Staged-combustion system of suspension roaster and application thereof

A suspension roasting furnace and staged combustion technology, applied in the roasting field, can solve the problems of large amount of high-temperature pollutants and insufficient fuel combustion, and achieve the effects of prolonging residence time, high fuel utilization rate, and sufficient fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

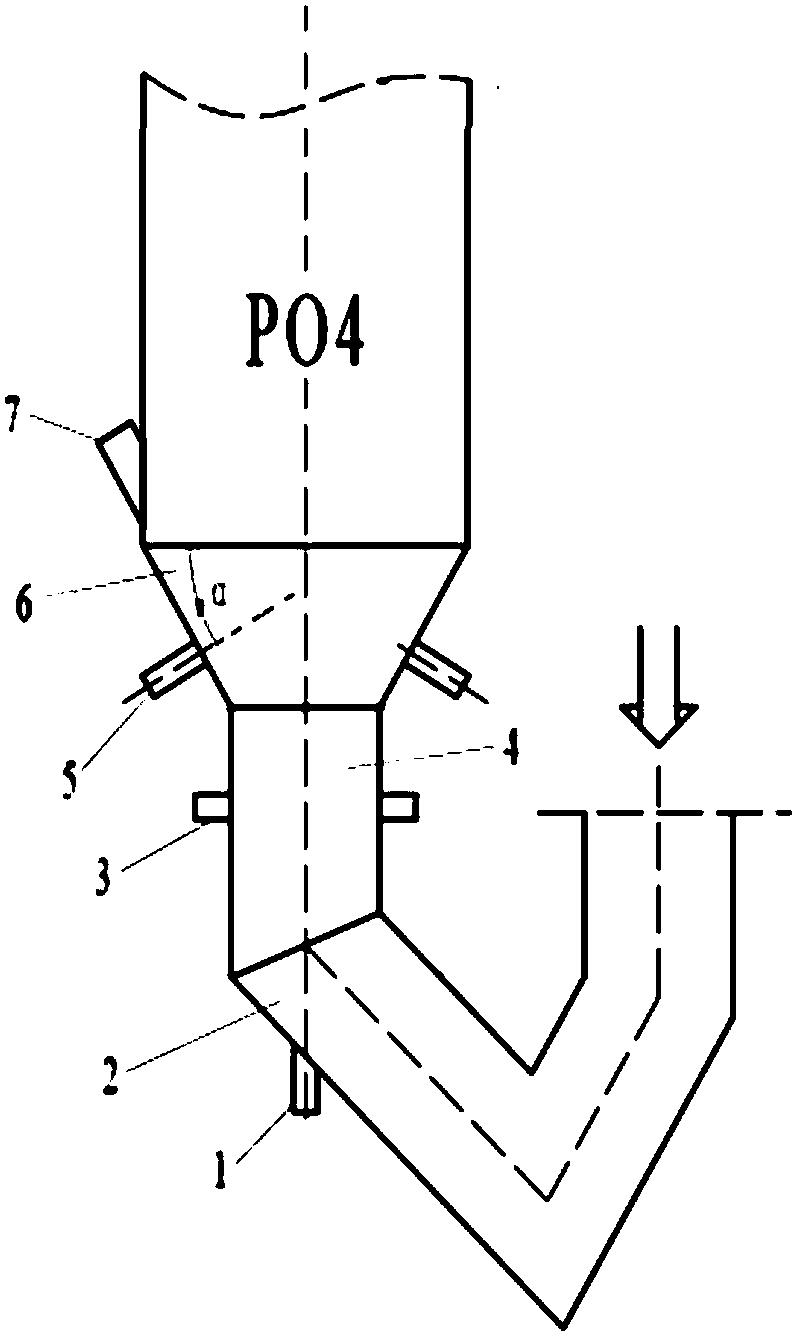

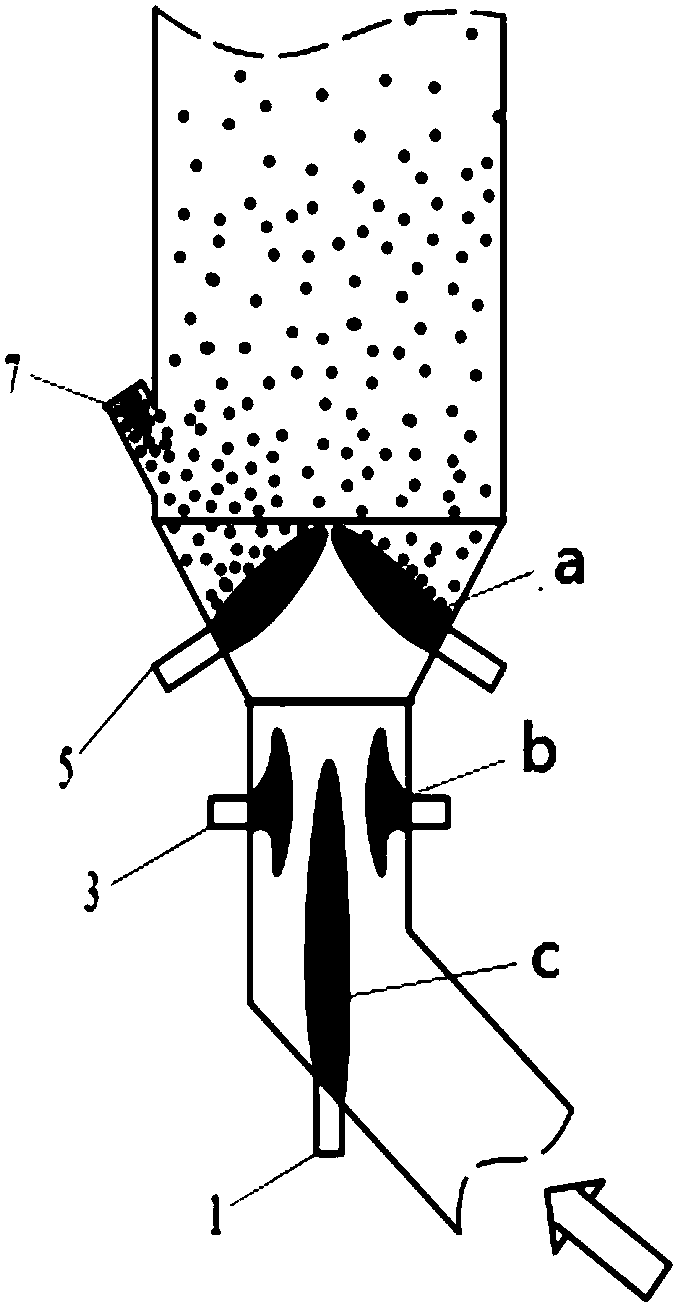

[0042] Such as figure 1 with figure 2 As shown, a suspension roaster staged combustion system includes main roaster PO4, main combustion pipe 4, gas-supporting pipe 2, primary burner 1 and secondary burner 3, said main roaster PO4, said main combustion The tube 4 and the gas-supporting tube 2 are connected sequentially, the primary burner 1 communicates with the bottom of the main combustion tube 4, and the central axis of the primary burner 1 coincides with the central axis of the primary combustion tube 4 , the secondary burner 3 is arranged on the main combustion pipe 4 along the circumferential direction and communicates with the main combustion pipe 4 .

[0043] The burners in the prior art are generally arranged on the gas-supporting pipeline connected with the PO4 of the main roaster, and the gas jet flow ejected from the burner can only enter the main gas flow of the supporting gas from the edge, so most of the gas can only be connected with the auxiliary gas at the ...

Embodiment 2

