A kind of degradable plastic wrap and its preparation method and application

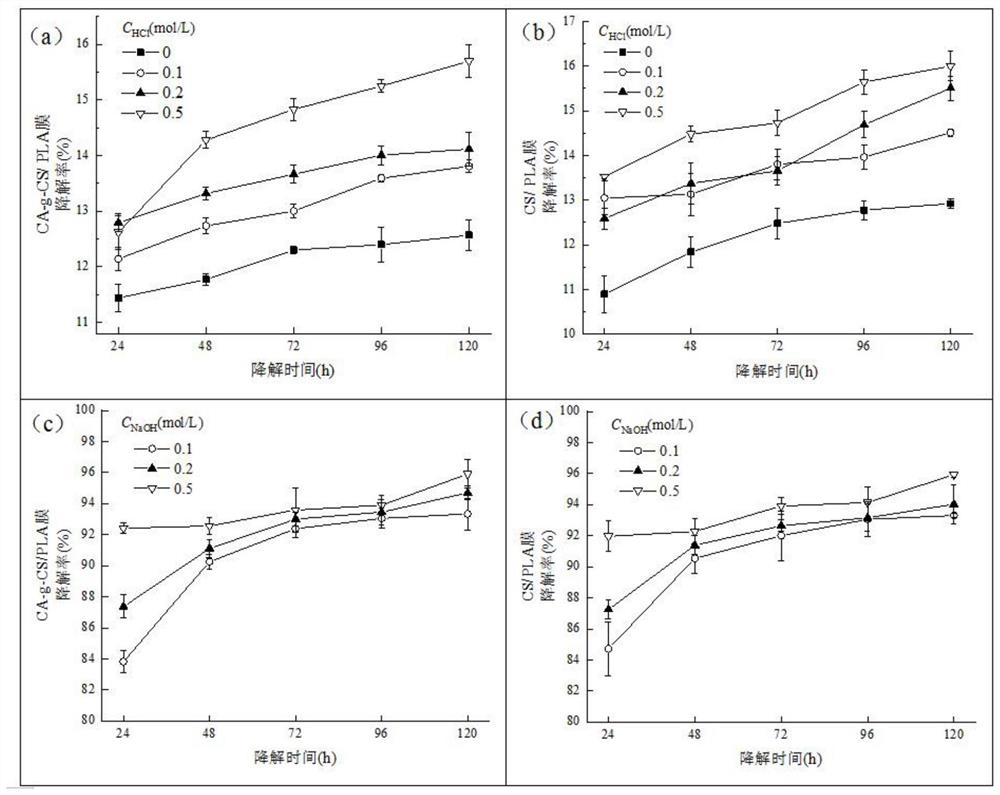

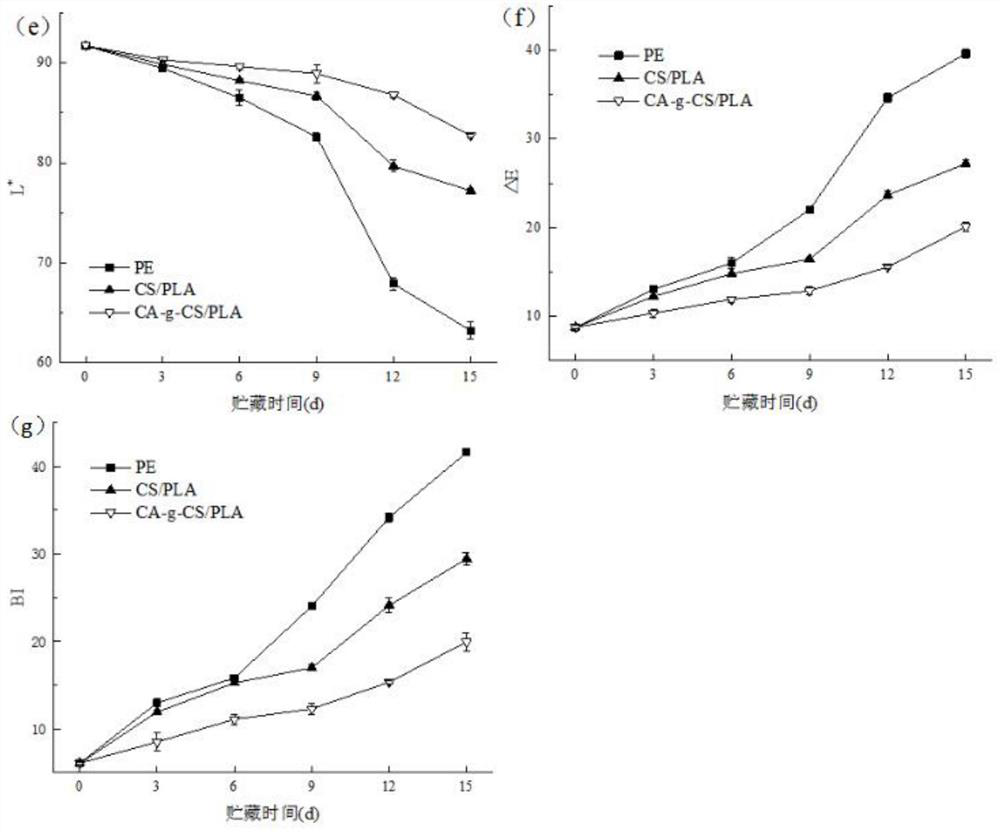

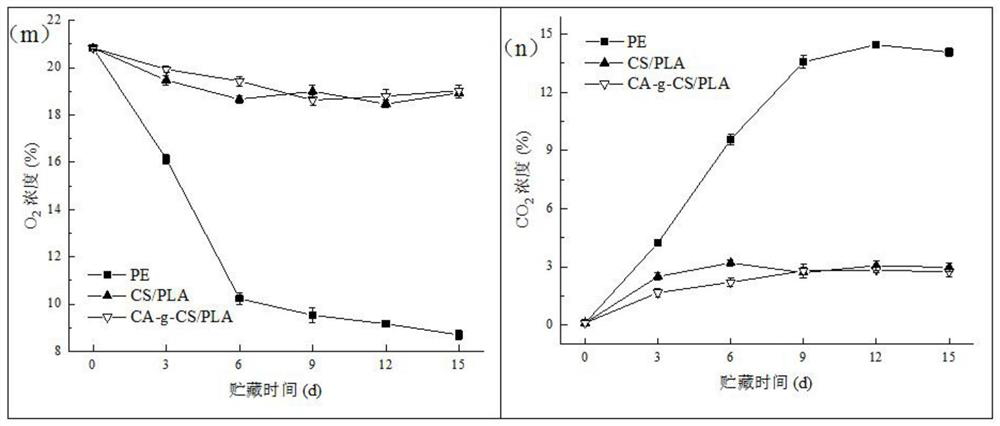

A technology of fresh-keeping film and polylactic acid-based film, which is applied in the field of degradable fresh-keeping film and its preparation, and can solve the problems of lack of moisture resistance, poor fresh-keeping effect, difficult to degrade and recycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of the degradable plastic wrap described in the above technical solution, comprising the following steps:

[0055] Chitosan-caffeic acid graft copolymer and polyethylene glycol blend are dissolved in chloroform to obtain a blend solution;

[0056] Polylactic acid is dissolved in chloroform to obtain a polylactic acid solution;

[0057] adding the blended solution to the polylactic acid solution to obtain a coating solution;

[0058] The coating liquid is formed into a film to obtain the degradable fresh-keeping film.

[0059] In the invention, the chitosan-caffeic acid graft copolymer and the polyethylene glycol blend are dissolved in chloroform to obtain a blend solution. In the present invention, the preparation method of the blend of described chitosan-caffeic acid graft copolymer and polyethylene glycol, preferably comprises the following steps:

[0060] Chitosan-caffeic acid graft copolymer, polyethylene g...

Embodiment 1

[0084] With 0.50g chitosan (2.61mmol) and 1.06g1-hydroxybenzotriazole (7.83mmol) dissolving (600r / min stirring 20h under rotating speed) in 50mL volume concentration is 2% acetic acid aqueous solution, obtains chitosan solution;

