Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Enhanced water vapor transmission rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

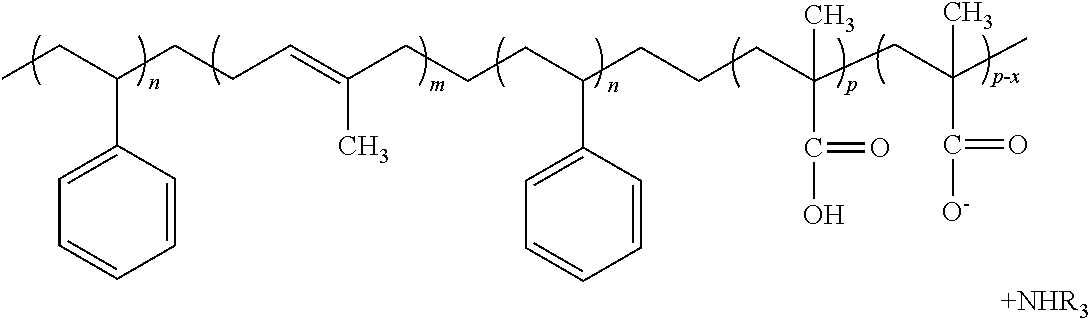

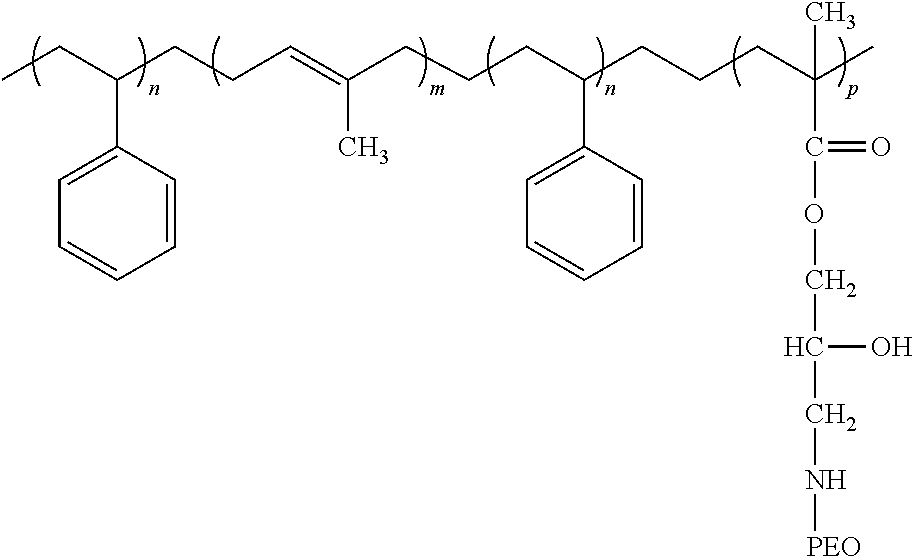

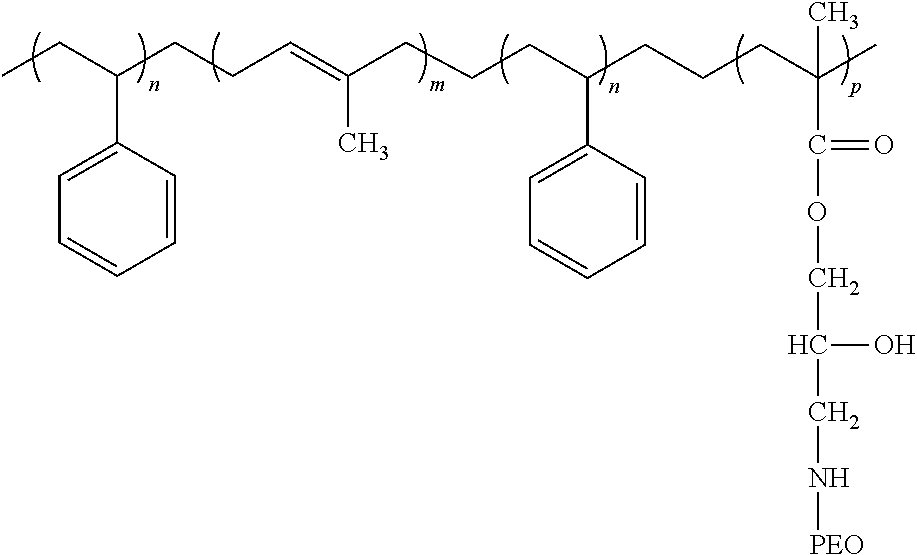

Substrate Coated With A Hydrophilic Elastomer

ActiveUS20110319848A1Improve hydrophilicityGood coating stabilitySynthetic resin layered productsPretreated surfacesElastomerPolymer science

Substrates, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:THE PROCTER & GAMBLE COMPANY

