MEMS gas sensor with heat insulation groove and processing method thereof

A technology of a gas sensor and a processing method, which is applied to electric solid devices, semiconductor devices, processes for producing decorative surface effects, etc. The effect of cracking, avoiding damage to the micro-hot plate, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

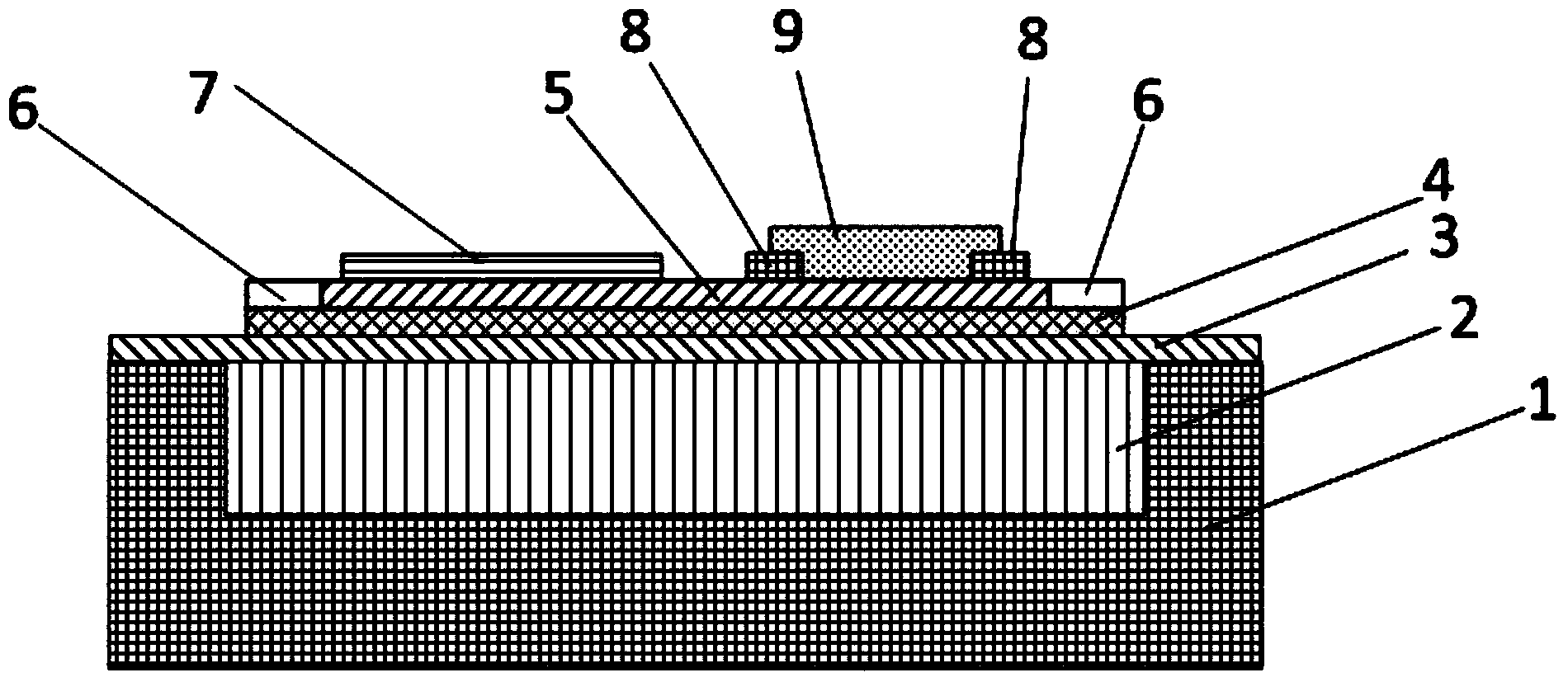

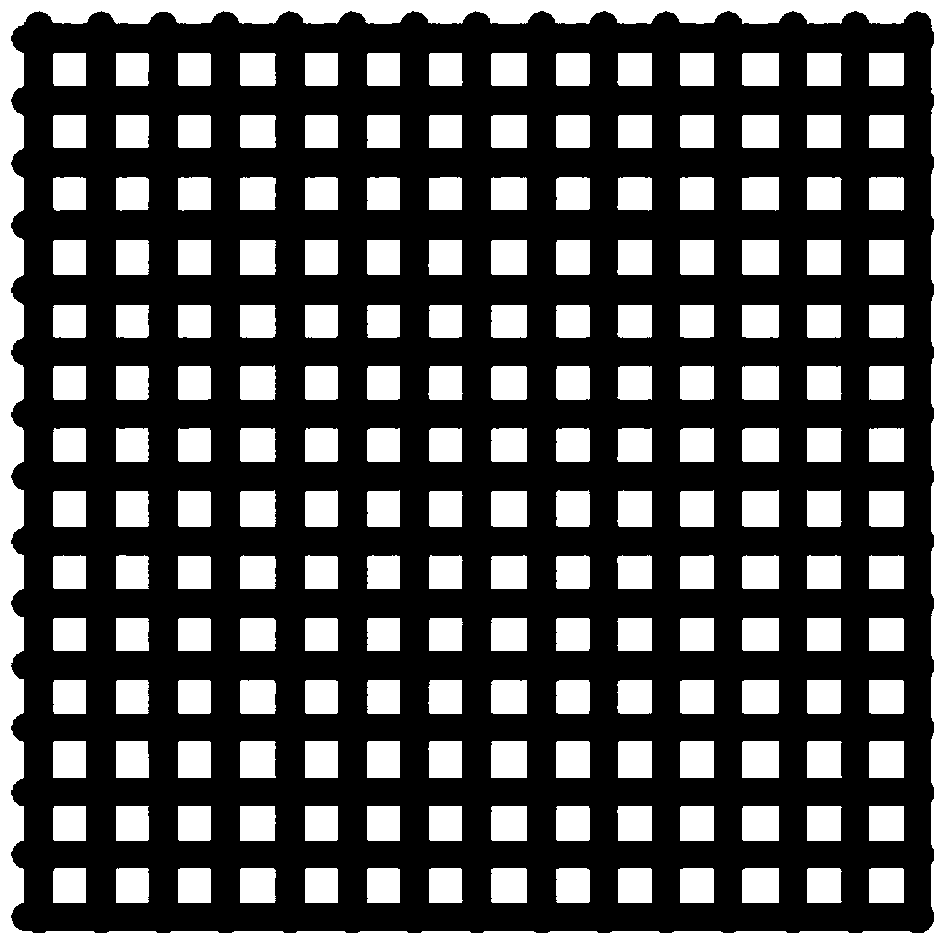

[0059] See figure 1 , figure 2 , Embodiment 1 of the present invention discloses a MEMS gas sensor with a thermal insulation groove, comprising: a single crystal silicon substrate 1; a thermal insulation groove 2 formed on the upper surface of the single crystal silicon substrate 1 and has a certain depth , the thermal insulation groove 2 includes one or more groups of grooves, wherein each group of grooves includes a plurality of linear grooves arranged in parallel; the lower insulating layer 3 covers the thermal insulation groove 2 and the single crystal silicon substrate 1 The upper surface of the upper surface; the heating layer 4 is arranged on the upper surface of the lower insulating layer 3, and the heating layer 4 is located in the area directly above the thermal insulation trench 2; the upper insulating layer 5 covers the heating layer 4 the upper surface of the upper surface; the gas sensitive layer 9 is disposed on the upper surface of the upper insulating layer ...

Embodiment 2

[0111] See figure 1 , image 3 , Embodiment 2 of the present invention discloses a MEMS gas sensor with adiabatic groove, comprising: a single crystal silicon substrate 1; , the thermal insulation groove 2 includes one or more groups of grooves, wherein each group of grooves includes a plurality