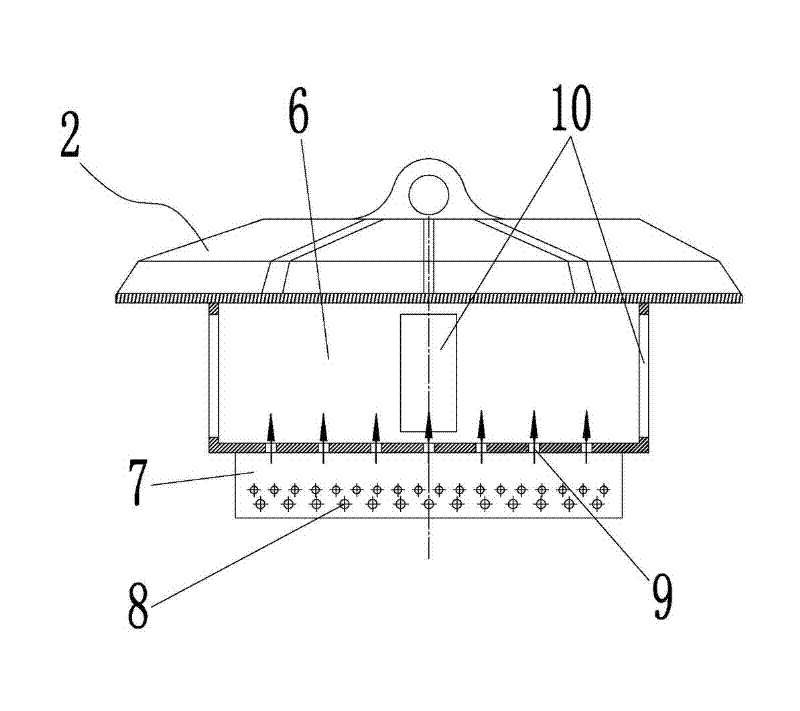

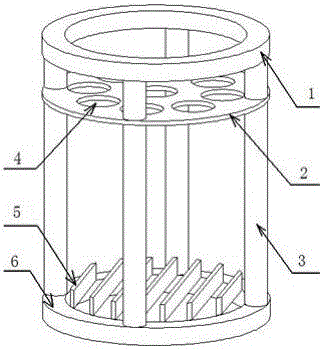

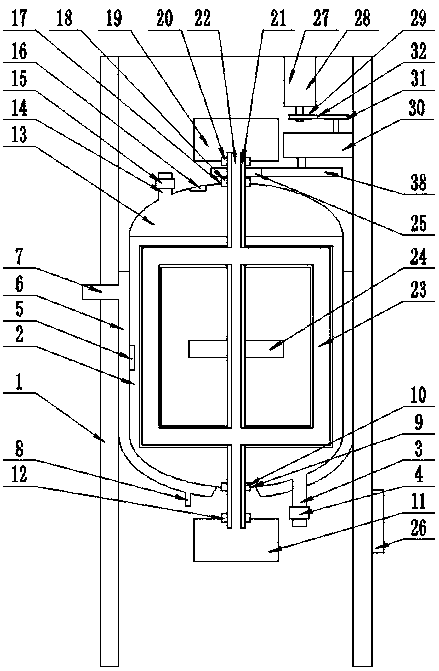

Tempering Furnace

ActiveCN102213544AEasy to control temperatureImprove tempering qualityVertical furnacesHearthEnergy conservation

The invention relates to a tempering furnace. The furnace comprises a furnace body, the top of which is provided with a furnace cover, an inner container is arranged in the furnace body, an air circulating and heating device is arranged on the furnace body, and a hearth is arranged at the bottom end of the furnace body. By properly arranging the furnace cover, the inner container, the air circulating and heating device and the like, the tempering furnace provided by the invention achieves omidirectional tempering of a workpiece which is suspended below the furnace cover by the process of uniformly heating, cycling and preheating the gas in the furnace, thus avoiding tempering blind spot in the furnace, obviously decreasing the temperature deviation in the furnace, and effectively improving the tempering quality of the workpiece in the furnace. Moreover, the tempering furnace maximally utilizes the heat created by burning the fuel, and further improves the furnace tempering effect. The tempering furnace of the invention has the advantages of reasonable and simple structure, low production cost, simplicity of operation, convenience of maintenance, high efficiency and energy conservation, and is suitable for popularization.

