A kind of preparation method of cellulose viscose and its application in cellulose casing

A technology of cellulose viscose and cellulose casing, applied in the field of viscose fiber, can solve the problems of poor elongation at break and dimensional stability, poor dimensional stability and wear resistance, poor elasticity and wear resistance, etc., and achieve water vapor High transmittance, high dimensional stability, and the effect of improving spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

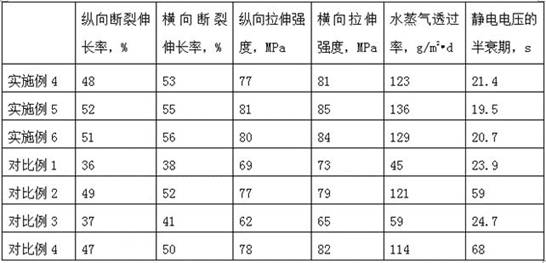

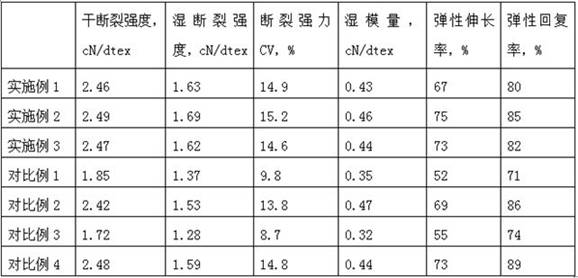

Examples

Embodiment 1

[0061] A preparation method of cellulose viscose, specifically:

[0062] 1. Prepare the viscose solution:

[0063] (1) Impregnation: soak the cotton pulp in alkaline solution, control the soaking temperature to 25°C, and soak the soaking time to 2.5h to obtain soaked cotton pulp;

[0064] The degree of polymerization of the cotton pulp is 650, and the content of methyl fiber is 95.5%.

[0065] The weight ratio of the cotton pulp to the lye is 1:1.5;

[0066] The composition of the alkaline solution, in parts by weight, includes: 100 parts of deionized water, 20 parts of sodium hydroxide, 3 parts of potassium phosphate, and 2 parts of aliphatic alcohol polyoxyethylene ether sodium sulfate.

[0067] (2) Pulverization: After the soaked cotton pulp is squeezed out of the lye by the press, it is sent to the pulverizer and pulverized to 100 mesh to obtain the pressed cotton pulp;

[0068] (3) Aging: The cotton pulp after pressing is subjected to aging treatment, the temperature o...

Embodiment 2

[0091] A preparation method of cellulose viscose, specifically:

[0092] 1. Prepare the viscose solution:

[0093] (1) Impregnation: soak the cotton pulp in alkali solution, control the soaking temperature to 30°C, and soak the soaking time to 2.7h to obtain soaked cotton pulp;

[0094] The degree of polymerization of the cotton pulp is 700, and the content of methyl fiber is 96%.

[0095] The weight ratio of the cotton pulp to the lye is 1:1.7;

[0096] The composition of the alkaline solution, in parts by weight, includes: 105 parts of deionized water, 22 parts of sodium hydroxide, 4 parts of potassium phosphate, and 3 parts of aliphatic alcohol polyoxyethylene ether sodium sulfate.

[0097] (2) Pulverization: After the soaked cotton pulp is squeezed out of the lye by the press, it is sent to the pulverizer and pulverized to 110 mesh to obtain the pressed cotton pulp;

[0098] (3) Aging: The cotton pulp after pressing is subjected to aging treatment, the temperature of th...

Embodiment 3

[0121] A preparation method of cellulose viscose, specifically:

[0122] 1. Prepare the viscose solution:

[0123] (1) Impregnation: soak the cotton pulp in the lye solution, control the soaking temperature to 35°C, and soak the soaking time to 3h to obtain the soaked cotton pulp;

[0124] The degree of polymerization of the cotton pulp is 750, and the content of methyl fiber is 97%.

[0125] The weight ratio of the cotton pulp to the lye is 1:1.8;

[0126] The composition of the alkaline solution, in parts by weight, includes: 110 parts of deionized water, 25 parts of sodium hydroxide, 5 parts of potassium phosphate, and 5 parts of fatty alcohol polyoxyethylene ether sodium sulfate.

[0127] (2) Pulverization: After the soaked cotton pulp is squeezed out of the lye by the press, it is sent to the pulverizer and pulverized to 120 mesh to obtain the pressed cotton pulp;

[0128] (3) Aging: The cotton pulp after pressing is subjected to the aging treatment, the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com