Antibacterial gas-permeable membrane and preparation method thereof

A breathable film and antibacterial agent technology, applied in the field of antibacterial breathable film and its preparation, can solve the problems of poor antibacterial and bacteriostatic effect, poor comprehensive performance of breathable film, leakage of liquid water, etc., and achieves good antibacterial and bacteriostatic effect, water vapor High transmittance and high hydrostatic pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

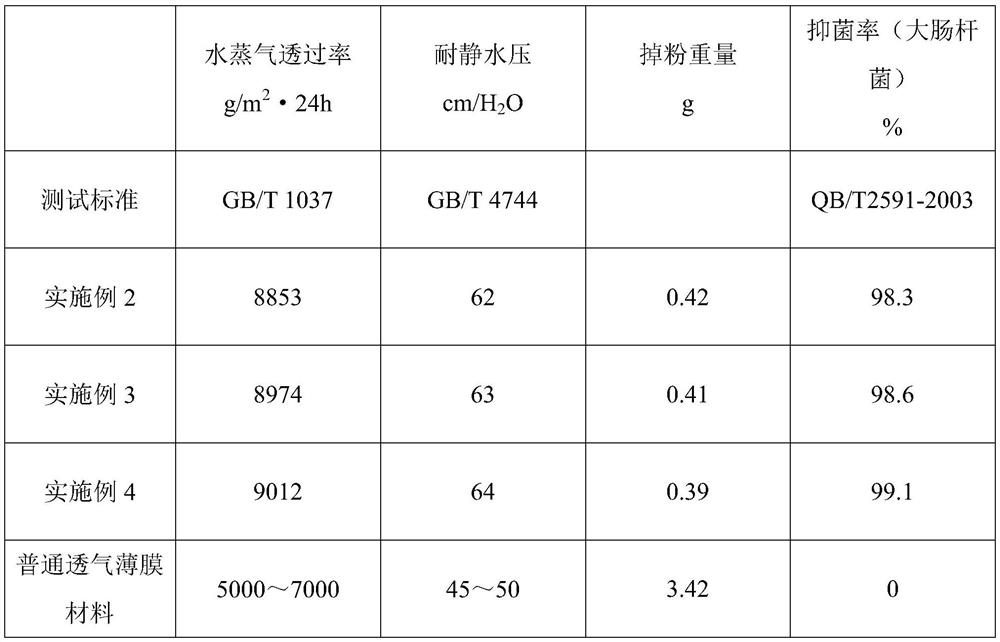

Examples

Embodiment 1

[0059] An antibacterial breathable film, comprising the following raw materials in parts by weight:

[0060] Polyethylene 62~72 parts,

[0061] 13-17 parts of ethylene-vinyl alcohol copolymer,

[0062] 8-12 parts of polylactic acid,

[0063] 5-7 parts of maleic anhydride grafted polyethylene,

[0064] 3-4 parts of light calcium carbonate,

[0065]3-4 parts of heavy calcium carbonate,

[0066] 2 to 3 parts of nanoporous silica,

[0067] 1.5-2.5 parts of sepiolite powder,

[0068] 1.3-1.6 parts of antibacterial agent,

[0069] 1.4-1.8 parts of coupling agent,

[0070] 2 to 4 parts of stearate,

[0071] Surfactant 1.2~1.4 parts,

[0072] 2 to 3 parts of dispersant.

[0073] In this embodiment, the antibacterial breathable film preferably but not limited to includes the following raw materials in parts by weight:

[0074] Polyethylene 67 parts,

[0075] 15 parts of ethylene-vinyl alcohol copolymer,

[0076] 10 parts of polylactic acid,

[0077] 6 parts of maleic anhy...

Embodiment 2

[0099] An antibacterial breathable film, comprising the following raw materials in parts by weight:

[0100] Polyethylene 62 parts,

[0101] 13 parts of ethylene-vinyl alcohol copolymer,

[0102] 8 parts of polylactic acid,

[0103] 5 parts of maleic anhydride grafted polyethylene,

[0104] 3 parts of light calcium carbonate,

[0105] 3 parts of heavy calcium carbonate,

[0106] Nanoporous silica 2 parts,

[0107] 1.5 parts of sepiolite powder,

[0108] 1.3 parts of antibacterial agent,

[0109] 1.4 parts of coupling agent,

[0110] 2 parts stearate,

[0111] Surfactant 1.2 parts,

[0112] 2 parts of dispersant.

[0113] In the present embodiment, the preparation method of the antibacterial breathable film comprises the following steps:

[0114] A. Inorganic powder activation treatment: Put nanoporous silica and sepiolite powder into a high-speed mixer, dehydrate at a speed of 500r / min and a temperature of 110°C for 14min; then cool down to 40°C, add an antibacteria...

Embodiment 3

[0125] An antibacterial breathable film, comprising the following raw materials in parts by weight:

[0126] Polyethylene 72 parts,

[0127] 17 parts of ethylene-vinyl alcohol copolymer,

[0128] 12 parts of polylactic acid,

[0129] 7 parts of maleic anhydride grafted polyethylene,

[0130] 4 parts of light calcium carbonate,

[0131] 4 parts of heavy calcium carbonate,

[0132] Nanoporous silica 3 parts,

[0133] 2.5 parts of sepiolite powder,

[0134] 1.6 parts of antibacterial agent,

[0135] 1.8 parts of coupling agent,

[0136] 4 parts stearate,

[0137] Surfactant 1.4 parts,

[0138] 3 parts of dispersant.

[0139] In the present embodiment, the preparation method of the antibacterial breathable film comprises the following steps:

[0140] A. Inorganic powder activation treatment: Put nanoporous silica and sepiolite powder into a high-speed mixer, dehydrate at a speed of 700r / min and a temperature of 140°C for 8 minutes; then cool down to 50°C, add an antibac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com