Owner:LISHUI HUAYI AUTOMATION TECH

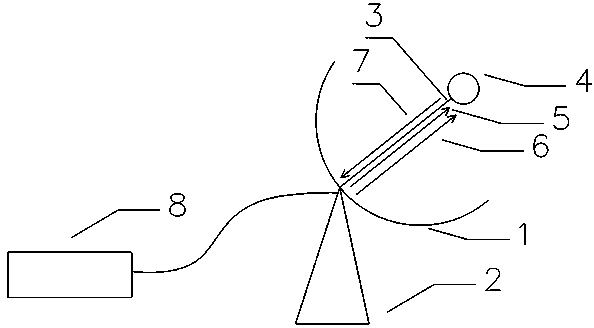

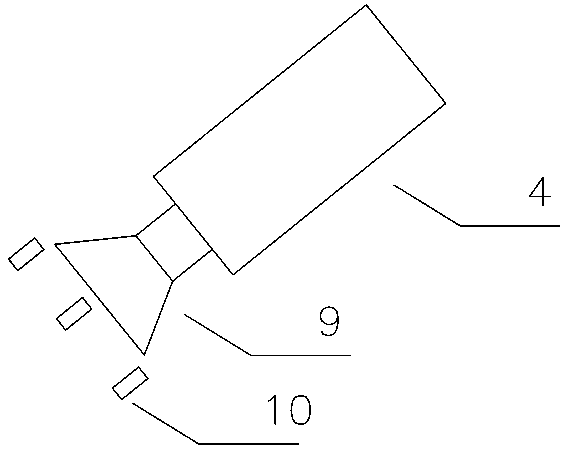

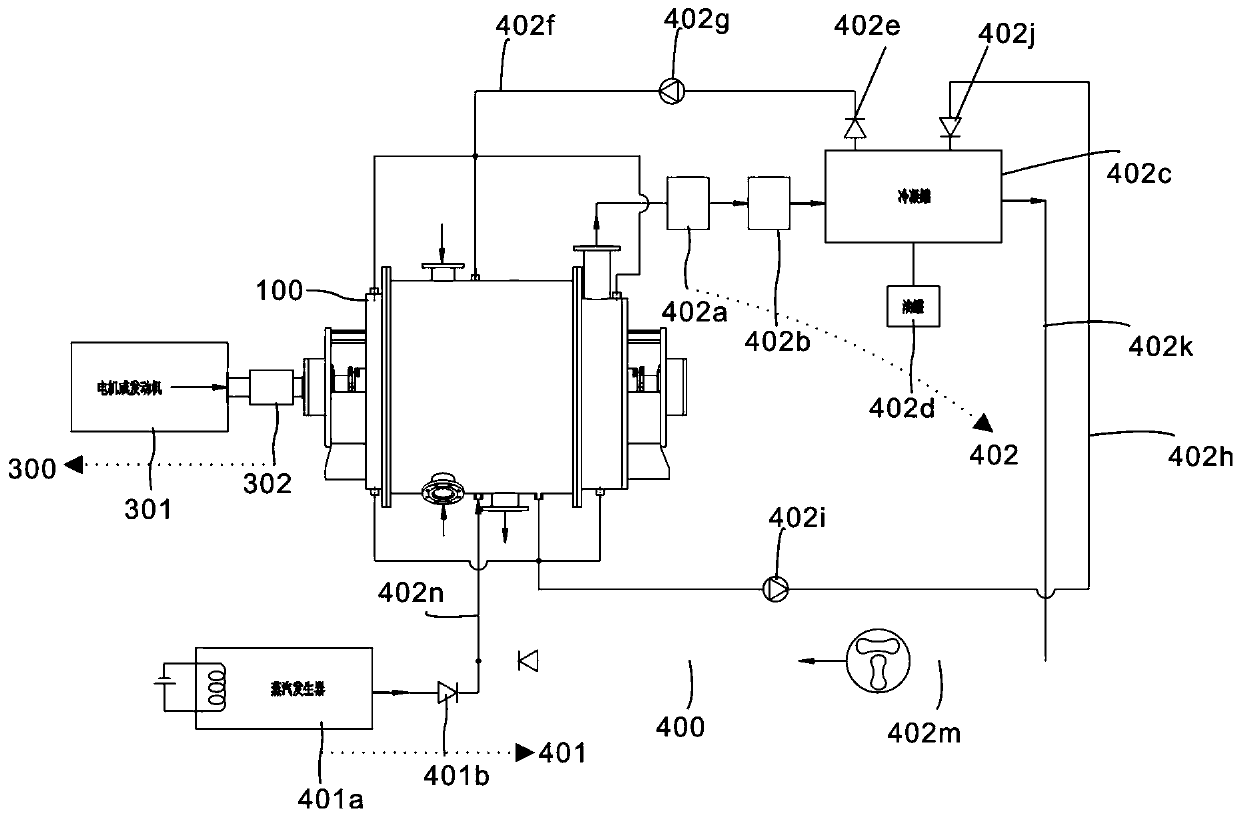

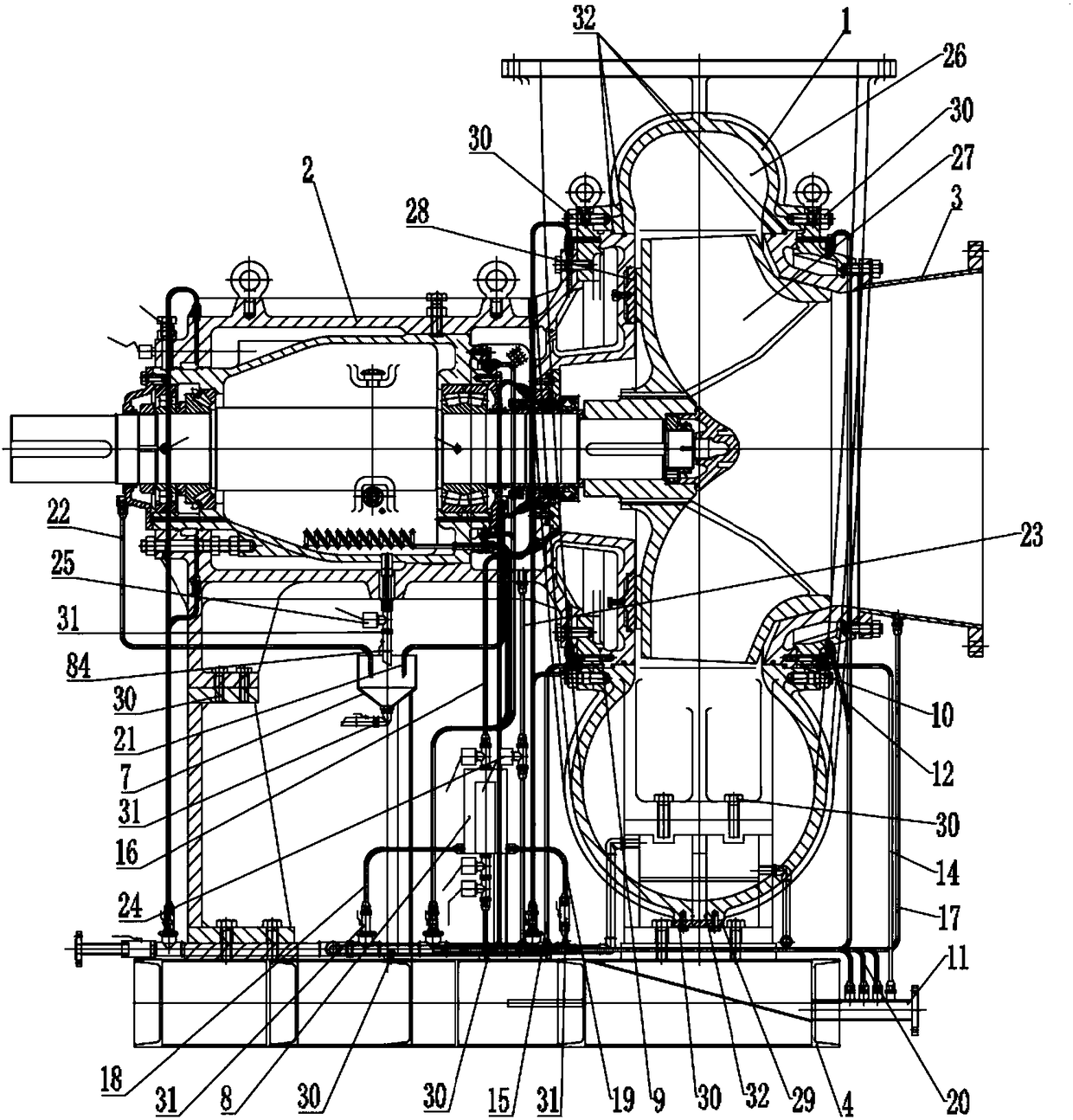

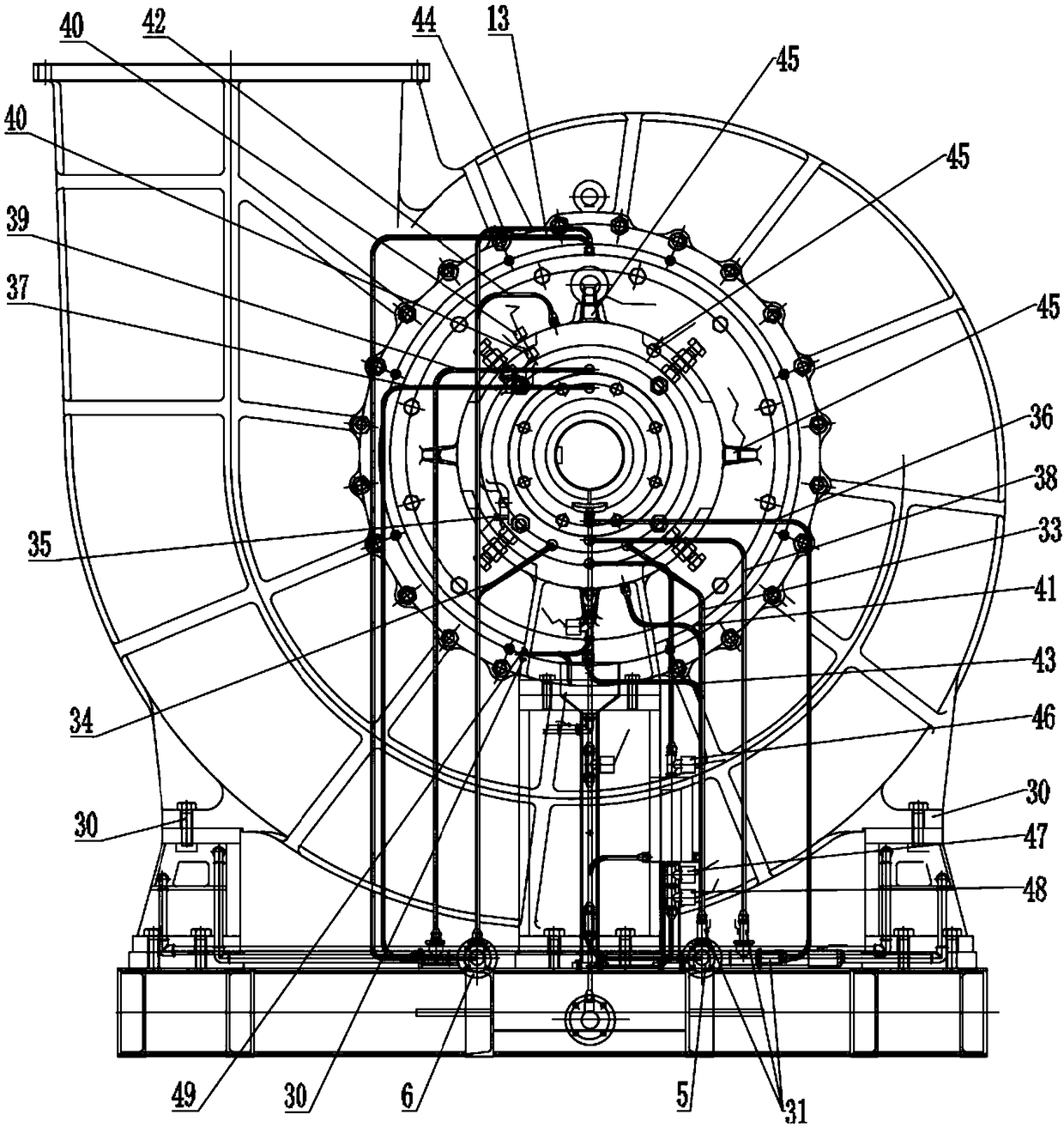

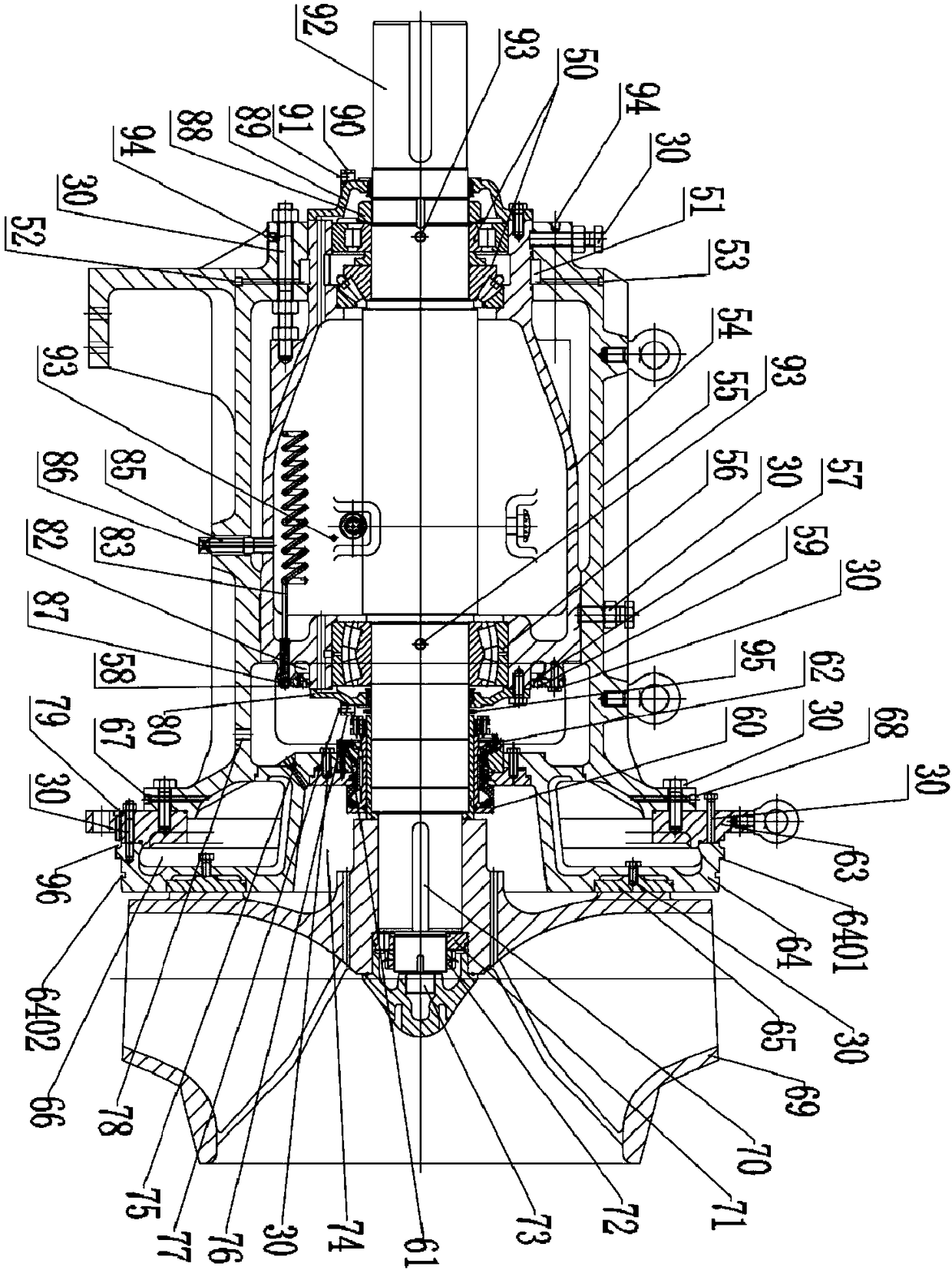

Disc-type solar power generation system and power generation method

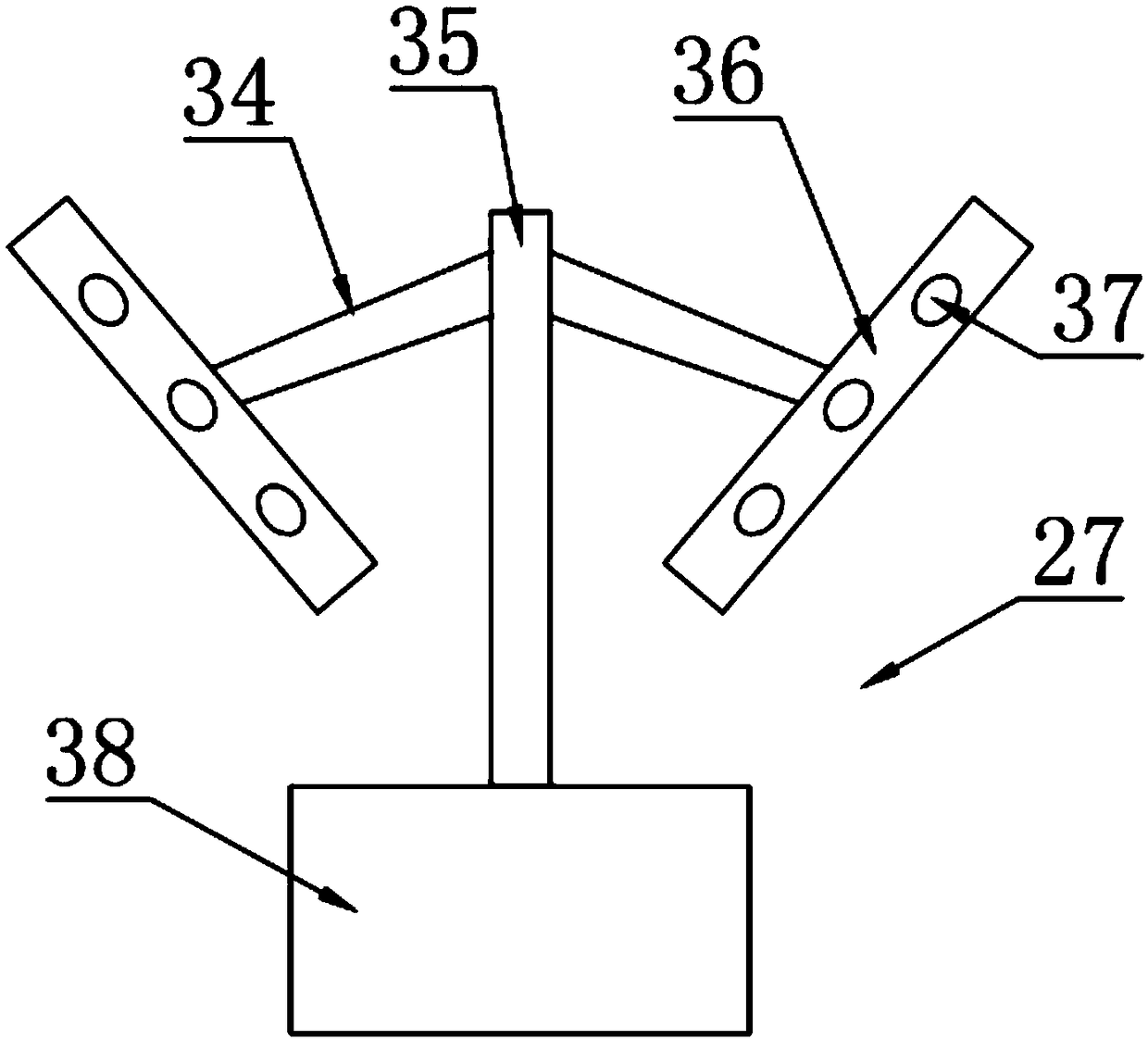

PendingCN108757356AImprove reliabilityImprove energy efficiencyFrom solar energyMachines/enginesEngineeringSolar power

The invention relates to a disc-type solar power generation system and a power generation method, and belongs to the technical field of solar heat utilization. The power generation method is particularly applied to the improvement of the disc-type solar power generation system and the comprehensive utilization of energy. The disc-type solar power generation system comprises a disc-type reflectingmirror, a vertical column, a supporting arm, a Stirling generator and a heat absorber, wherein the disc-type reflecting mirror is mounted on the vertical column; the Stirling generator is mounted on the disc-type reflecting mirror through the supporting arm; and the heat absorber is mounted on the Stirling generator. The disc-type solar power generation system is structurally characterized by further comprising an afterburner, a cooling fluid circulation device and a waste heat utilization device; the afterburner comprises gas pipelines and nozzles; the gas pipelines communicate with the nozzles; the nozzles are mounted on the heat absorber; the cooling fluid circulation device comprises an upper flow tube and a lower flow tube; both the upper flow tube and the lower flow tube are in contact with the Stirling generator; the upper flow tube communicates with the lower flow tube; and the lower flow tube communicates with the waste heat utilization device.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

