Breathable polyurethane fixing film

A polyurethane film and polyurethane technology, which is applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet adhesive, etc., can solve the problem of poor moisture permeability and air permeability of fixed film, and poor air permeability Poor performance, skin redness and itching, etc., to reduce discomfort, reduce the area of glue application, and reduce allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

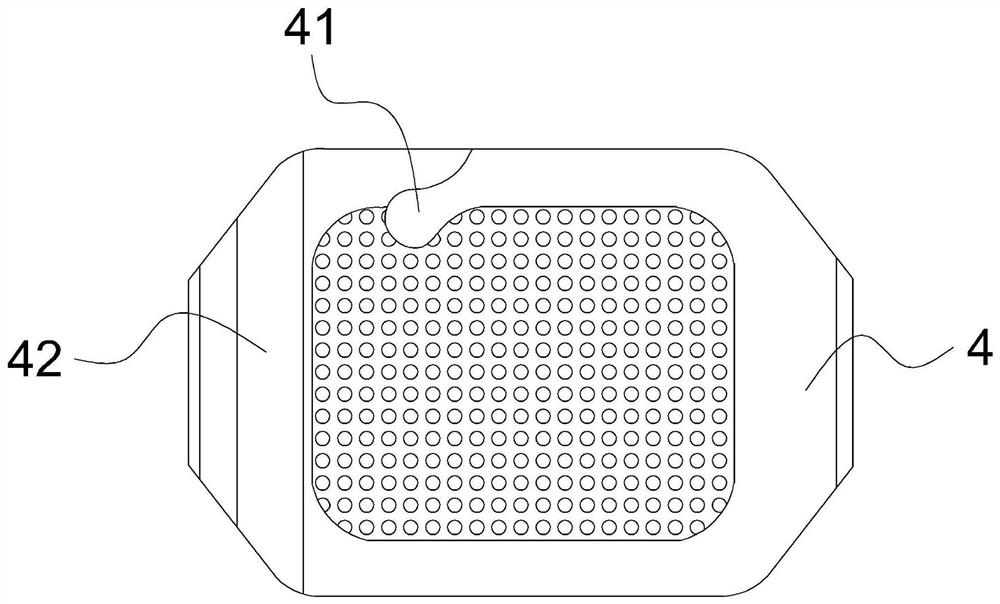

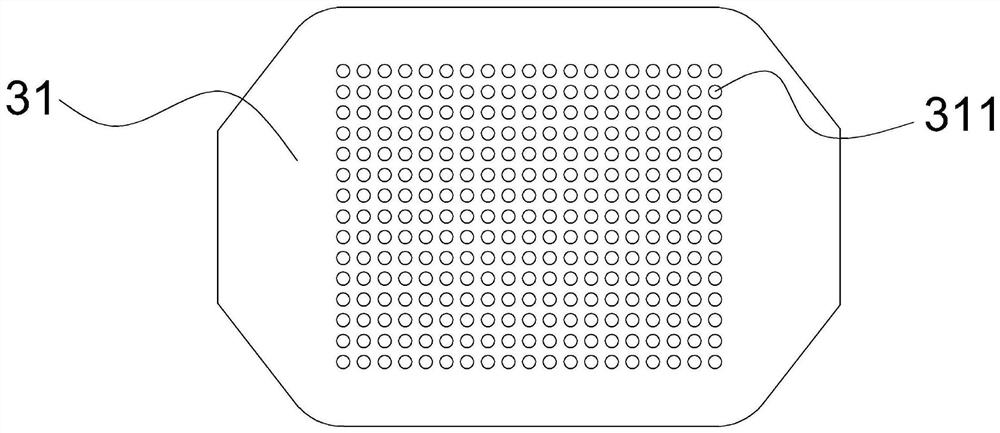

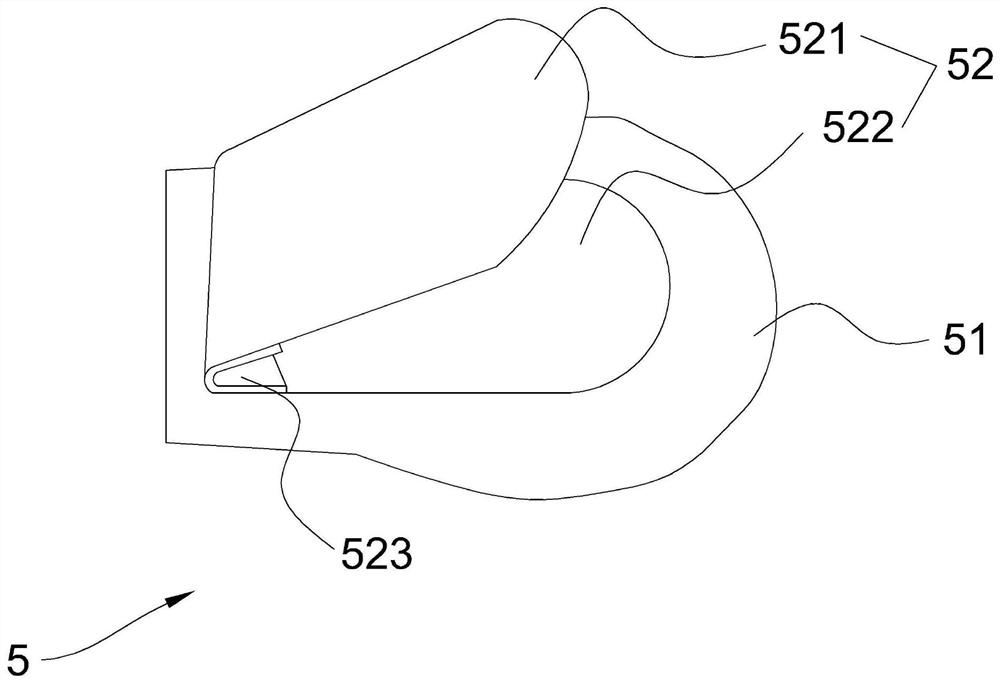

[0057] Such as Figures 1 to 4 As shown, the present invention provides a breathable polyurethane fixed film, comprising a paper frame layer 1, a polyurethane layer 2, an adhesive layer 3 and a release layer 4 arranged in sequence;

[0058] The polyurethane layer 2 is a hydrophilic and highly moisture-permeable polyurethane film, the adhesive layer 3 is a pressure-sensitive adhesive 31, and the pressure-sensitive adhesive 31 is provided with a through hole 311, and the diameter of the through hole 311 is 1- 3mm;

[0059] The preparation method of the hydrophilic high moisture-permeable polyurethane film comprises the following steps:

[0060] a) Prepare polyurethane prepolymer A, prepare by following proportioning and process:

[0061] 30-60 parts of toluene diisocyanate;

[0062] 5-50 parts of polyethylene glycol;

[0063] 0.01 to 30 parts of polypropylene glycol;

[0064] 0.01 to 5 parts of glycerol;

[0065] 0.01 to 5 parts of 1,4-butanediol;

[0066] 0.01 to 5 parts...

Embodiment 2