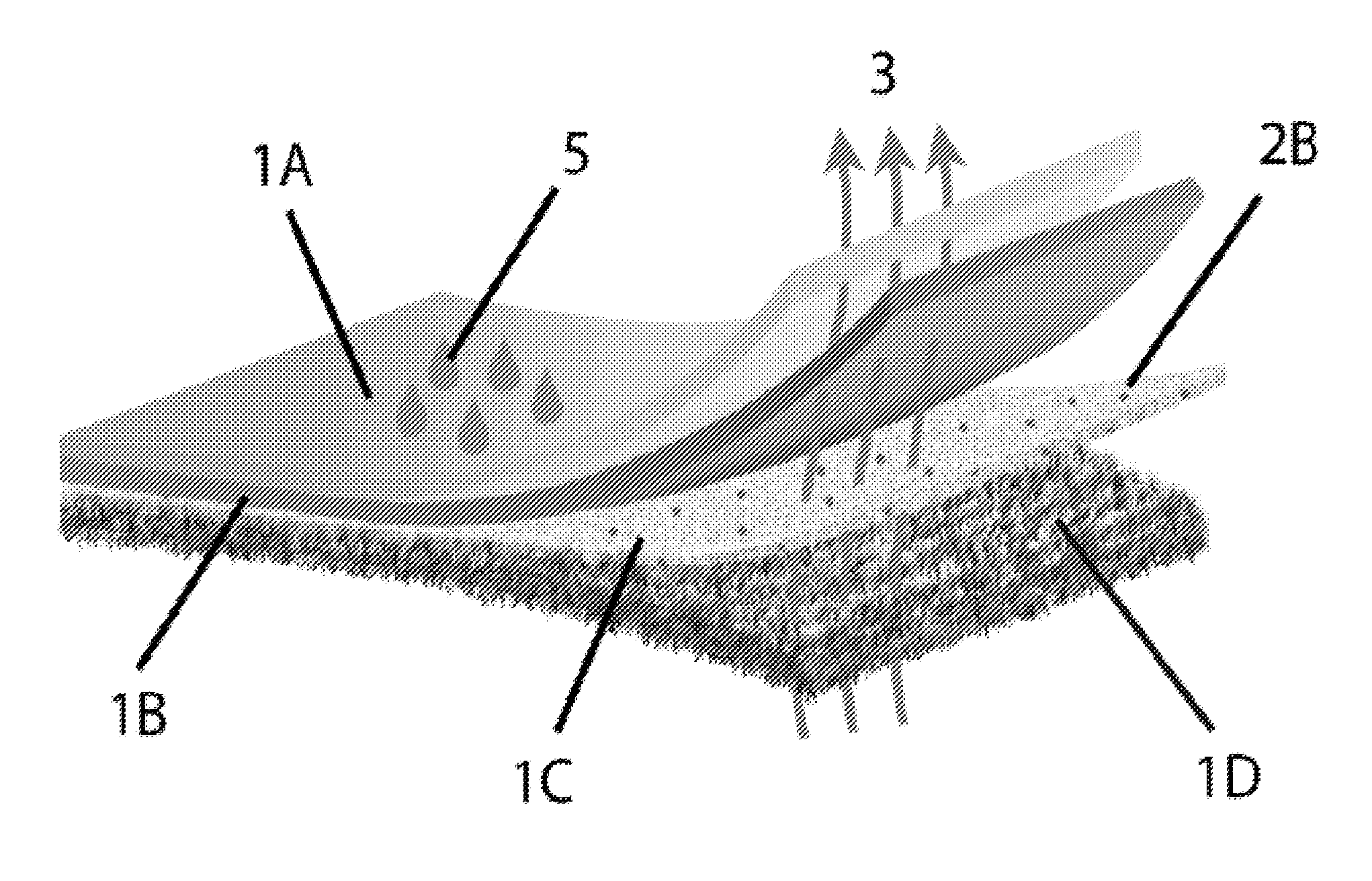

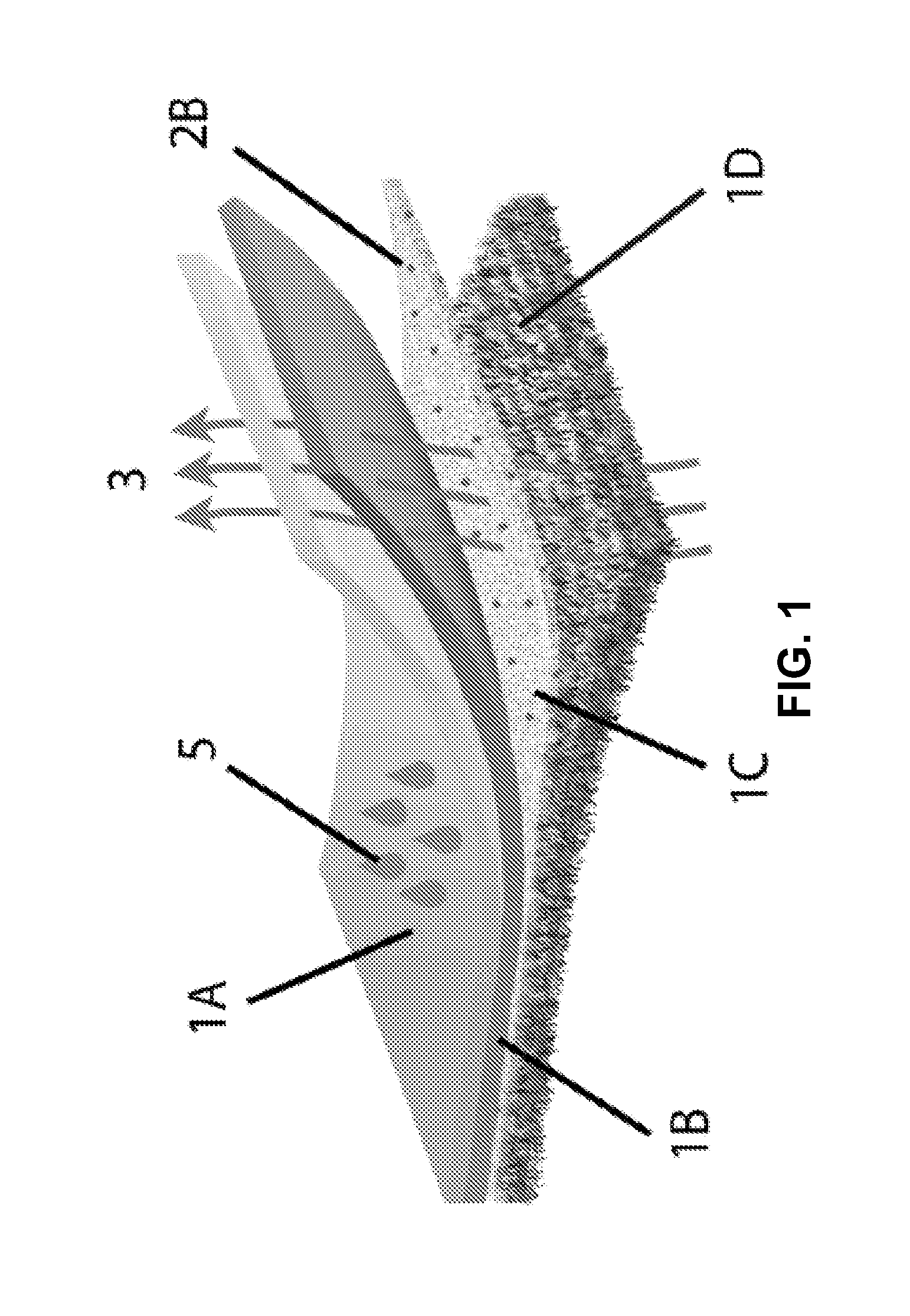

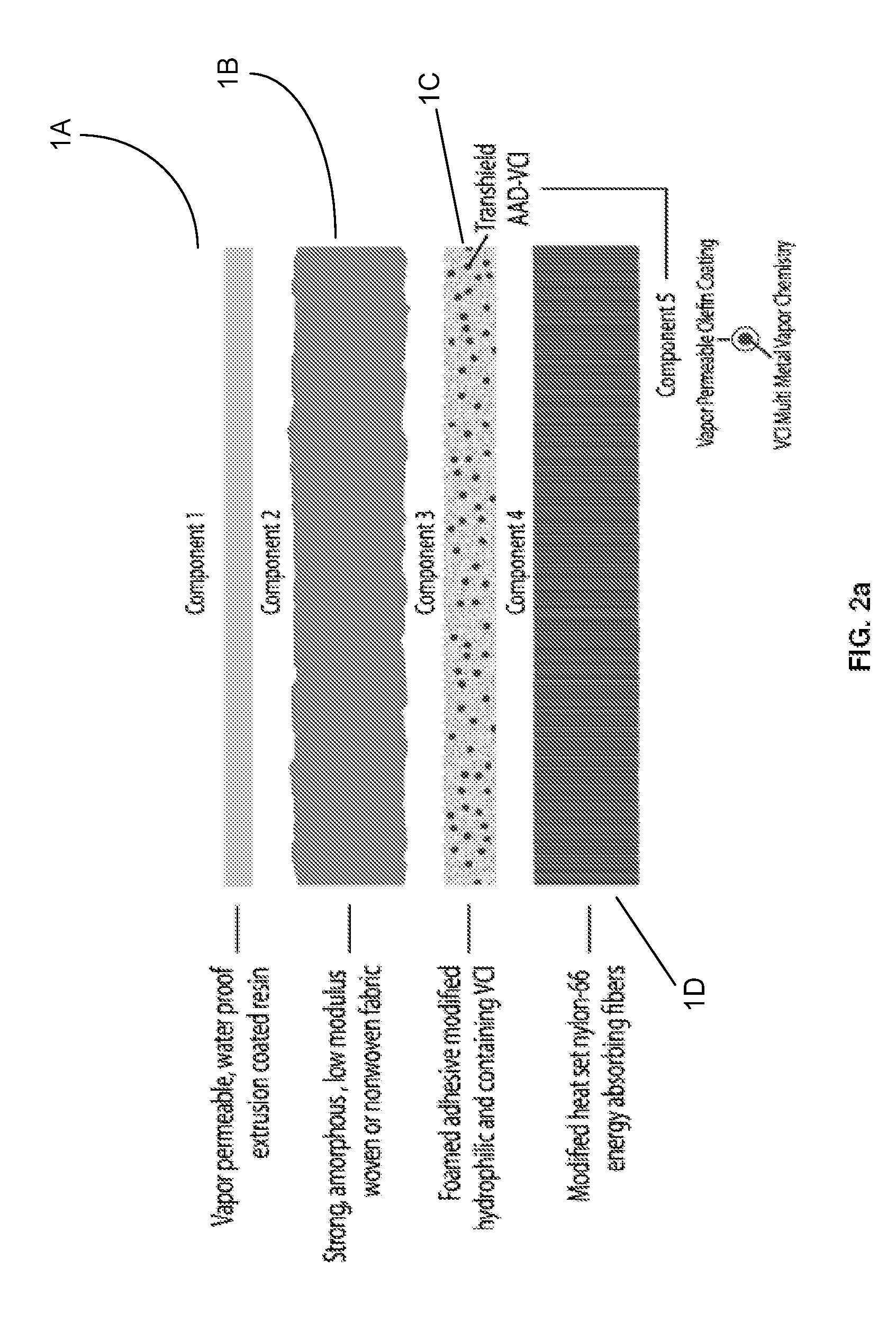

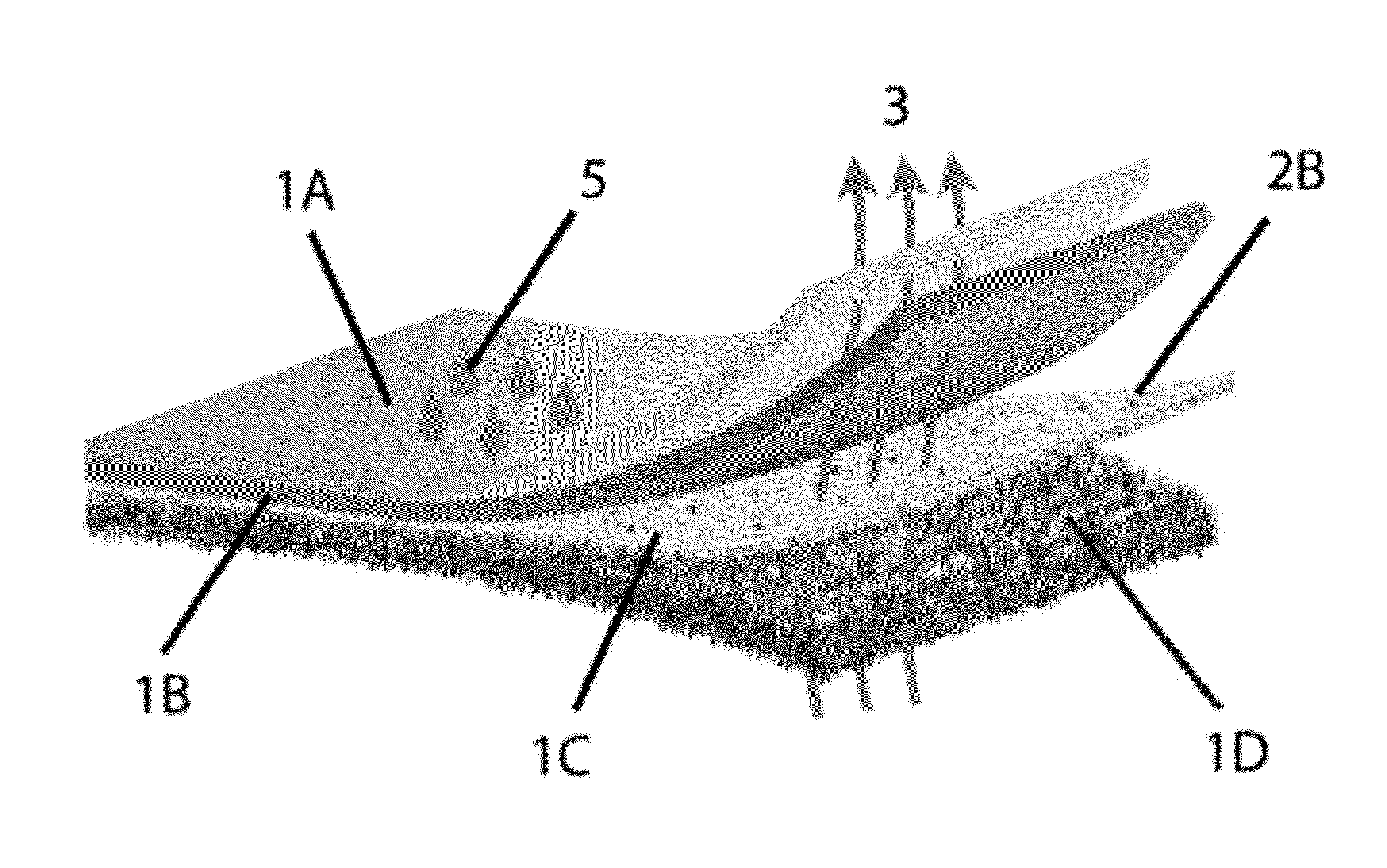

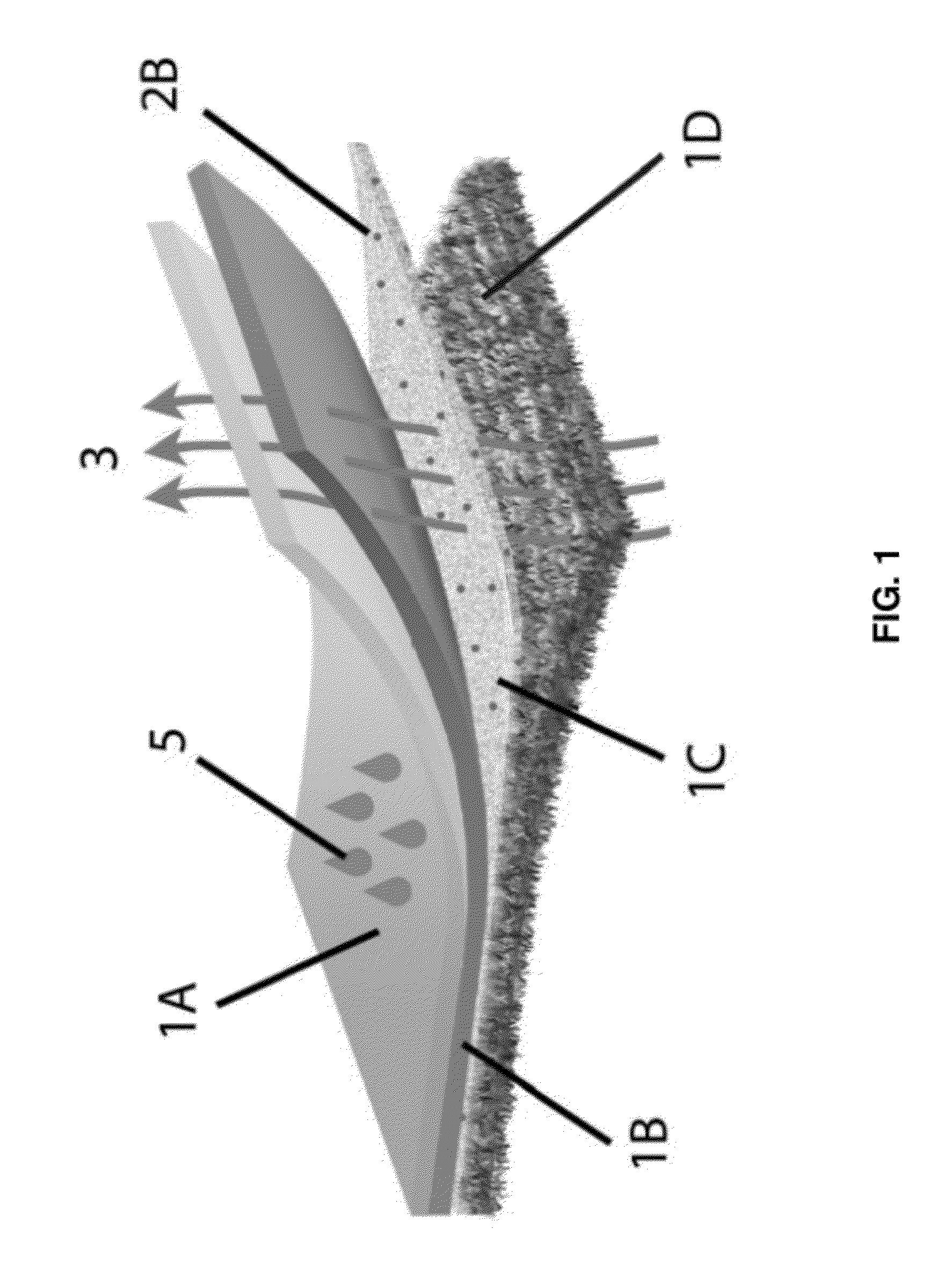

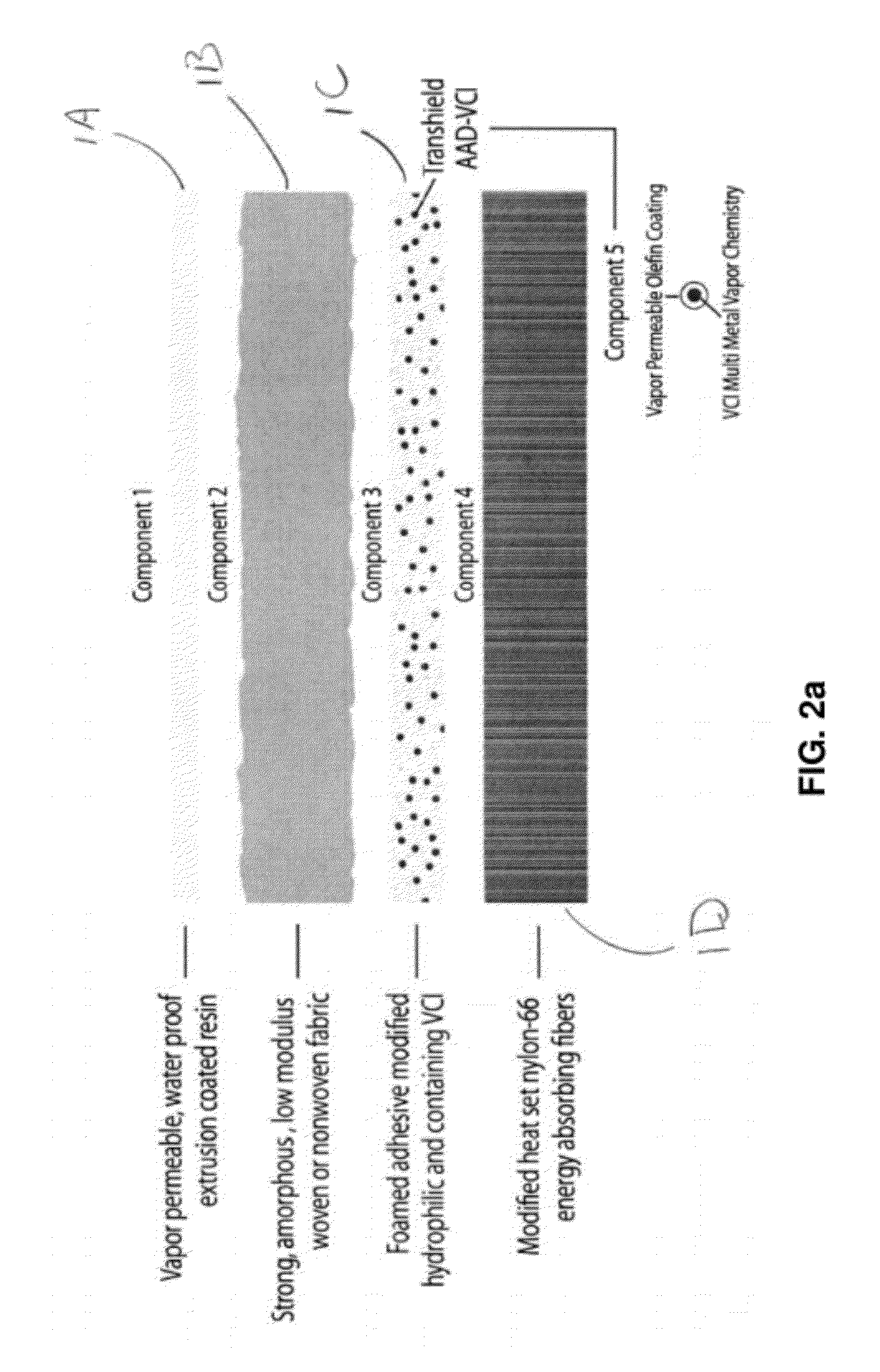

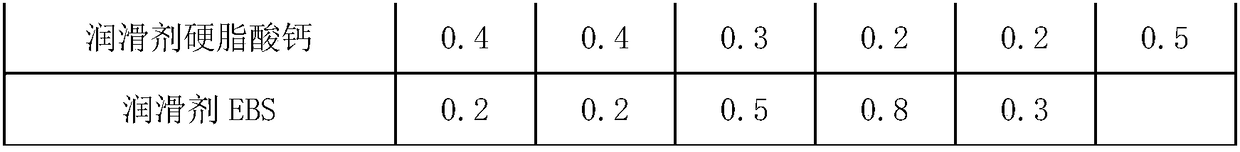

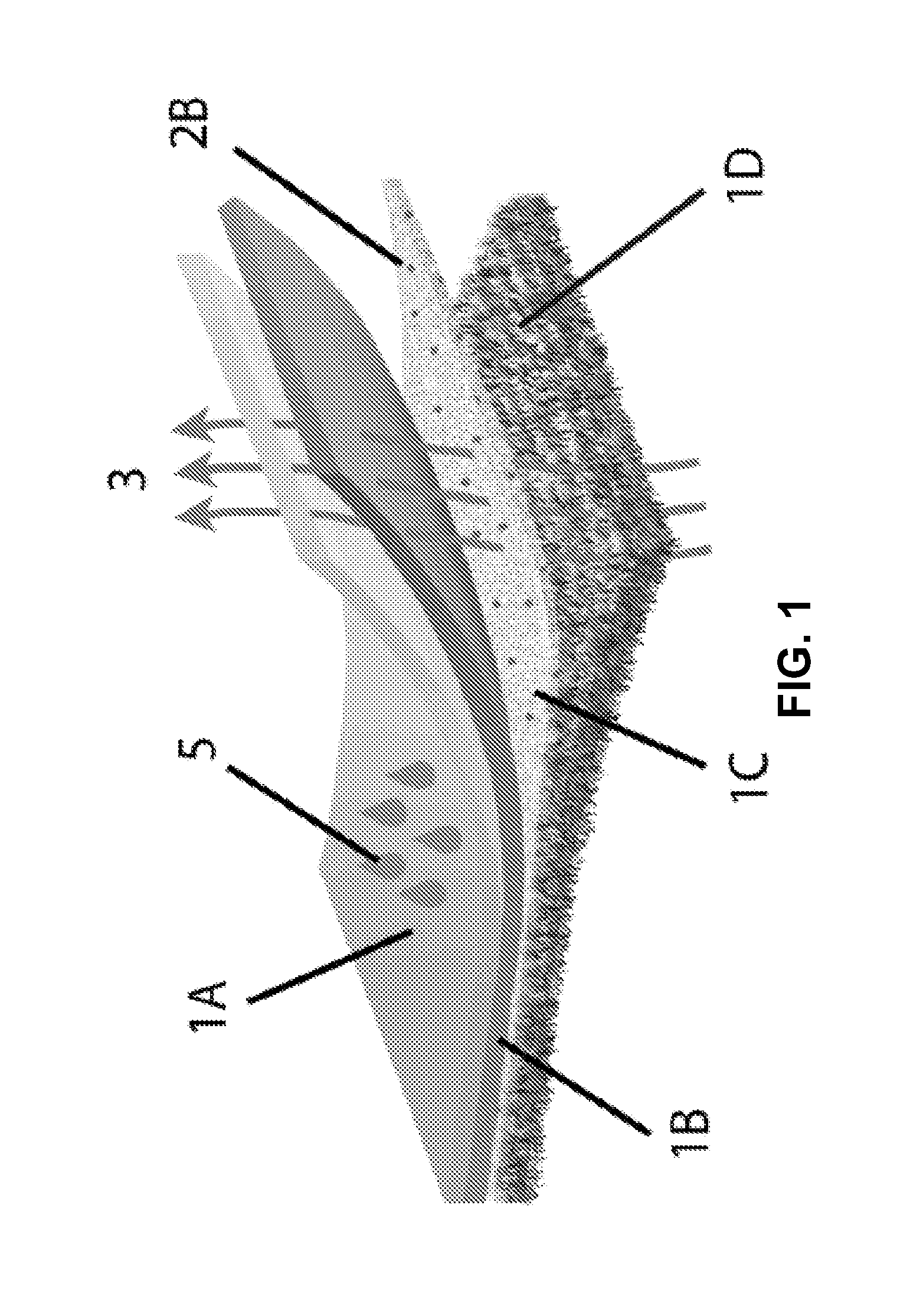

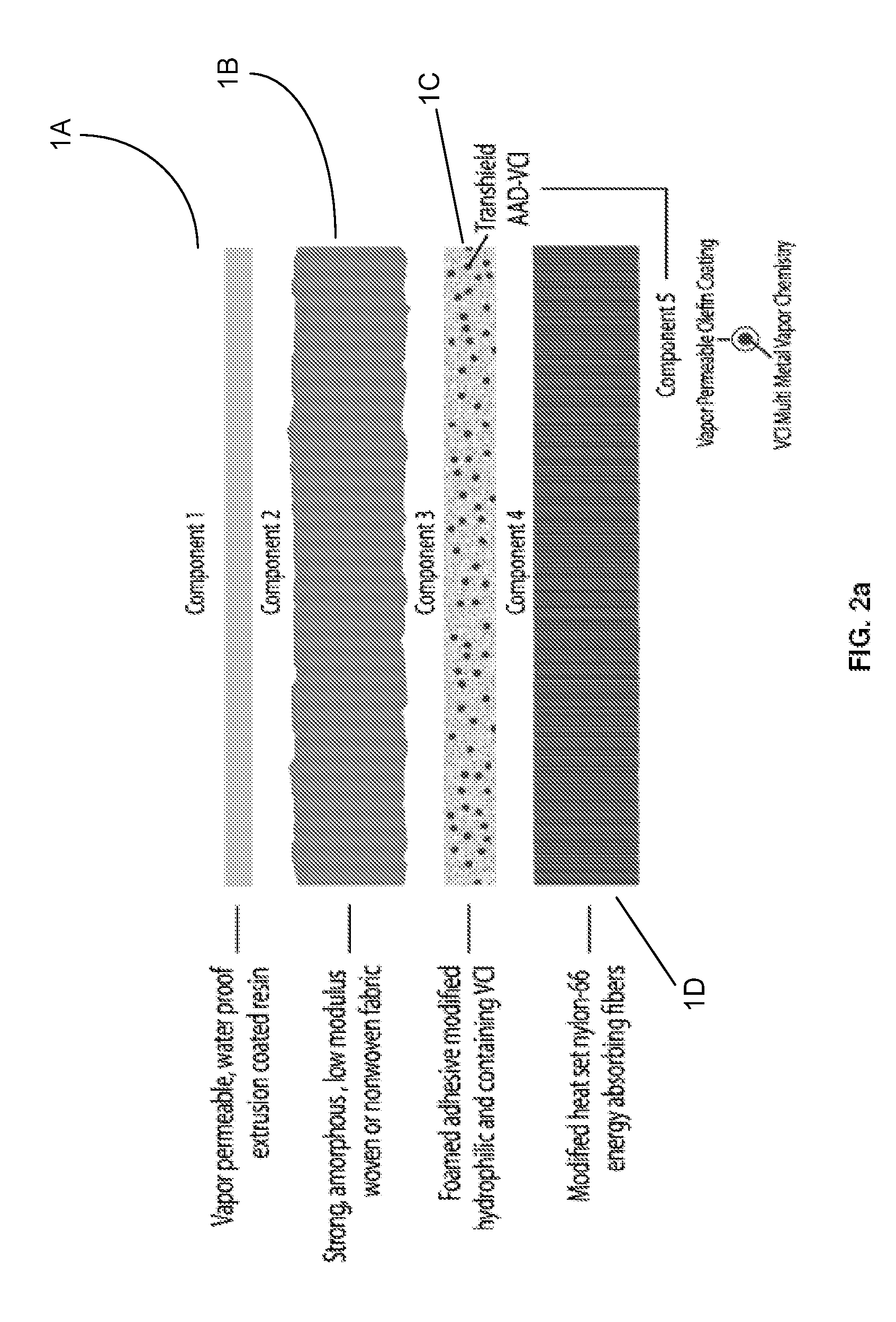

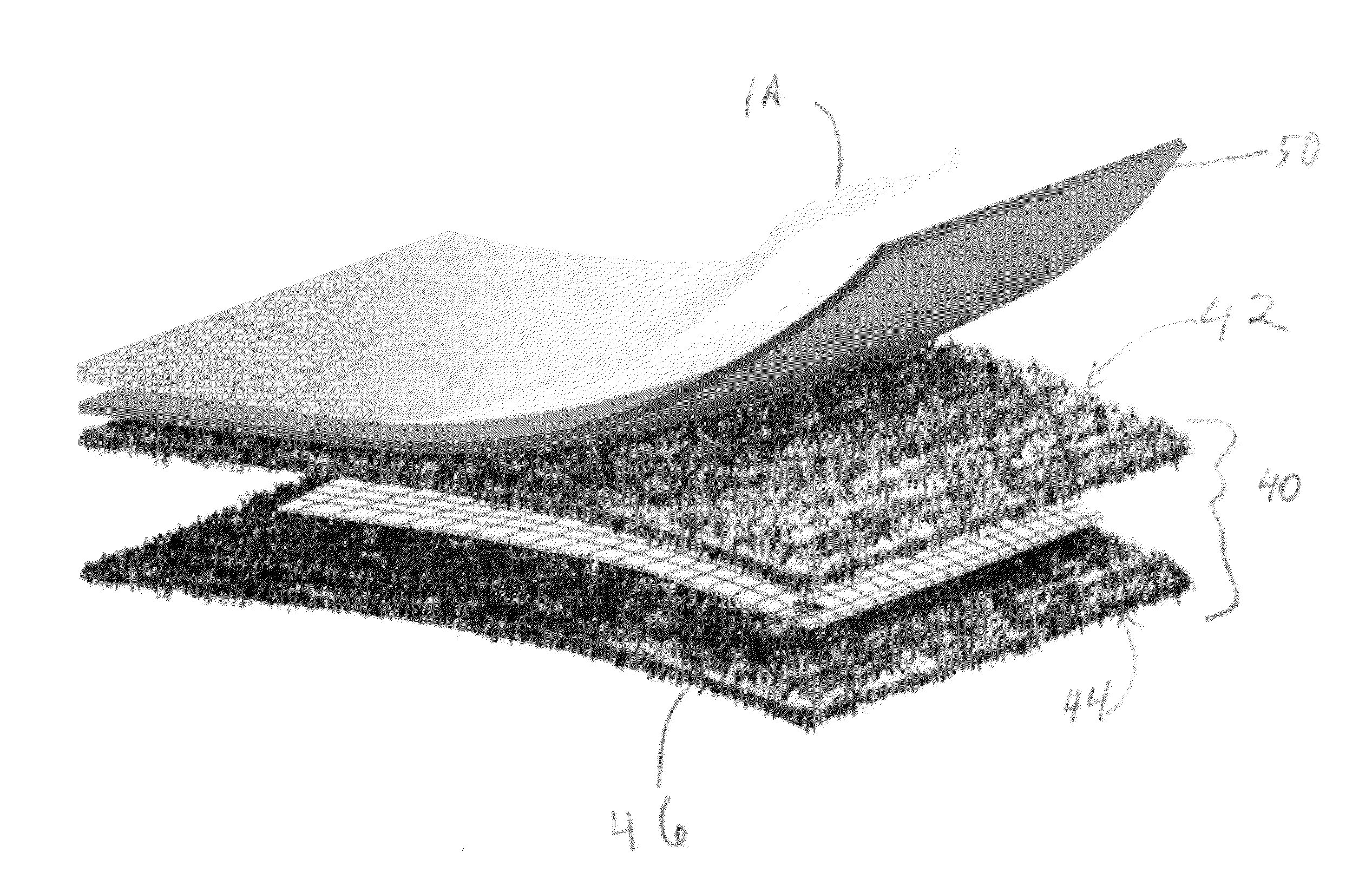

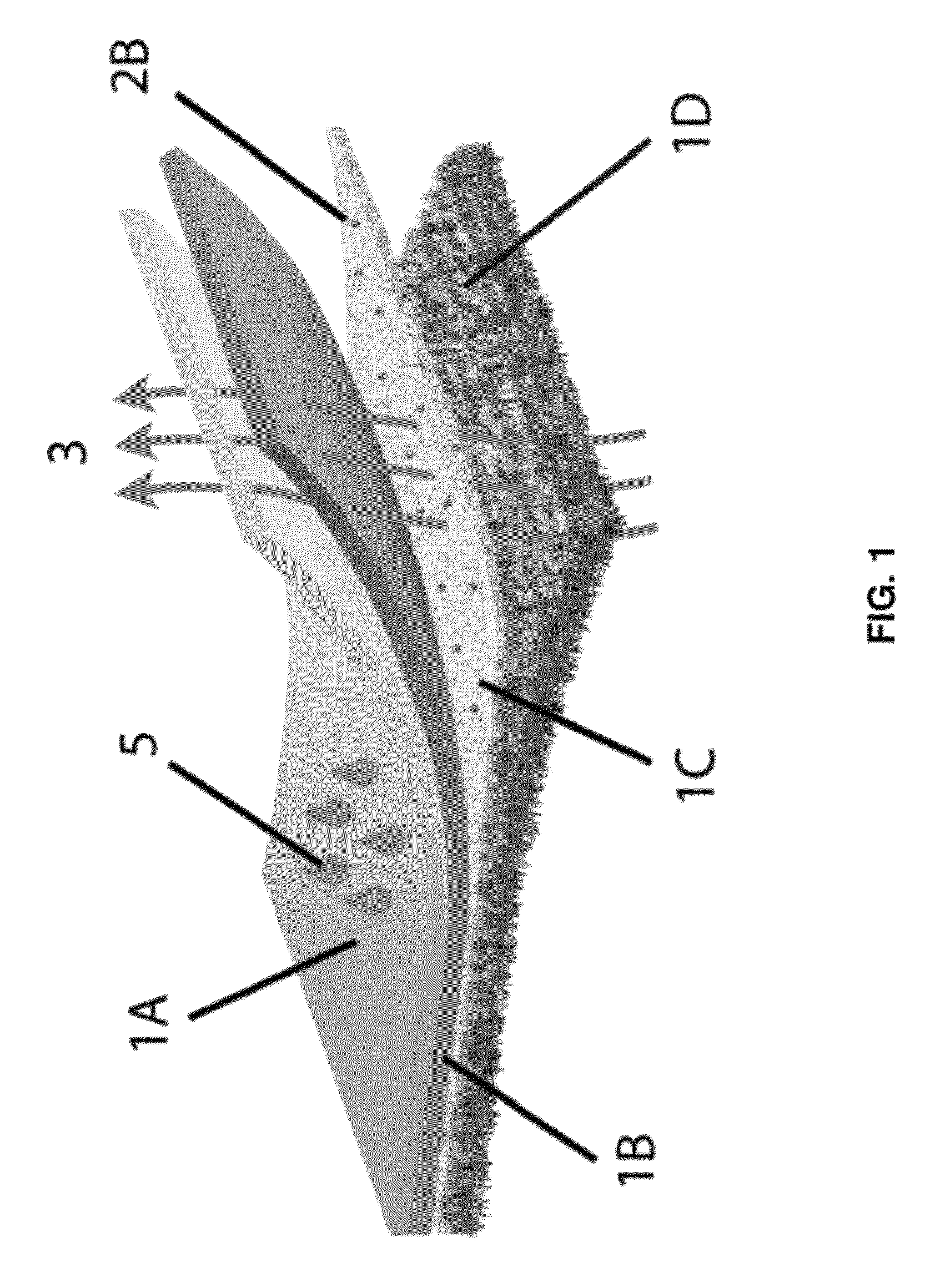

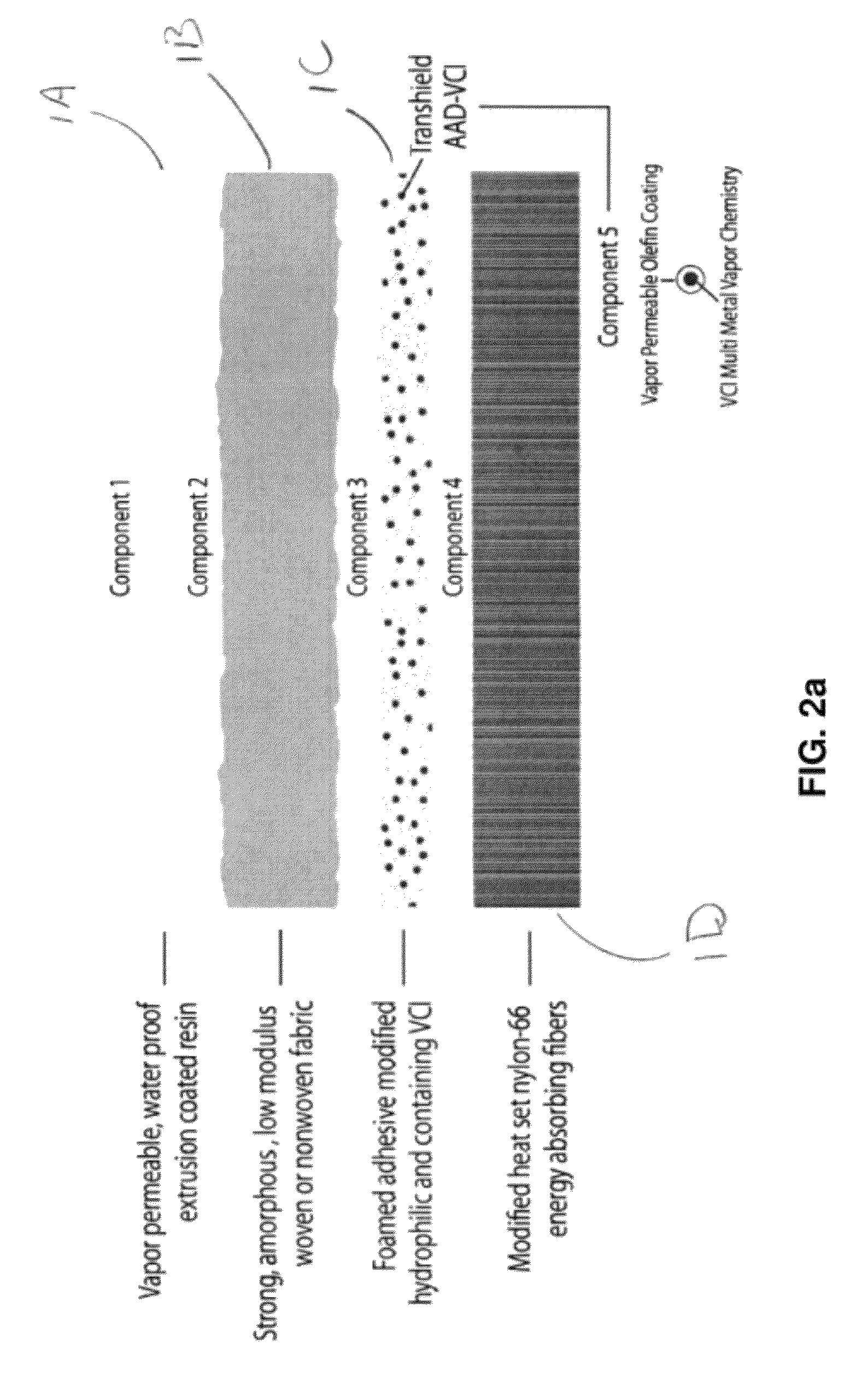

Vapor Permeable Fabric Constructs with Static or Dynamic Antimicrobial Compositions

ActiveUS20120171409A1Corrosive environmentEliminating ease of handling—takingLiquid surface applicatorsDecorative surface effectsFiberEngineering

Protective, multi-layered, breathable fabric constructs having dynamic or static antimicrobial compositions incorporated into adhesive components. The flexible constructs employ a fabric layer and a breathable coating layer applied to the fabric. Under certain preferred embodiments, the fabric constructs also employ an energy dissipating fiber material disposed opposite the coating layer. Also, the present invention teaches a method of protecting a valuable or sensitive object from damage caused by corrosion, weather, biomass, or other environmental related conditions using the fabric material. The fabric constructs may be post-formed using heat or other methods to create shaped-to-form covers.

Owner:TRANSHIELD INC

Vapor permeable fabric constructs

ActiveUS20120058294A1Easy to useSoft touchLiquid surface applicatorsWood working apparatusFiberEngineering

This invention relates to protective, multi-layered, breathable fabric constructs. The constructs which are flexible employ a fabric layer and a breathable coating layer applied to the fabric. Under certain preferred embodiments, the fabric constructs also employ an energy dissipating fiber material disposed opposite the coating layer. Also, the present invention teaches a method of protecting a valuable or sensitive object from damage caused by corrosion, weather, bio mass, or other environmental related conditions using the fabric material. The fabric constructs may be post-formed using heat or other methods to create shaped-to-form covers.