[0046] Such as figure 1 with figure 2 As shown, a suspension roasting furnace graded combustion system, its structure is compared with embodiment 1, the difference is: in order to make the gas that secondary burner 3 ejects to the impact disturbance of main combustion gas main flow in main combustion tube 4 maximum , the residence time in the main combustion tube 4 is also relatively long, and the secondary burner 3 is set in such a way that the central axis of the secondary burner 3 is perpendicular to the central axis of the main combustion tube 4. This arrangement In this way, the mixing effect of the gas ejected from the secondary burner 3 and the assisted gas at the edge of the main airflow is also better.

Embodiment 3

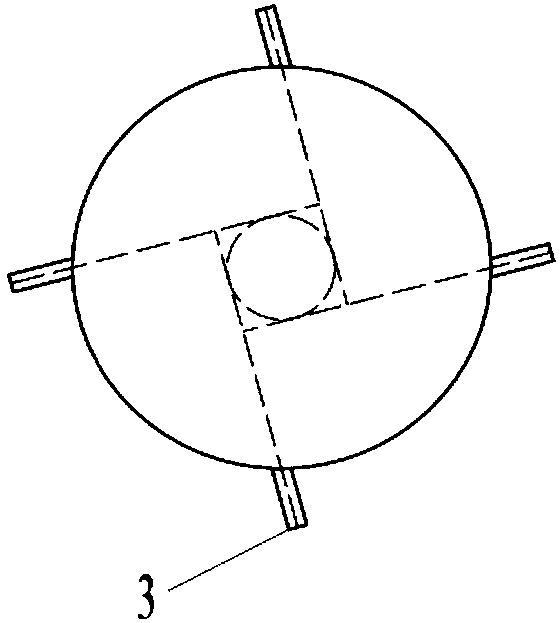

[0048] Such as figure 1 , figure 2 with image 3 As shown, a suspension roaster staged combustion system, its structure compared with embodiment 1, the difference is: the number of the secondary burner 3 is at least two, and evenly arranged in the main combustion tube 4 On the outer wall, the jet flow direction at the outlet of the secondary burner 3 forms a tangential circle. In actual application, the number of the secondary burner 3 can be two, three, four, five, six, etc., in this implementation In the example, four secondary burners 3 are set, and the outlet jet directions of the four secondary burners 3 form a tangential circle, and the gas is injected through the secondary burners 3 and is discharged in the main A swirling flow is formed in the combustion tube 4, and the gas in the swirl state helps to prolong the residence time of the gas in the main combustion tube 4 on the one hand, and also strengthens the disturbance between the gas and the supporting gas on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com