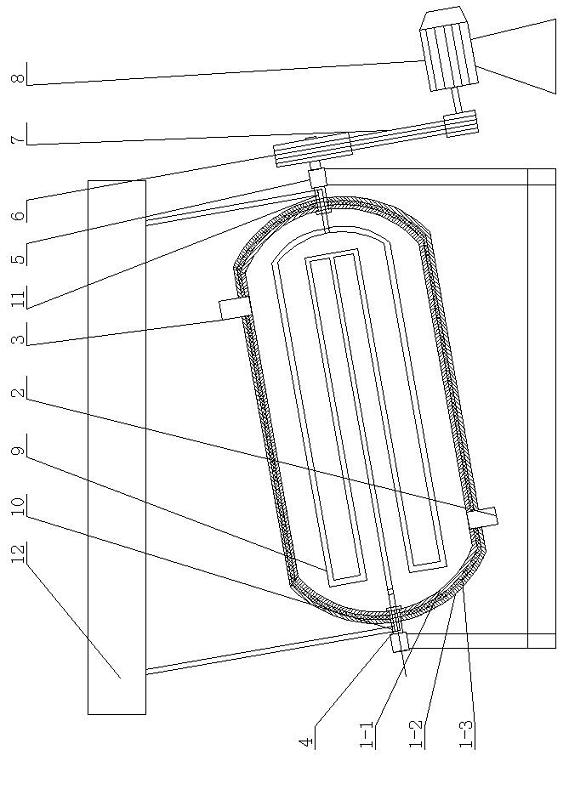

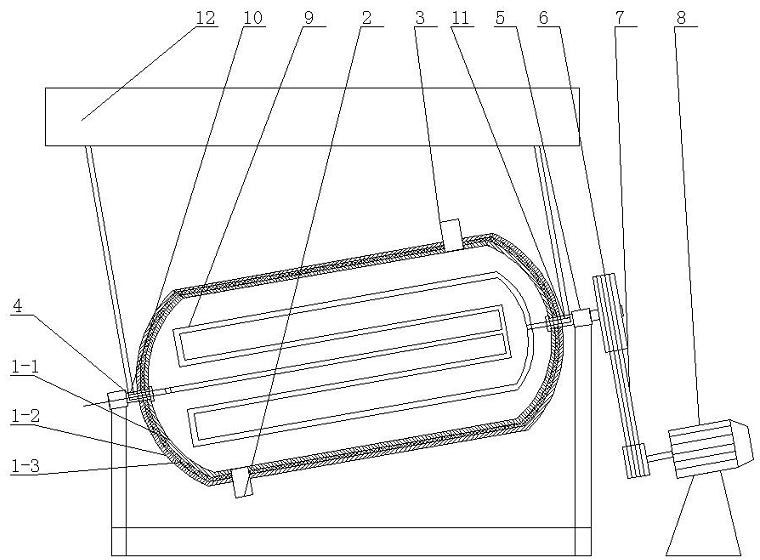

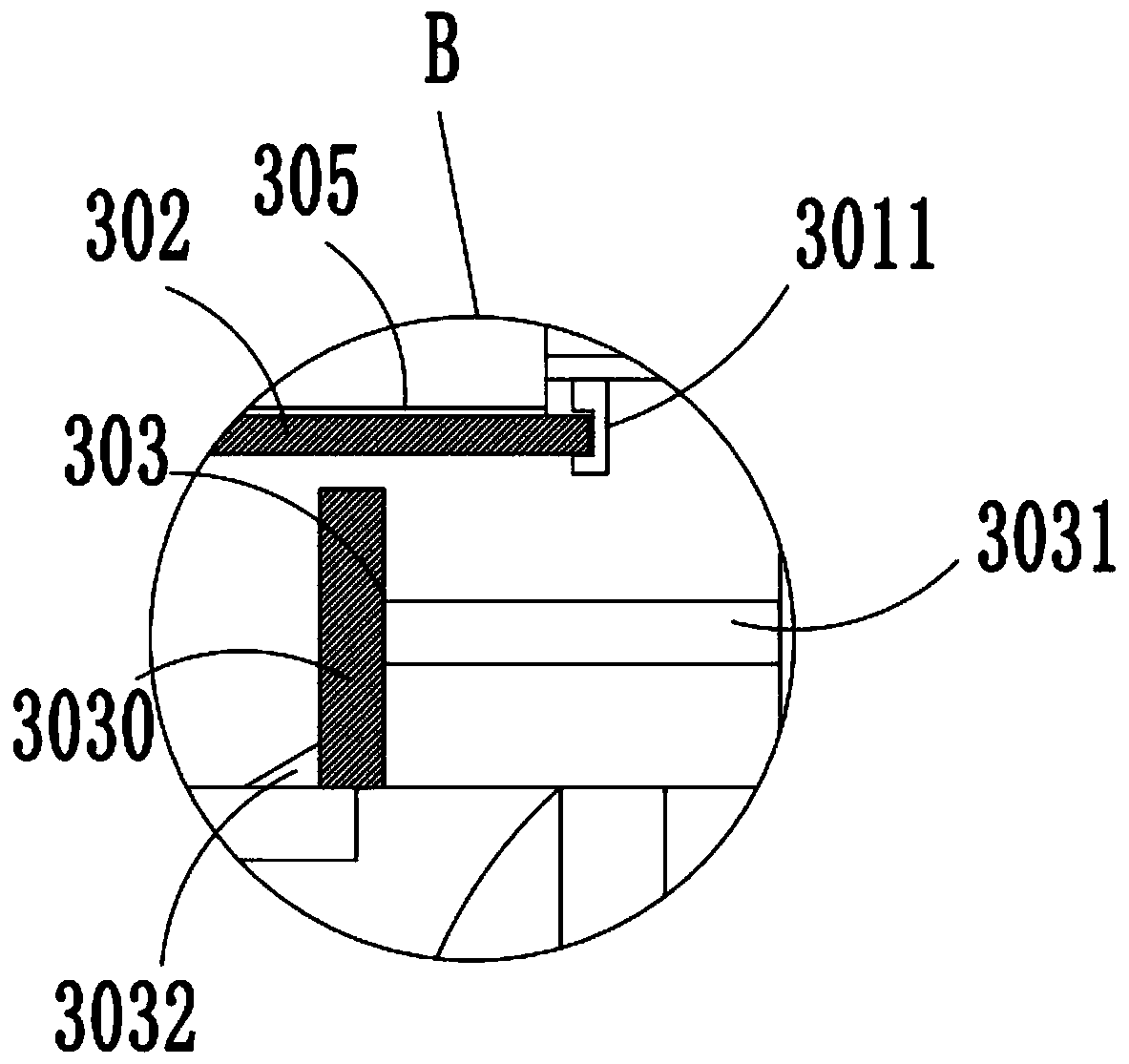

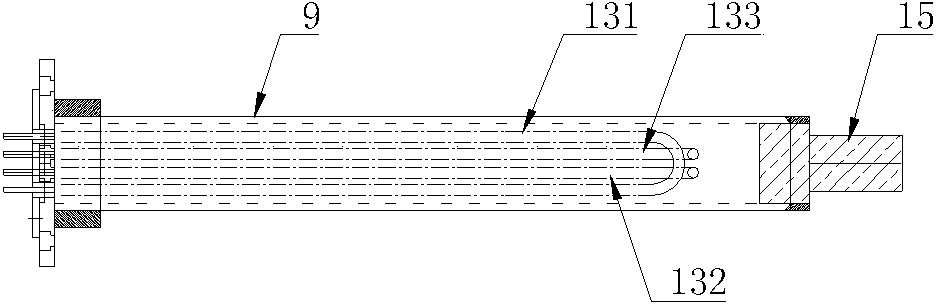

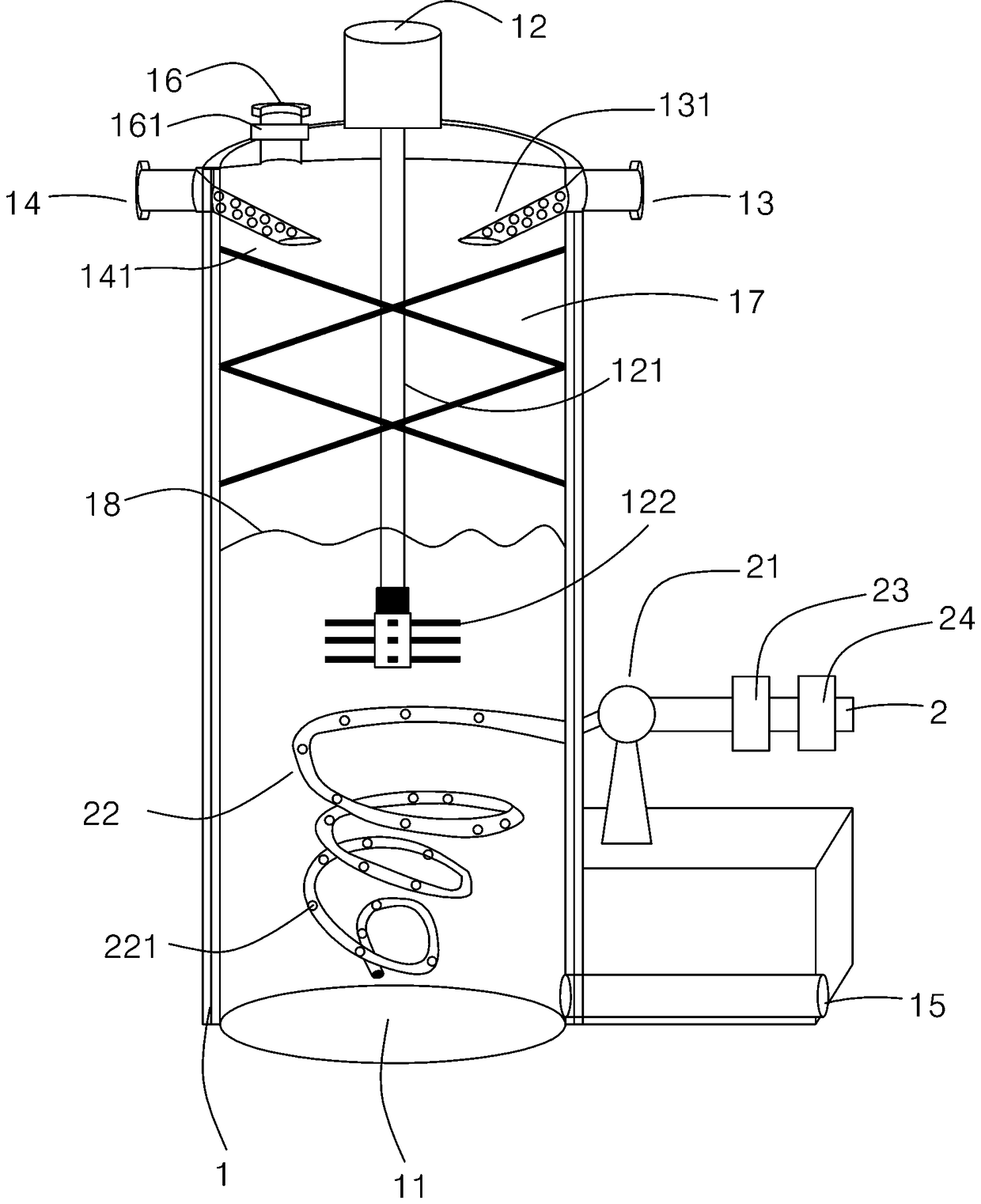

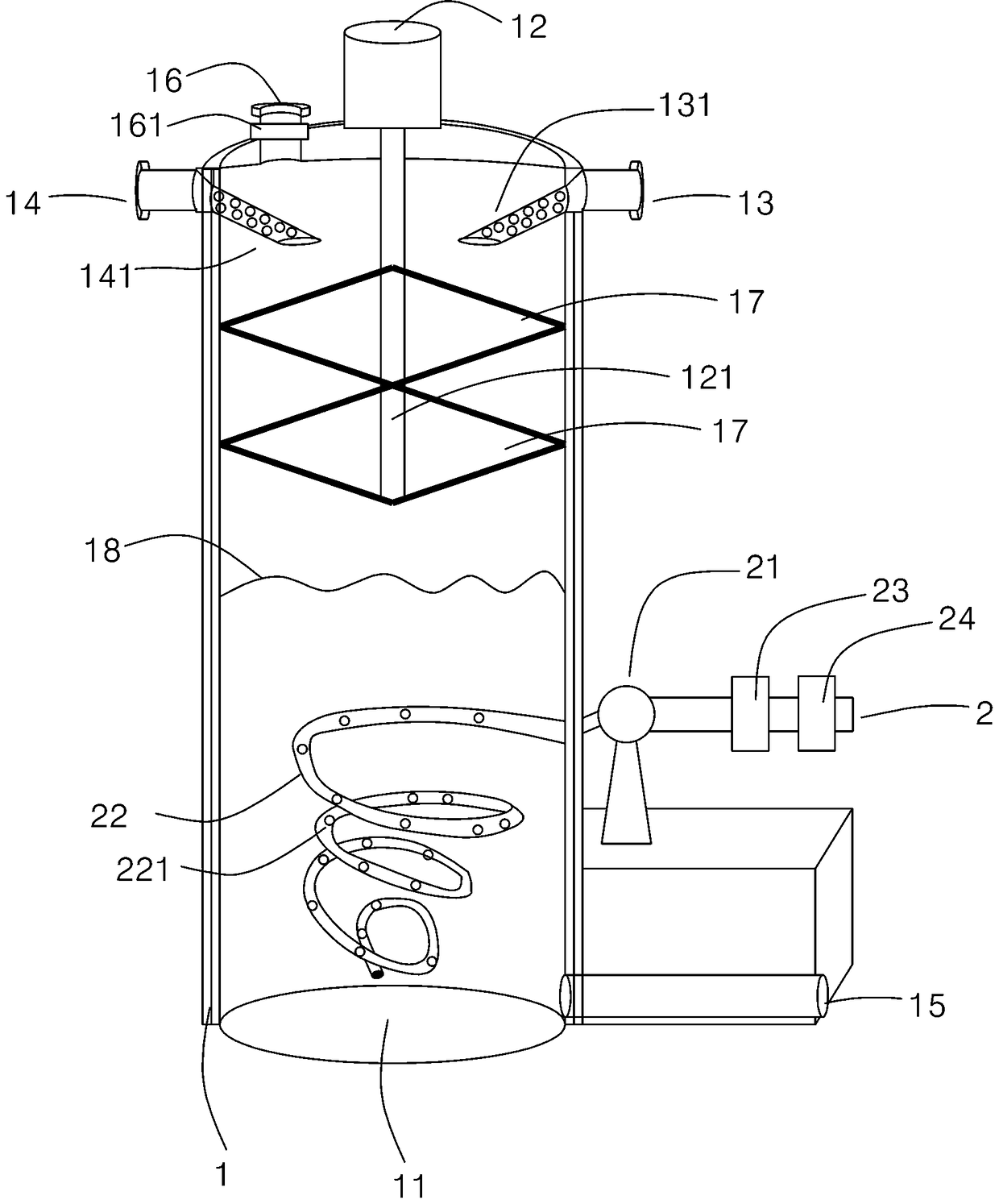

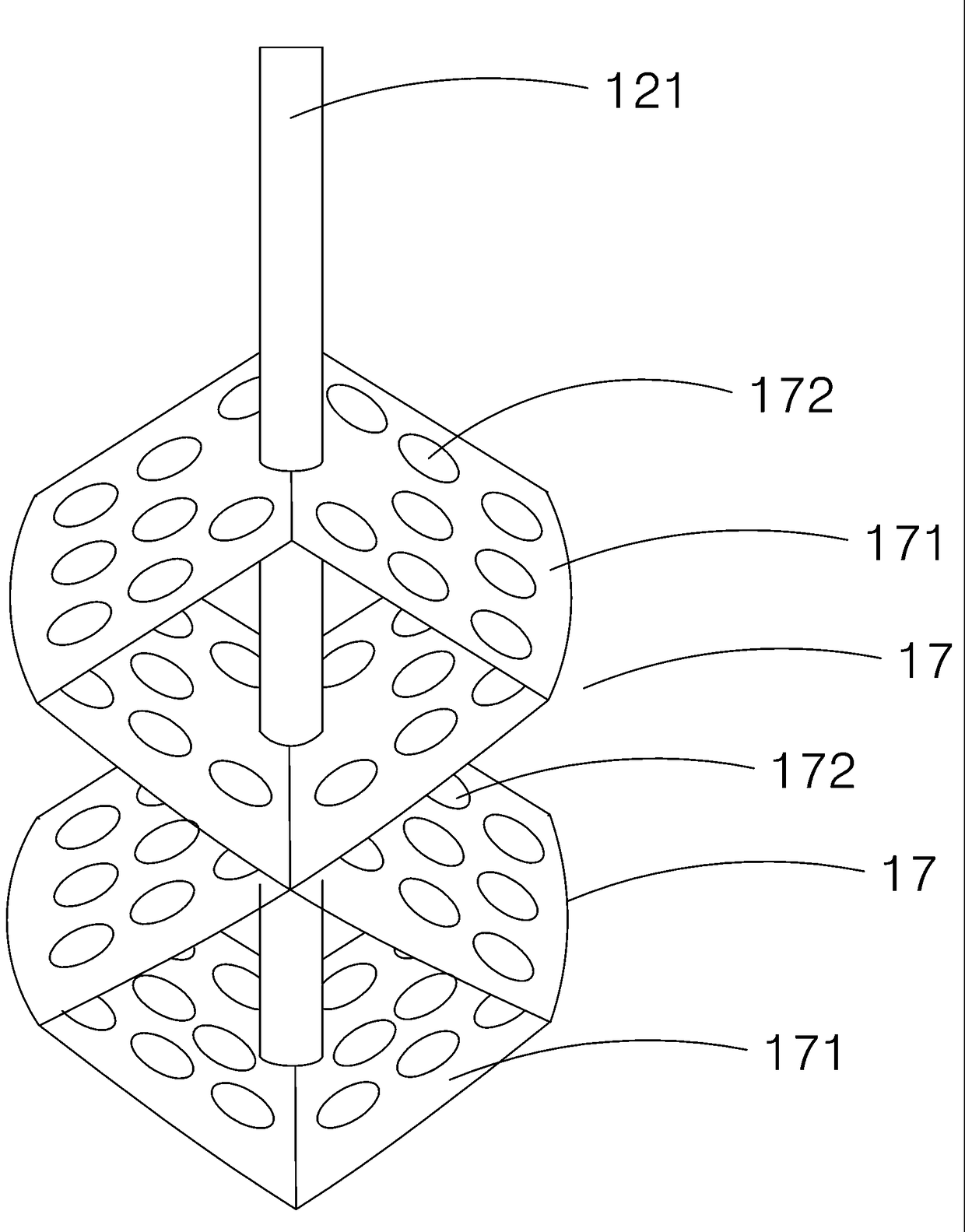

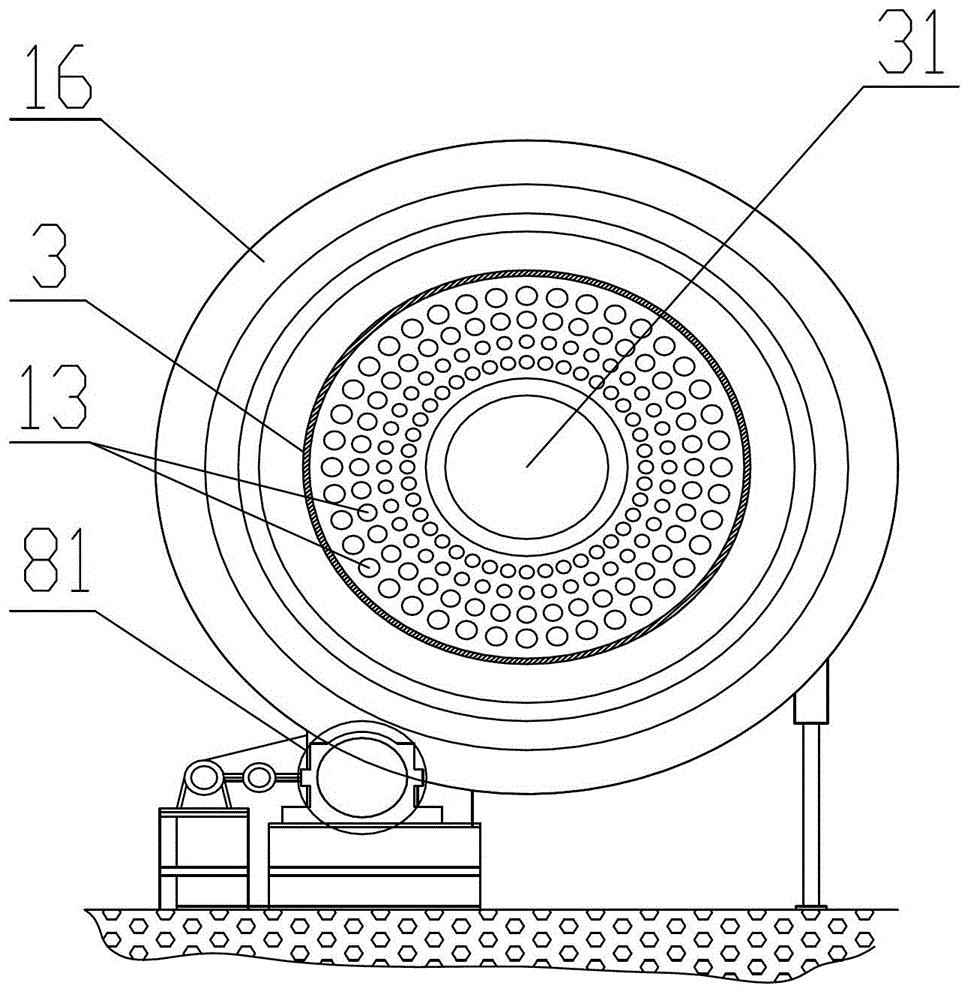

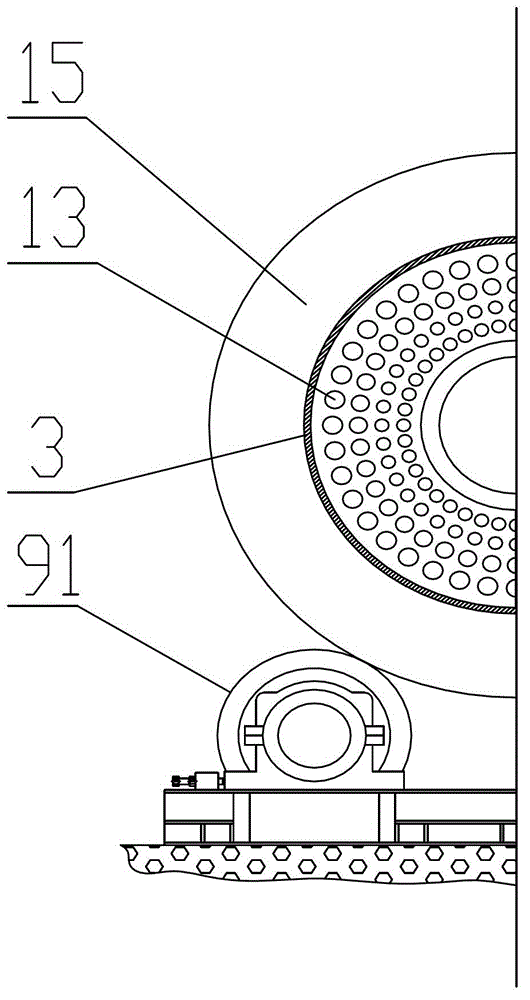

Reaction kettle with uniform heating effect

InactiveCN102671613AEvenly heatedImprove responseFeed devicesPressure vessels for chemical processChemical reactionHeating effect

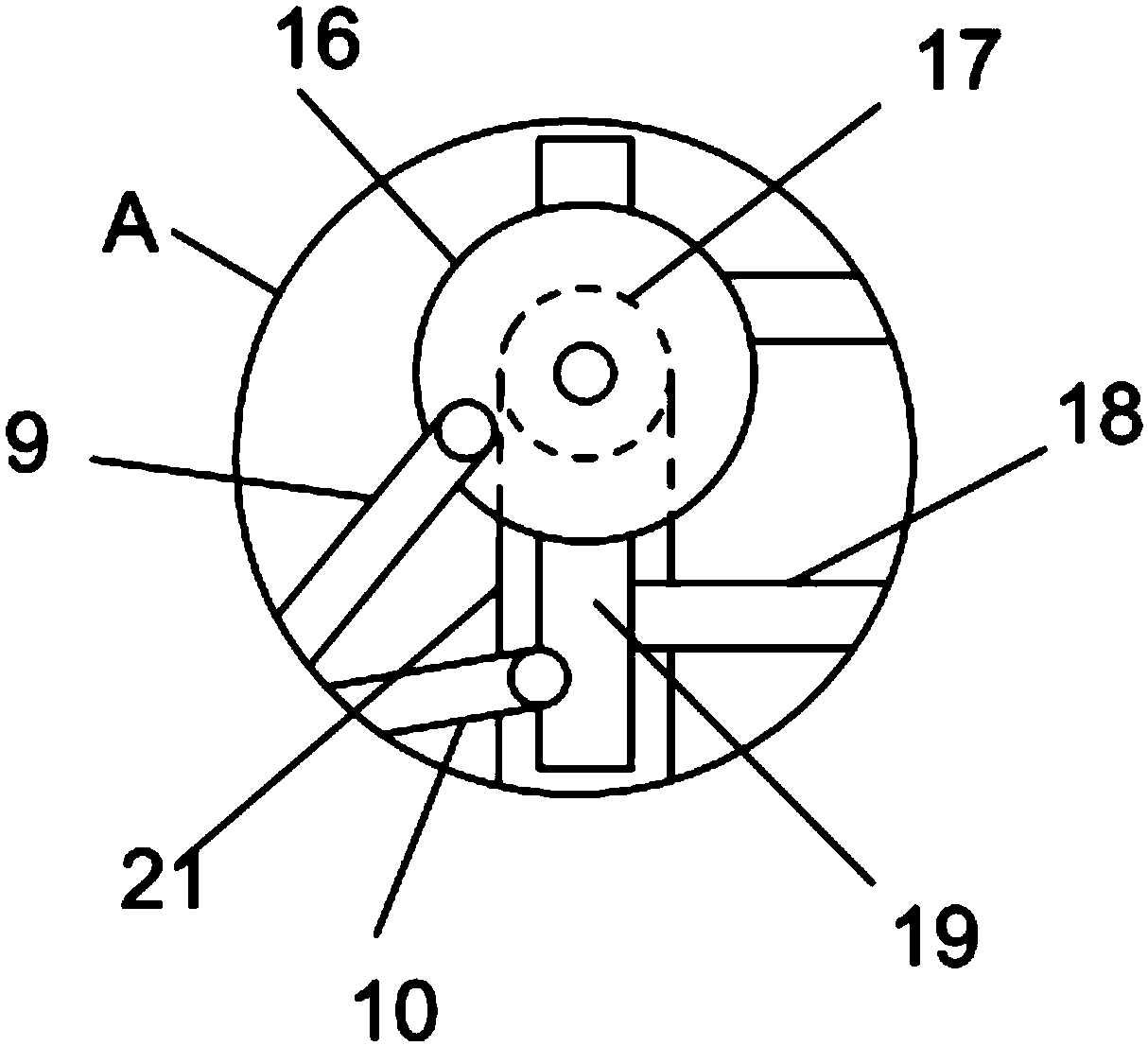

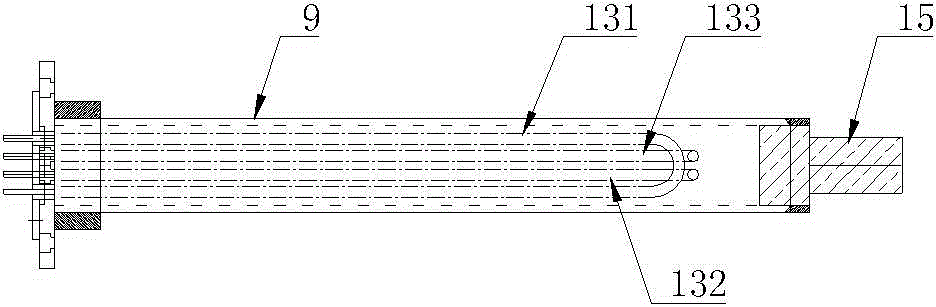

The invention provides a reaction kettle with a uniform heating effect. The existing reaction kettles all have the same heating mode of heat transfer through the kettle walls of the reaction kettles, which leads to non-uniform heating of the materials in the kettles bodies and adverse effect on chemical reactions. The reaction kettle comprises a kettle body (1), wherein a feed port (2) and a discharge port (3) are formed on the kettle body respectively, connecting shafts (4) are arranged o the two sides of the kettle body respectively, the connecting shafts are mounted on a bearing (5), a belt pulley (6) is arranged on the connecting shaft on either side, the belt pulley is connected with a driving motor (8) through a belt (7), a group of heat exchange tubes (9) are arranged in the kettle body, and the heat exchange tubes are connected with heat supply equipment (12) through a water inlet (10) and a water outlet (11) respectively. The reaction kettle is applied to chemical reactions.

Owner:南京瑞旭产品技术有限公司

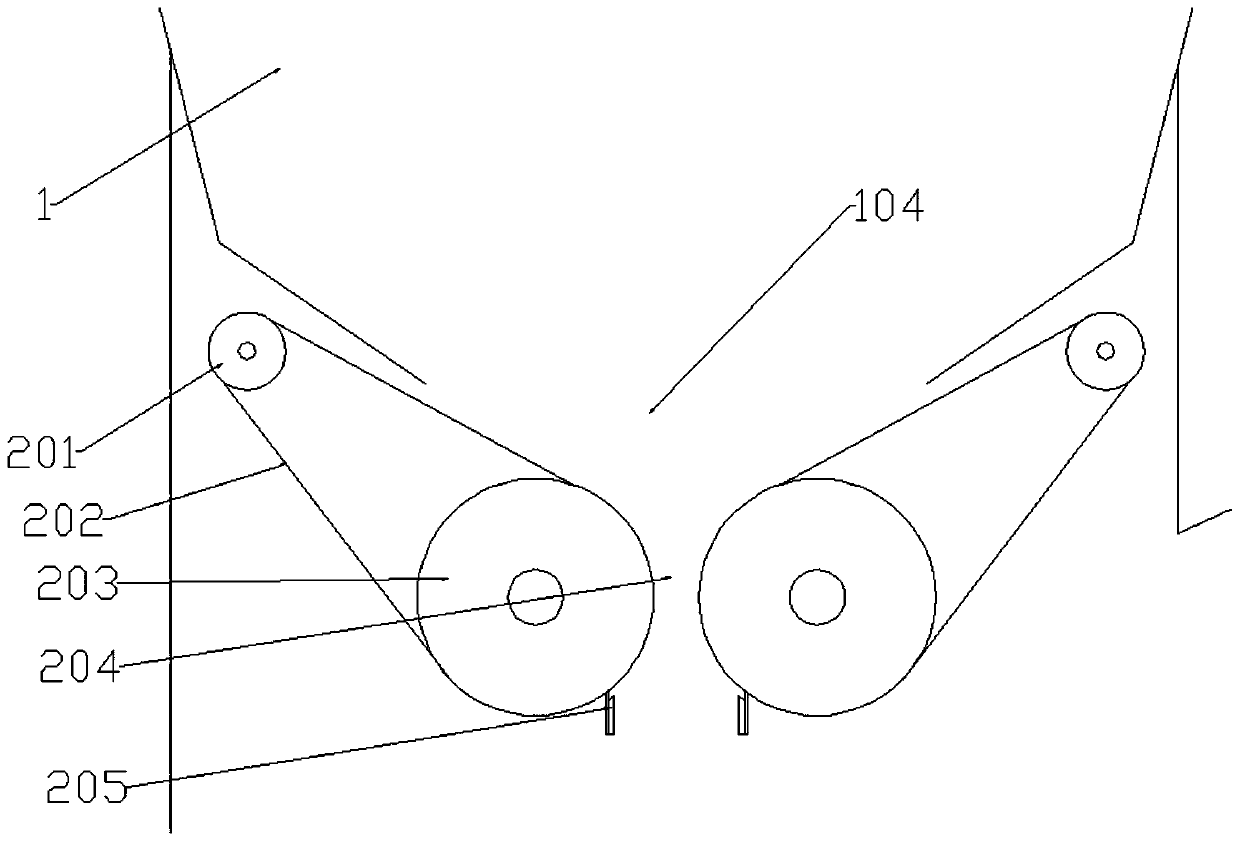

Sunflower seed stir-frying and drying device for agricultural production

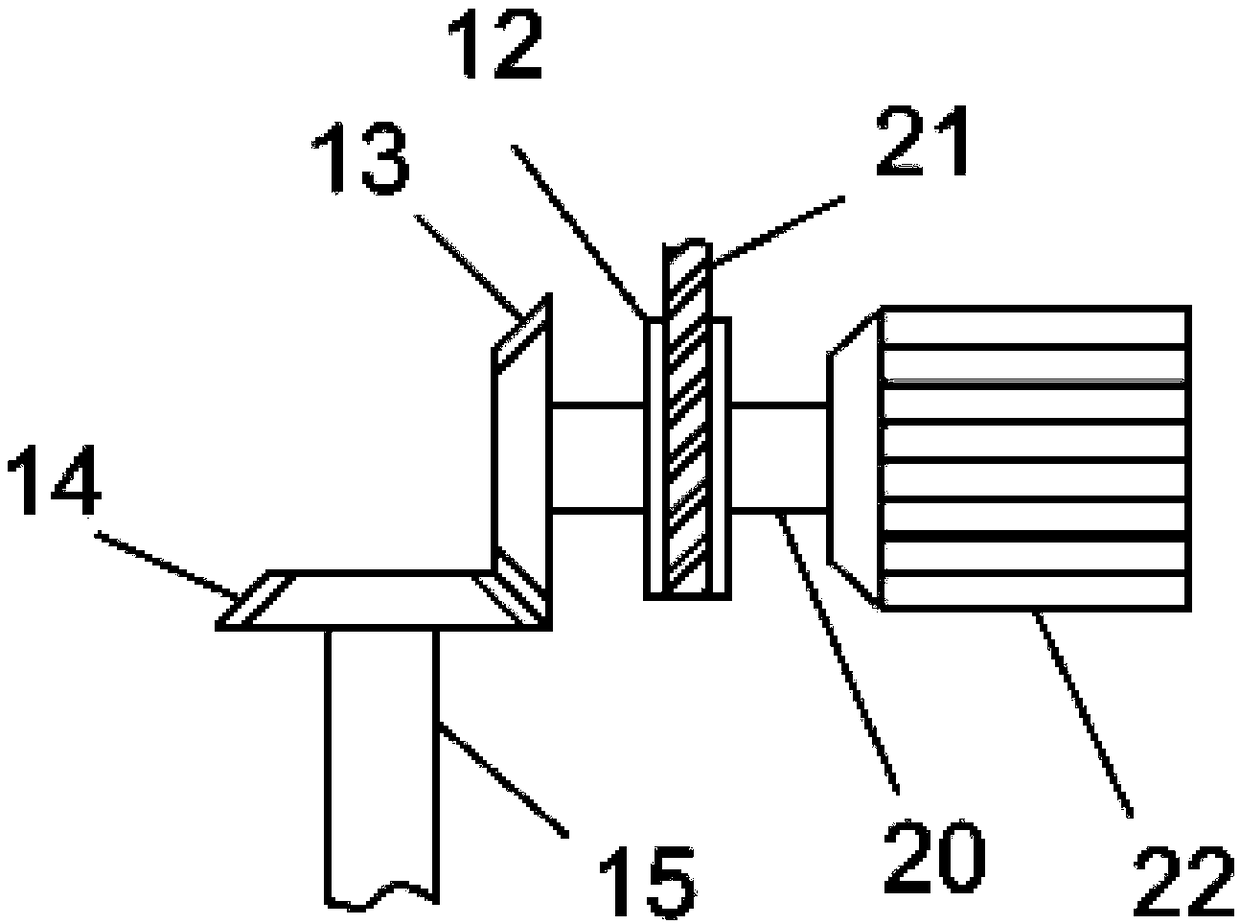

InactiveCN108731430ARealize repeated scraping and stir fryingFull heating effectDrying machines with non-progressive movementsDrying solid materialsTransmission beltDrive shaft

The invention discloses a sunflower seed stir-frying and drying device for agricultural production. The sunflower seed stir-frying and drying device comprises a bottom plate. A vertical plate is vertically and fixedly mounted on the bottom plate. Two cantilever beams are horizontally and fixedly mounted on the left side wall of the vertical plate. A vertical rod is vertically and fixedly mounted at the left ends of the cantilever beams. A first driven belt wheel and a first driving belt wheel are connected with a first transmission belt in a sleeved mode. A stir-frying groove is fixedly formedin the upper end of a driven shaft. An electric heater making contact with the bottom face of the stir-frying groove is fixedly mounted on the upper surface of a horizontal plate in an embedded mode.A stir-frying rod is hinged to a rotating wheel. The left end of a supporting rod is hinged to the stir-frying rod. The stir-frying rod extends rightwards into the stir-frying groove. According to the sunflower seed stir-frying and drying device, a stir-frying plate is driven to swing by the stir-frying rod so as to achieve repeated scraping and stir-frying of sunflower seeds in the stir-frying groove, meanwhile, rotation of the stir-frying groove promotes full stirring of the sunflower seeds in the stir-frying groove, the interior of the stir-frying groove is fully heated through the electric heater on the horizontal plate, drying is more even, and the drying efficiency is improved greatly.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

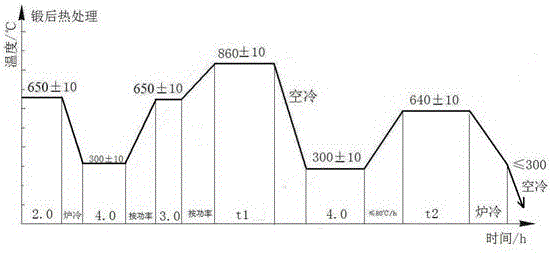

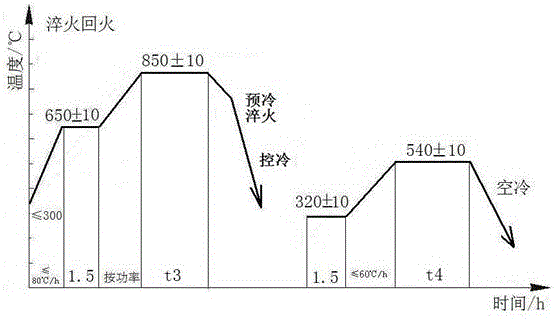

Non-deformation thermal refining process of main shaft of kilowatt-level blower

InactiveCN105886737AGuaranteed StrengthReduce plasticityFurnace typesHeat treatment furnacesQuenchingMaterials science

The invention discloses a non-deformation thermal refining process of a main shaft of a kilowatt-level blower. The process is characterized in that a special tool is utilized to effectively avoid deformation which probably occurs in the thermal refining; meanwhile, a controlled-cooling measure is carried out in the quenching process, thus the quenching temperature and the final cooling temperature can be controlled on the premise that the thermal refining quality of the main shaft of the blower is ensured, and accordingly, the thermal stress and the structural stress of the main shaft of the blower in the quenching process can be effectively reduced, and as a result, the deformation can be minimized, and the strength, plasticity and toughness can meet the technological requirements.