Owner:TRANSHIELD INC

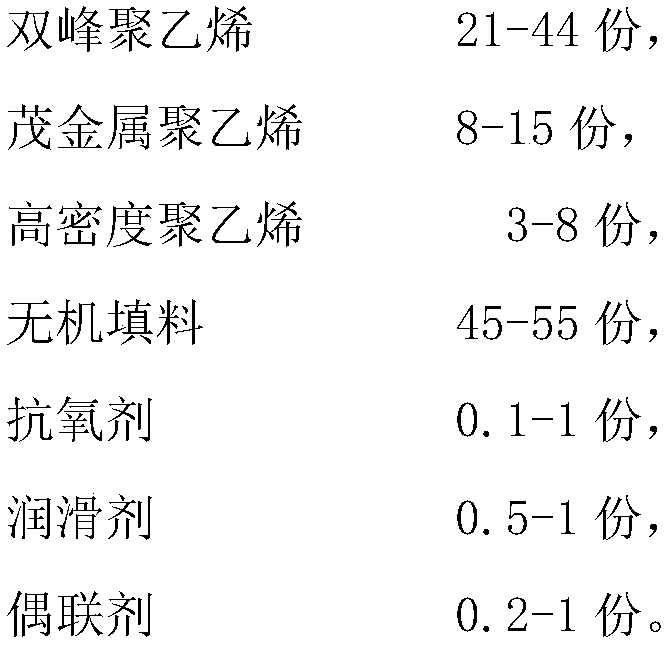

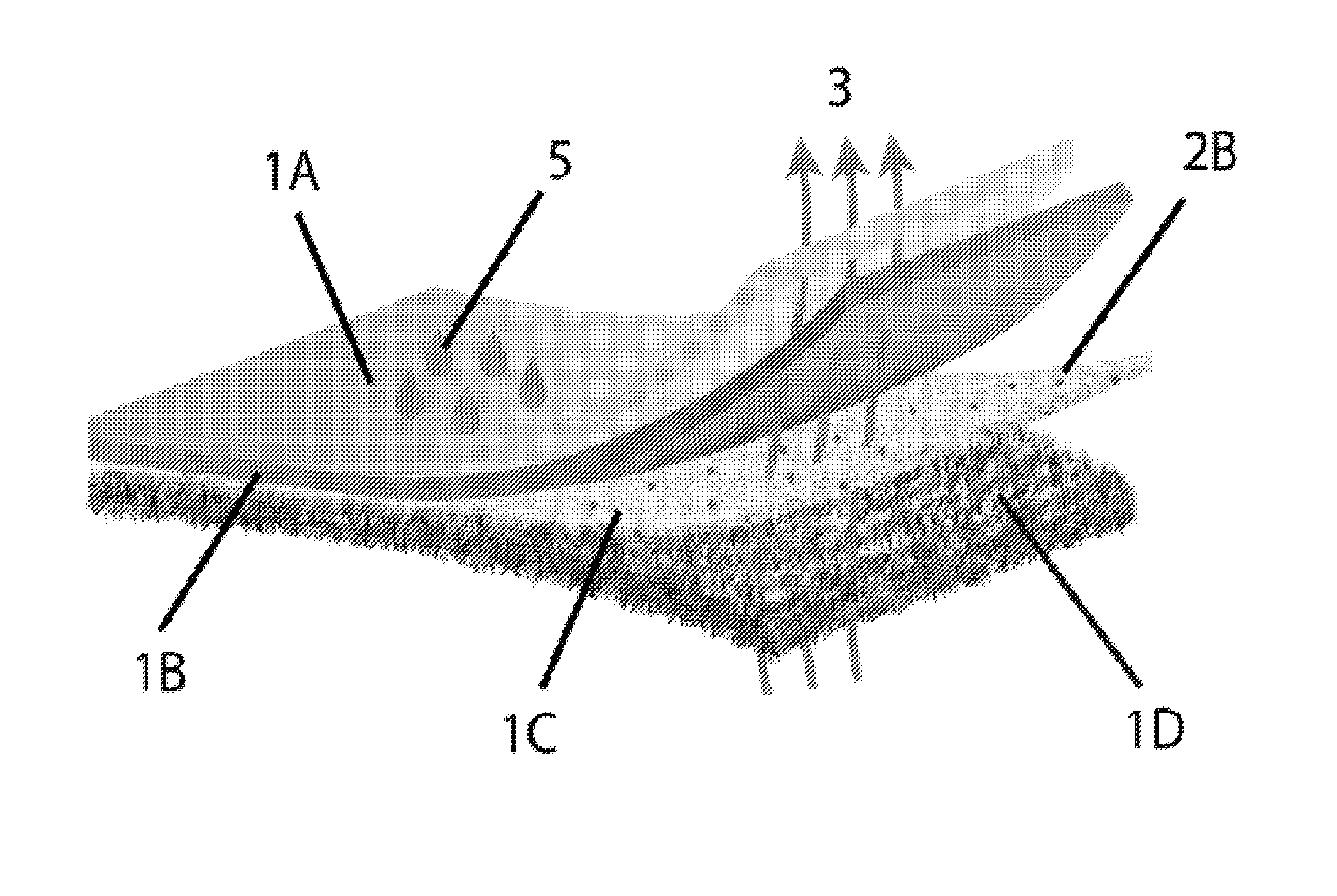

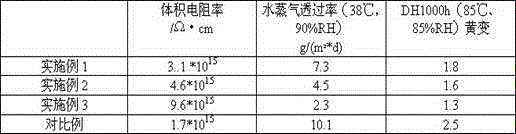

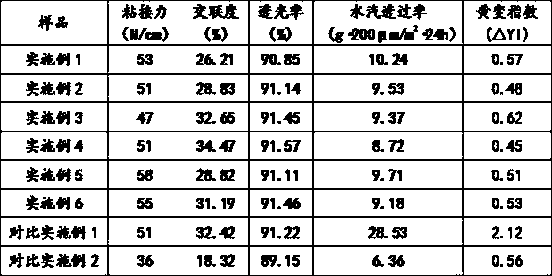

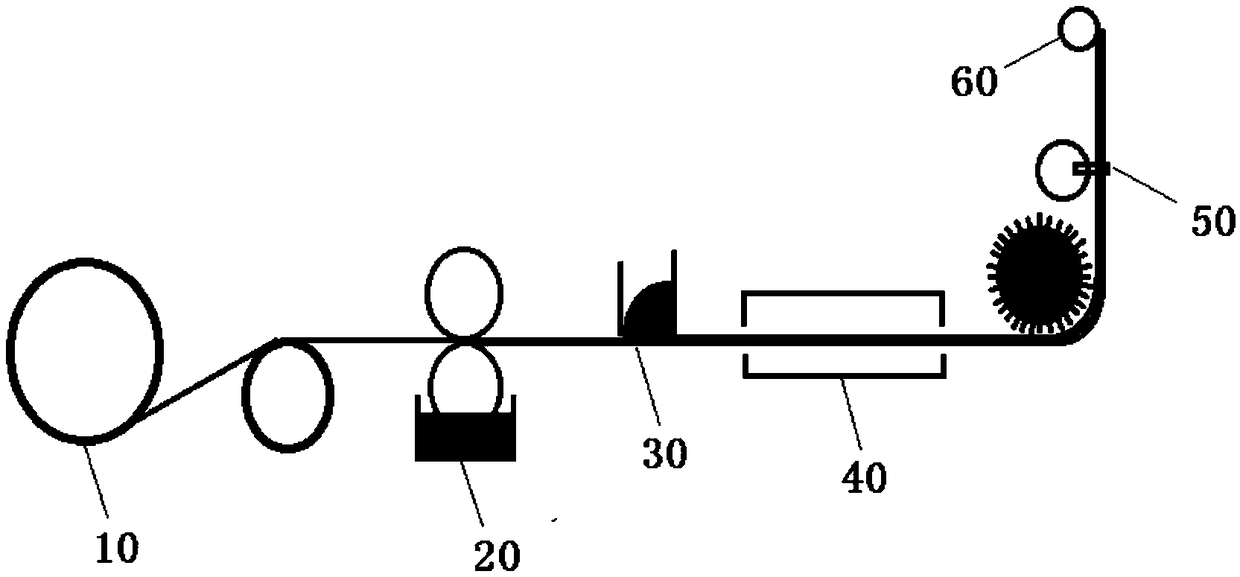

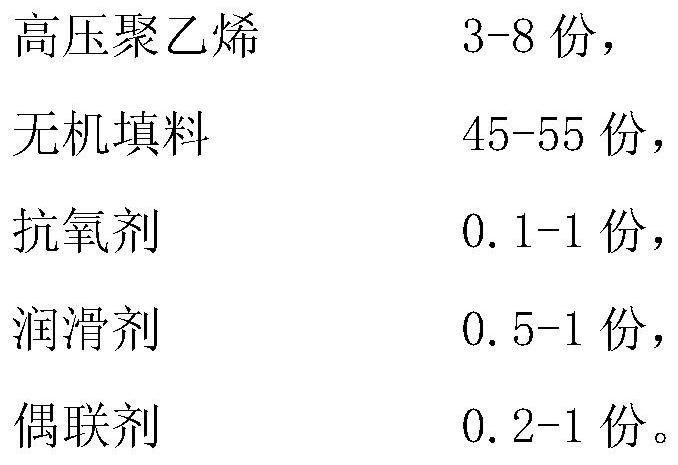

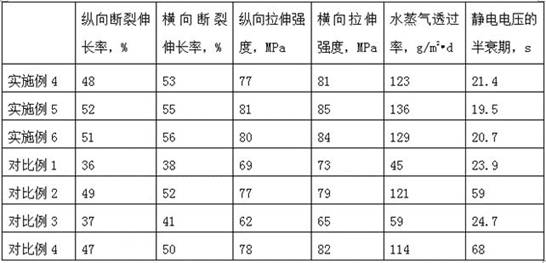

High-strength composite material for breathable film and preparation method thereof

The invention discloses a high-strength composite material for a breathable film and a preparation method thereof. The high-strength composite material is prepared by performing mixing and extrusion granulating on the following components in parts by weight: 21-44 parts of bimodal polyethylene, 8-15 parts of metallocene polyethylene, 3-8 parts of high-density polyethylene, 45-55 parts of inorganicfiller, 0.1-1 part of antioxidant, 0.5-1 part of lubricant and 0.2-1 parts of coupling agent. According to the composite material for the breathable film, bimodal polyethylene is selected as a base material, the puncture resistance of a product is adjusted by using metallocene polyethylene, so that the prepared composite material not only can fully exert the characteristics of high strength and the like of the high molecular weight in bimodal polyethylene, but also has good puncture resistance of metallocene polyethylene, and the prepared film has waterproof and breathable functions and veryhigh water vapor permeability which exceeds 2000 g / m<2> / 24h; and the composite material is suitable for being used as a back material of paper diapers, sanitary napkins and the like, so that the use comfort can be improved, and the air permeability can be ensured.