of linear grooves arranged in parallel; the lower insulating layer 3 covers the thermal insulation groove 2 and the single crystal silicon substrate 1 The upper surface of the upper surface; the heating layer 4 is arranged on the upper surface of the lower insulating layer 3, and the heating layer 4 is located in the area directly above the thermal insulation trench 2; the upper insulating layer 5 covers the heating layer 4 the upper surface of the upper surface; the gas sensitive layer 9 is disposed on the upper surface of the upper insulating layer 5 , and the gas sensitive layer 9 is located in the area directly above the heating layer 4 . The gas sensor also includes: a temperatu...

Embodiment 3

[0163] See figure 1 , Figure 4 , Embodiment 3 of the present invention discloses a MEMS gas sensor with a thermal insulation groove, comprising: a single crystal silicon substrate 1; a thermal insulation groove 2 formed on the upper surface of the single crystal silicon substrate 1 and has a certain depth , the thermal insulation groove 2 includes one or more groups of grooves, wherein each group of grooves includes a plurality of linear grooves arranged in parallel; the lower insulating layer 3 covers the thermal insulation groove 2 and the single crystal silicon substrate 1 The upper surface of the upper surface; the heating layer 4 is arranged on the upper surface of the lower insulating layer 3, and the heating layer 4 is located in the area directly above the thermal insulation trench 2; the upper insulating layer 5 covers the heating layer 4 the upper surface of the upper surface; the gas sensitive layer 9 is disposed on the upper surface of the upper insulating layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com