[0076] Such as Figures 1 to 4 As shown, the present invention provides a breathable polyurethane fixed film, comprising a paper frame layer 1, a polyurethane layer 2, an adhesive layer 3 and a release layer 4 arranged in sequence;

[0077] The polyurethane layer 2 is a hydrophilic and highly moisture-permeable polyurethane film, the adhesive layer 3 is a pressure-sensitive adhesive 31, and the pressure-sensitive adhesive 31 is provided with a through hole 311, and the diameter of the through hole 311 is 1- 3mm;

[0078] The preparation method of the hydrophilic high moisture-permeable polyurethane film comprises the following steps:

[0079] a) Prepare polyurethane prepolymer A, prepare by following proportioning and process:

[0080] 40 parts of toluene diisocyanate;

[0081] 50 parts of polyethylene glycol;

[0082] 4.5 parts of polypropylene glycol;

[0083] 3 parts of glycerol;

[0084] 2 parts of 1,4-butanediol;

[0085] 0.5 part of triethanolamine;

[0086] Put ...

Embodiment 3

[0104] A breathable polyurethane fixed film, the difference from Example 2 is that the polyurethane prepolymer A is prepared in step a), prepared according to the following proportioning and process:

[0105] 40 parts of toluene diisocyanate;

[0106] 45 parts of polyethylene glycol;

[0107] 9.5 parts of polypropylene glycol;

[0108] 4.5 parts of glycerol;

[0109] 0.5 parts of 1,4-butanediol;

[0110] 0.5 part of triethanolamine;

[0111] Put the above raw materials into the reaction kettle, the reaction temperature is 60°C-90°C, the reaction time is 80-180min, and the polyurethane prepolymer A is prepared through polymerization reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com