Owner:HEFEI GENIUS NEW MATERIALS

Vapor permeable fabric constructs with static or dynamic antimicrobial compositions

ActiveUS8883284B2Corrosive environmentEliminating ease of handling—takingDecorative surface effectsDuplicating/marking methodsFiberEngineering

Protective, multi-layered, breathable fabric constructs having dynamic or static antimicrobial compositions incorporated into adhesive components. The flexible constructs employ a fabric layer and a breathable coating layer applied to the fabric. Under certain preferred embodiments, the fabric constructs also employ an energy dissipating fiber material disposed opposite the coating layer. Also, the present invention teaches a method of protecting a valuable or sensitive object from damage caused by corrosion, weather, biomass, or other environmental related conditions using the fabric material. The fabric constructs may be post-formed using heat or other methods to create shaped-to-form covers.

Owner:TRANSHIELD INC

EVA adhesive film with high water vapor barrier property

InactiveCN105647406AImprove water vapor barrier performanceImprove heat and humidity resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryMica

The invention discloses an EVA adhesive film with the high water vapor barrier property. The EVA adhesive film is prepared from, by weight, 100 parts of EVA resin, 0.1-5 parts of a cross-linking agent, 0.1-1 part of an antioxidant, 0.3-1 part of an ultraviolet screening agent, 0.3-0.7 part of a light stabilizer and 1-20 parts of lamella packing, wherein the lamella packing is one of sericite, talcum powder, glass flake and mica. The EVA adhesive film with the high water vapor barrier property has good ultraviolet resistance and good main mechanical properties such as tensile strength and tear strength, and can have the good compatibility with other photovoltaic packaging materials and lamination technologies.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

Process for increasing the shelf life of a food or agricultural product

InactiveUS20140311098A1Enhanced water vapor transmission ratePackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringFood item

The present invention relates to packaging material and its use in the shelf-life extension and quality improvement of products.

Owner:DSM IP ASSETS BV

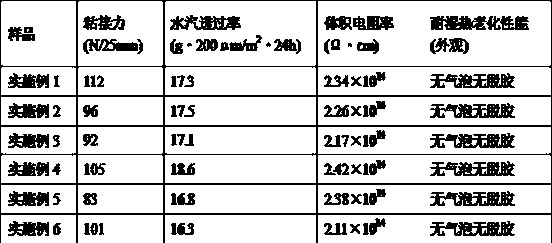

EVA hot melt adhesive film for wall covering and preparation method thereof

PendingCN108949046AImprove water vapor transmission rateImprove water resistanceMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesSolventMaleic anhydride

The invention discloses an EVA hot melt adhesive film for wall covering and a preparation method thereof. The EVA hot melt adhesive film for wall covering is prepared from 40-70 parts by weight of ethylene-vinyl acetate copolymer, 15-30 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 10-25 parts of ethylene-acrylic acid copolymer, 5-20 parts of polyolefin copolymer, 5-30 partsof tackifier, and 0.2-1 part of antioxidant by premixing and tape casting. The EVA hot melt adhesive film prepared by the invention can quickly bond the wall covering to a wall body, has the characteristics of high adhesion, moisture resistance, mildew resistance and no perishability, and does not contain harmful solvents such as benzene, toluene and xylene; the EVA hot melt adhesive film meets environmental requirements and can replace liquid glue applied to the wall covering bonding. The invention also discloses the preparation method of the EVA hot melt adhesive film for wall covering, andthe method has the advantages of simple process, convenient processing and easy operation.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

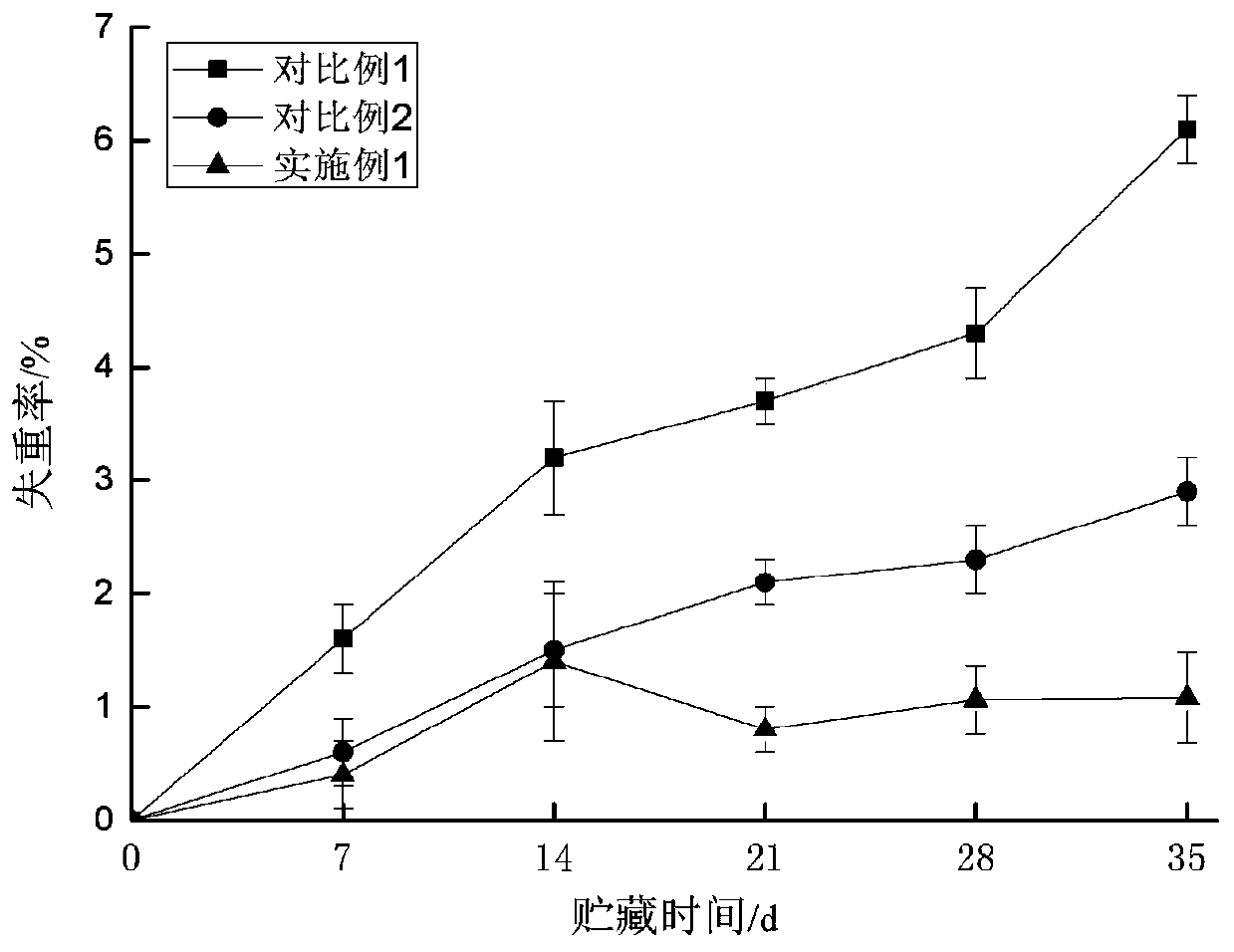

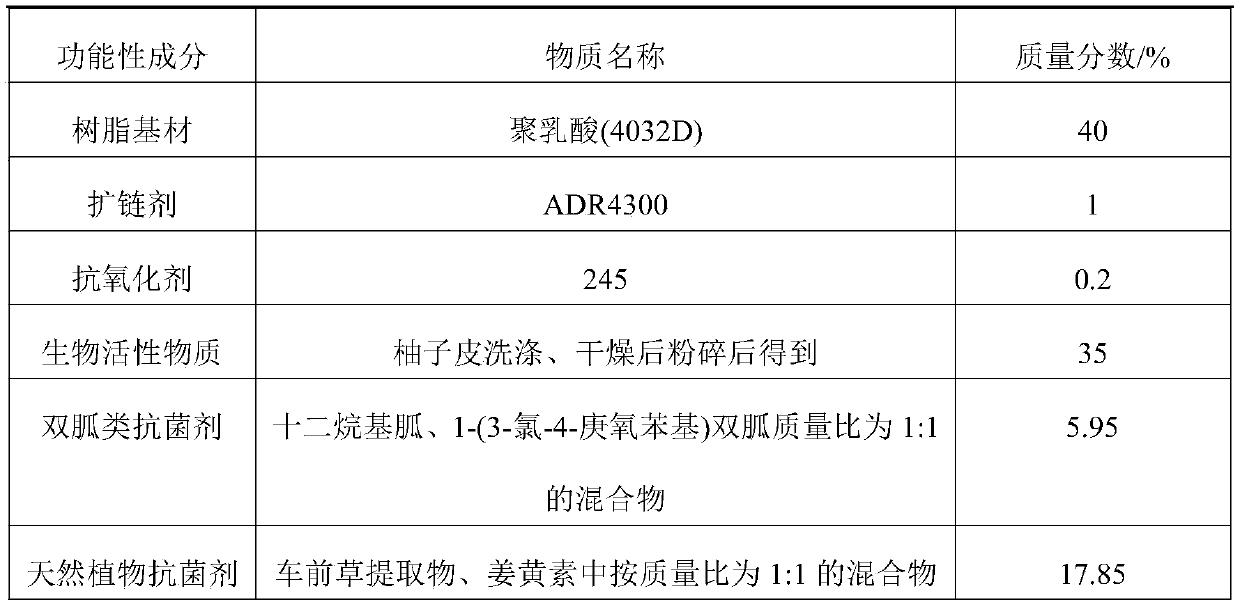

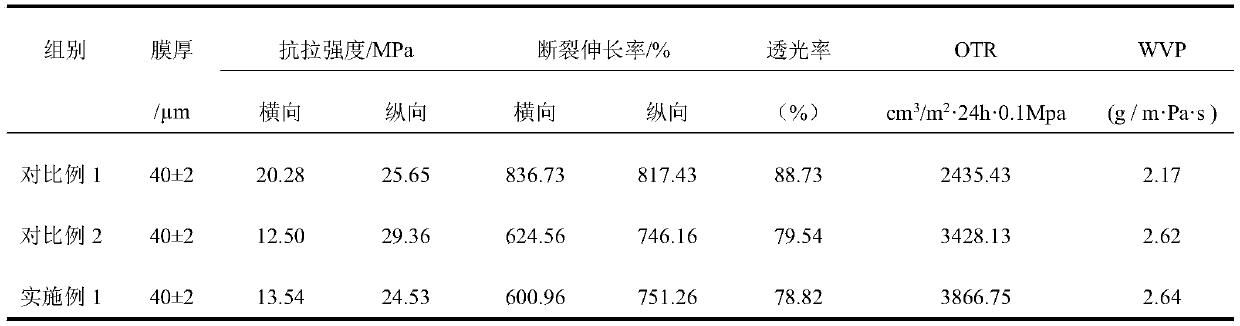

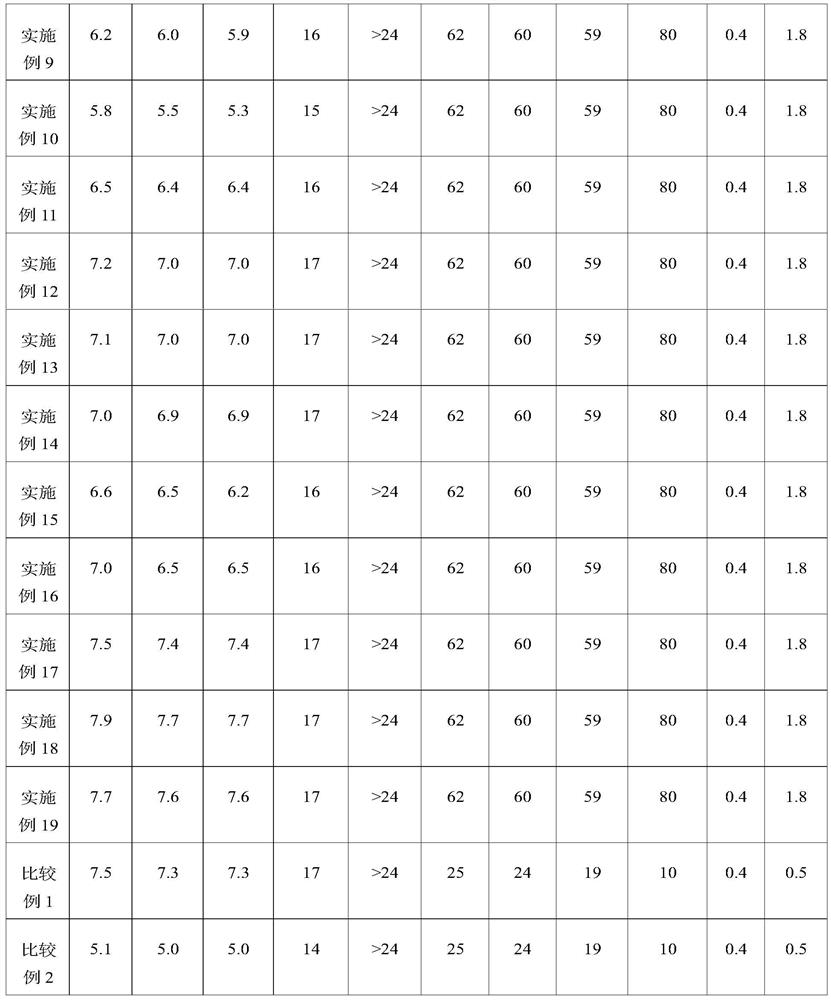

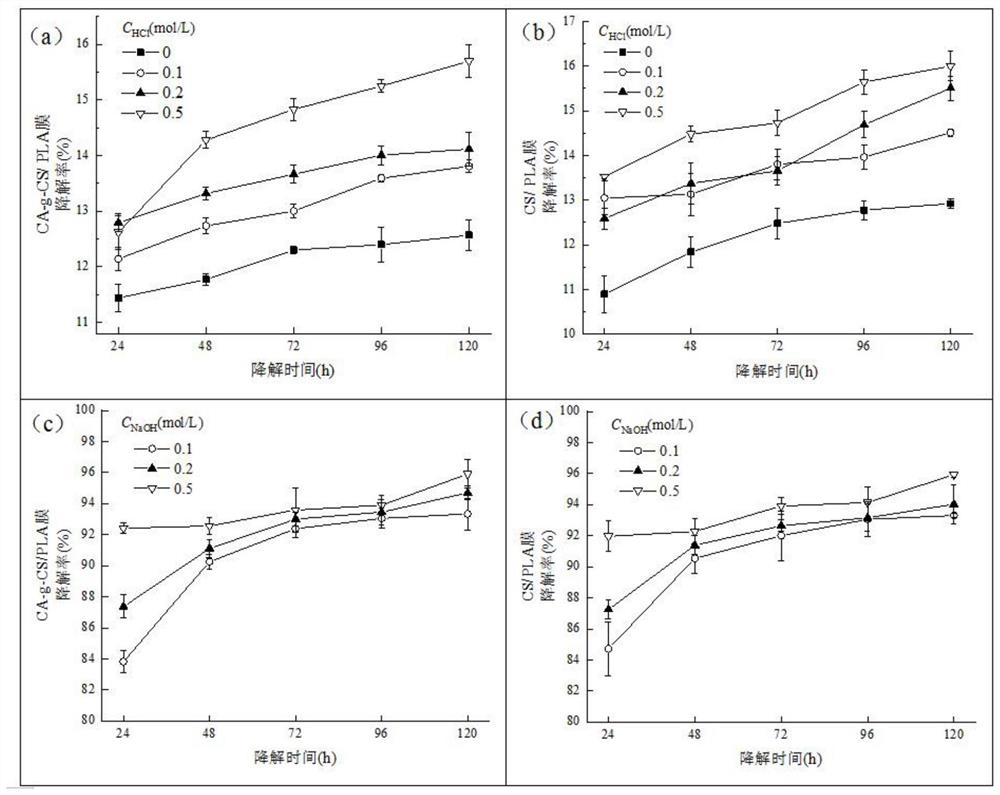

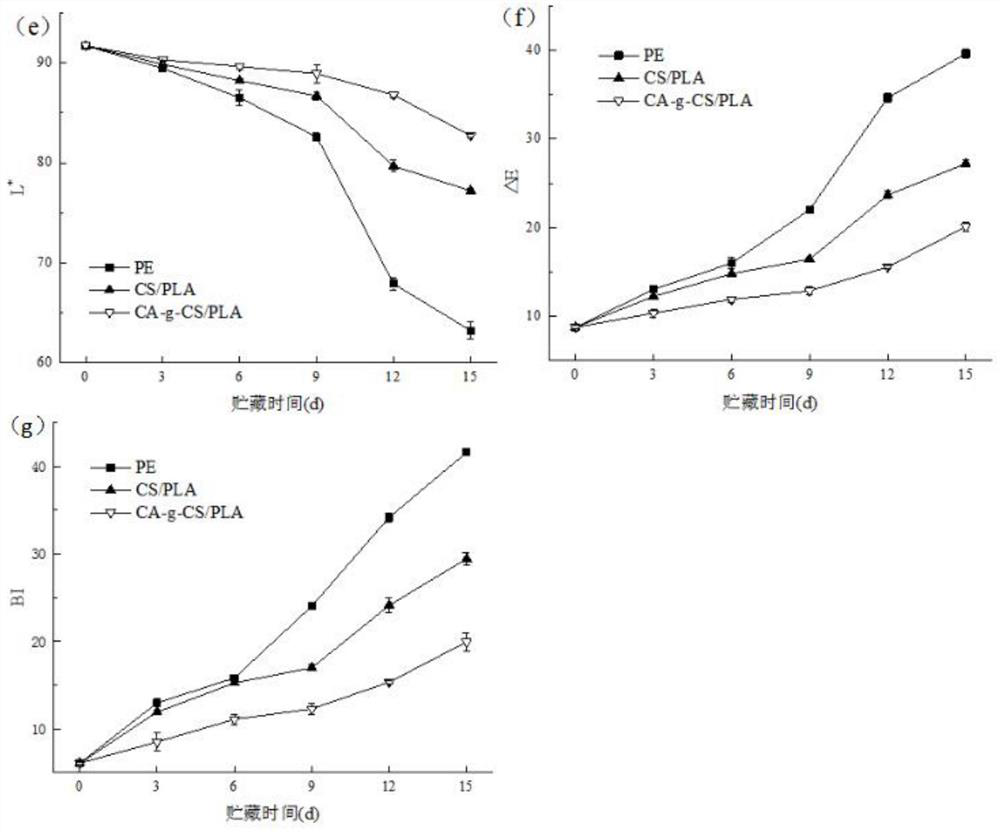

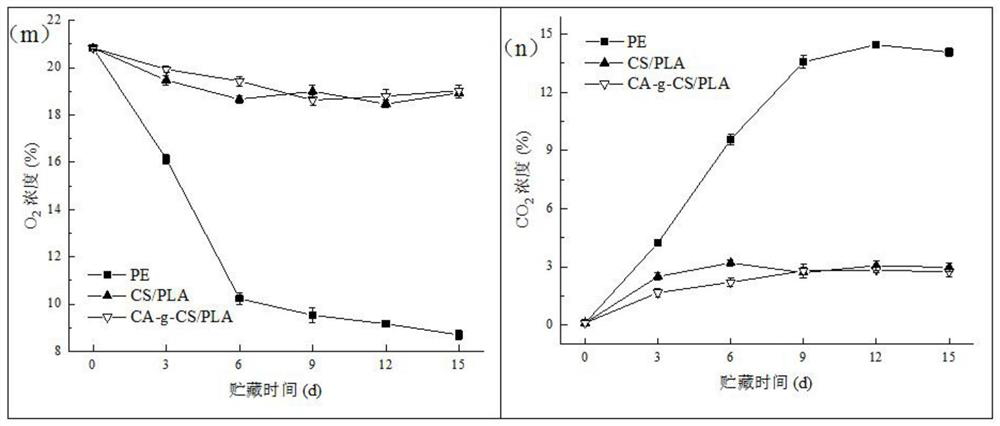

Full-biomass porous material slow-release antibacterial active preservative film and preparation method thereof

InactiveCN110835457AWide variety of sourcesSolve pollutionAntimicrobial actionBiochemical engineering

The invention provides a full-biomass porous material slow-release antibacterial active preservative film and a preparation method thereof. The full-biomass porous material slow-release antibacterialactive preservative film comprises 35-45 wt% of a matrix resin, 30-40 wt% of a biological porous substance, 20-25 wt% of an antibacterial agent and 0.9-1.3 wt% of a processing aid. The preparation method comprises the following steps: mixing the biological porous substance with the antibacterial agent to make the biological porous substance fully adsorb the antibacterial agent, mixing the obtainedmixture with the matrix resin and the processing aid, granulating the obtained mixture, and carrying out tape casting to prepare the film. Hyphae, pomegranate rind, shaddock peel, orange peel, bark and straw are porous substances, and can effectively adsorb the active antibacterial agent so as to achieve the slow release effect of the active antibacterial agent and improve the film performance, so that the long-term antibacterial effect on mutton is achieved; and the raw materials are degradable substances, so the pollution problem of agricultural byproducts and the white pollution problem ofplastic package can be solved, and the additional values of agricultural products can be improved.

