EVA hot melt adhesive film for wall covering and preparation method thereof

A hot-melt adhesive film and hot-melt adhesive technology, used in adhesives, films/sheets without carriers, monocarboxylate copolymer adhesives, etc., can solve the problems of high technical requirements and difficult work for laminating workers , to achieve the effect of improving water vapor transmission rate, improving water blocking performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

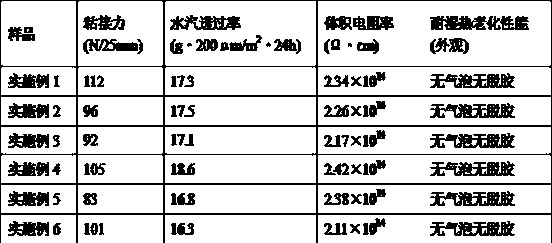

Examples

Embodiment 1

[0031] 40 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 33wt% and a melting peak temperature of 70°C, and 25 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer with a graft rate of 1.1wt% 25 parts of ethylene-acrylic acid copolymer with AA content of 9.5wt% and peak melting temperature of 97°C, 10 parts of polyolefin copolymer with melt index of 30g / 10min (190°C / 2.16kg) and peak melting temperature of 58°C material, 5 parts of terpene resin, 0.5 part of thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] mixed with a high-speed mixer, and extruded Extrude and granulate at 110°C. After drying, put the hot-melt rubber granules into the casting machine, melt and plasticize at 95°C, and make a film with a thickness of 0.2mm EVA hot melt adhesive film.

Embodiment 2

[0033] 50 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 33wt% and a melting peak temperature of 70°C, and 30 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer with a graft rate of 1.3wt% 10 parts of ethylene-acrylic acid copolymer with AA content of 9.5wt% and peak melting temperature of 97°C, 10 parts of polyolefin copolymer with melt index of 30g / 10min (190°C / 2.16kg) and peak melting temperature of 58°C , 10 parts of C9 petroleum resin, 0.8 parts of dioctadecyl pentaerythritol bisphosphite are mixed with a high-speed mixer, extruded and granulated with an extruder at 150 ° C, and after drying, the hot melt rubber particles are put into Casting machine, melting and plasticizing under the condition of 120 ℃, through the process of extrusion, stretching, traction and winding, the EVA hot-melt adhesive film with a film thickness of 0.2mm is obtained.

Embodiment 3

[0035] 60 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 33wt% and a melting peak temperature of 70°C, and 20 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer with a graft rate of 2.1wt% 10 parts of ethylene-acrylic acid copolymer with AA content of 9.5wt% and peak melting temperature of 97°C, 10 parts of polyolefin copolymer with melt index of 30g / 10min (190°C / 2.16kg) and peak melting temperature of 58°C , 20 parts of C9 petroleum resin, 0.2 parts of 3,5-di-tert-butyl-4-hydroxybenzyl diethylphosphonate are mixed with a high-speed mixer, extruded and granulated with an extruder at 120°C, and dried After the treatment, put the hot-melt rubber particles into the casting machine, melt and plasticize at 103°C, and go through the processes of extrusion, stretching, traction, and winding to obtain an EVA hot-melt adhesive film with a film thickness of 0.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting peak temperature | aaaaa | aaaaa |

| Melting peak temperature | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com