Owner:SHANDONG IRAETA HEAVY IND

Industrial solid waste recycling cyclic utilization device

ActiveCN111482447AAvoid pollutionAvoid accumulationSolid waste disposalChemical industryIndustrial wasteWaste treatment technologies

The invention discloses an industrial solid waste recycling cyclic utilization device, and belongs to the technical field of waste treatment. A screening pulverizing element, a mixing impurity removing element, a waste drying element, a pyrolysis furnace, a dust removal device and a power source are mainly included. The mixing impurity removing element is used for adding related reagents into crushed industrial solid waste for pretreatment, and part of organic pollutants in the waste are removed; and in addition, the pyrolysis furnace is utilized for conducting pyrolysis treatment on the pretreated waste, surplus organic matter in the waste is removed, and after pyrolysis gas generated in the pyrolysis process is subjected to purification treatment through the dust removal device, combustible gas and biological oil are obtained, carbon high-quality fuel is generated due to pyrolysis, and the above products can be repeatedly utilized. Recycling treatment of the industrial solid waste isachieved, energy saving and environment protection are achieved, and pollution caused to the environment from the industrial waste is avoided.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

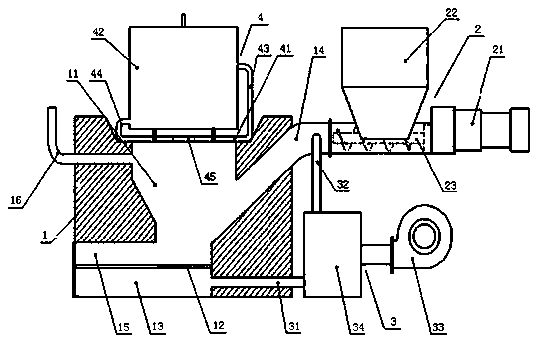

Combusting and heating boiler for biomass fuel

InactiveCN105509031ABurn fullyImprove combustion efficiencyFuel feeding arrangementsSolid fuel combustionThermal energyCombustion chamber

The invention discloses a combusting and heating boiler for biomass fuel. The combusting and heating boiler comprises a combustion boiler body, a feed mechanism, an air supply mechanism and a heating tank. A combustion chamber is formed in the middle of the combustion boiler body, the heating tank is arranged above the combustion chamber, the feed mechanism is communicated with a feed channel of the combustion boiler body, the air supply mechanism is communicated with a fire grate and the feed channel of the combustion boiler body, and the heating tank is provided with a cold water circulating pipe and a hot water circulating pipe both communicated with a tank body and a heating layer. The combusting and heating boiler has the advantages that the structure is simple, the biomass fuel can be combusted more fully, the combustion efficiency is high, flames are stable, the utilization rate of the thermal energy is high, the energy-saving effect is remarkable, the slagging and coking problems of a device in the combustion process of the biomass fuel are solved, and application is wide.

Owner:广西节得乐生物质能源科技有限公司

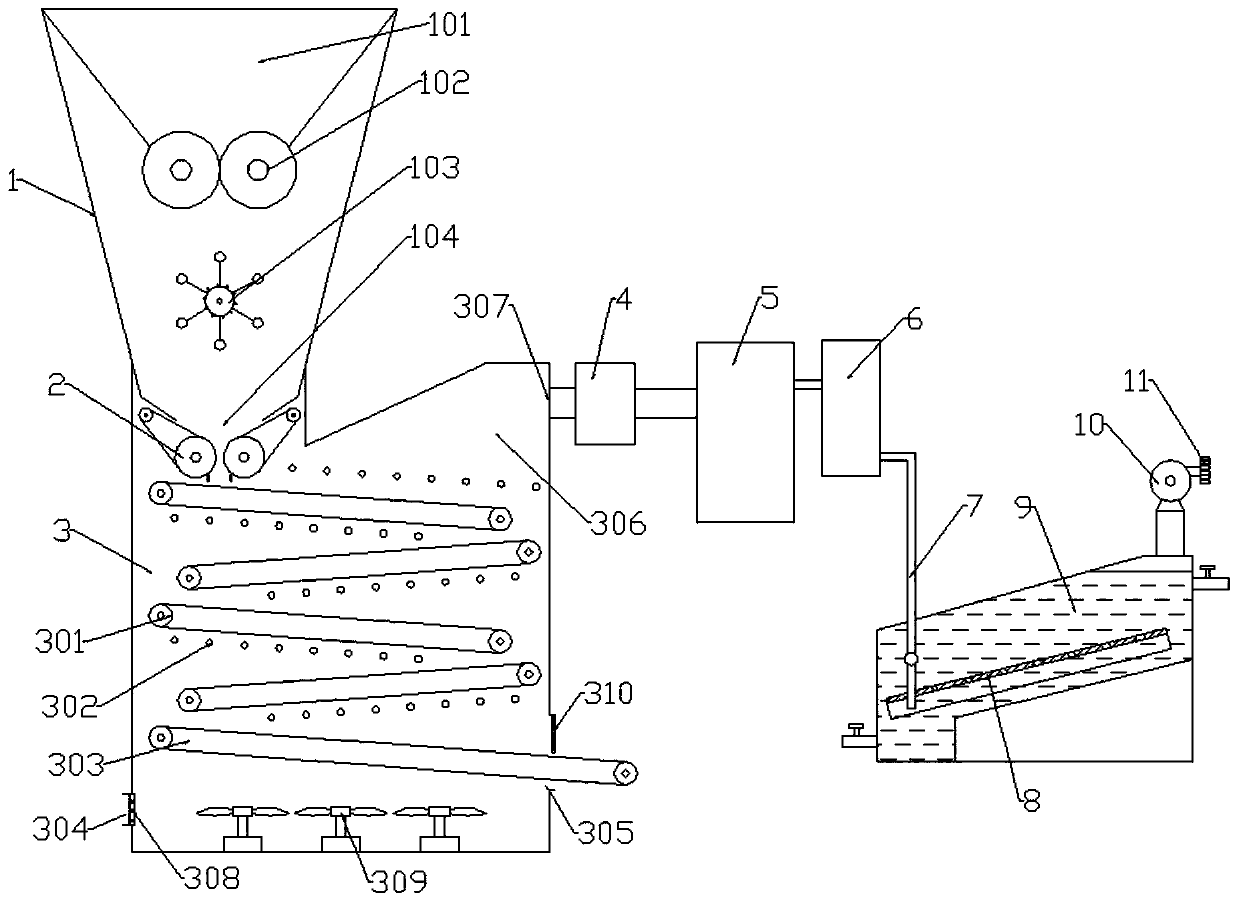

Halogenated hydrocarbon-contaminated soil remediation device

InactiveCN109967506AFully break upFully heatedDispersed particle separationContaminated soil reclamationHeating timeSoil remediation

The invention discloses a halogenated hydrocarbon-contaminated soil remediation device. The halogenated hydrocarbon-contaminated soil remediation device comprises a halogenated hydrocarbon removal box, wherein a hopper is arranged on the upper left portion of the halogenated hydrocarbon removal box, a plurality of soil conveyor belts are obliquely arranged in the halogenated hydrocarbon removal box from top to bottom alternatively in a Z-shaped mode, a soil discharging conveyor belt is arranged on the bottom of the interior of the halogenated hydrocarbon removal box, infrared ray heating modulator tubes are distributed above the soil conveyor belts and the soil discharging conveyor belt, a gas collecting cavity used for collecting hot gas flows is formed in the upper right portion of the halogenated hydrocarbon removal box, a first exhausting fan is connected with the outer portion of the gas collecting cavity, the first exhausting fan is connected with a halogenated hydrocarbon catalytic combustion furnace, the halogenated hydrocarbon catalytic combustion furnace is connected with a heat exchanger, the heat exchanger is connected with a gas inlet pipe assembly, the gas inlet pipeassembly introduces tail gas into a tail gas purification box in which an alkaline solution is placed, a gas outlet is formed in the upper right portion of the tail gas purification box, and a secondexhausting fan is arranged on the gas outlet. The halogenated hydrocarbon-contaminated soil remediation device uses infrared ray, soil heating time is long, a heated surface of soil is large, and theremediation efficiency is high.

Owner:泰顺县王日飞家庭农场

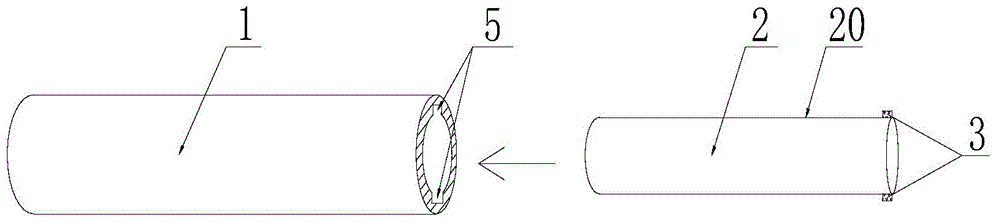

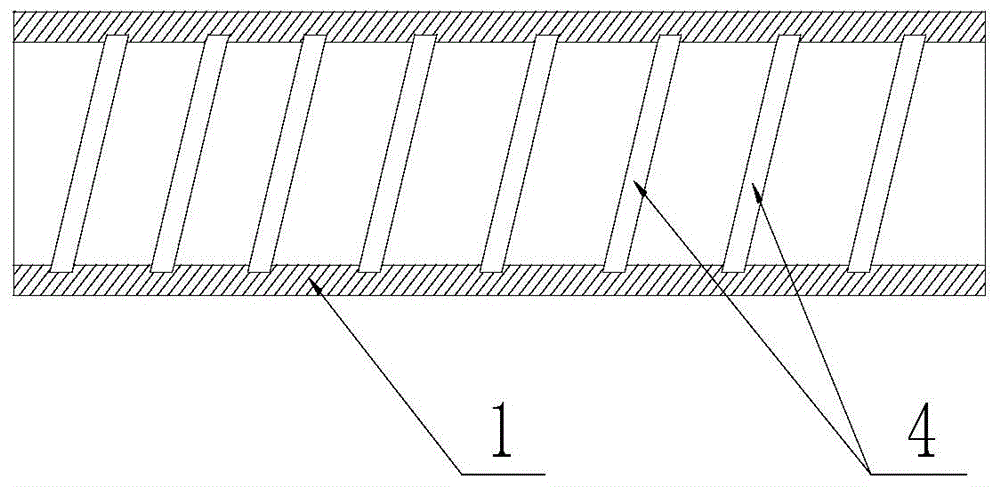

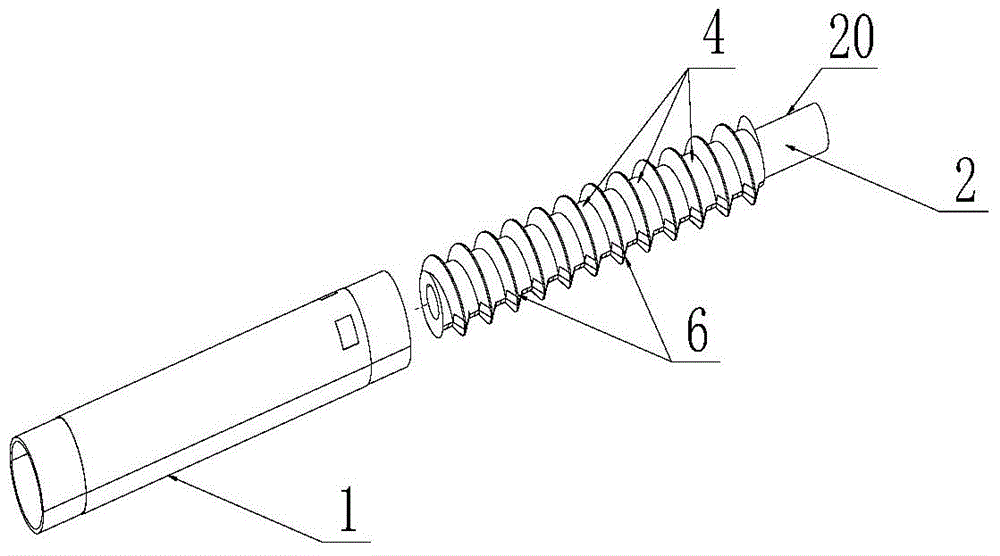

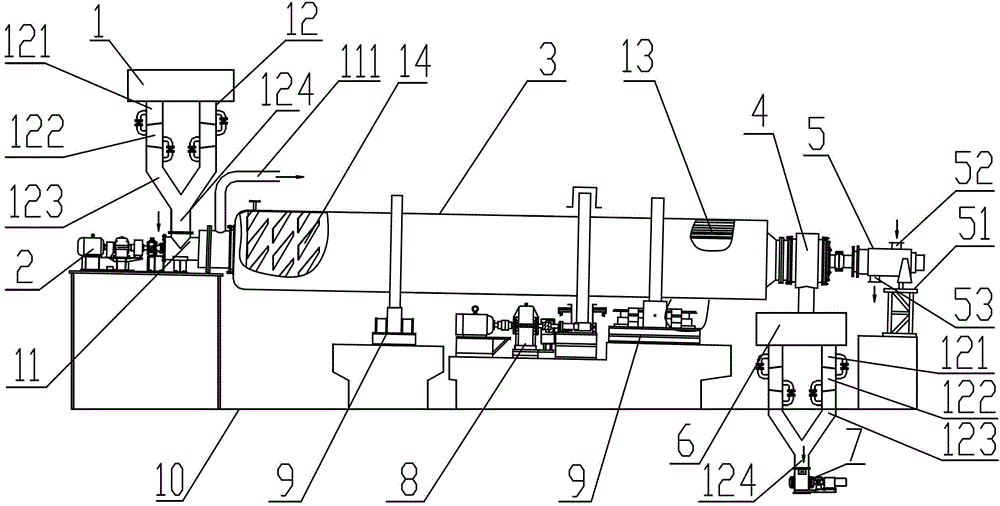

Plastic extruder

The invention provides a plastic extruder, which can solve the problems that a traditional plastic extruder cannot stir raw materials sufficiently, and the power consumption of a motor is large. With the plastic extruder, the extrusion quality is ensured, and the production cost is reduced. A feeding device is arranged on a machine barrel; an external heating device is arranged on the periphery of the machine barrel in sections; screw blades extending along the axial direction is arranged on the periphery of a screw. The plastic extruder is characterized in that the screw comprises a feeding section screw rod and a discharge section screw rod connected with each other in the axial connection; the feeding section screw rod is coupled to an output shaft of a drive motor; one end of the discharge section screw rod is connected with the feeding section screw rod while the other end of the discharge section screw rod is connected with an extrusion die of the discharge hole section of the machine barrel; the discharge section screw rod is in the shape of a hollow barrel; a screw blade extending along the axial direction is arranged on the outer periphery of the feeding section screw rod; screw blades which are in the same direction as the screw blade at the outer periphery of the feeding section screw rod are arranged on the outer periphery and the inner periphery of the hollow barrel-shaped discharge section screw rod; the screw blade at the outer periphery of the feeding section screw rod and the screw blade at the outer periphery of the discharge section screw rod are connected to form a whole body.

Owner:常熟市绿草根机械制造有限公司

Full-automatic heating and stirring intelligent emulsifying device for cosmetic production

InactiveCN107551876AReduce emulsification timeReduce wasteRotary stirring mixersMixing methodsLiquid level sensorElectromagnetic valve

The invention discloses a full-automatic heating and stirring intelligent emulsifying device for cosmetic production. The full-automatic heating and stirring intelligent emulsifying device comprises aframework, wherein the framework is fixedly arranged on the ground and is provided with a reaction kettle device; the reaction kettle device is provided with a reaction kettle cover device; a reaction kettle is internally provided with an inner heating and stirring device; a driving device is arranged above the reaction kettle device; the framework is provided with a controller; a signal receiving end of the controller is electrically connected with a temperature sensor and a liquid level sensor; a power supply output end of the controller is electrically connected with an electromagnetic valve I, an electromagnetic valve II and the driving device. The full-automatic heating and stirring intelligent emulsifying device disclosed by the invention has the beneficial effects that the structure is simple, and the practicability is strong.