Owner:SHANGHAI OCEAN UNIV

Vapor permeable fabric constructs

ActiveUS8828487B2Corrosive environmentEliminating ease of handling—takingWood working apparatusBaby linensFiberEngineering

This invention relates to protective, multi-layered, breathable fabric constructs. The constructs which are flexible employ a fabric layer and a breathable coating layer applied to the fabric. Under certain preferred embodiments, the fabric constructs also employ an energy dissipating fiber material disposed opposite the coating layer. Also, the present invention teaches a method of protecting a valuable or sensitive object from damage caused by corrosion, weather, bio mass, or other environmental related conditions using the fabric material. The fabric constructs may be post-formed using heat or other methods to create shaped-to-form covers.

Owner:TRANSHIELD INC

EMMA optical film for full fitting of electronic screen and preparation method thereof

InactiveCN108165181AImprove processing phenomenonSolve process defects such as difficulty in laminationNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveControl layerWater vapor

The invention discloses an EMMA optical film for full fitting of an electronic screen and a preparation method thereof. The EMMA optical film for full fitting of the electronic screen is prepared by pre-mixing 100 parts by weight of an ethylene-methyl methacrylate copolymer (EMMA), 0.5-2.0 parts by weight of a photoinitiator, 0.3-1.5 parts by weight of a crosslinking agent, 0.3-1.2 parts by weightof a tackifier, 0.1-0.6 part by weight of an optical stabilizer, 0.1-1.1 parts by weight of a plasticizer and 0.2-1.0 part by weight of an antioxidant by a stirrer, putting the mixture into a single-screw tape-casting machine and tape-casting into the optical film according to set process parameters. The prepared EMMA optical film has the advantages of excellent bonding properties, high light transmittance, low water vapor transmittance and high weather resistance, also is in thermal plasticity before curing, easily fills segment gaps, adapts to the complex interface fitting, and can adapt torequirements of fitting of electronic screen protection layers, touch control layers and display layers with different sizes.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

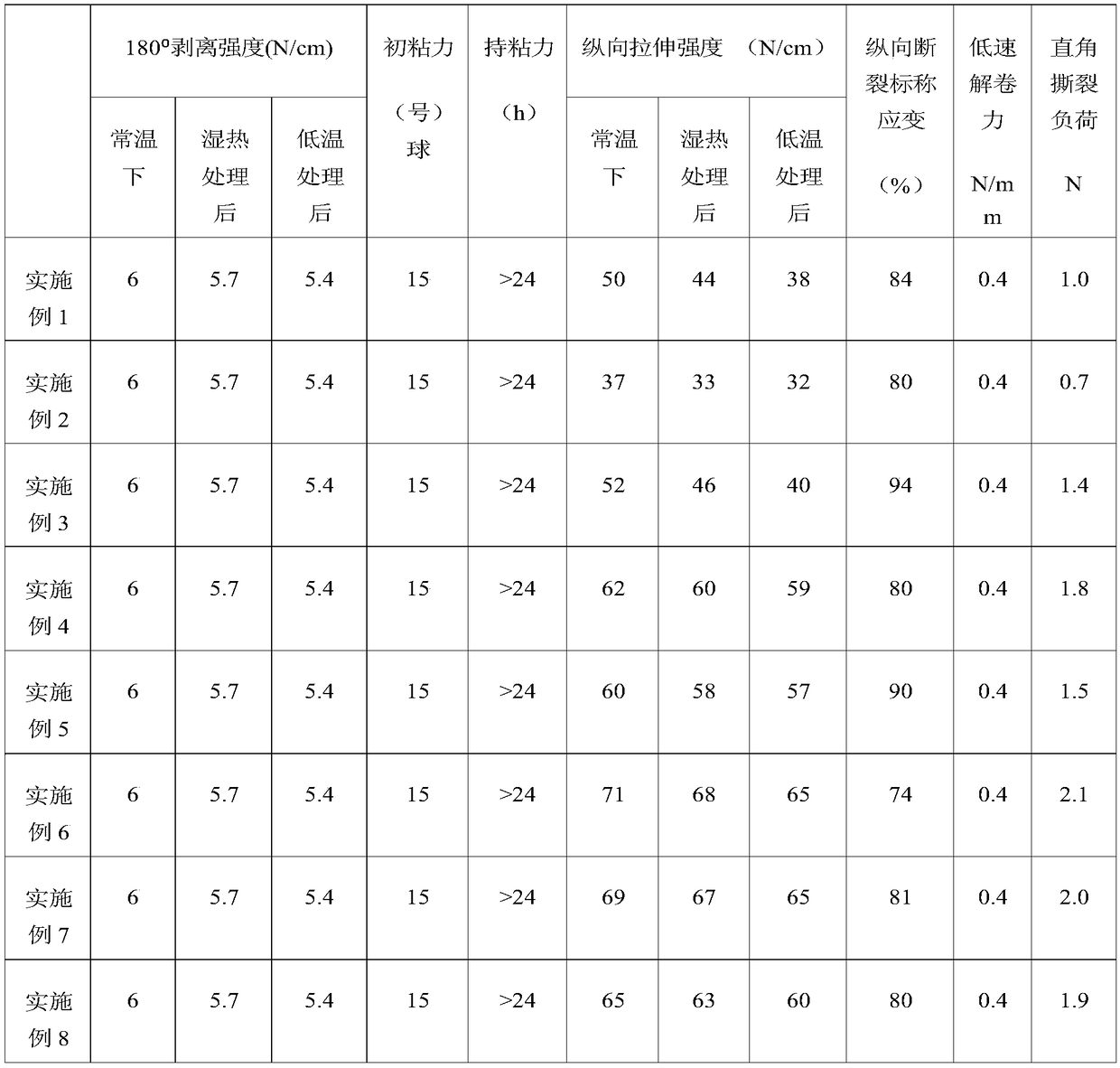

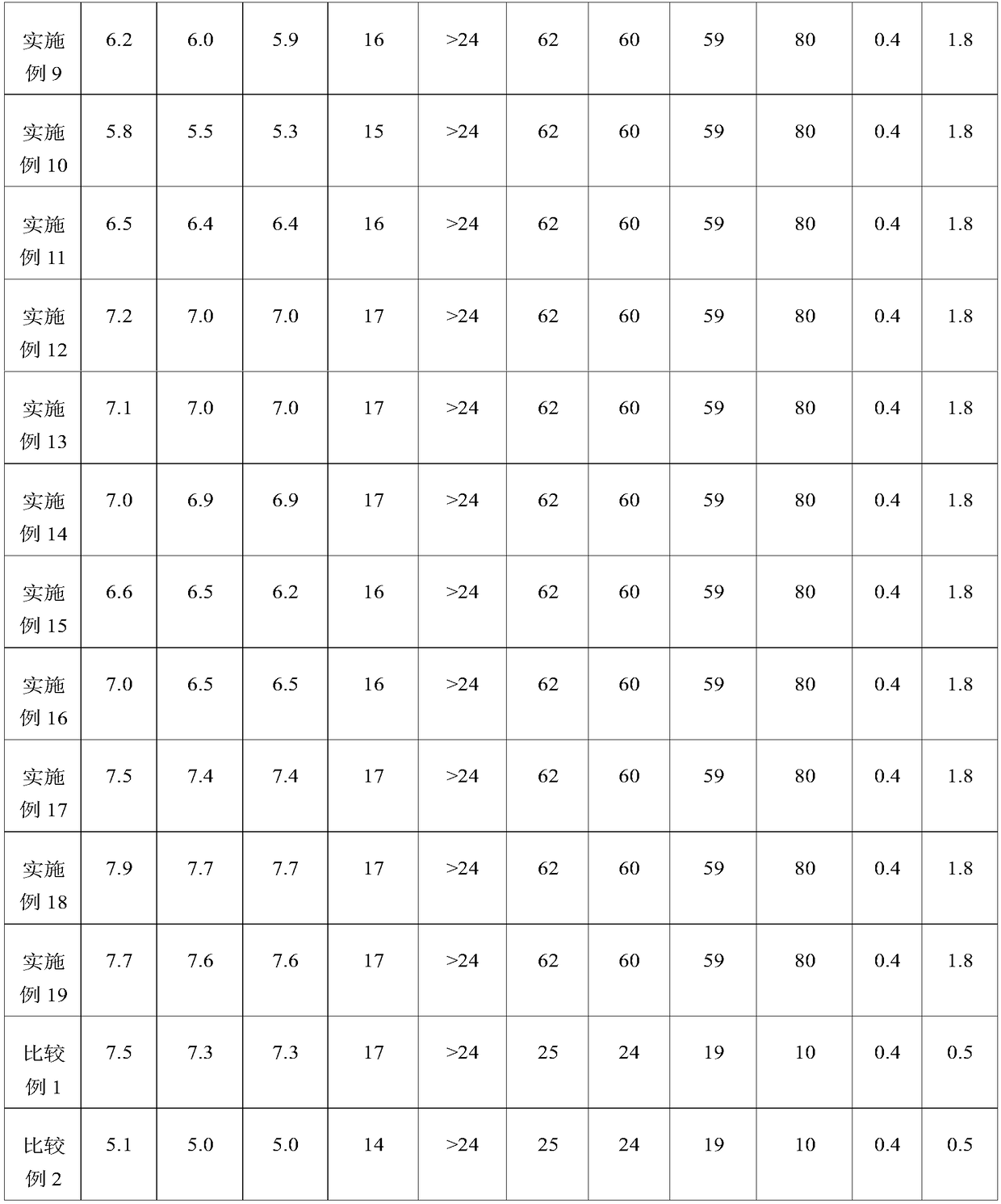

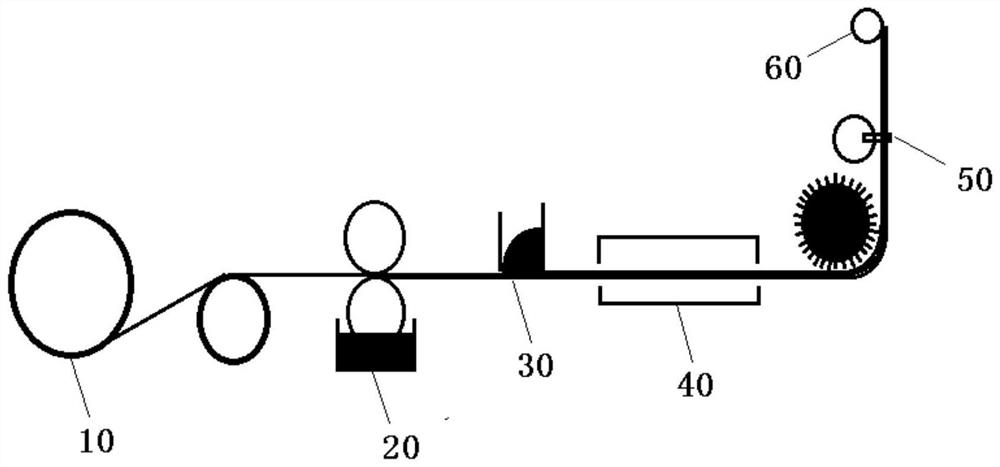

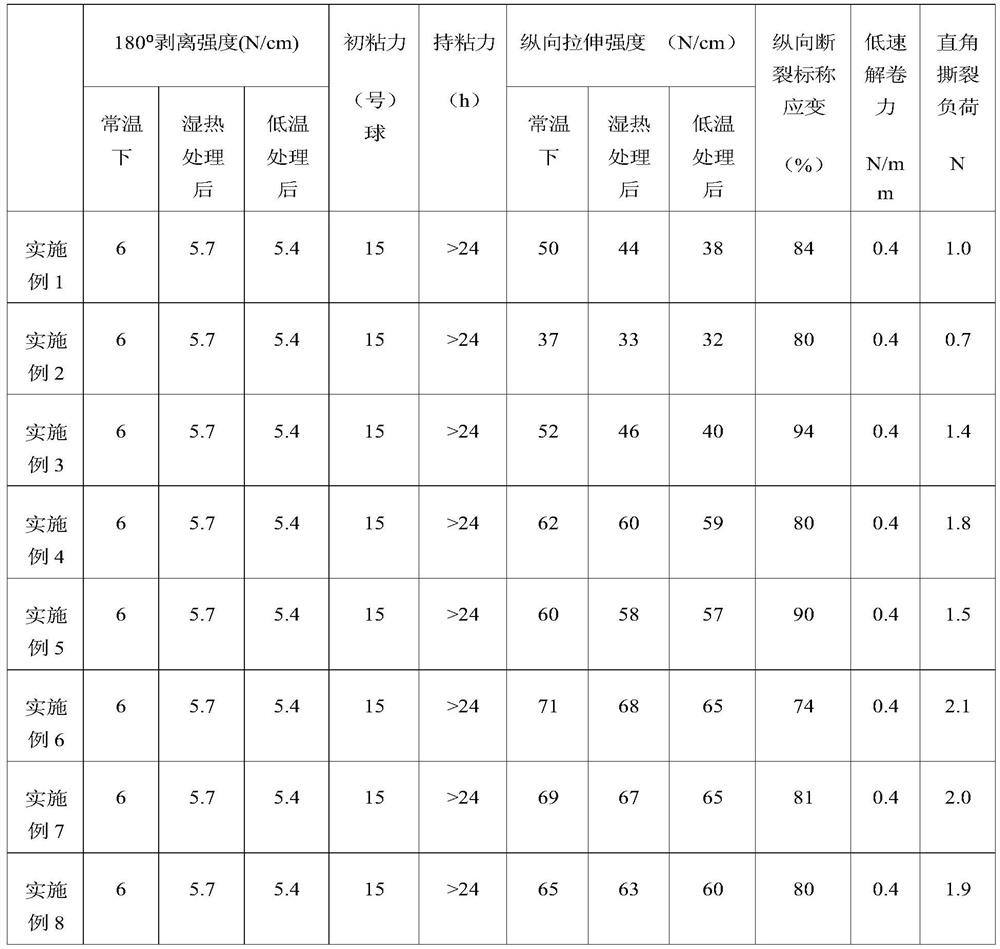

Adhesive tape base material, adhesive tape provided with same and preparation method

InactiveCN109266233AMedium Oxygen Transmission RateEnhanced water vapor transmission rateMacromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesWater vaporTransmittance

The invention provides an adhesive tape base material, an adhesive tape provided with the same and a preparation method. The adhesive tape base material comprises a continuous phase and a disperse phase dispersed in the continuous phase; the material of the continuous phase is 55-95 parts by weight of L-polylactic acid, and the material of the disperse phase is 0.25-2.5 parts by weight of toughening filler and 0.25-2.5 parts by weight of a dispersing agent. Raw materials such as L-polylactic acid have biological degradability, so that pollution, on the environment, of the adhesive tape with the base material is reduced; and the proportion of the components is prescribed, so that the adhesive tape base material has medium oxygen gas transmittance and relatively high water vapour transmittance, and can be used for realizing encapsulating agricultural products.

Owner:北京众邦健业印刷有限责任公司

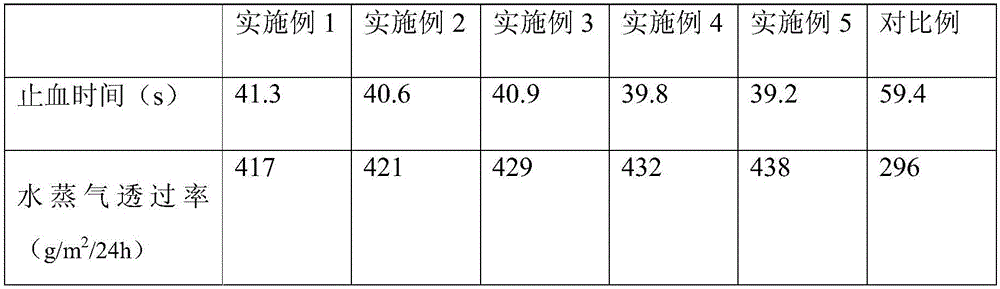

Breathable and hemostatic alginate dressing and preparation method thereof

InactiveCN105854064AHemostatic water vapor transmission rateEnhanced water vapor transmission ratePharmaceutical delivery mechanismAbsorbent padsSodium hyaluronatePolyvinyl alcohol

The invention discloses a breathable hemostatic alginate dressing and a preparation method thereof. The dressing consists of the following components in parts by mass: 46-62 parts of potassium alginate, 15-29 parts of carboxymethyl chitosan, phosphoric acid 3‑12 parts of ammonium dihydrogen, 2‑12 parts of hydrogenated lecithin, 8‑21 parts of polyvinyl alcohol, 6‑17 parts of sorbitol, 3‑9 parts of acetyl tributyl citrate, 15‑24 parts of butylene glycol , 2‑10 parts of sodium hyaluronate, 5‑13 parts of licorice extract. The preparation method is as follows: mix potassium alginate, carboxymethyl chitosan and butanediol, and ultrasonicate; then add the remaining components, mix, heat, stir evenly, keep warm, and cool to room temperature; soak degreasing gauze in it, dry Machine dried, sealed, packaged and sterilized by ultraviolet light. The dressing prepared by the invention achieves the effect of hemostasis and improvement of water vapor transmission rate through the synergistic effect of the components, and can be widely used for wound healing.

