Reaction kettle with uniform heating effect

A technology of uniform heating and reactor, which is applied in chemical/physical/physical chemical mobile reactors, pressure vessels used in chemical processes, and methods of chemically changing substances by using atmospheric pressure, which can solve safety hazards and other issues. Achieve uniform heating and good reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

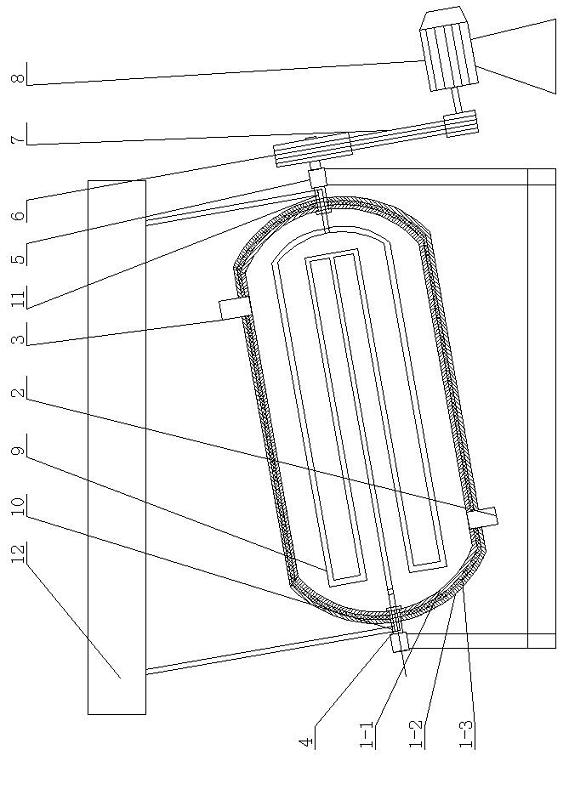

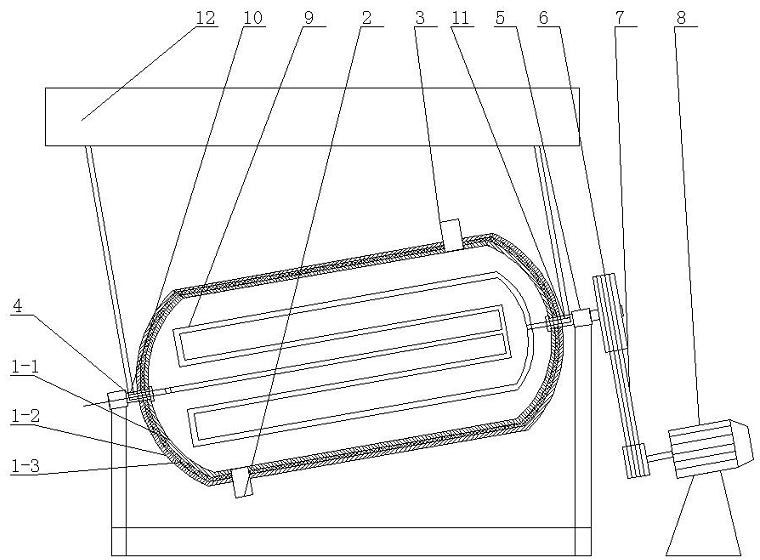

[0020] as attached figure 1 Shown: the reaction kettle of uniform heating of the present invention comprises kettle body 1, and described kettle body is respectively provided with feed inlet 2 and discharge port 3 above, and the both sides of described kettle body have connecting shaft 4 respectively, The connecting shaft is installed on the bearing 5, and a pulley 6 is installed on the connecting shaft on one side, and the pulley is connected to the driving motor 8 through the belt 7, and a group of heat exchange tubes 9 are installed inside the kettle body. The heat exchange tubes are respectively connected to the heating equipment 12 through the water inlet 10 and the water outlet 11 .

Embodiment 2

[0022] In the uniformly heated reaction kettle, the central axis of the kettle body forms an included angle of 5-15° with the horizontal plane.

Embodiment 3

[0024] In the uniformly heated reaction kettle, the heat exchange tubes are closely arranged on the inner wall of the kettle body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com