Method and apparatus for preparing rapid-solidified hydrogen-storage alloy powder material

A technology for hydrogen storage alloys and powder materials, which is applied in the field of preparation of rapidly solidified hydrogen storage alloy powder materials, can solve the problems of consumption of protective gas, reduced hydrogen absorption capacity, increased production cost, etc., and achieves improved oxygen absorption and activation capacity, The effect of increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention provides a preparation method and device of a rapidly solidified hydrogen storage alloy powder material. The method includes the following steps:

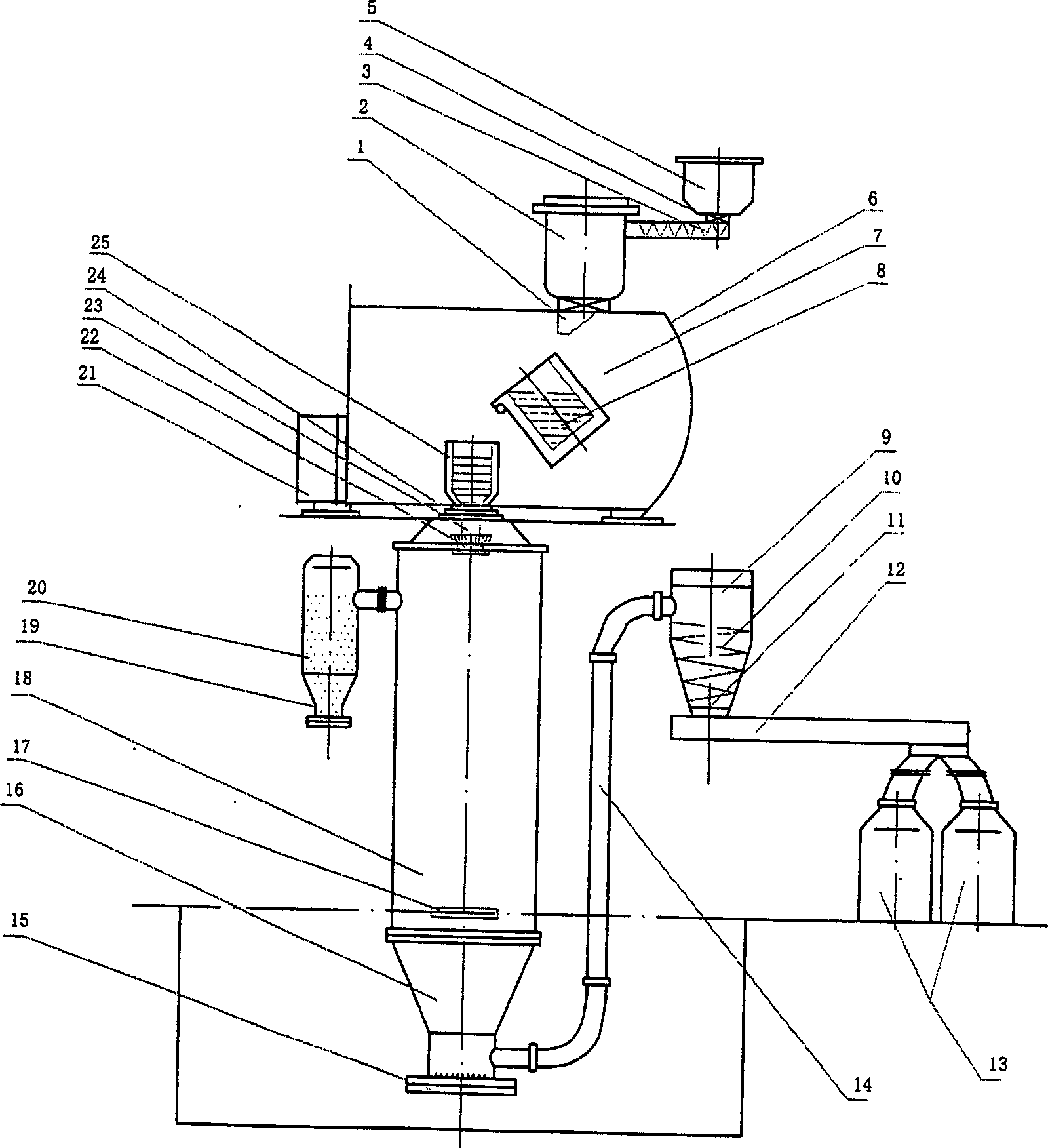

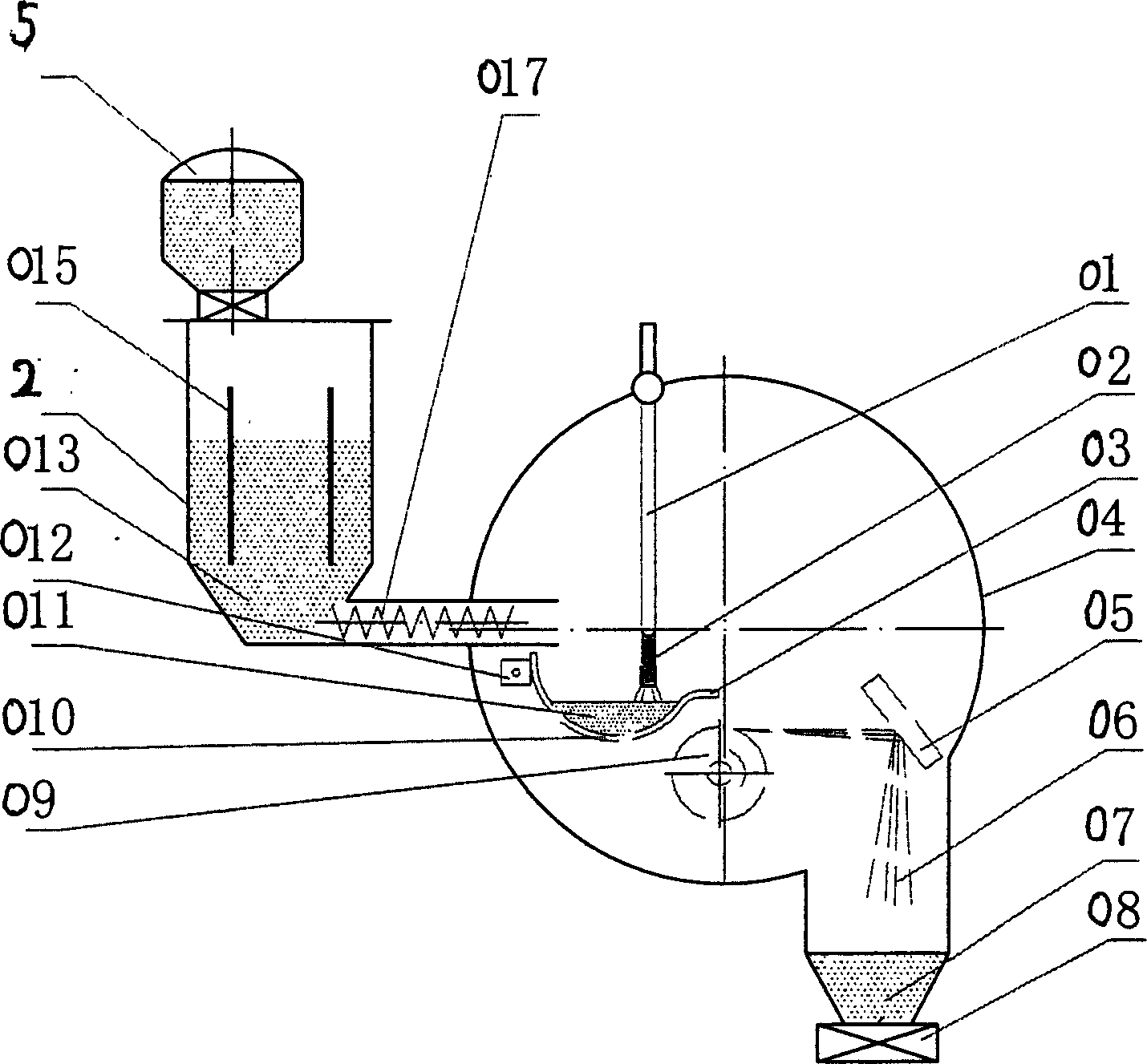

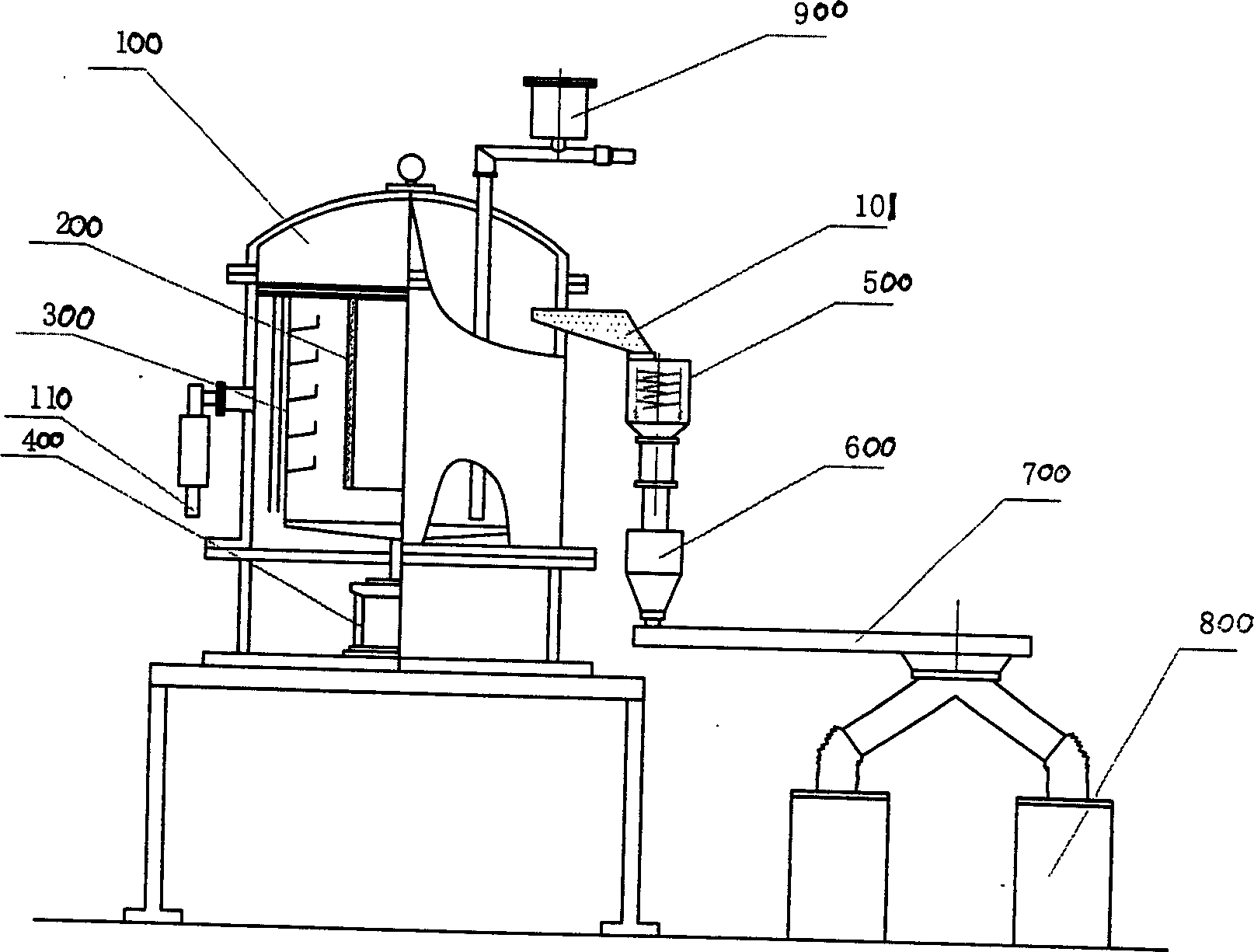

[0040] (a) Pretreatment of raw materials, adjusting the composition of master alloys or alloys as raw materials, and adding rare earth metals and hydrogen storage alloy scraps to raw materials. use as figure 1 The shown fully continuous vacuum argon induction furnace high-pressure inert gas atomization powder making device, through its continuous feeding tank 5, control valve 4, and screw feeder 3, raw materials are continuously fed into its vacuum-argon-protected heat-conducting intermediate material Preheating is carried out in the tank 2, and the preheating temperature of the raw materials is 650°C.

[0041] (b) Put the preheated raw material directly into the vacuum-argon induction furnace 8 through the vibrating feeding plate 1 at the bottom of the heat-conducting intermediate material tank 2 for melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com