Owner:SUZHOU COSMETIC MATERIALS

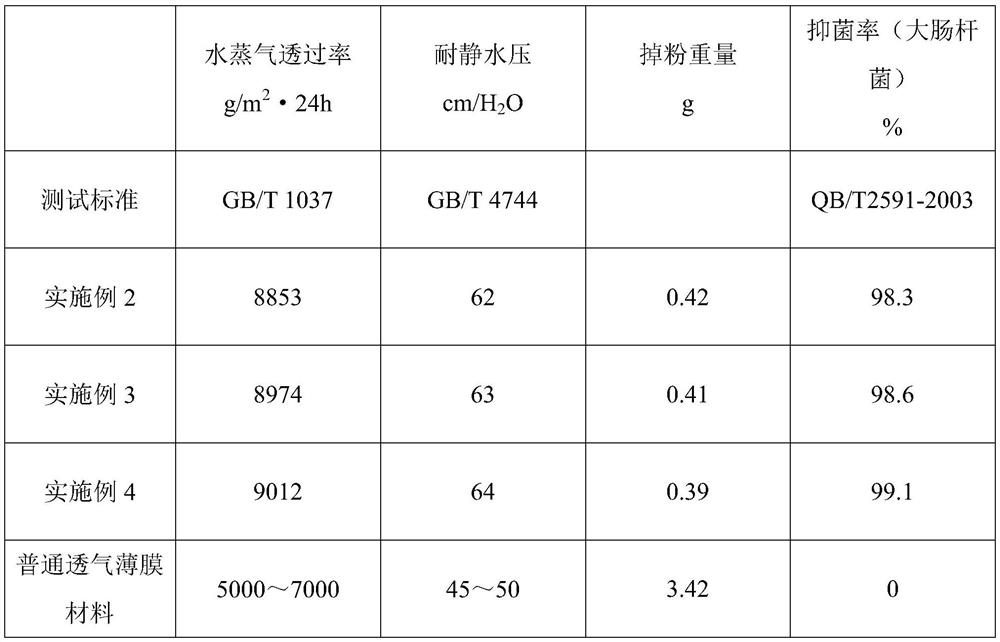

Antibacterial gas-permeable membrane and preparation method thereof

PendingCN112143079AEnhanced water vapor transmission rateGood air permeabilityMaleic anhydrideLiquid water

The invention discloses an antibacterial gas-permeable membrane and a preparation method thereof. The antibacterial gas-permeable membrane comprises the following raw materials in parts by weight: 62-72 parts of polyethylene, 13-17 parts of an ethylene-vinyl alcohol copolymer, 8-12 parts of polylactic acid, 5-7 parts of maleic anhydride grafted polyethylene, 3-4 parts of light calcium carbonate, 3-4 parts of heavy calcium carbonate, 2-3 parts of nano porous silicon dioxide, 1.5-2.5 parts of sepiolite powder, 1.3-1.6 parts of an antibacterial agent, 1.4-1.8 parts of a coupling agent, 2-4 partsof stearate, 1.2-1.4 parts of a surfactant and 2-3 parts of a dispersant. The antibacterial gas-permeable membrane is high in water vapor transmission rate, good in breathability, and high in static water pressure resistance, cannot leak liquid water during use, is low in powder falling weight, low in powder falling amount, high in antibacterial rate and good in antibacterial effect, can be completely degradedwithin 4-6 months in a composting state, and does not cause pollution to the environment,.

Owner:福建琦峰科技有限公司

Preparation method of PVA/tapioca starch/LAE active composite film, and application of PVA/tapioca starch/LAE active composite film in antibacterial aspect of food packaging

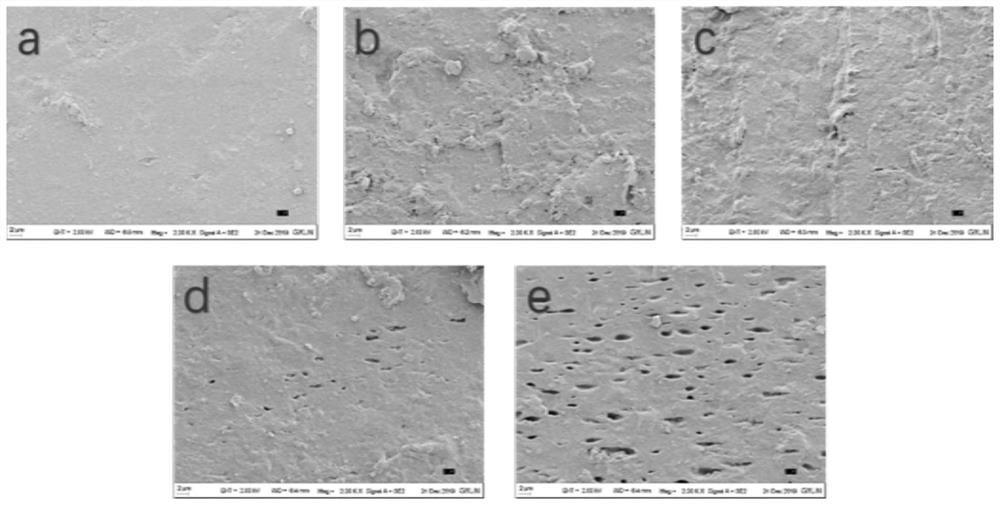

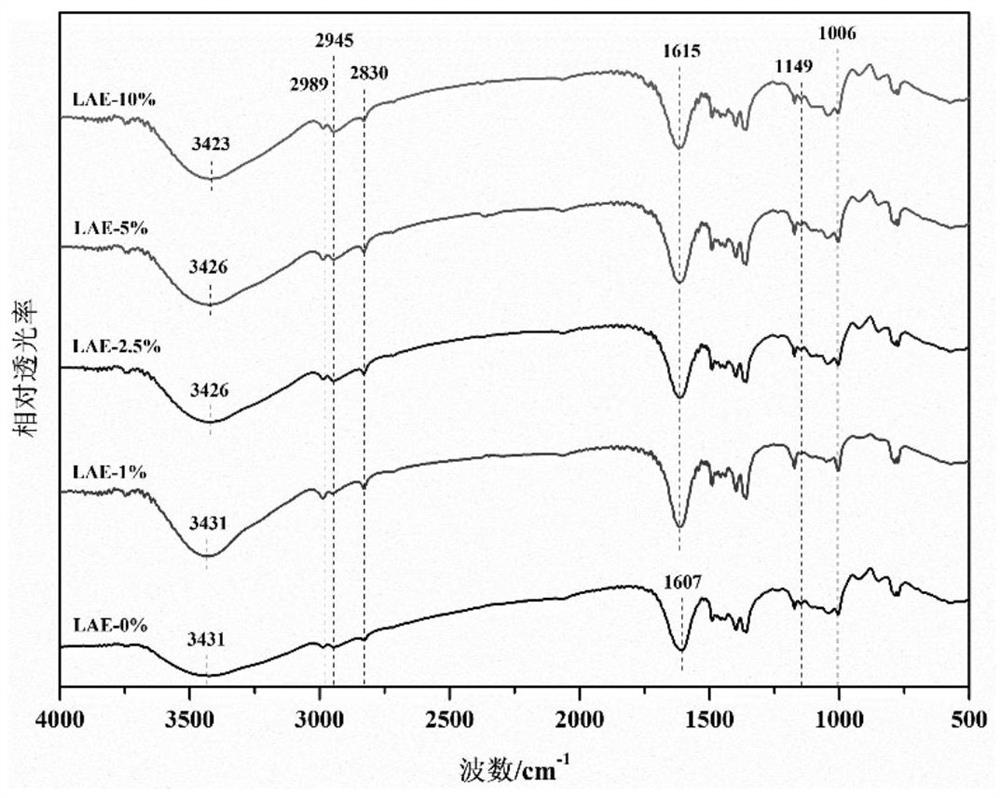

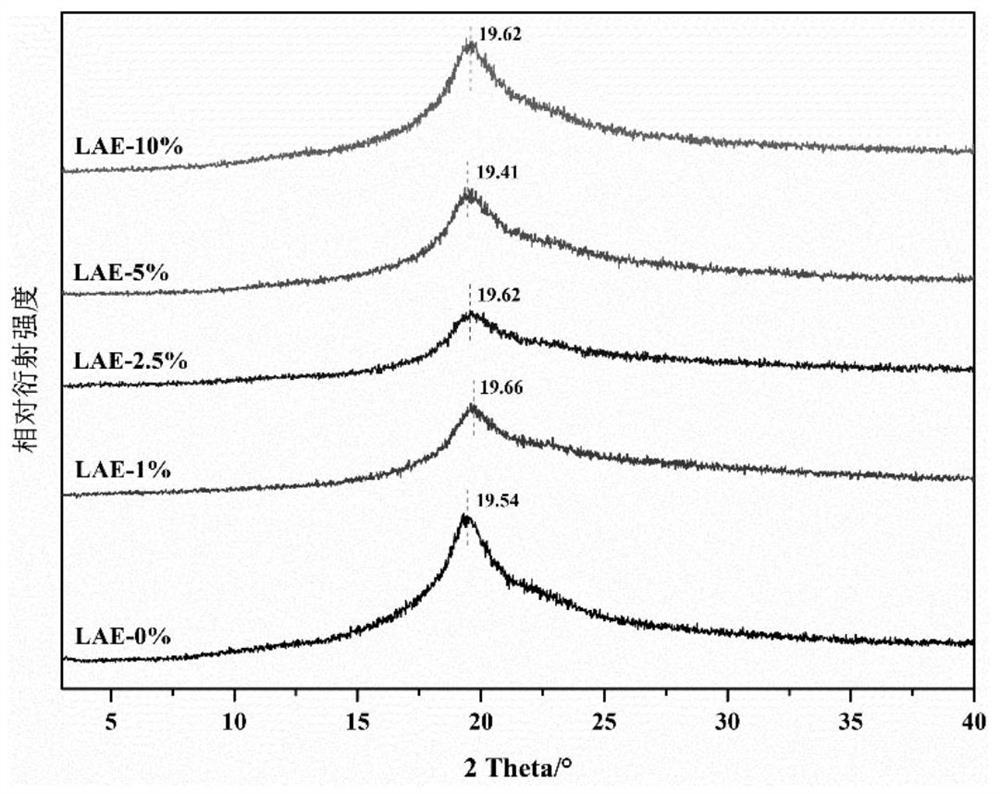

PendingCN113388135AMicroscopic morphology changesLow tensile strengthBio-packagingComposite filmWater vapor permeability

The invention provides a preparation method of a PVA / cassava starch / LAE active composite film, and application of the PVA / cassava starch / LAE active composite film in the aspect of bacteriostasis of food packaging, and belongs to the technical field of food packaging materials. Cassava starch is gelatinized and then mixed with a PVA solution and an auxiliary solvent, LAE with the mass concentration being 1-10% is added, heating, stirring and mixing are conducted in a water bath environment to obtain a film casting solution, and finally, tape casting is carried out on the film casting solution to obtain the finished product composite film. The composite film disclosed by the invention can better prevent ultraviolet rays and visible light from penetrating, and is beneficial to preventing food from being degraded and oxidized; and the obtained composite film has relatively high water absorption and water vapor permeability, and has a relatively good fresh-keeping effect.

Owner:GUANGXI UNIV FOR NATITIES

Adhesive tape and method for producing same

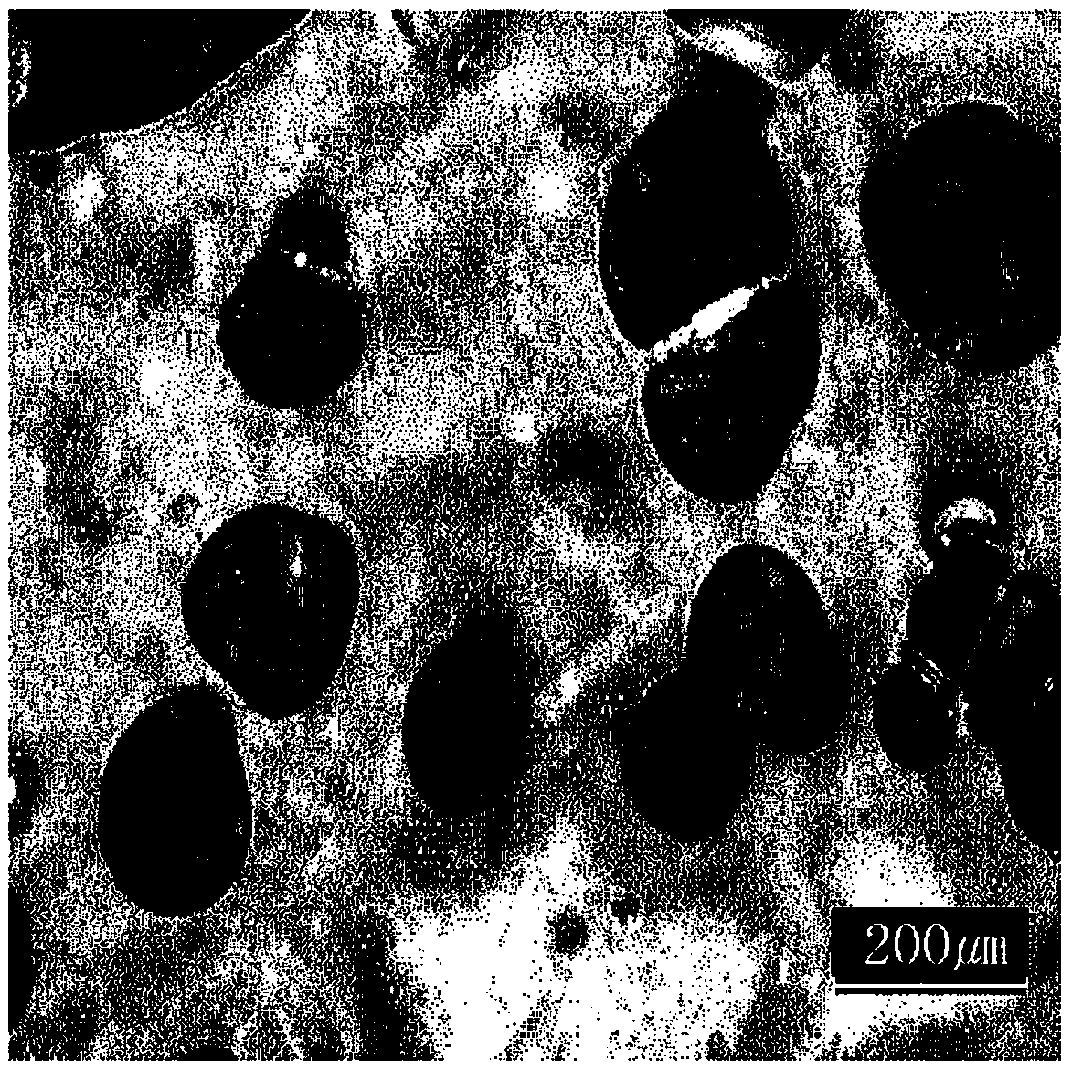

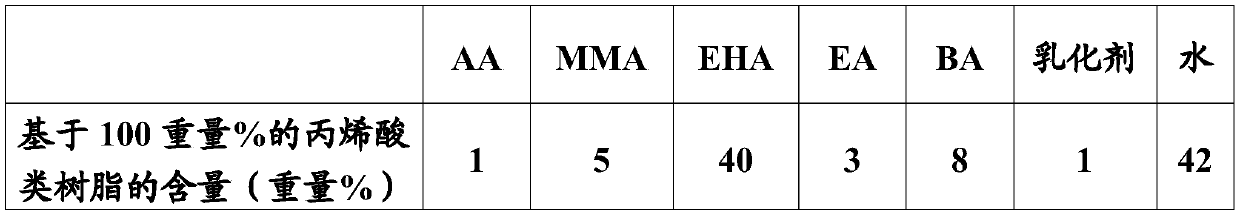

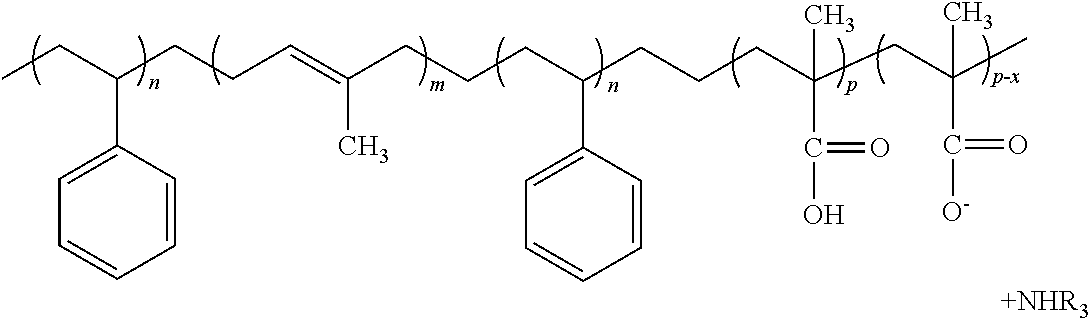

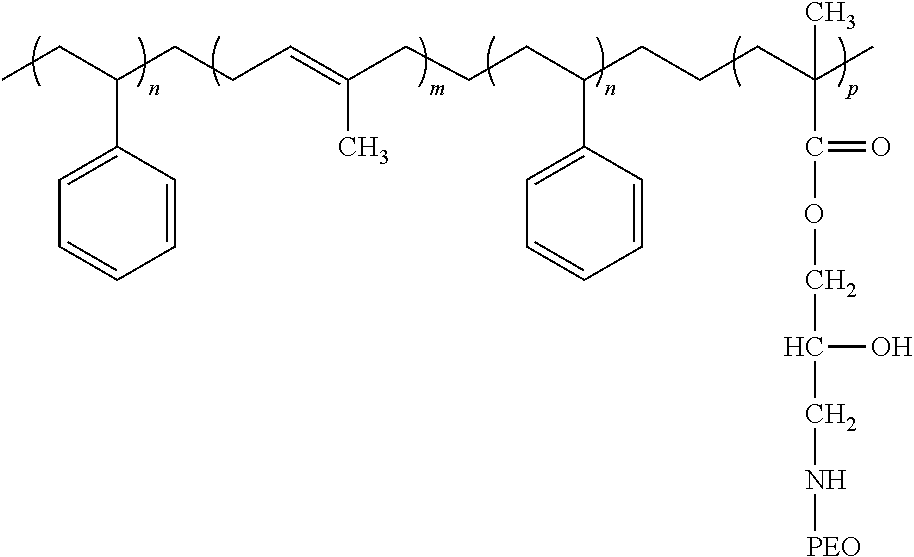

ActiveCN107849405AExcellent water vapor transmission rateEasy dischargeFilm/foil adhesivesSemiconductor/solid-state device manufacturingWater basedWater vapor

The present invention provides an adhesive tape and a method for producing same, the adhesive tape comprising: a substrate; and an adhesive sheet provided on one surface of the substrate and comprising hardened material of water-based acrylic adhesive composition, wherein the adhesive sheet has a porous structure comprising holes and water vapor transmission rate of 3,000-5,000 g / m<2>*day under the condition of 40 DEG C temperature and 20% relative humidity.