Owner:王昭

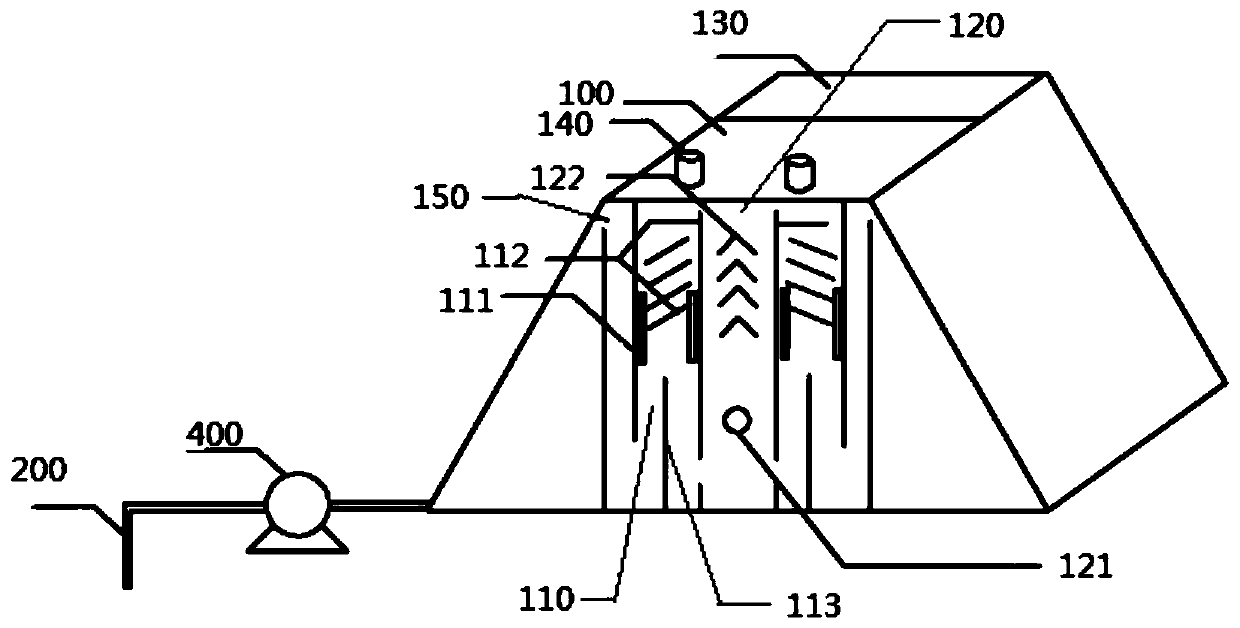

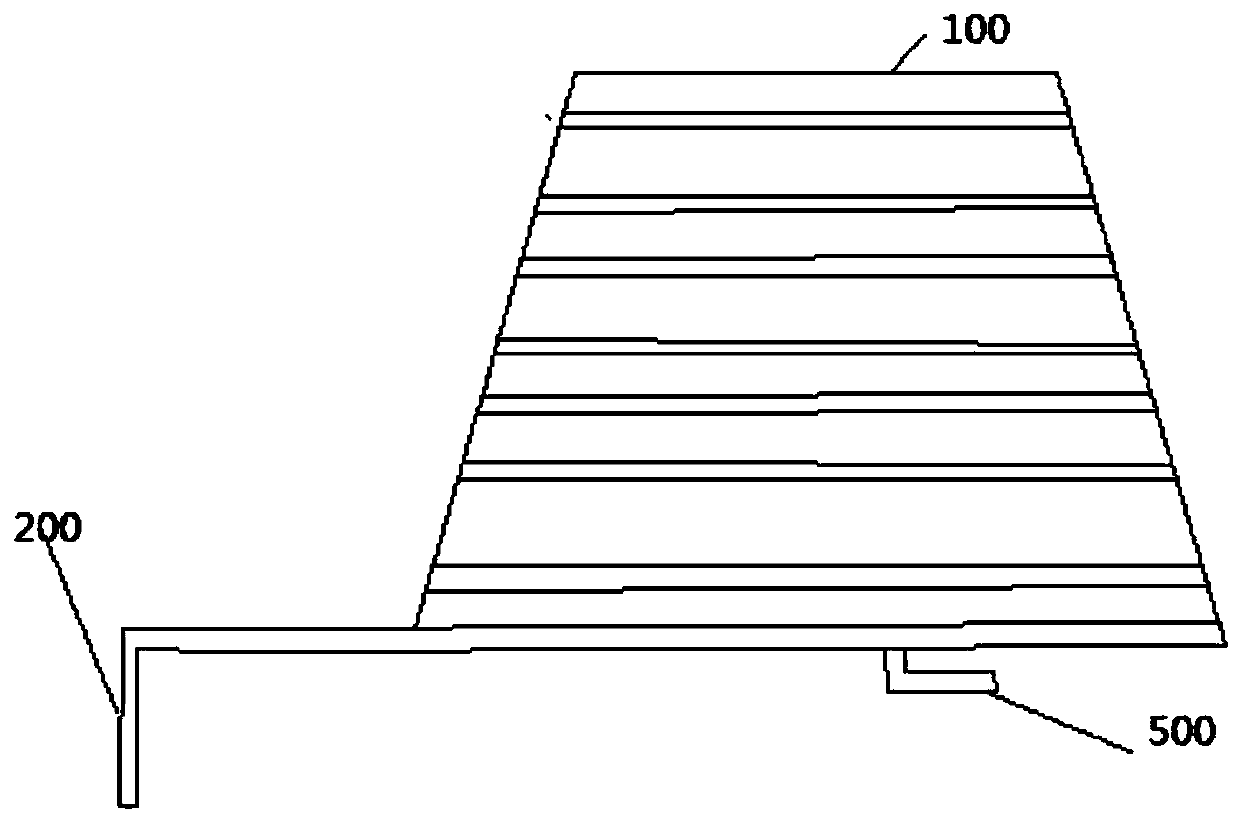

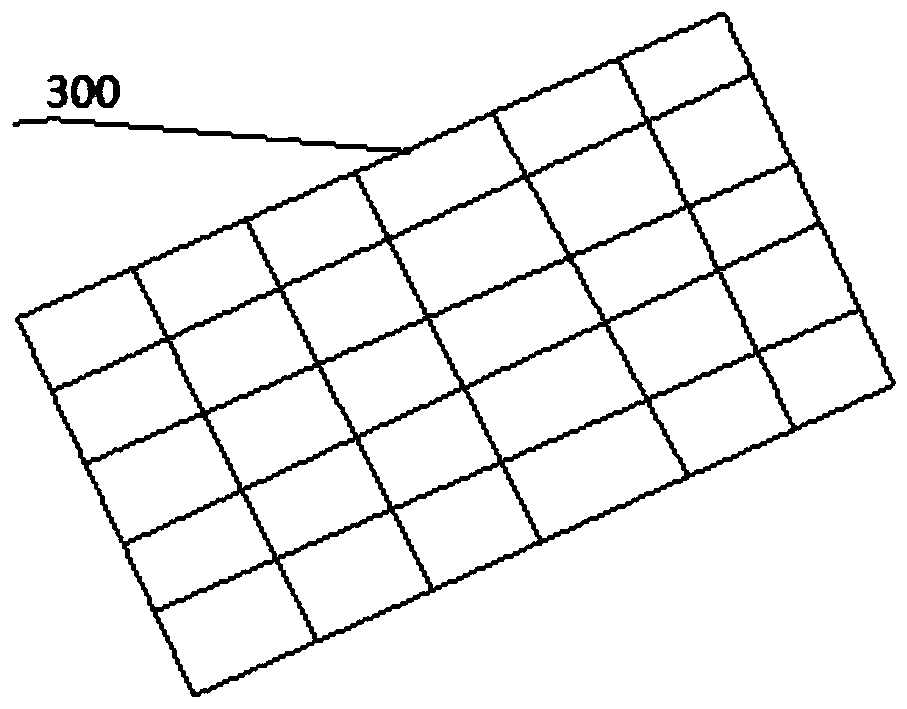

Solar auxiliary heating air-stripping tower for repairing VOC-polluted underground water

PendingCN110642445AAdequate initial heatingThe effect of improving the removal rateWater contaminantsWater aerationEngineeringSewage

The invention discloses a solar auxiliary heating air-stripping tower for repairing VOC-polluted underground water. The solar auxiliary heating air-stripping tower comprises: an air stripping tower, wherein a heating chamber, an aeration tank and a temporary storage tank which are sequentially communicated with each other are arranged in the air stripping tower; a water inlet pipeline, which is wound on the outer wall of the air stripping tower, wherein one end of the water inlet pipeline is communicated with underground sewage, and the other end of the water inlet pipeline is communicated with the heating chamber; a solar heat absorption plate, which is fixed on the outer wall of the air stripping tower, wherein the back surface of the solar heat absorption clings to the water inlet pipeline; a water pump, which is arranged on the water inlet pipeline; and a water outlet pipeline, which is communicated with the temporary storage pool, wherein the solar heat absorption plate heats sewage in the water inlet pipeline for the first time, and the heating chamber heats the sewage for the second time. According to the invention, since the water inlet pipeline is wound on the outer wall of the air stripping tower, and the back surface of the solar heat absorption plate clings to the water inlet pipeline, sufficient primary heating of sewage is effectively realized; and the sewage having undergone primary heating is subjected to secondary heating through the heating chamber, so the problem of insufficient heating efficiency is effectively solved, and the effect of increasing the removal rate of VOCs is achieved.

Owner:上海洁壤环保科技有限公司

Pressure reduction irrigation device for medical gastrointestinal surgery care

PendingCN109498881AStable gastrointestinal pressureImprove gastrointestinal conditionCannulasEnemata/irrigatorsIntestinal structurePressure reduction

The invention relates to the technical field of medical instruments, in particular to a pressure reduction irrigation device for medical gastrointestinal surgery care. The pressure reduction irrigation device comprises a body, a negative-pressure pump is arranged at the top of the body and connected with the top of a pressure reduction cavity through a negative-pressure pipe, an anti-inversion plate is arranged on the inner side of the pressure reduction cavity, a heating rod and a stirring component are arranged on the lower portion of an irrigation cavity, a pressuring pump is arranged at the top of the body and connected with the top of the irrigation cavity through a pressuring pipe, a first connecting pipe and a second connecting pipe are arranged in the body, and a pressure reductionirrigation pipe is arranged on the left side of the body and positioned at the ends of the first connecting pipe and the second connecting pipe. The pressure reduction irrigation device is novel in structure and high in function, the stomach and intestine can be safely, reliably and rapidly cared, working loads of medical staff are relieved, and working efficiency is improved.

Owner:JINAN CENTER HOSPITAL

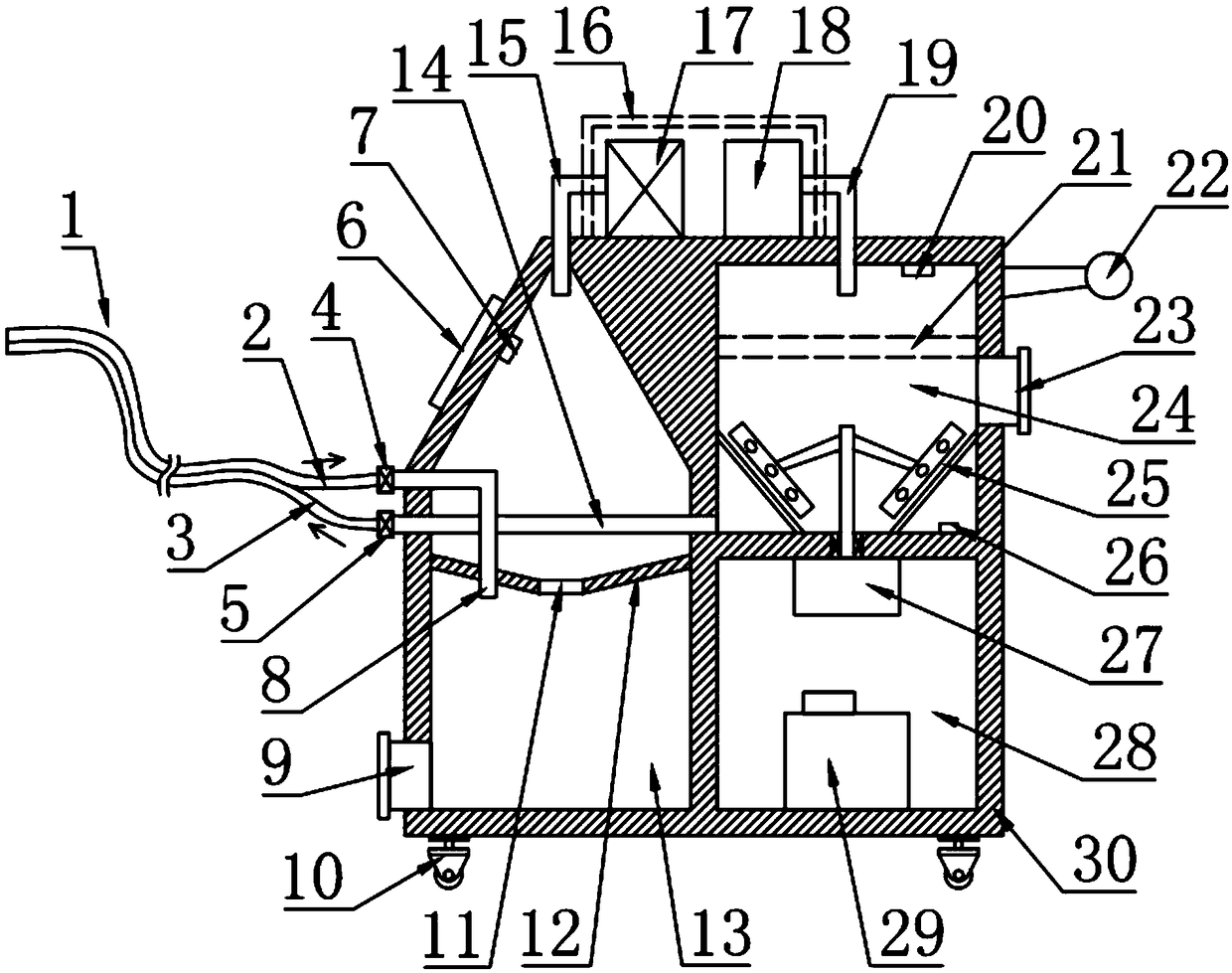

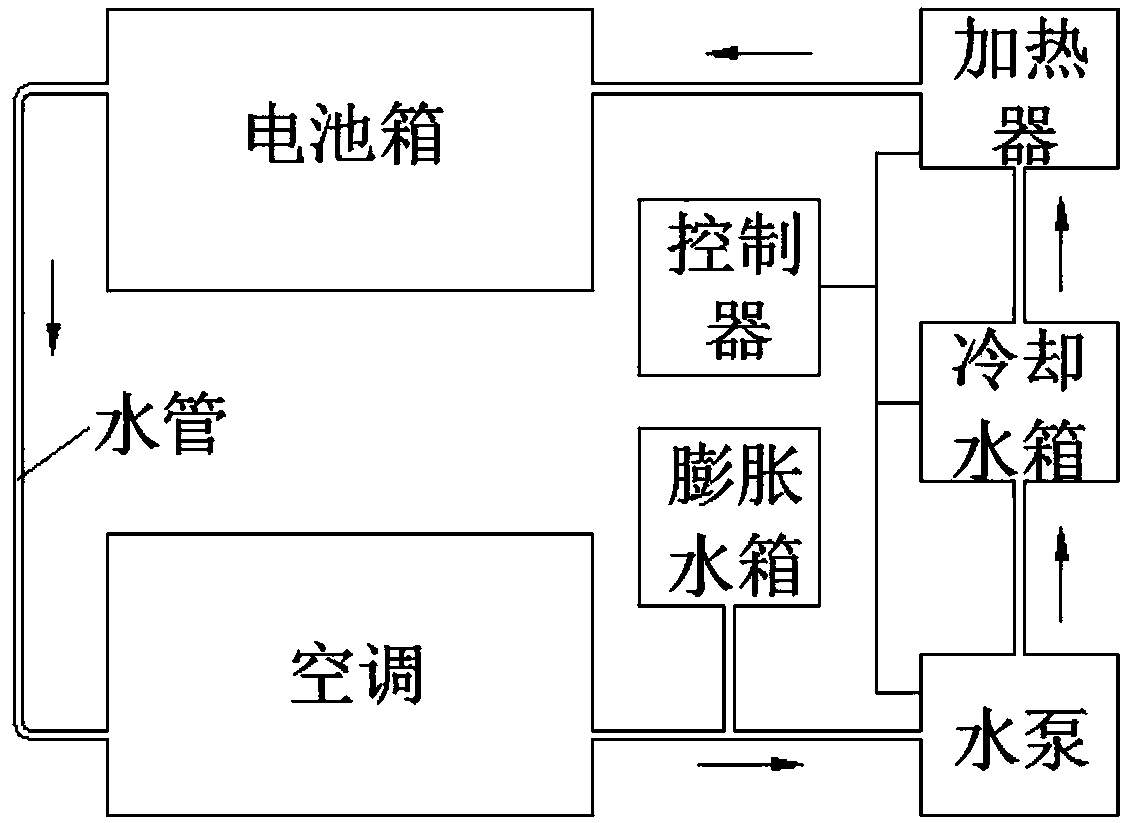

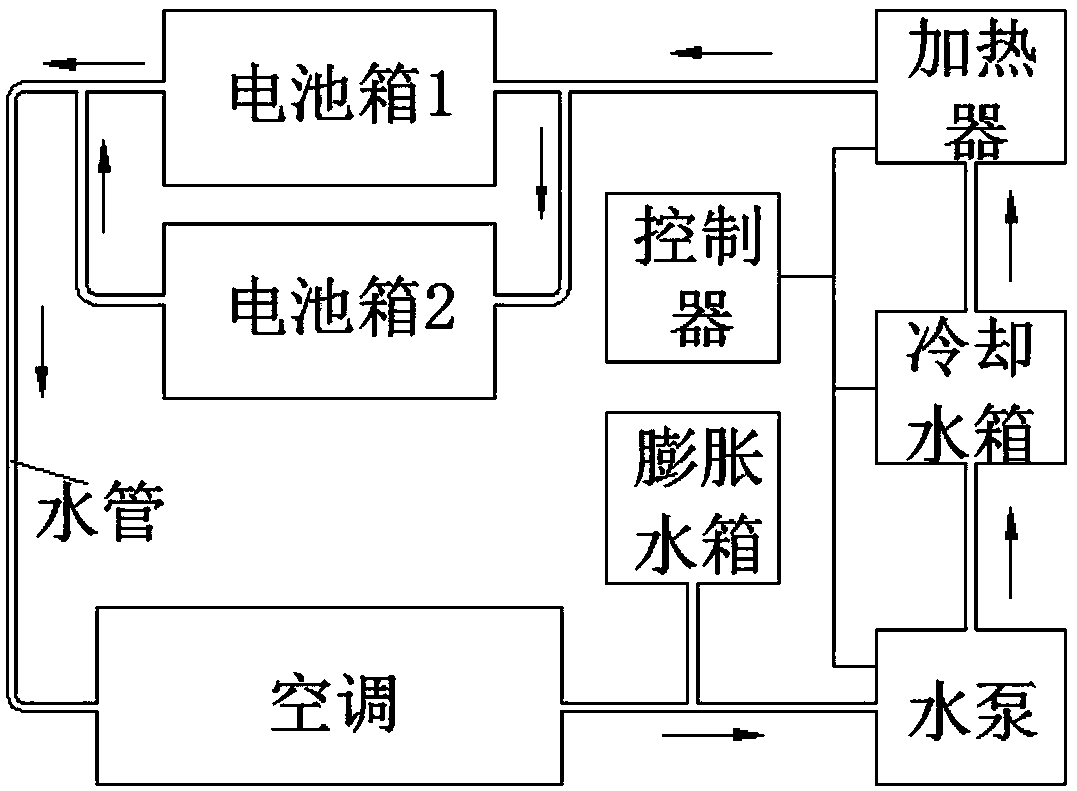

Liquid phase thermal management system for power battery

PendingCN108242578ASolve the lack of cooling capacityFull heating effectSecondary cellsExpansion tankPower battery

The invention discloses a liquid phase thermal management system for a power battery. The liquid phase thermal management system comprises an air conditioner, a cooling water tank, a water pump, a heater, a swelling water tank, a battery box, water pipes and a controller, wherein the air conditions is sequentially connected with the water pump, the cooling water tank, the heater and the battery box through the water pipes; the battery box is connected to the air conditioner through the water pipe; the swelling water tank is arranged between the air conditioner and the water pump; and the controller is connected with the water pump, the cooling water tank and the heater respectively through wires. According to the liquid phase thermal management system, the battery is refrigerated by virtueof the complete machine air conditioner and the auxiliary cooling water tank and is heated by virtue of a heater, so that the energy resources of a complete machine can be adequately utilized, the refrigeration performance and the heating performance are reliable, and the battery can be adequately cooled and heated.

Owner:ANHUI ANKAI AUTOMOBILE

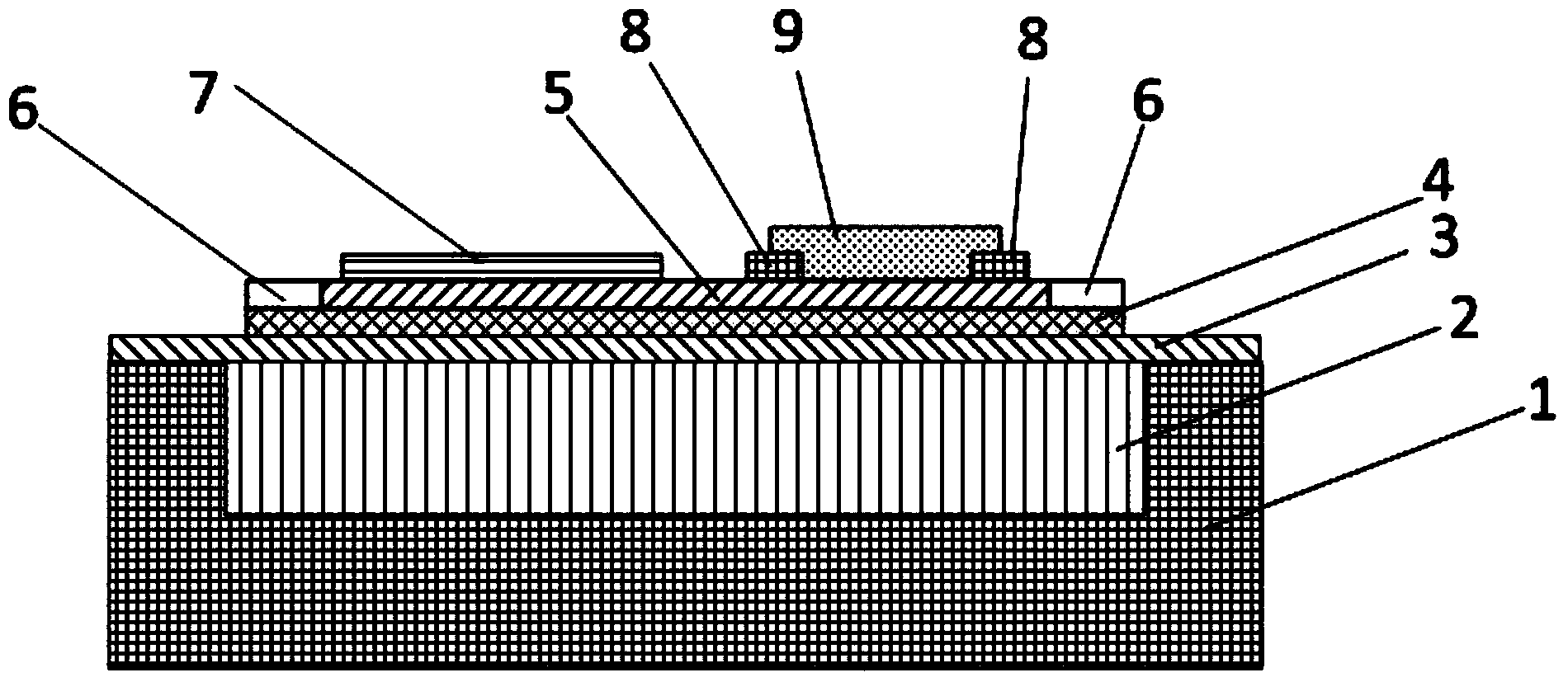

MEMS gas sensor with heat insulation groove and processing method thereof

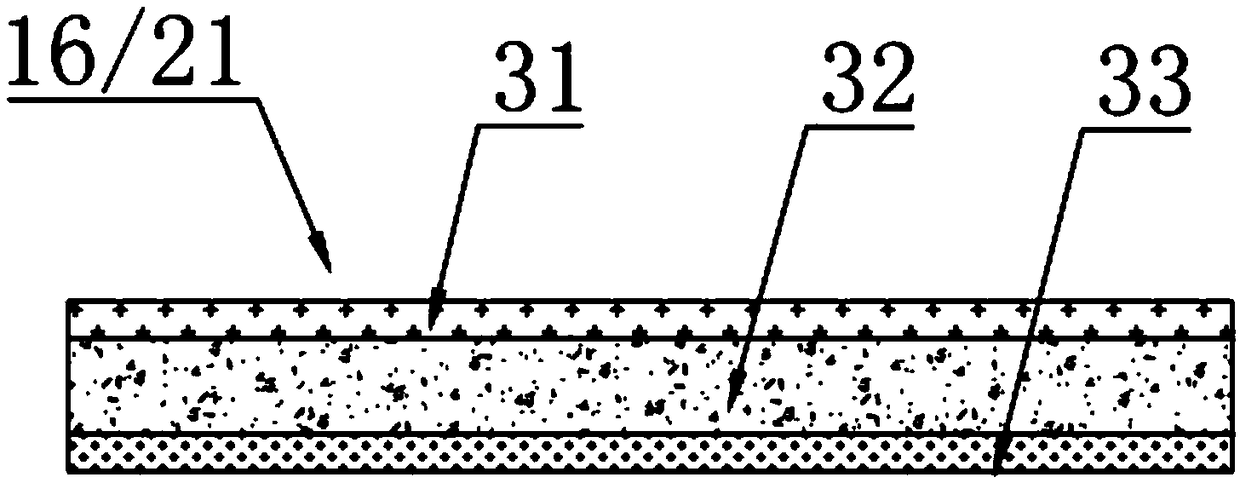

ActiveCN104165902AStable supportInhibit sheddingDecorative surface effectsSolid-state devicesInsulation layerGas detector

