Non-deformation thermal refining process of main shaft of kilowatt-level blower

A quenching and tempering, distortion-free technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as bending, cracking, production efficiency, etc., and achieve the effects of ensuring strength, uniform heating and cooling, and reducing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

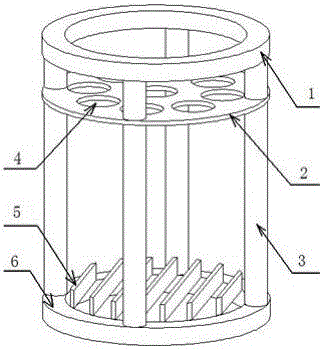

[0030] A kind of non-distortion quenching and tempering treatment process for the spindle of a kilowatt-level fan of the present invention uses special tooling to charge the spindle of the fan. figure 1 It can be seen that the special tooling includes a bottom support plate 6, an intermediate spacer plate 2, and an upper hoisting ring 1. The bottom support plate 6, the middle spacer plate 2, and the upper hoisting ring 1 are connected in series with the column 3. A set of through holes 4 is set on the plate 2 , and a set of vertical plates 5 are set on the bottom supporting plate 6 . The set of through holes 4 is provided with at least two, the diameter of which is larger than that of the main shaft 7, and they are evenly distributed on the middle spacer disc 2. There will be a gap between the set of vertical plates 5, and its length cannot exceed the bottom support plate 6.

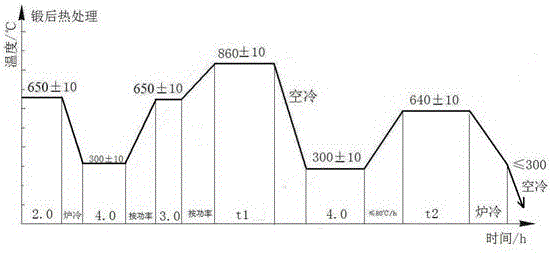

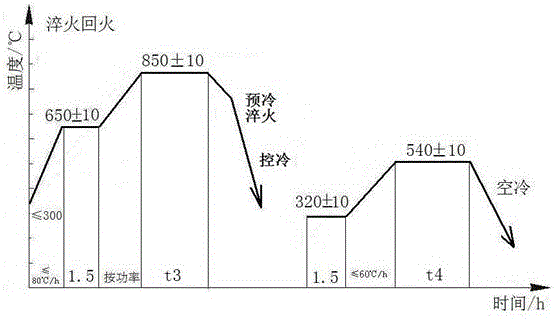

[0031] After forging, the main shaft of the fan is normalized and tempered, and then controlled coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com