Owner:LG CHEM LTD

Hand sanitizer

InactiveCN107998013AEnhanced water vapor transmission rateGuaranteed wettabilityCosmetic preparationsToilet preparationsHand sanitizerGlycerol

The invention belongs to the field of articles for daily life and in particular relates to a hand sanitizer. The hand sanitizer is prepared by taking sodium alginate as a film forming base material and chitosan as a raw material of a blended film; a molecular chain of the chitosan has primary amino and a molecular chain of the sodium alginate has carboxyl; under the action of an electrostatic force, a polyelectrolyte film can be formed through positive and negative charge attraction, so that one layer of protection film is formed on skin; by a low molecular weight plasticizer glycerol, a plasticizer molecule and a polymer have a mutual effect, so that a mutual action force between macromolecules is weakened and the hydrogen-bond interaction in the molecules is weakened; the ratio of a crystallization region to an amorphous region of the film is reduced and the water seepage steam penetration rate of the film is improved, so that the loss of moisture in the skin is prevented or alleviated and the wetting property of the skin is kept; rosemary essential oil is added and essential oil molecules exist in the film with a plurality of micro-pores; after active substances with a bacterium-inhibition effect in the essential oil molecules enter the film, the active substances are dispersed to the surface of the film gradually through the micro-pores, so that the antibacterial performance of the surface of the skin is improved.

Owner:袁玲燕

Substrate coated with a hydrophilic elastomer

ActiveUS8680362B2Improve hydrophilicityGood coating stabilitySynthetic resin layered productsBaby linensElastomerPolymer science

Substrates, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:PROCTER & GAMBLE CO

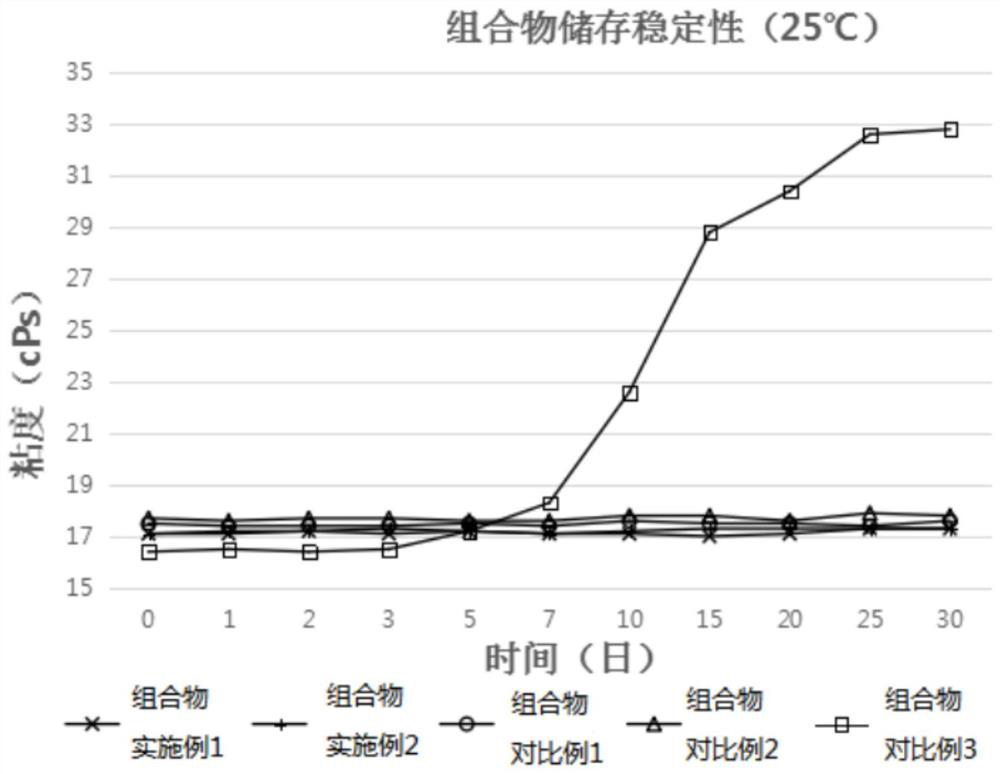

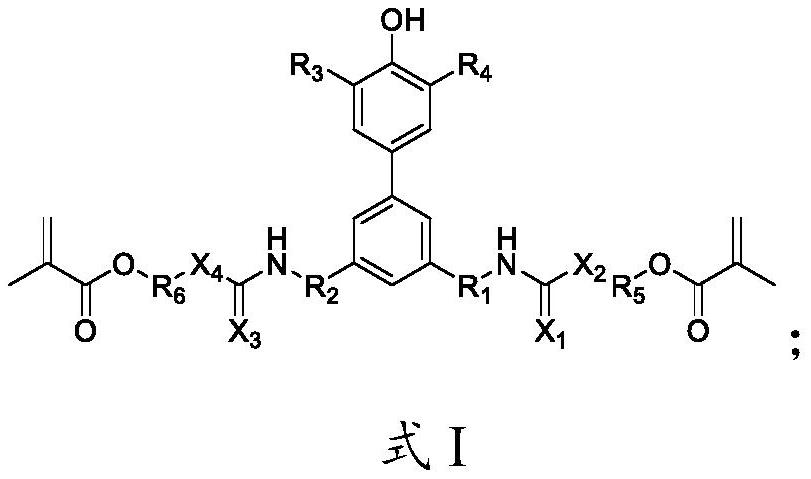

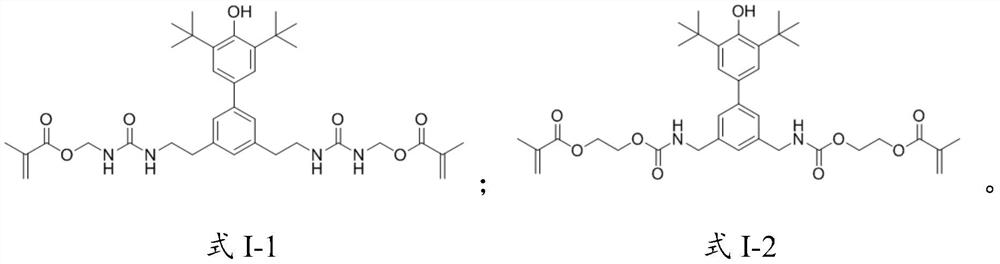

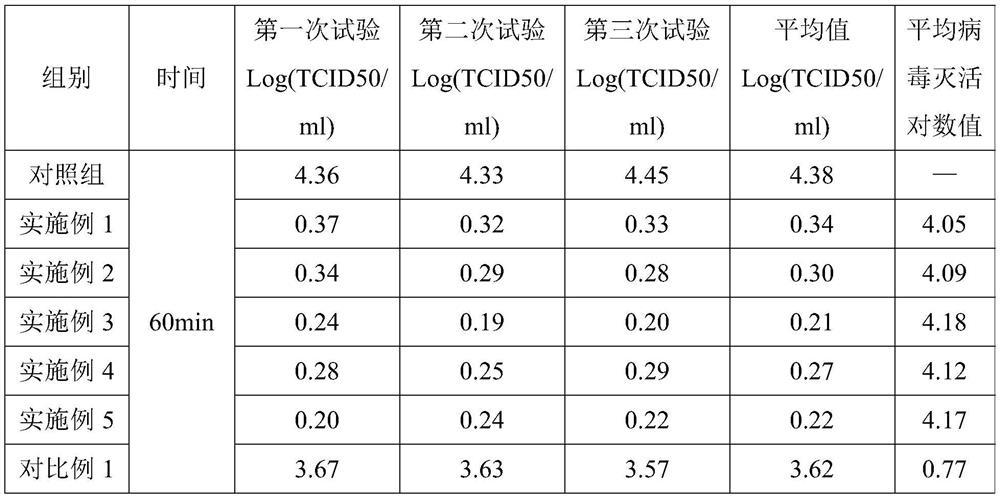

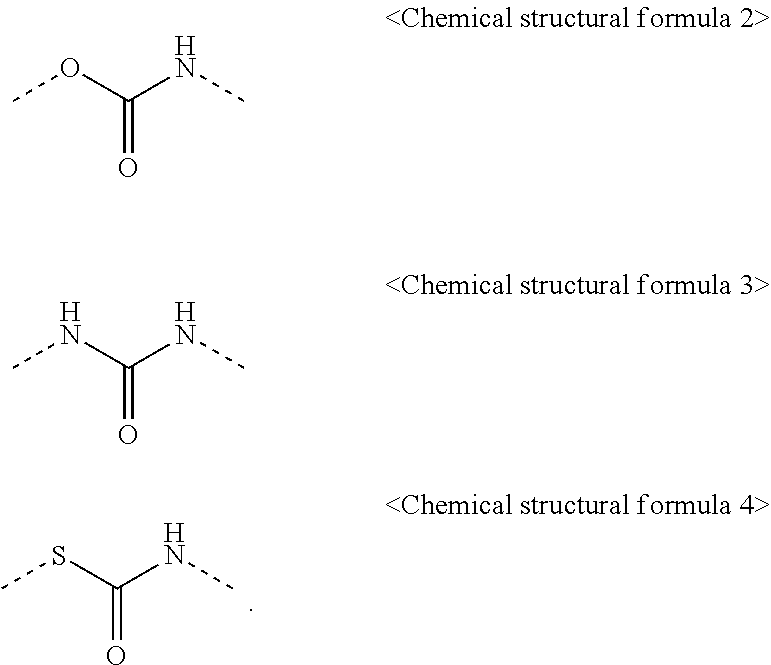

Antioxidant for thin film encapsulation, composition and application of composition

ActiveCN112538031AEnhanced water vapor transmission rateEmission reductionUrea derivatives preparationCarbamic acid derivatives preparationOrganic light emitting deviceThin membrane

The invention is applicable to the technical field of thin film packaging structures, and provides an antioxidant for thin film encapsulation, a composition and application of the composition. The structural general formula of the antioxidant is shown in the specification, in the formula, R1, R2, R5 and R6 are independently one of substituted or unsubstituted alkylene of C1 to C20 and substitutedor unsubstituted arylene of C6 to C30; R3 and R4 are independently one of hydrogen, substituted or unsubstituted alkyl groups of C1 to C20, and substituted or unsubstituted aryl groups of C6 to C30 and are same or different; and X1, X2, X3 and X4 are independently one of O, S and substituted or unsubstituted NH. The antioxidant provided by the invention has propenyl with a plurality of photocuringgroups, can optimize the water vapor transmission rate of a packaging film, and reduces miscellaneous gas emission after film formation, so that the service life of the packaging film structure of the organic light emitting device can be prolonged.

Owner:JILIN OPTICAL & ELECTRONICS MATERIALS

Method for preparing breathable self-adhesion elastic bandage

InactiveCN104825273AHigh compressive strengthExtended protection timeAbsorbent padsBandagesPolymer sciencePolyvinyl alcohol

The invention discloses a method for preparing a breathable self-adhesion elastic bandage. The method includes the following steps that acetone and rosin are mixed by weight, ultrasound treatment is conducted for 5-15 minutes at the temperature of 60-90 DEG C, and accordingly a first mixture is obtained; the first mixture, polyving akohol, polyurethane, potassium sorbate, isopropyl palmitate and fatty alcohol-polyoxyethylene ether are placed in a mixing agitator to be stirred, and after the PH value is adjusted to be neutral, a second mixture is obtained; the second mixture is arranged in a drying oven for 10-30 minutes, then the second mixture is smeared on a non-woven fabric base material through a double-roller coating method under the protection of nitrogen, and the elastic bandage is obtained after the processes of coiling, shearing, nitrogen sealing and sealing. The bandage obtained through the method has the advantages of being high in compressive strength, long in protection time, high in water vapor permeability and capable of being widely applied to clinic treatment.

Owner:李孟平

Preparation method and application of antiviral moisture-permeable coating

InactiveCN111849328AImprove hydrophilicityGood moisture permeabilityAntifouling/underwater paintsPaints with biocidesOXALIC ACID DIHYDRATEHalohydrocarbon

The invention discloses a preparation method of an antiviral moisture-permeable coating and an application of the antiviral moisture-permeable coating in preparation of an antiviral moisture-permeablefilm. The preparation method comprises the following steps: 1) reacting polyethyleneimine with halogenated hydrocarbon to obtain polyethyleneimine quaternary ammonium salt; and 2) matching polyethyleneimine quaternary ammonium salt and oxalic acid into a water-based polymer to obtain the antiviral moisture-permeable coating. After the antiviral moisture-permeable coating is attached to a porous base film, heat treatment is performed. The porous base film serves as a base material of the moisture-permeable film, and the antiviral moisture permeable film is obtained. The moisture-permeable filmprovided by the invention has an antiviral capability; the quaternary ammonium salt polymer is added, so that the influence on the water vapor permeability is not obvious, and thus the antiviral moisture-permeable film disclosed by the invention not only has the characteristic of high moisture permeability, but also has excellent antiviral performance, has the functions of blocking aerosol and inhibiting viruses, and is high in water vapor permeability, and can be used for preparing medical protective clothing.

Owner:绍兴百立盛新材料科技有限公司

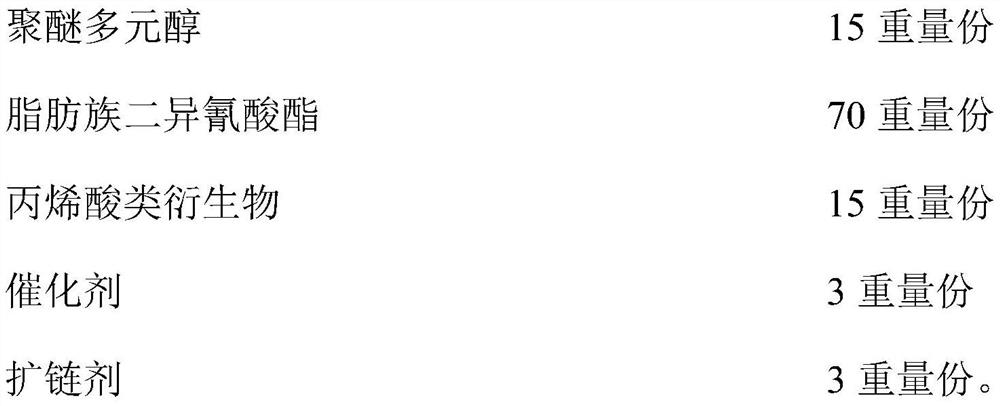

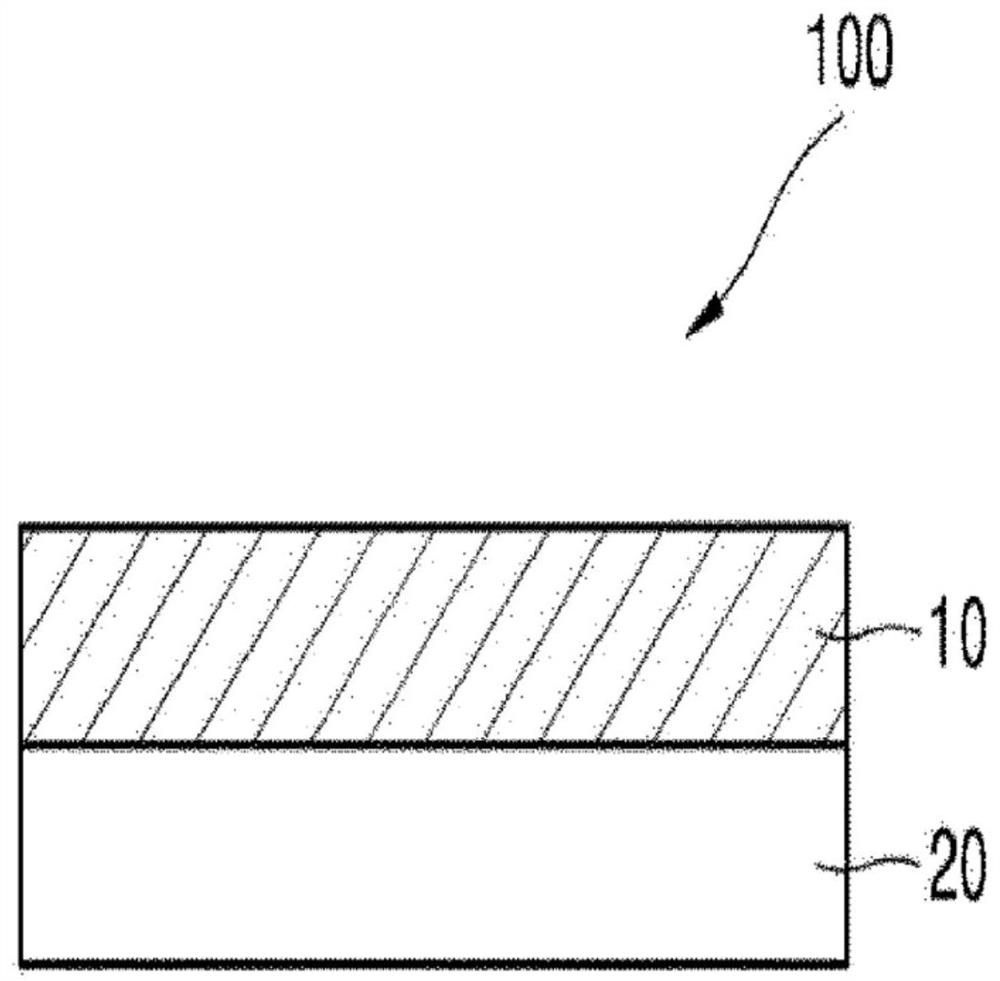

Low-permeability TPU film for automobile headrest and preparation method of low-permeability TPU film

ActiveCN112175219AReduce barrier effectRaw materials are easy to getCoatingsPolymer sciencePtru catalyst

The invention provides a low-permeability TPU film for an automobile headrest and a preparation method of the low-permeability TPU film. The low-permeability TPU film for the automobile headrest comprises a TPU film layer and a water vapor barrier layer which are laminated, wherein the water vapor barrier layer comprises layered silicate minerals and synthetic resin; and the TPU film layer is prepared from the following components in parts by weight: 10-20 parts of polyether polyol, 60-80 parts of aliphatic diisocyanate, 10-20 parts of an acrylic acid derivative, 1-4 parts of a catalyst and 1-5 parts of a chain extender. On the premise that the TPU film for the automobile headrest has good mechanical performance, the TPU film for the automobile headrest further has low water vapor permeability and oxygen permeability; and the preparation method of the TPU film for the automobile headrest is simple, raw materials are easy to obtain, the price is low, and the implementation is convenient.