[0085] Dissolve 0.61712g caffeic acid (7.83mmol) (37kHz ultrasound 20min) in 2mL absolute ethanol to obtain caffeic acid ethanol solution; Amine hydrochloride was dissolved (37kHz ultrasound 20min) in 2mL absolute ethanol to obtain 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride ethanol solution; the caffeic acid ethanol solution And 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride ethanol solution is added dropwise in the chitosan solution according to the dropping rate of 60 drops / min, in dark (with tin foil Paper wrapped reactor) under the conditions of coupling reaction 24h; the coupling reaction product 10000r / min centrifugal 15min, get the supernatant; add 2mL of 11mol / L hydrochloric acid solution to mix and then dialyze...

Embodiment 2

[0093] Prepare chitosan-caffeic acid graft copolymer according to the method of embodiment 1;

[0094] 0.2g chitosan-caffeic acid graft copolymer was dissolved (37kHz ultrasonic 30min) in 20mL ultrapure water to obtain a copolymer solution; 0.5g molecular weight was 8000 polyethylene glycol dissolved (600r / min magnetic stirring 30min) In 25mL of ultrapure water, polyethylene glycol solution was obtained; the copolymer solution and polyethylene glycol solution were magnetically stirred at 25°C for 1 hour to obtain an aqueous solution of chitosan-caffeic acid graft copolymer and polyethylene glycol;

[0095] The aqueous solution of chitosan-caffeic acid graft copolymer and polyethylene glycol was magnetically stirred at 90°C for water evaporation until the solution was viscous and then dried at 60°C for 12 hours; the dried product was soaked in liquid nitrogen for 10 minutes and placed in Grinding in a mixed ball mill; pass the ground product through a 150-mesh sieve, and take t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com