The invention relates to the gas detection field, and discloses an MEMS gas sensor with a heat insulation groove and a processing method thereof. The MEMS gas sensor comprises a monocrystalline silicon substrate, a heat insulation groove, which is formed on the upper surface of the monocrystalline silicon substrate, has a certain depth, and comprises one or more groups of grooves, wherein each groove group comprises a plurality of parallel grooves; a lower insulation layer, which covers the heat insulation groove and the upper surface of the monocrystalline silicon substrate; and a heating layer and an upper insulation layer, which are arranged above the lower insulation layer. The heat insulation groove can stably support the lower insulation layer membrane, the heating plate and the upper insulation layer, and is capable of preventing the deformation of the lower insulation layer when the gas detector is operated at a high temperature so as to avoid the falling of the heating layer. At the same time, the groove surface of the heat insulation groove is covered by a silicon dioxide membrane, and thus the heat insulation performance of the groove is enhanced, so the energy consumption can be reduced, the detection sensitivity of the gas sensor is improved, and the service life of the gas sensor is also prolonged.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

Fresh air purifying system for air source heat pump

InactiveCN107036198AImprove qualityFull heating effectMechanical apparatusHeat pumpsPlate heat exchangerFresh air

The invention discloses a fresh air purifying system for an air source heat pump. The fresh air purifying system is characterized in that the air source heat pump serves as a cold / heat source for heating / refrigerating fresh air. Working medium coils of two outdoor fluorine / gas heat exchangers forming the air source heat pump are designed to be two parts of working medium coils which are connected in parallel, one part of the working medium coils are provided with electromagnetic valves. By means of the fresh air purifying system for the air source heat pump, working media can selectively flow through part of or all the working medium coils according to different seasons; and filtering nets are further designed, outdoor fresh air passes through an air channel, the initial-efficiency filtering net, the intermediate-efficiency filtering net, the outdoor fluorine / gas heat exchangers, the high-efficiency filtering net, an air supply machine and an air supply channel and enters a room from an air supply port.

Owner:李元哲

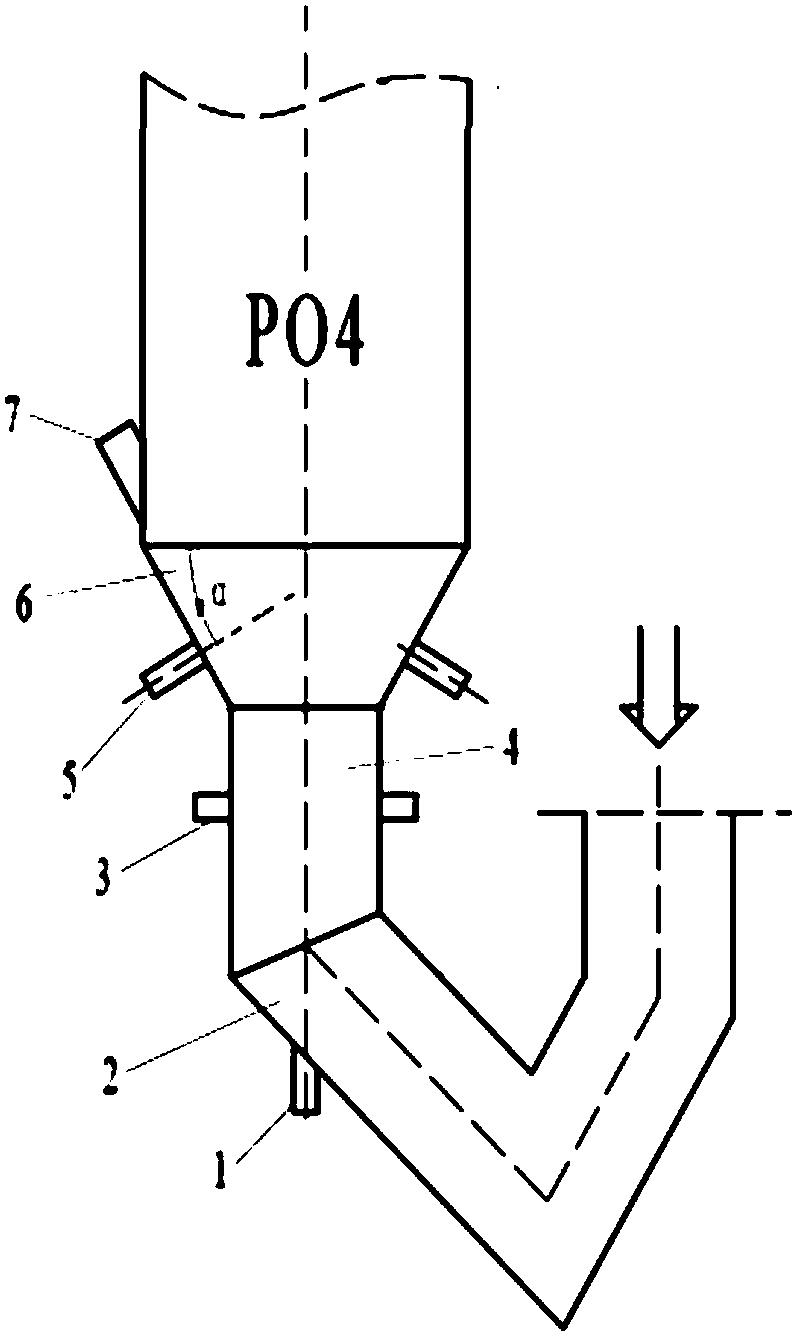

Staged-combustion system of suspension roaster and application thereof

PendingCN107559826AIncrease profitImprove the mixing effectGaseous fuel burnerCombustion systemInstability

The invention discloses a staged-combustion system of a suspension roaster and an application thereof, belonging to the field of roasting. The staged-combustion system comprises a main roaster PO4, amain combustion pipe, an auxiliary gas pipe, a first-stage combustor and a second-stage combustor, wherein the main roaster PO4, the main combustion pipe and the auxiliary gas pipe are connected in sequence; the first-stage combustor is connected to the bottom of the main combustion pipe; the central axis of the first-stage combustor and the central axis of the main combustion pipe coincide; and the second-stage combustor is arranged on the main combustion pipe along a periphery direction and is connected to the main combustion pipe. The staged-combustion system solves the problems existing ina tradition suspension roaster that the insufficient mixing of gas and combustion-supporting gas causes the insufficient combustion of fuel, low utilization rate of fuel and formation of a large amount of high-temperature pollutants, and material dropping causes the flameout of the combustors and the instability of the combustion system. The staged-combustion system has the characteristics of high efficiency, stability and low emission load of pollutants.

Owner:KEDA MAS CLEAN ENERGY +1

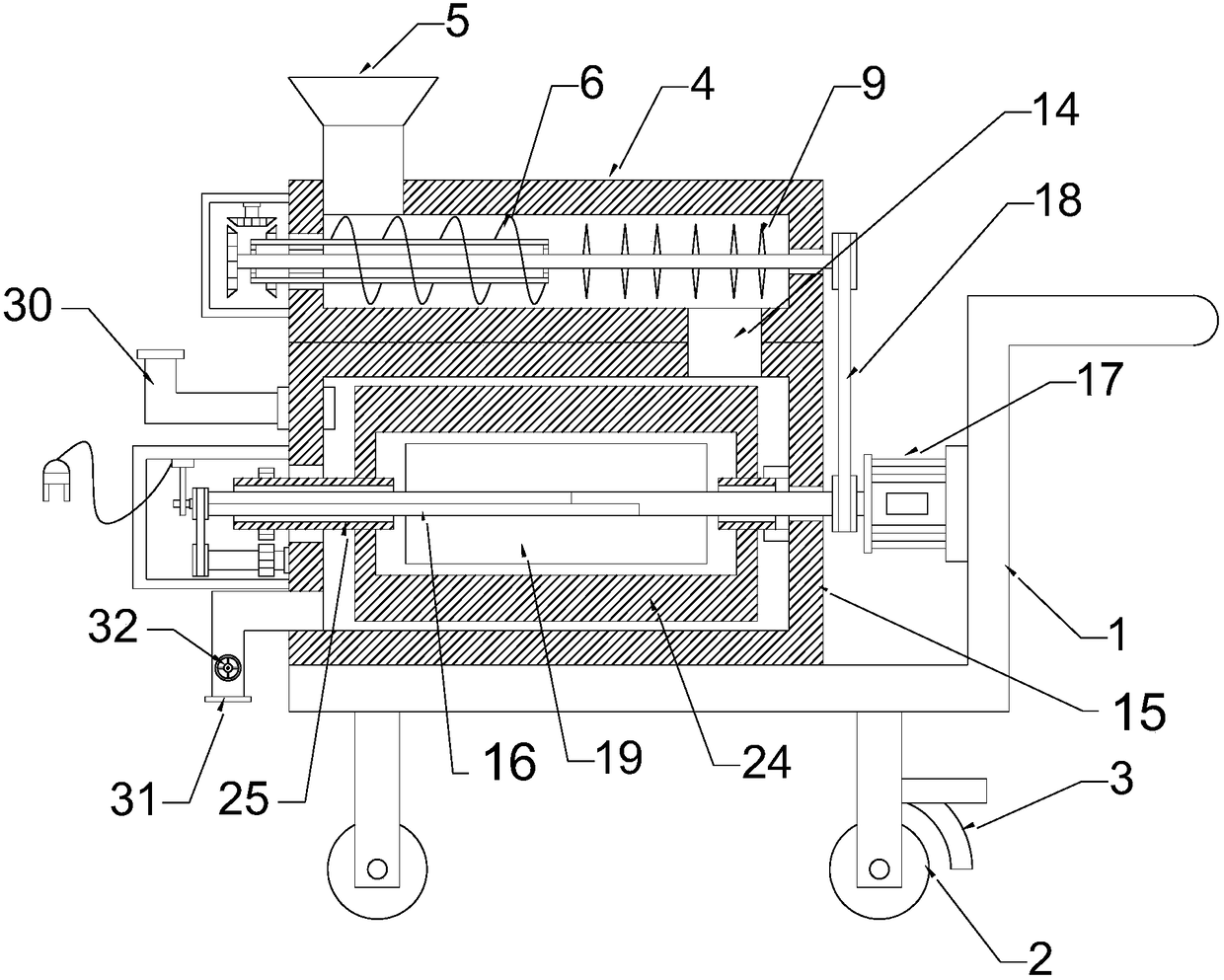

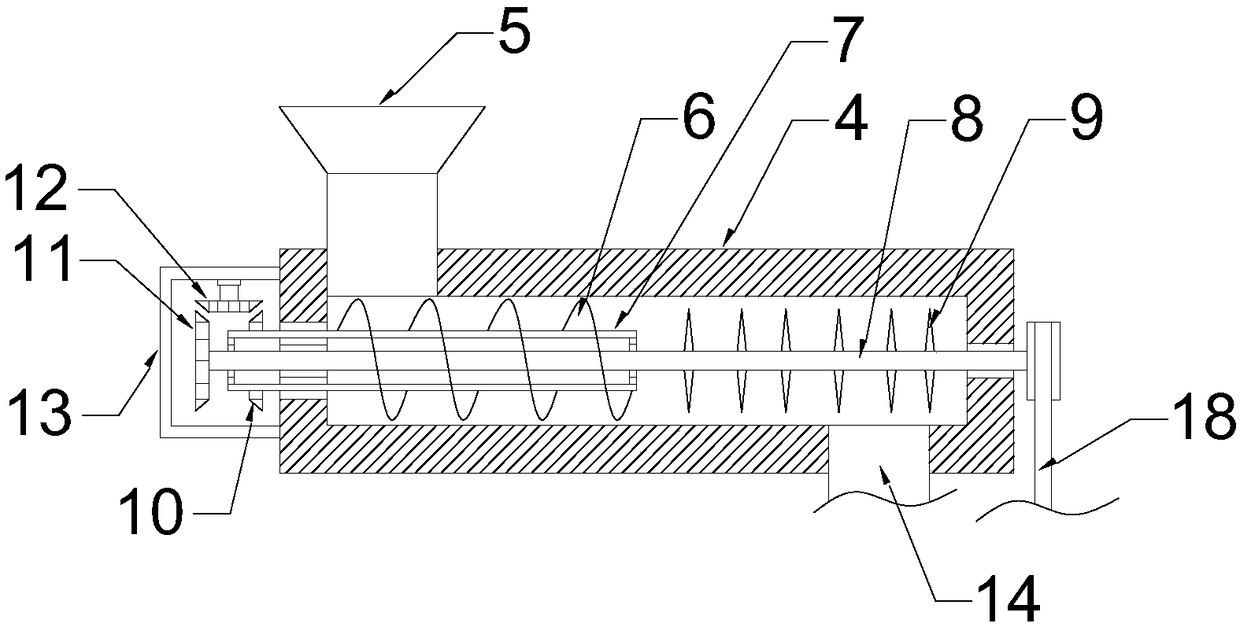

Feed mixing apparatus with uniform and high-efficiency heating function

The invention discloses a feed mixing apparatus with uniform and high-efficiency heating function. The feed mixing apparatus with uniform and high-efficiency heating function comprises a trolley, a crushing barrel, and a stirring and mixing box; the crushing barrel is arranged above the trolley; a feeding hopper communicates with an upper left end of the crushing barrel; and the stirring and mixing box communicates with a lower right side of the crushing barrel via an unloading passage. By arranging helical blades and crushing blades, high-efficiency crushing can be performed on feeds so as tofacilitate subsequent stirring and heating so as to control feeding rate. By arranging heating plates and stirring plates which are distributed in inner and outer nesting, the feed mixing apparatus is capable of performing full stirring on feeds so as to avoid caking of feeds at the bottom; moreover, the feeds can also be uniformly and rapidly heated so as to ensure uniform and high-efficiency heating, and thus, the feed mixing apparatus is economical in energy consumption and good in heating effect.

Owner:陈鹏

Fluid heating and sterilization immediate synchronization supply device

InactiveCN105066425AFull heating effectSimple processWater/sewage treatment by irradiationHeating element shapesEngineeringElectric heating

The invention provides a fluid heating and sterilization immediate synchronization supply device. The fluid heating and sterilization immediate synchronization supply device comprises an electric heating pipe and a sterilization pipe arranged in a pipe cavity of the electric heating pipe. A sleeve on the periphery of the sterilization pipe is a transparent cylinder type sleeve. A fluid channel is formed in an interlayer cavity formed by the sleeve and the electric heating pipe. The fluid heating and sterilization immediate synchronization supply device is simple in structure, and two different processing operation processes of heating and sterilization of fluid are successfully carried out synchronously. In addition, it is guaranteed that no heating or sterilization blind area exists in the flowing process of the fluid in the fluid channel. Meanwhile, it is guaranteed that partial fluid flowing in the channel at the initial stage can also be well heated and sterilized.

Owner:周通

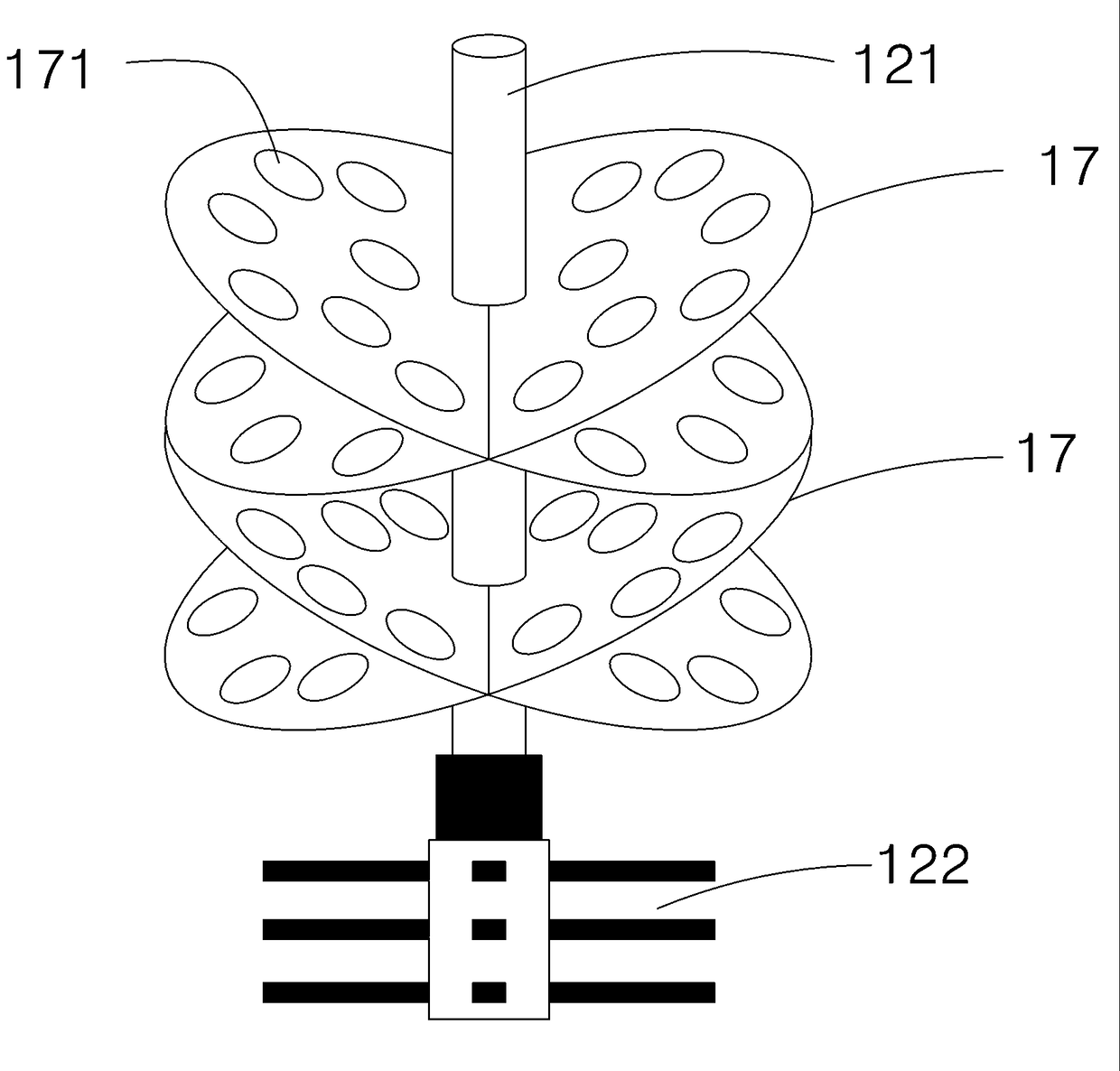

Liquid material mixing apparatus

InactiveCN108579596AExtensive discharge coverageThoroughly mix and diluteTransportation and packagingMixing methodsDrive shaftLiquid state

The invention discloses a liquid material mixing apparatus, comprising a liquid material mixing apparatus body. A mixture dilution chamber is arranged inside the liquid material mixing apparatus body.A drive motor and an exhaust port are disposed at the top end of the liquid material mixing apparatus. Liquid materials are added through multiple feed inlets which are arranged on the mixture dilution chamber. The liquid materials are added through multiple air permeable baffle apertures of an X-shaped feeding board which is fixedly sleeved on a drive shaft. The end portion of the drive shaft isconnected with a stirring blade. The drive shaft extending into the mixture dilution chamber is driven by the drive motor, and then the X-shaped feeding board sleeved on the drive shaft and the stirring blade are rotated under the driving of the drive shaft. The heated atomization gas is delivered to the liquid material mixture by a helical inlet pipe which is arranged at the bottom of the mixture dilution chamber and connected to an atomization gas inlet. The liquid material mixing apparatus is capable of mixing uniformly rapidly and diluting and heating the liquid material.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

plastic extruder

The invention provides a plastic extruder, which can solve the problems of insufficient mixing of raw materials and high power consumption of a motor in a traditional plastic extruder, ensure extrusion quality and reduce production cost. The barrel is provided with a feeding device, and the external heating device is installed on the outer periphery of the barrel in sections, and the outer periphery of the screw is provided with helical blades extending in the axial direction. The screw in the feed section, the screw in the feed section is connected to the output shaft of the drive motor, one end of the screw in the discharge section is connected to the screw in the feed section, and the other end is connected to the extrusion die at the discharge port of the barrel, the screw in the discharge section is in the shape of Hollow cylindrical, the outer periphery of the screw in the feeding section is provided with helical blades extending in the axial direction, and the outer and inner peripheries of the hollow cylindrical screw in the discharging section are provided with spiral blades in the same direction as the outer periphery of the screw in the feeding section. The helical blade, the helical blade on the outer periphery of the screw rod in the feeding section is connected with the helical blade on the outer periphery of the screw rod in the discharging section.