Owner:SUZHOU XIONGLIN NEW MATERIAL SCI & TECH CO LTD +1

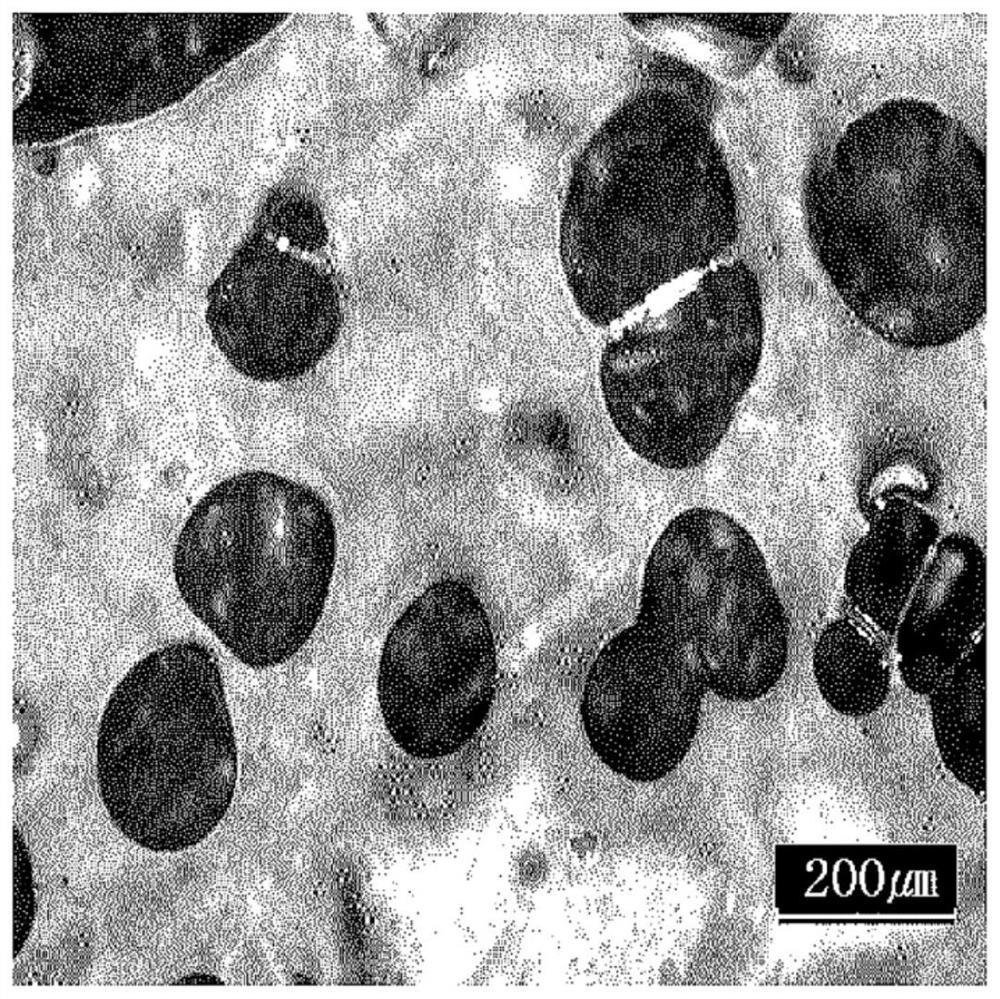

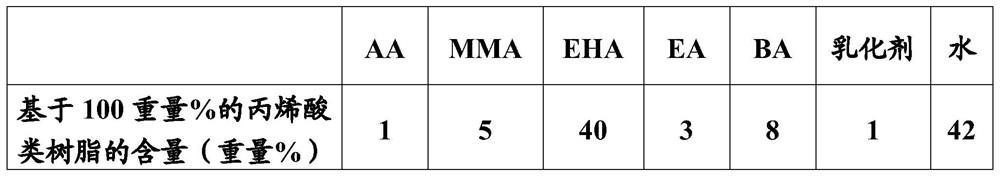

Adhesive tape and its manufacturing method

ActiveCN107849405BExcellent water vapor transmission rateEasy dischargeFilm/foil adhesivesAdhesive processes with adhesive heatingPolymer scienceWater vapor

The present invention provides an adhesive tape comprising: a substrate; and an adhesive sheet provided on one surface of the substrate and comprising a water-based acrylic adhesive composition and a method for producing the same. wherein the adhesive sheet has a porous structure including pores, and wherein the adhesive tape has a water vapor transmission rate of 3,000 g / m under conditions of a temperature of 40°C and a relative humidity of 20% 2 ・Day or more and 5,000g / m 2 · days or less.

Owner:LG CHEM LTD

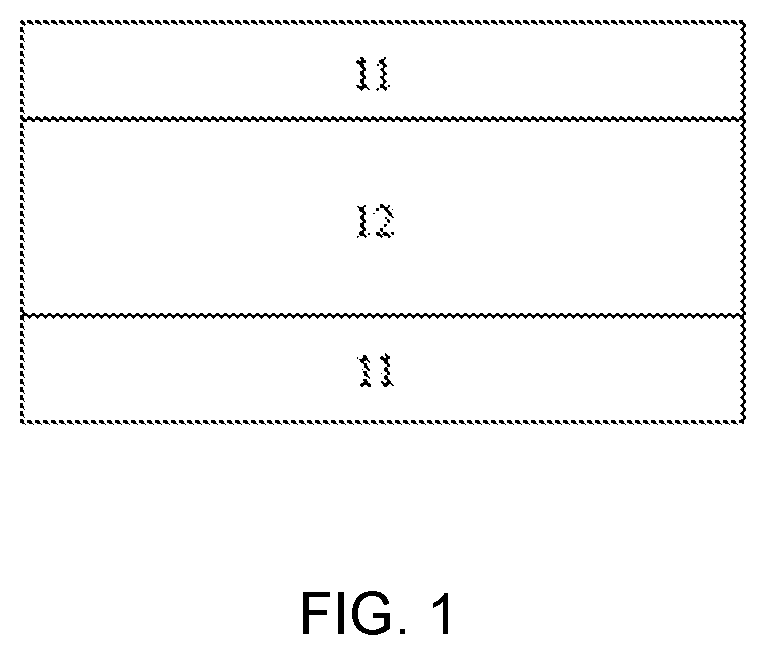

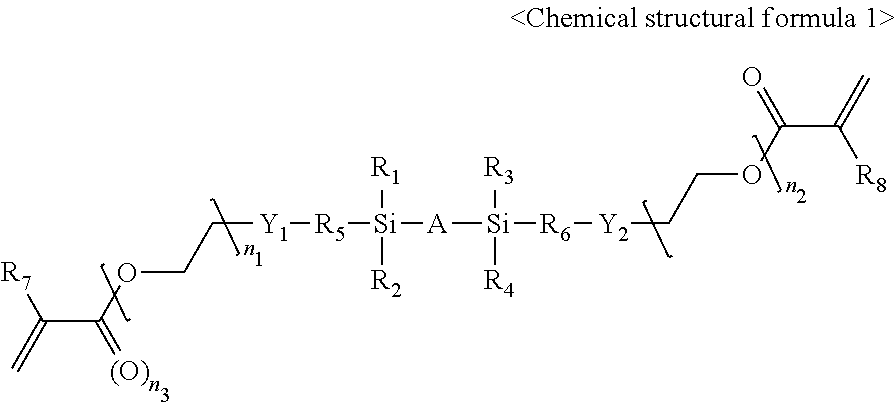

Compound for encapsulation film and composition thereof, and film, organic light-emitting device and encapsulation method

PendingUS20220259352A1Enhanced water vapor transmission rateImprove flatnessSilicon organic compoundsSolid-state devicesOrganic light emitting devicePropenyl

A compound for an encapsulation film and a composition thereof, a film, an organic light-emitting device, and an encapsulation method are provided. The compound has the structure shown in formula 1, and the composition comprises the compound, one or more photocurable and thermocurable propenyl compounds, and one or more compounds that produce a free radical and produce an acid under light or heat. The encapsulation film includes the composition as a film of an organic layer. The organic light-emitting device includes the film. The encapsulation method involves encapsulating the organic light-emitting device using the encapsulation film. The composition containing the compound serves as an organic layer. An encapsulation film for the organic light-emitting device is manufactured by repetitively and alternately laminating an inorganic layer and the organic layer.

Owner:JILIN OPTICAL & ELECTRONICS MATERIALS

A kind of preparation method of liquid band-aid

The invention discloses a preparation method of a liquid band-aid, comprising: dispersing a block polymer composed of a non-polar segment and a polar segment into a mixed solvent composed of a non-polar solvent and a polar solvent to prepare a polymerized Thickener solution; disperse the thickener into a mixed solvent composed of non-polar solvent and polar solvent to make a thickener solution; add the thickener solution into the polymer solution, then add the bacteriostat, and mix evenly Afterwards, it is made into a liquid band-aid. The preparation method of the present invention is simple in process, and compared with traditional band-aids, the prepared liquid band-aids have the advantages of simple and convenient use, and are not limited by the size and position of the wound. High water vapor transmission rate and good water resistance provide a moist and sterile environment for the wound, better promote wound healing and shorten the healing time.

Owner:绍兴百立盛新材料科技有限公司

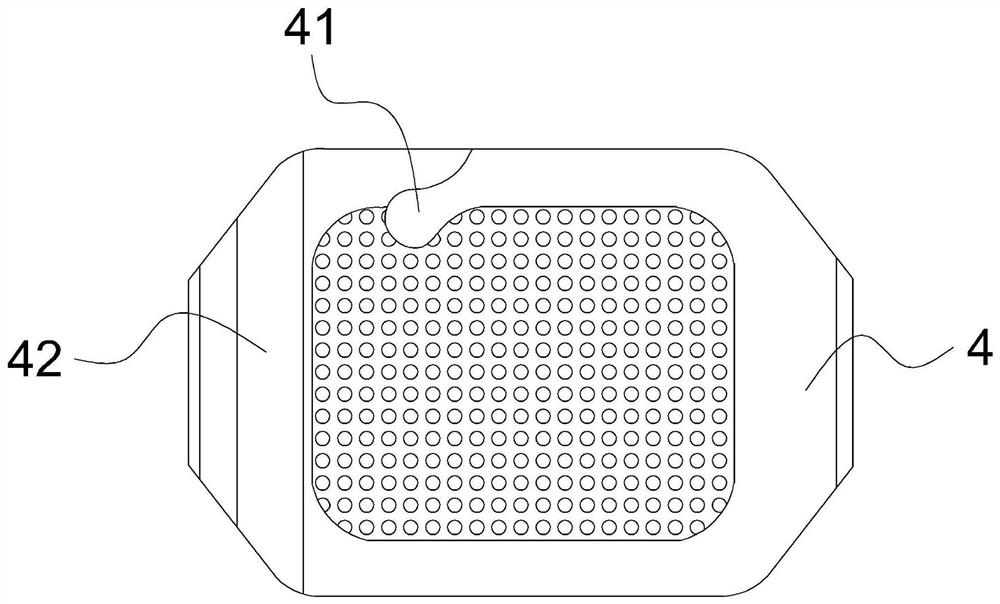

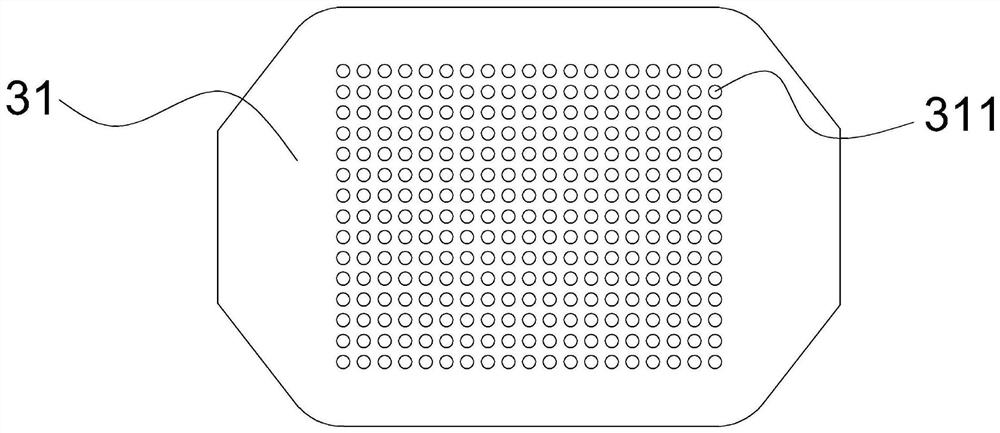

A waterproof and breathable cast film composite material and its preparation method

The invention discloses a waterproof and breathable casting film composite material and a preparation method thereof, which is prepared from the following components in parts by weight: 42-47 parts of metallocene polyethylene, 3-8 parts of high-pressure polyethylene, and 45-55 parts of inorganic filler 0.1-1 part of antioxidant, 0.5-1 part of lubricant and 0.2-1 part of coupling agent are prepared by mixing, extruding and granulating. The preparation process of the present invention is simple and the cost is low. The prepared waterproof and breathable cast film composite material is combined with the cast film processing technology, and it is easier to produce a cast film with waterproof and breathable functions, and the produced cast film is light and thin, Soft touch, high tensile strength, good puncture resistance; and the casting film made of this composite material has a high water vapor transmission rate, exceeding 2000g / ㎡ / 24h; it is suitable as the back material of diapers, sanitary napkins, etc. It can not only improve the user's comfort but also ensure breathability.

Owner:合肥纳仕捷新能源科技有限公司

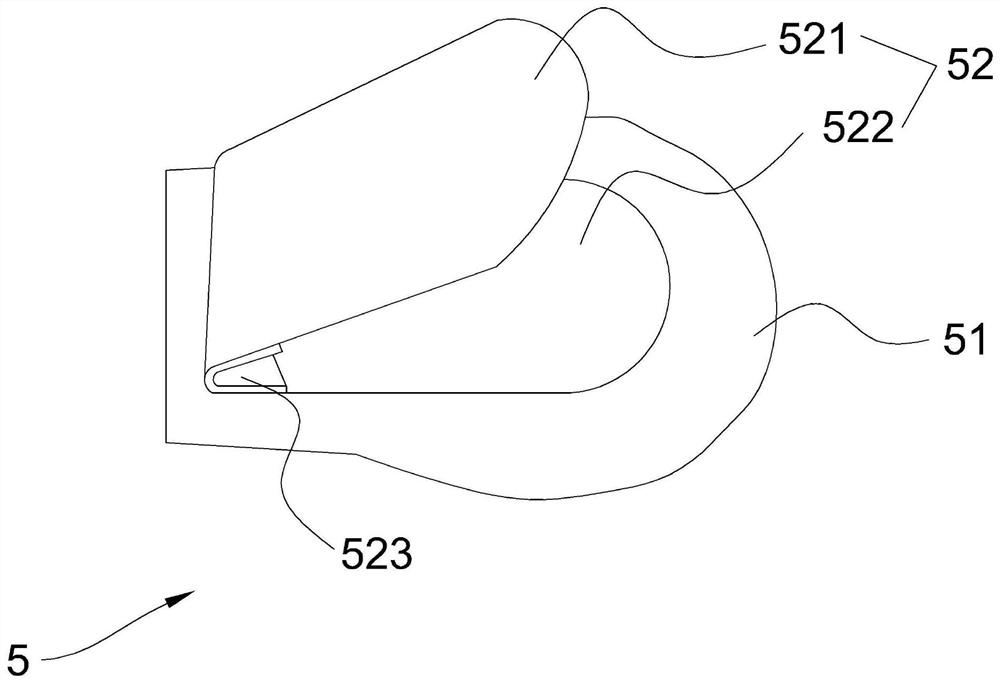

Breathable polyurethane fixing film

ActiveCN113604163AEnhanced water vapor transmission rateLess discomfortPressure sensitive film/foil adhesivesFilm/foil adhesive release linersPolymer scienceAdhesive

The invention discloses a breathable polyurethane fixing film. The breathable polyurethane fixing film comprises a paper frame layer, a polyurethane layer, an adhesive layer and a release layer which are sequentially arranged; the polyurethane layer is a hydrophilic high-moisture-permeability polyurethane film, the adhesive layer is a pressure-sensitive adhesive, through holes are formed in the pressure-sensitive adhesive, and the aperture of each through hole is 1-3 mm; the preparation method of the hydrophilic high-moisture-permeability polyurethane film comprises the following steps: a) preparing a polyurethane prepolymer A, b) preparing a polyurethane prepolymer B, and c) coating the release layer with the polyurethane prepolymer B, and drying the release layer in a tunnel drying oven at the drying temperature of 60-150 DEG C to prepare the hydrophilic high-moisture-permeability polyurethane film with the thickness of 15-25 microns. According to the breathable polyurethane fixing film, the paper frame layer, the polyurethane layer, the adhesive layer and the release layer are arranged in a matched mode, meanwhile, the polyurethane layer with high breathability is prepared, the higher water vapor permeability is achieved, the film is softer and more comfortable, the film is soft and breathable when being attached to the skin, and the comfort of a patient is improved.

Owner:浙江敷茂生物科技有限公司

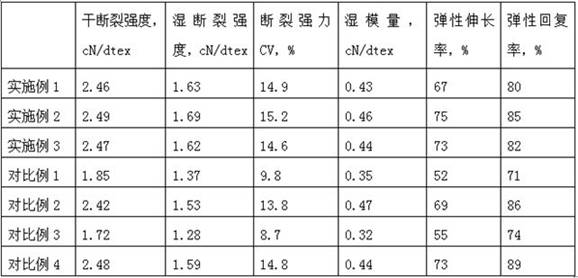

A kind of preparation method of cellulose viscose and its application in cellulose casing

ActiveCN114517338BImprove toughnessHigh strengthArtificial filaments from viscoseTextile/flexible product manufactureCellulosePolymer science

The invention discloses a preparation method of cellulose viscose and its application in cellulose casing, belonging to the technical field of viscose fibers. The preparation method of cellulose viscose includes preparing a viscose solution, modifying the viscose solution , spinning and post-processing; the application of the cellulose viscose in the cellulose casing includes weaving, shaping, primary drying, washing and setting, and secondary drying; the present invention can improve the toughness and antistatic properties of the cellulose casing. While improving the spinnability, the water vapor transmission rate, wet modulus, dimensional stability, elasticity, abrasion resistance and acid and alkali resistance of cellulose casing are improved.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

Adhesive base material, adhesive tape with same and preparation method

InactiveCN109266233BMedium Oxygen Transmission RateEnhanced water vapor transmission rateMacromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer scienceAdhesive belt

The invention provides an adhesive tape base material, an adhesive tape having the same and a preparation method. The tape base material includes a continuous phase and a dispersed phase dispersed in the continuous phase, the material of the continuous phase is L-polylactic acid, and the material of the dispersed phase is a toughening filler and a dispersant, wherein by weight, the L-polylactic acid is 55 to 95 parts, 0.25 to 2.5 parts of toughening filler, and 0.25 to 2.5 parts of dispersant. Since raw materials such as L-polylactic acid are biodegradable, the environmental pollution caused by the tape with this substrate is reduced, and by limiting the ratio of the above components, the tape substrate can have a moderate oxygen transmission rate As well as high water vapor transmission rate, it can be used to realize the encapsulation of agricultural products.

Owner:北京众邦健业印刷有限责任公司

A kind of degradable plastic wrap and its preparation method and application

ActiveCN113354930BEnhanced water vapor transmission rateImprove moisture resistanceFlexible coversWrappersPolymer sciencePolyethylene glycol

The invention belongs to the technical field of composite materials, and in particular relates to a degradable plastic wrap and its preparation method and application. The invention provides a degradable plastic wrap, which comprises a polylactic acid base film, polyethylene glycol and chitosan-caffeic acid graft copolymer contained in the polylactic acid base film. In the present invention, the chitosan-caffeic acid graft copolymer can destroy the dense structure of polylactic acid, thereby improving the air permeability of the degradable plastic wrap, and then improving the moisture resistance of the degradable plastic wrap, and inhibiting the growth of edible fungi in the degradable fresh-keeping film. The quality deterioration under the packaging of the film prolongs the shelf life of the edible fungi. In the present invention, the polylactic acid as a base material has good biocompatibility and degradability, and the present invention uses polylactic acid as a base material to make the degradable fresh-keeping film degradable.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com