Owner:常熟市绿草根机械制造有限公司

Material mixing and diluting equipment with heating function

InactiveCN108607426AExtensive discharge coverageThoroughly mix and diluteRotary stirring mixersTransportation and packagingDrive shaftDrive motor

The invention discloses material mixing and diluting equipment with a heating function. The material mixing and diluting equipment comprises a material mixing and diluting equipment body; a material mixing and diluting cavity is formed inside the material mixing and diluting equipment body; a driving motor and an exhaust opening are arranged at the top end of the material mixing and diluting equipment body; material liquid is added through a plurality of feed openings in the material mixing and diluting cavity and a plurality of permeable diversion holes of U-shaped discharging plates on discharging blocks which fixedly sleeve and are arranged on a driving shaft; a driving motor drives the driving shaft extending into the material mixing and diluting cavity to drive the discharging blockssleeving the driving shaft to rotate; the material mixing and diluting equipment is provided with an atomizing steam inlet communicated with the material mixing and diluting cavity; an atomizer for generating atomizing steam is arranged at the atomizing steam inlet; the heated atomizing steam is exhausted into the mixed material liquid by a spiral steam inlet pipe which is communicated with the atomizing steam inlet and is arranged at the bottom of the material mixing and diluting cavity. The material mixing and diluting equipment provided by the invention is material mixing and diluting equipment with the heating function, which can quickly and uniformly mix the materials, and dilute and heat the materials.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

Heating assembly and aerosol generating device

PendingCN114788585AAvoiding the Burning ProblemImprove heating uniformityTobaccoInfraredMaterials science

The invention provides a heating assembly and an aerosol generating device. The heating assembly comprises a base body, an infrared heating layer, a first electrode, a second electrode and a first conductive module. Wherein the base body is used for inserting or accommodating an aerosol generating product; the infrared heating layer is arranged on the base body and is used for radiating infrared rays to heat the aerosol generating product when being electrified; the first electrode and the second electrode are arranged on the surface of the substrate at an interval, are respectively connected with the infrared heating layer, and are respectively used for being connected with a power supply assembly so as to supply power to the infrared heating layer; the first conductive module is arranged on the surface of the base body, the first conductive module is electrically connected with the first electrode and the second electrode, and at least part of the first conductive module makes contact with the infrared heating layer. The heating assembly is simple in structure, and the manufacturing process is effectively simplified.

Owner:SHENZHEN MERIT TECH CO LTD

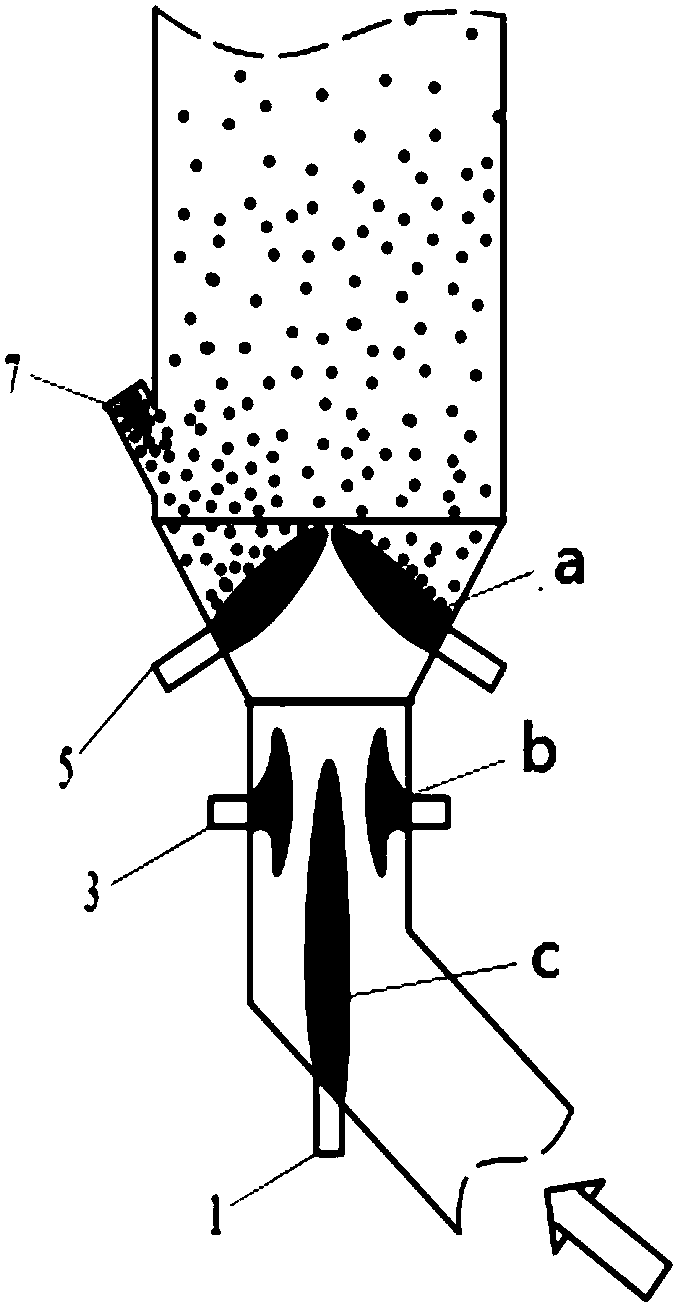

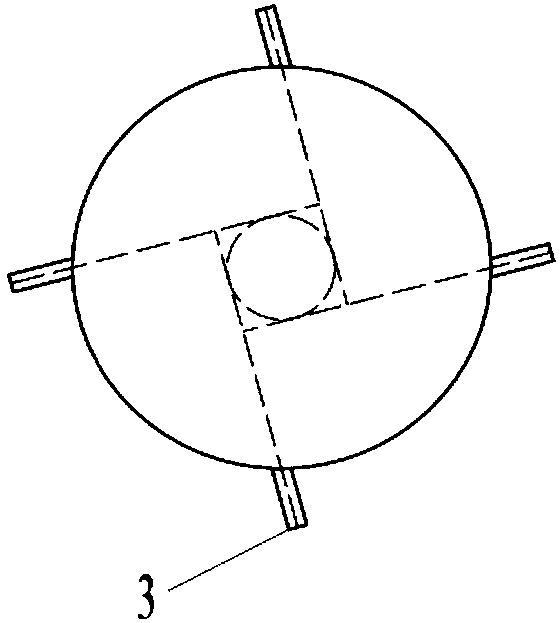

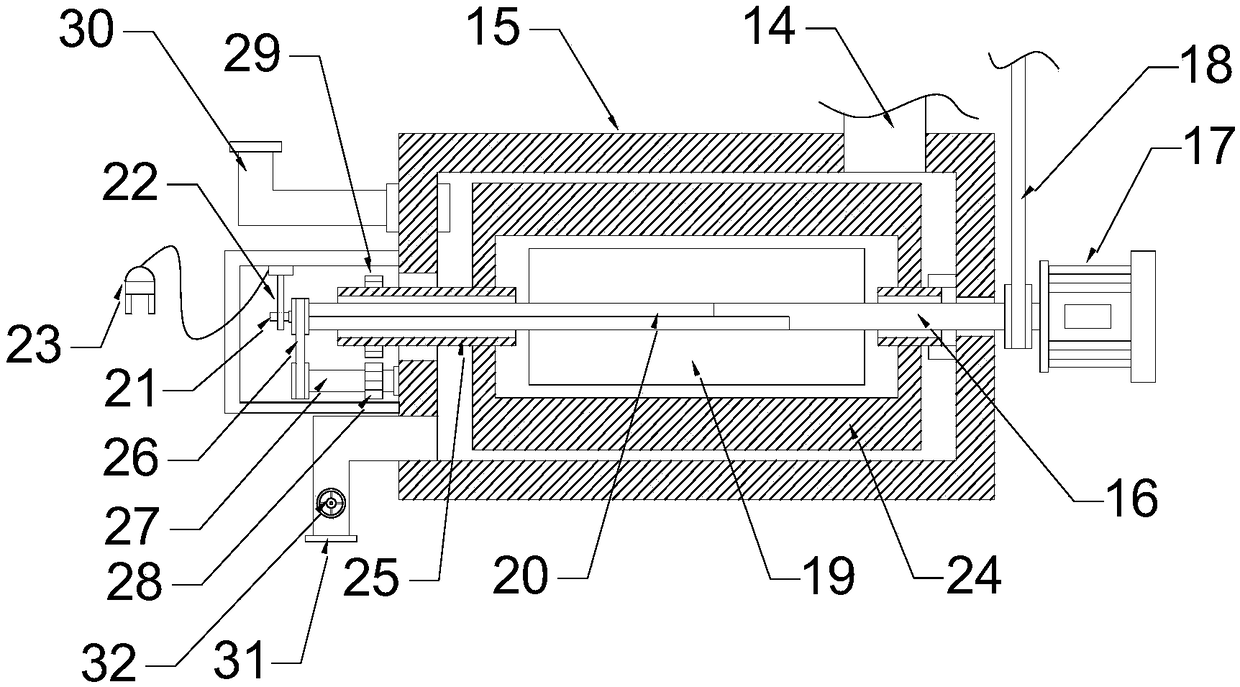

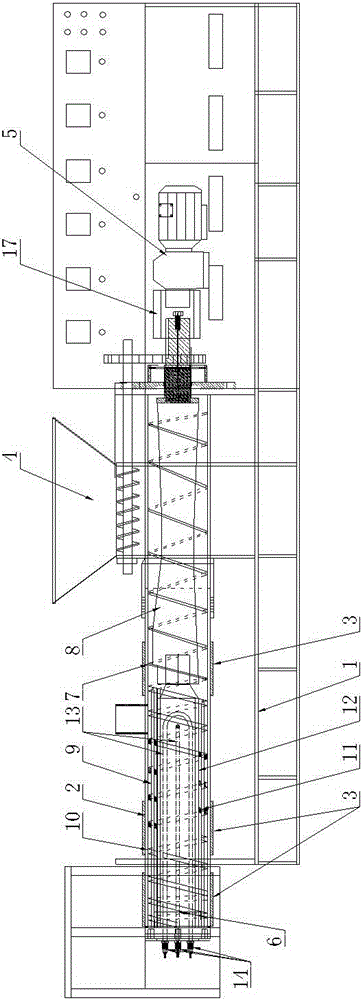

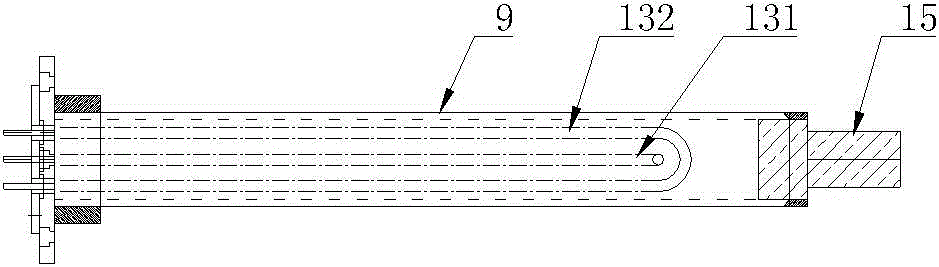

Steam calcining furnace under pressure

ActiveCN103148680ASmooth shippingGuaranteed continuityDrying machines with non-progressive movementsDrying solid materialsThree stageEngineering

The invention discloses a steam calcining furnace under pressure, which mainly consists of a raw material cabin, a feeding cabin, a furnace body and a steam inlet shaft, wherein a reaction cavity is arranged inside the furnace body, the feeding cavity is communicated with the front end of the furnace body, a transmission device is arranged outside the furnace body, the raw material cabin and the feeding cabin are communicated through a three-stage material conveying device, the front end of the furnace body is a gas outlet cavity, a furnace gas outlet is arranged on the gas outlet cavity, the steam inlet shaft is communicated with the back end of the furnace body, a steam inlet is arranged on the steam inlet shaft, a middle cabin is also arranged between the steam inlet shaft and the furnace body, a finished product cabin is communicated on the middle cabin, a heating pipe is arranged in a reaction cavity of the furnace body, and a pipeline opening of the heating pipe is communicated with the steam inlet passage of the steam inlet shaft. The steam calcining furnace under pressure realizes the continuous dewatering or production of materials, the material loss is reduced, the work environment of the production site is improved, and the pollution is reduced. In addition, the generated furnace gas can also be recovered and utilized, the resource waste is reduced, and further energy-saving and environment-protection effects are realized.

Owner:CHENGDU TIANBAO HEAVY IND

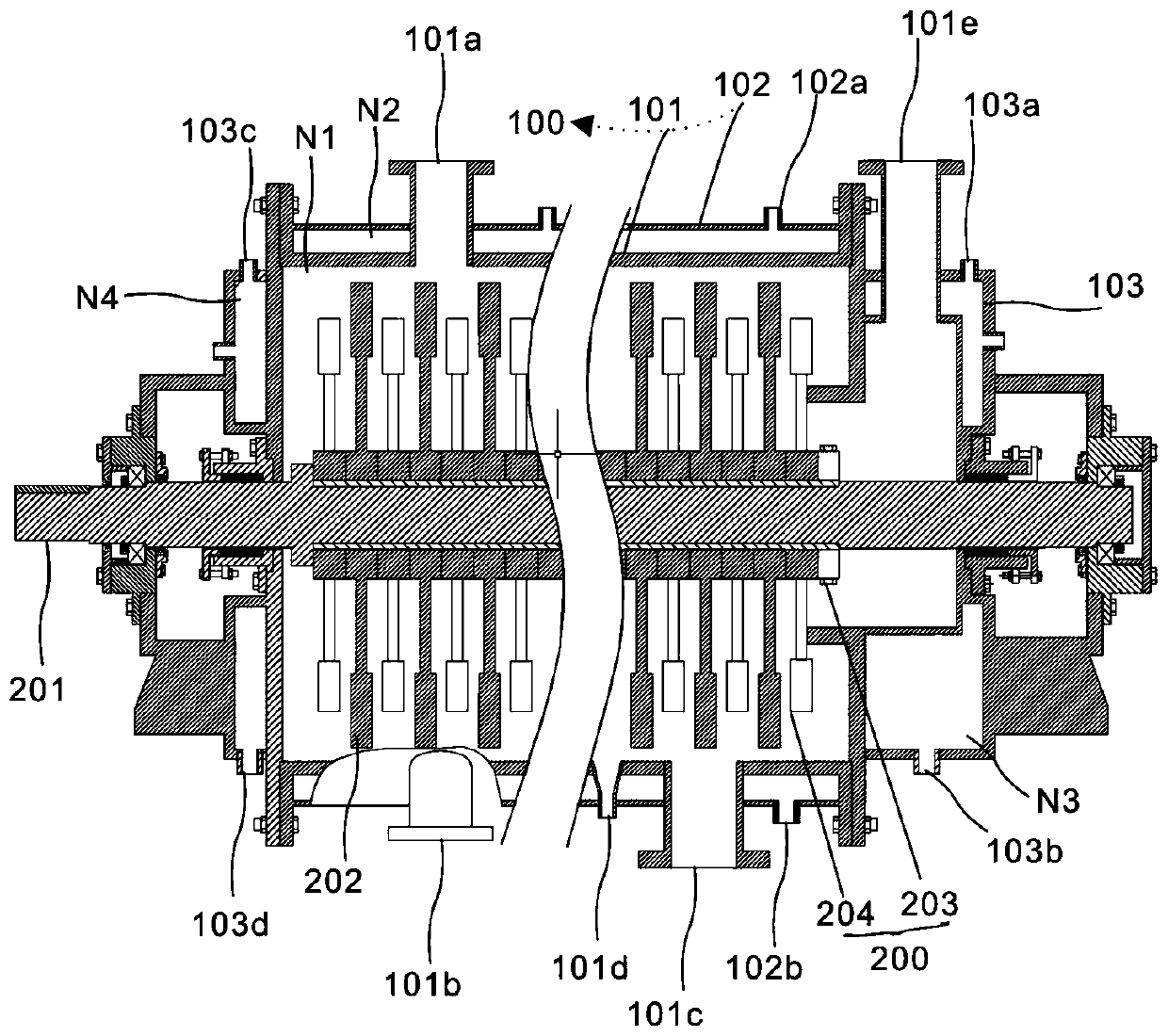

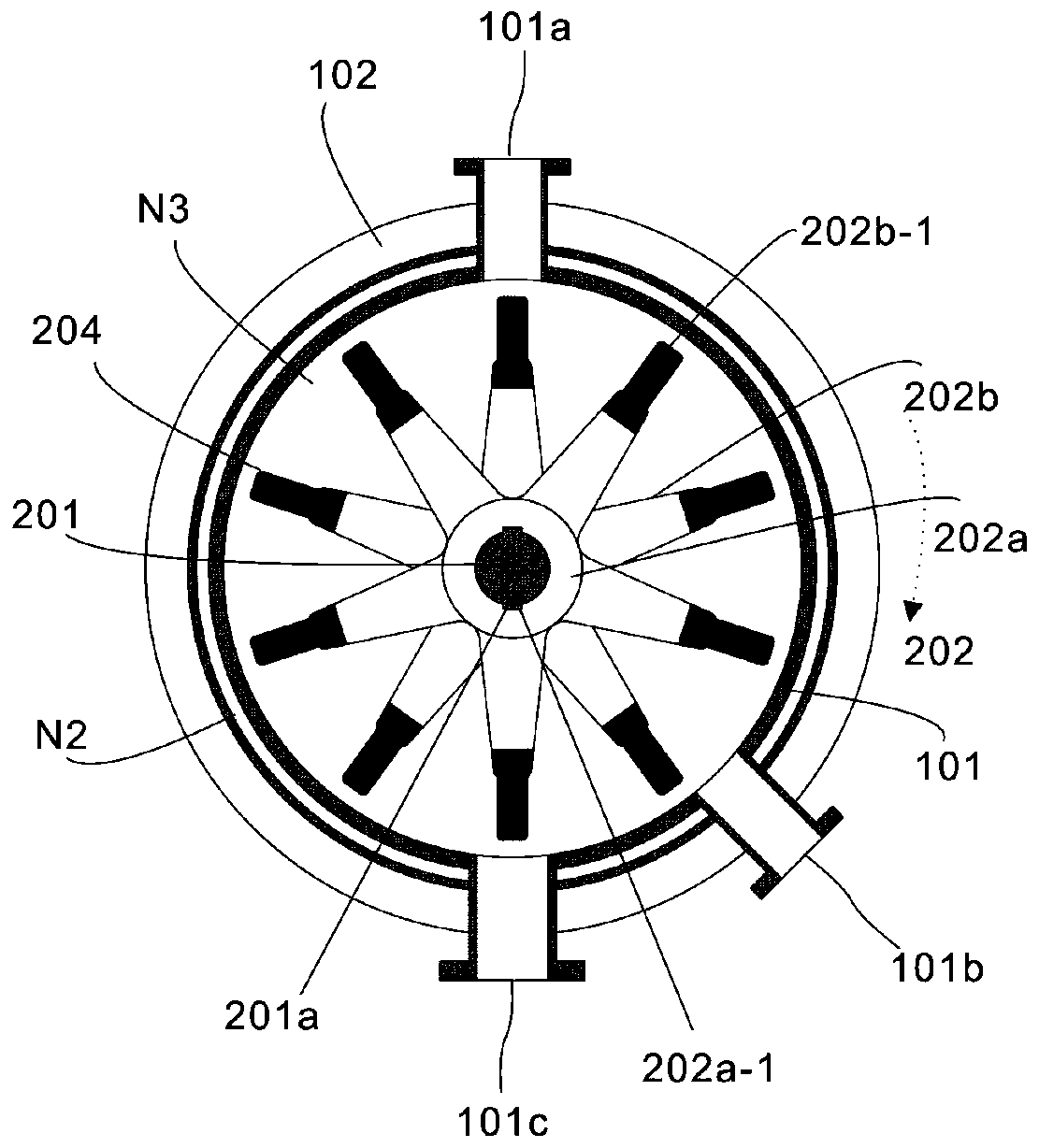

Oil sludge treatment device and system

PendingCN111547981AFull heating effectDecompose fullySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEngineeringOil sludge

The invention discloses an oil sludge treatment device, which comprises: a bearing assembly that includes an inner shell, an outer shell arranged at the periphery of the inner shell, and spacing bodies located at the two sides of the inner shell; the hammer grinding assembly that comprises a rotating shaft, a first rotor piece and a second rotor piece, wherein the first rotor piece and the secondrotor piece are arranged on the rotating shaft in a staggered mode through a locking piece, and the first rotor piece and the second rotor piece are both arranged in the reaction cavity of the inner shell; a first heating separation cavity is formed between the inner shell and the outer shell; according to the invention, the rotor pieces and a plurality of heating cavities are arranged, so the oily sludge can be fully heated and hammer-milled; therefore, the oily sludge can be fully decomposed; meanwhile, a thermal desorption mode of combined action of steam heating and hammer milling is adopted, the evaporation temperature of oil is greatly reduced by injecting steam, the treatment efficiency is improved, and the problem that fine hammer milling dust is difficult to treat is solved; the process temperature is reduced, the service life of a mechanical structure is prolonged, and the operation stability is enhanced.

Owner:上海浦源科技有限公司

Environment-friendly slurry circulating pump set

ActiveCN108488073AGuaranteed uptimeExtended service lifeSpecific fluid pumpsPump componentsCollection systemSlurry

The invention provides an environment-friendly slurry circulating pump set. The environment-friendly slurry circulating pump set is provided with a front bearing cooling system, a rear bearing coolingsystem, a front pump cavity cooling system, a rear pump cavity cooling system, a lubricating oil cooling system, a mechanical seal cooling flushing system, a base cooling system, a pump set residualaxial force automatic balance system, a lubricating oil cooling system, a mechanical seal leak detection and residual discharging system, an oil chamber water inlet detection system, a lubricating oilleakage collecting system and a pump cavity leakage residual discharging system. All parts of the pump set can be heated or cooled according to the need, so that the pump set operates normally, safely and stably, the pump set is protected, the service life of the pump set is prolonged, the pump set can work under different temperature environments and working conditions, mediums of different temperatures can further be pumped and conveyed, diversified application is achieved, pumped and conveyed residuals, the leaked medium and leaked bearing lubricating oil of a slurry circulating pump can be recycled completely, and the cleanliness and sanitation of the environment are ensured.

Owner:GUANGZHOU XINHENG PUMP MFG

Magnetic stirring water bath kettle provided with support

InactiveCN103657760AHeating safetyAchieving stirringMixersWater/sand/air bathsMagnetic tension forceWater baths

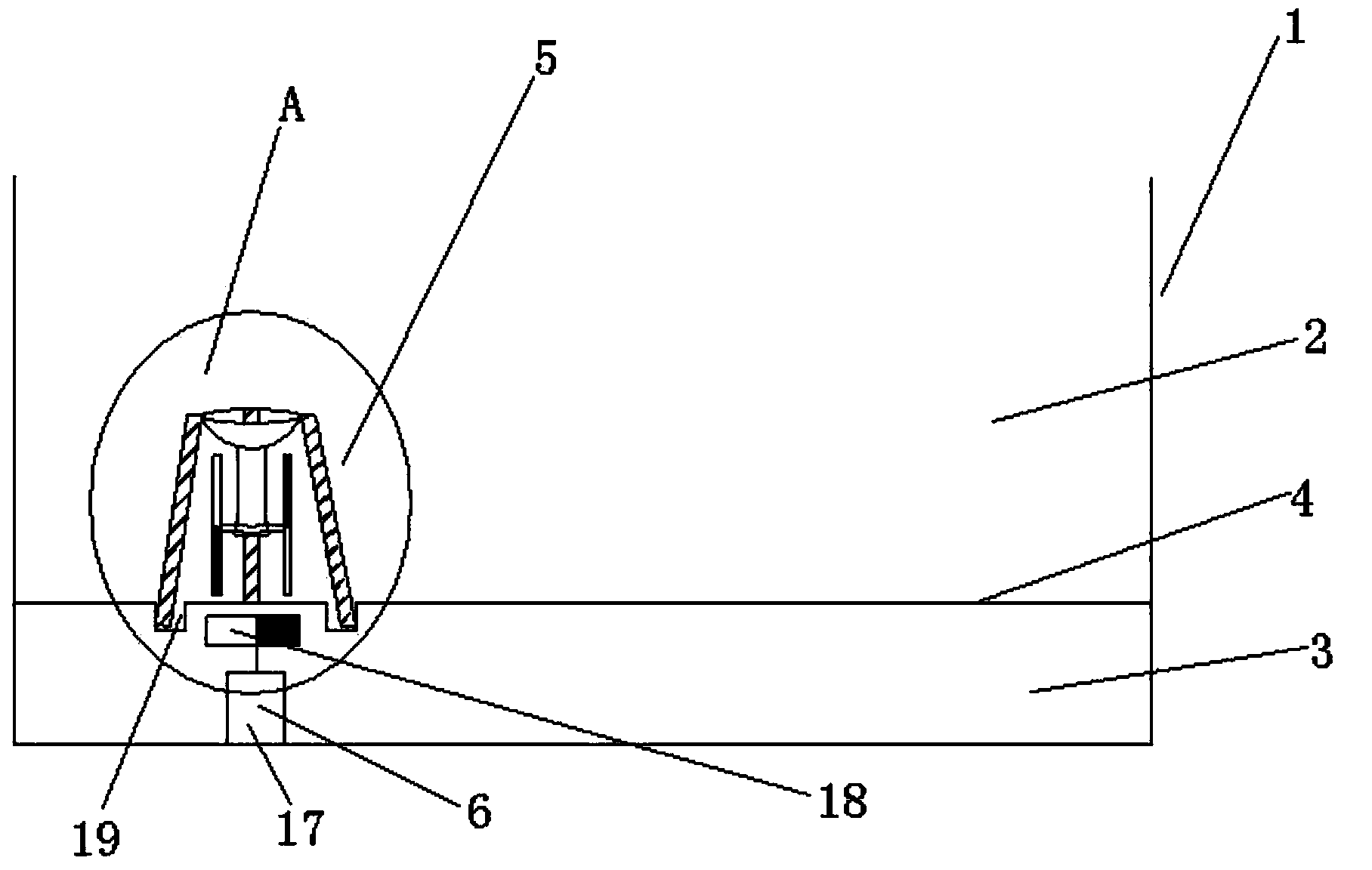

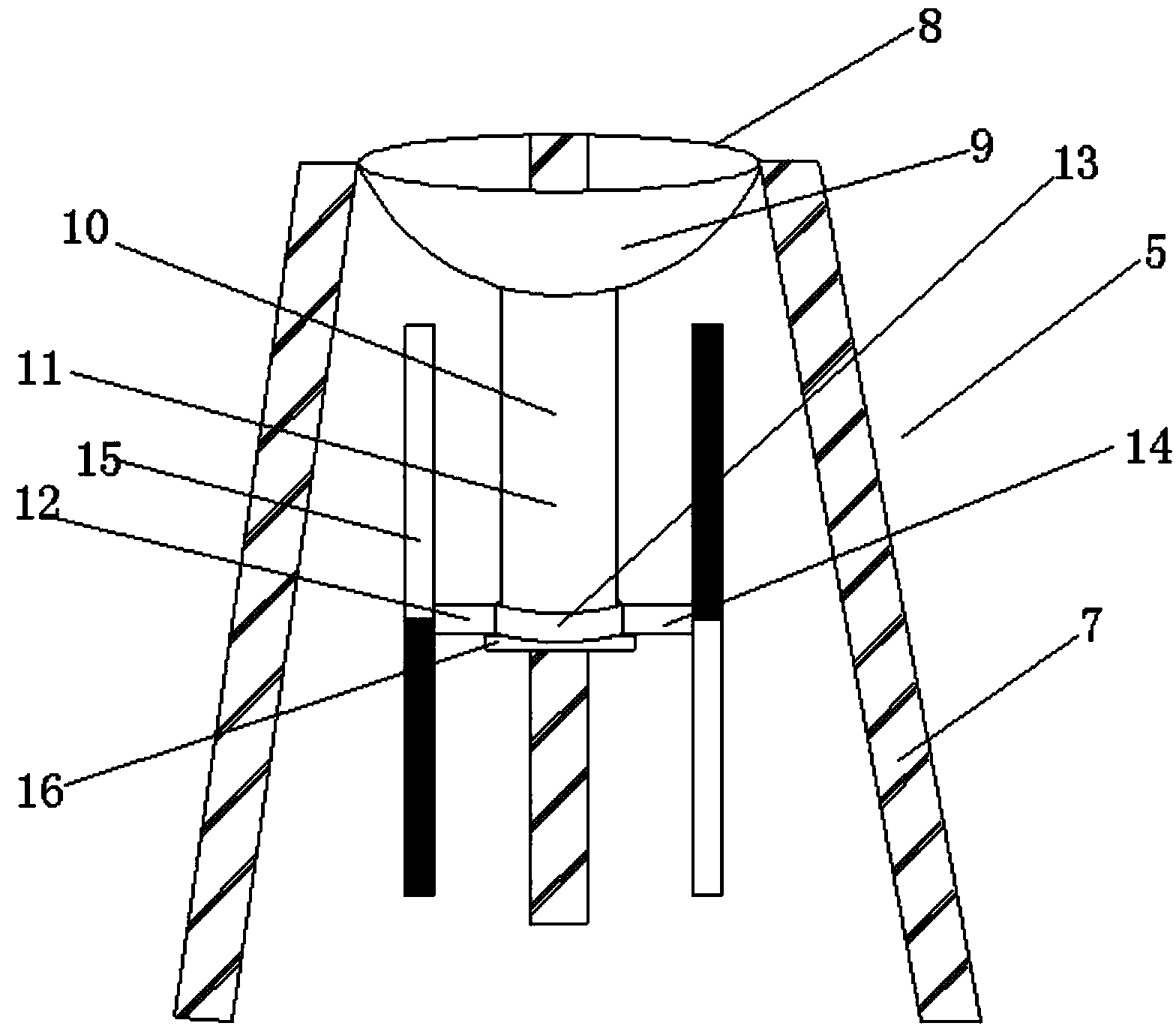

The invention discloses a magnetic stirring water bath kettle provided with a support. The magnetic stirring water bath kettle comprises a water bath kettle body (1) and is characterized in that the water bath kettle body (1) comprises a water tank layer (2) located on the upper layer and a driving layer (3) located on the lower layer, the water tank layer (2) and the driving layer (3) are separated by a baffle (4), the water tank layer (2) is provided with the support (5), and the driving layer (3) is provided with a magnetic stirring driving system (6) located right below the support (5). The magnetic stirring water bath kettle provided with the support is simple in structure, reasonable in design, capable of realizing operations such as heating of a large container and a small container and the like simultaneously and stirring a test solution, and suitable for being widely popularized and applied to laboratories.

Owner:SUZHOU ORIGIN IND DESIGN

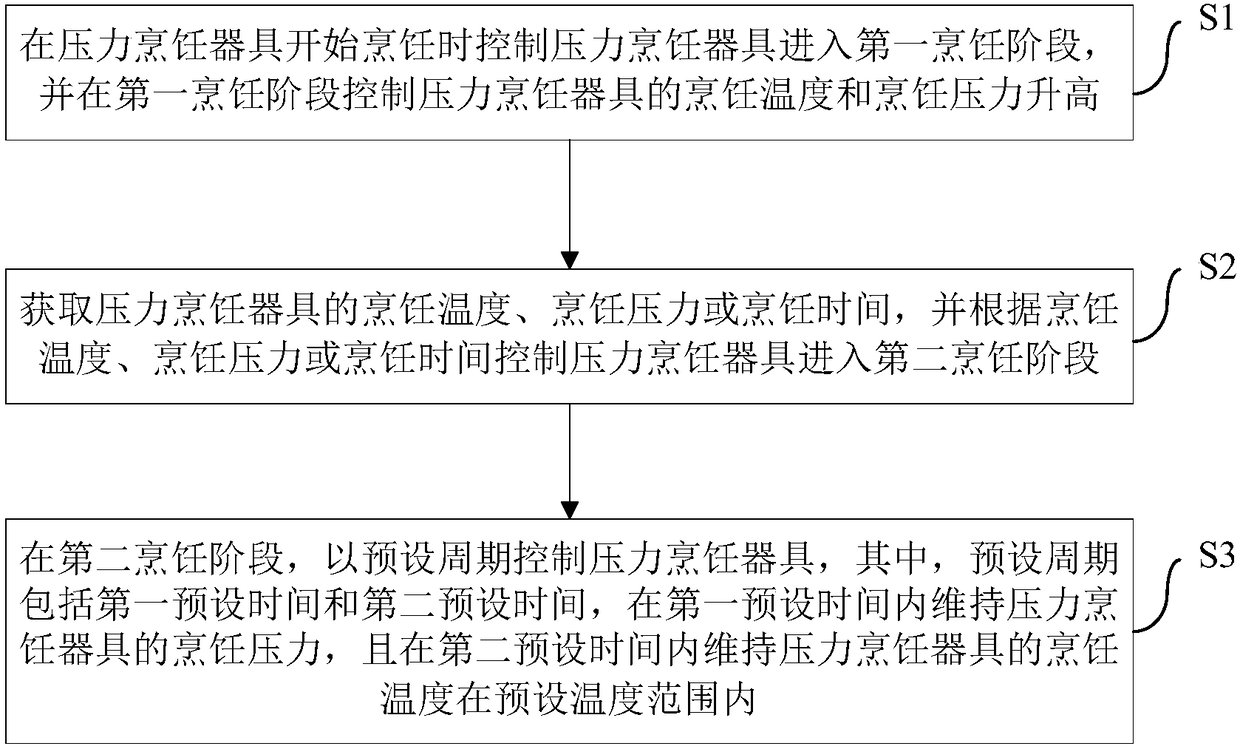

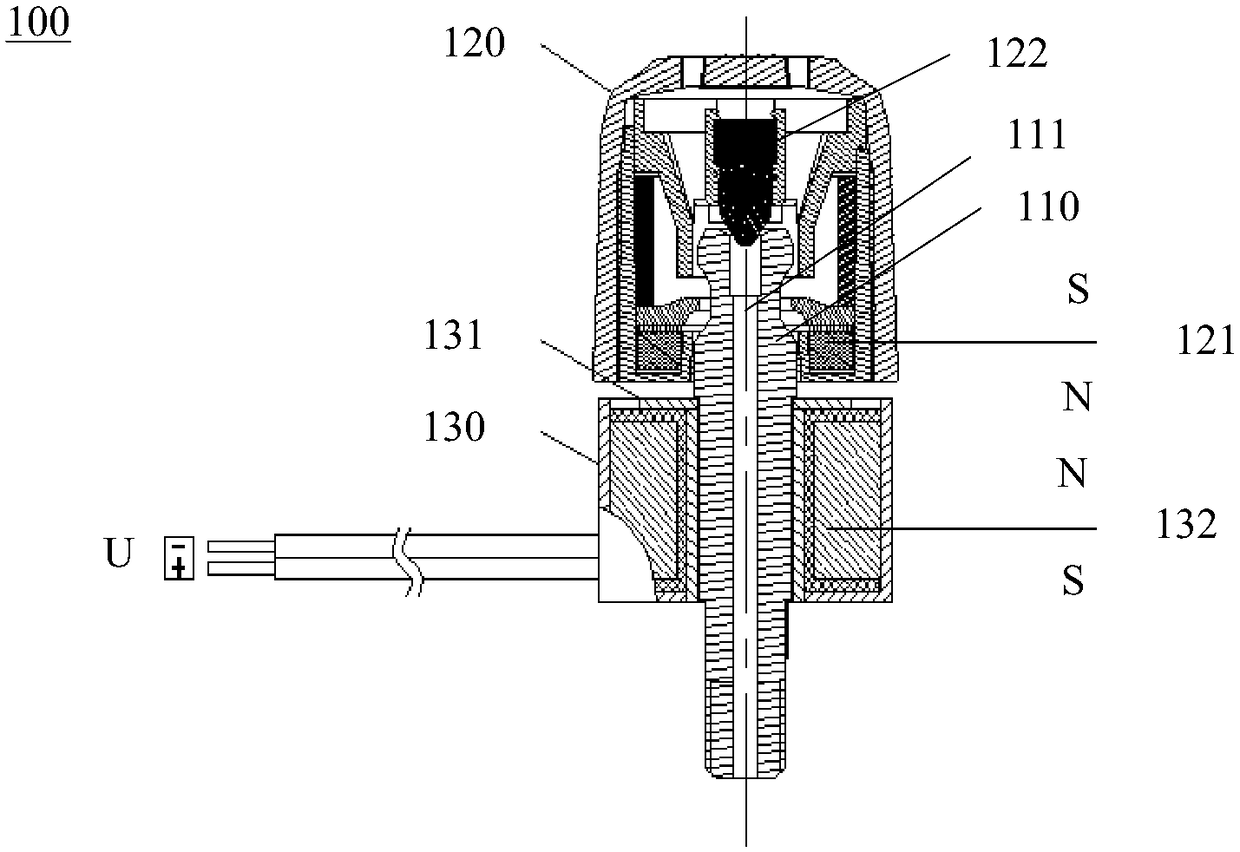

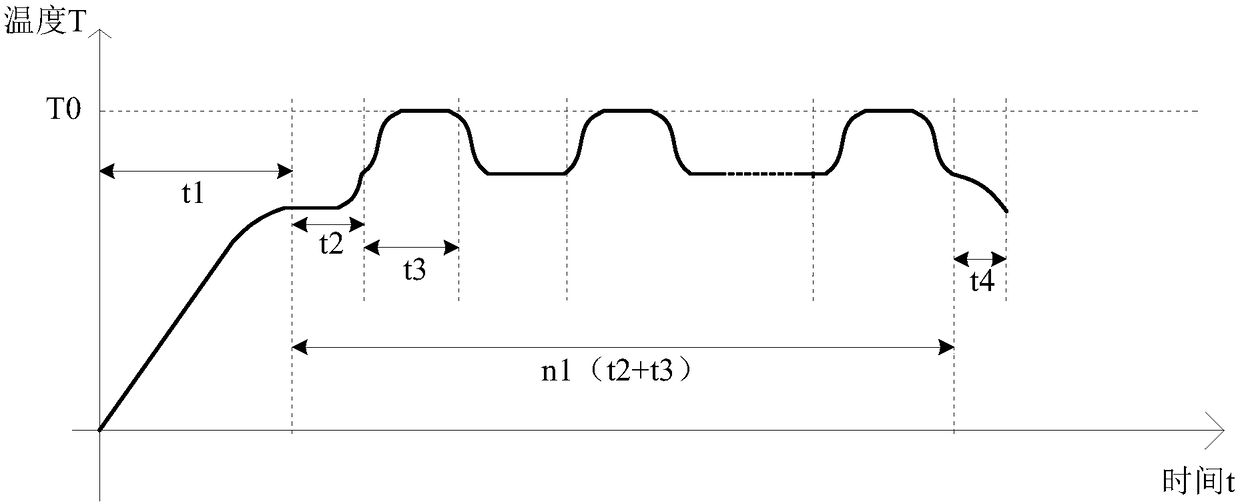

Pressure cooking utensil and control method and device thereof

The invention discloses a pressure cooking utensil and a control method and device thereof. The method comprises the following steps of controlling the pressure cooking utensil to enter a first cooking stage when the pressure cooking utensil begins to cook, and controlling the cooking temperature and the cooking pressure of the pressure cooking utensil to be increased in the first cooking stage; obtaining the cooking temperature, the cooking pressure or the cooking time of the pressure cooking utensil, and controlling the pressure cooking utensil to enter a second cooking stage according to the cooking temperature, the cooking pressure or the cooking time; in the second cooking stage, controlling the pressure cooking utensil within a preset period, wherein the preset period comprises a first preset time and a second preset time; maintaining the cooking pressure of the pressure cooking utensil within the first preset time and maintaining the cooking temperature of the pressure cooking utensil to be within a preset temperature range within the second preset time. By means of the method, the cooking effect can be greatly improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com