Adhesive tape and its manufacturing method

A technology of adhesive tape and adhesive sheet, which is applied in the direction of adhesive heating, adhesive method using foam adhesive, adhesive type, etc., which can solve the limitation of water vapor transmission rate, The adhesive tape has no problems such as air permeability and difficulty in expelling sweat, and achieves excellent water vapor transmission rate, increased water vapor transmission rate, and improved foaming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] According to an exemplary embodiment of the present invention, the substrate may be formed of organic fiber or inorganic fiber material fabric, paper, or the like.

[0027] According to an exemplary embodiment of the present invention, the adhesive tape can secure a high water vapor transmission rate through a porous structure including holes.

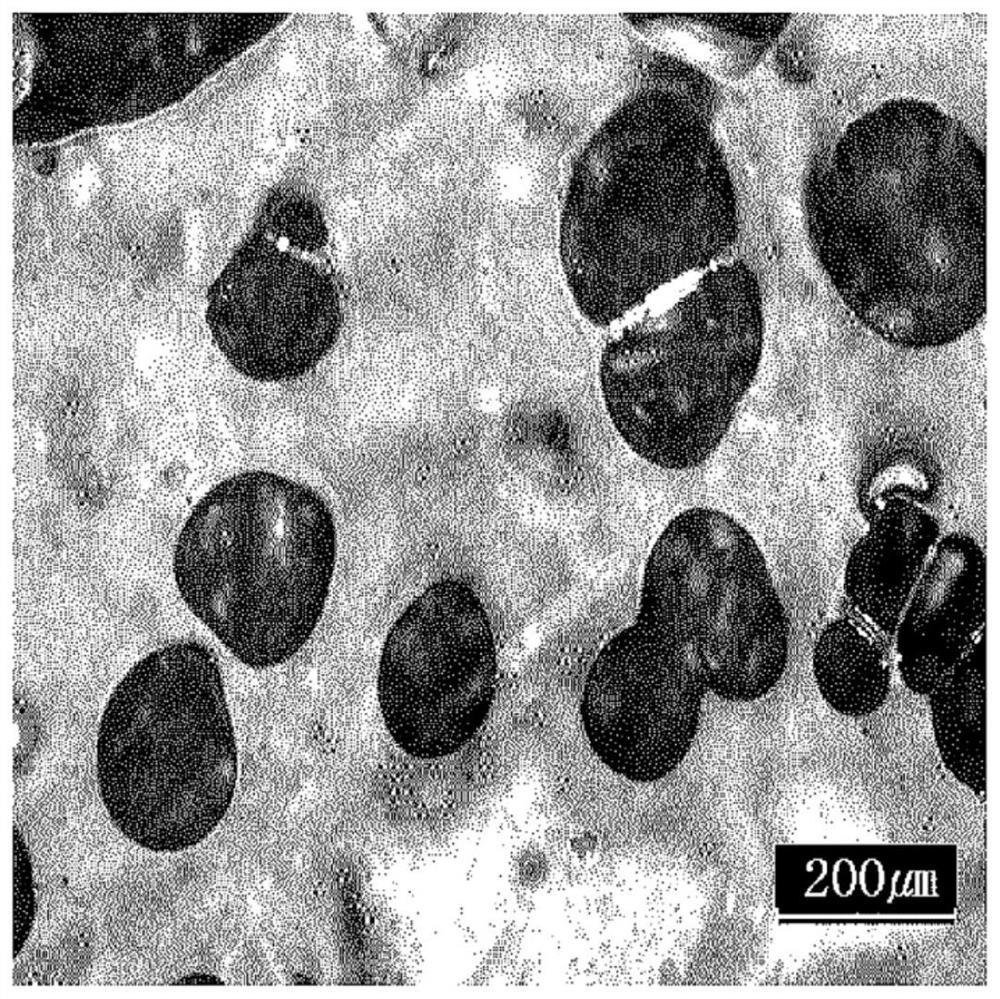

[0028] According to an exemplary embodiment of the present invention, the porous structure may include a plurality of pores, and the plurality of pores may be classified into, for example, two forms of closed pores or open pores.

[0029] According to an exemplary embodiment of the present invention, the porous structure may be a structure including any one of closed cells and open cells, or a structure including both closed cells and open cells. A closed cell is a cell formed by a structure in which the wall surface of the cell is completely closed, and thus is not connected to other cells, also called a closed cell. An open c...

Embodiment approach

[0082] Hereinafter, the present invention will be described in detail with reference to Examples for specifically describing the present invention. However, the embodiments according to the present invention can be modified in various forms, and it should not be construed that the scope of the present invention is limited to the embodiments to be described below. The embodiments of this specification are provided to more fully explain the present invention to those skilled in the art.

Embodiment

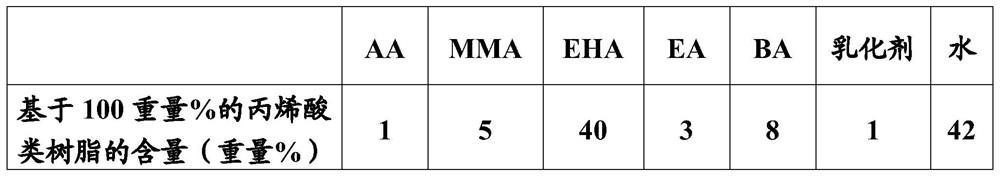

[0084] Acrylic acid (AA), methyl (meth)acrylate (MMA), ethylhexyl acrylate (EHA), ethyl acrylate (EA), butyl acrylate (BA), water and poly(ethylene glycol) nonyl Copolymerize with tetraammonium phenylsulfate emulsifier to obtain acrylic resin with weight average molecular weight of 10,000,000g / mol. The contents of the various components are shown in [Table 1] below.

[0085] [Table 1]

[0086]

[0087] A water-based acrylic adhesive composition was prepared, which included 0.9 parts by weight of p,p'-oxybis(benzenesulfonyl hydrazide) as a blowing agent based on 100 parts by weight of acrylic resin, 1.2 parts by weight of N,N-dimethyllaurylamine oxide as a surfactant, and 35 parts by weight of zinc oxide based on 100 parts by weight of acrylic acid as a curing agent.

[0088] After the adhesive composition is applied to the release film formed by the PET material, it is carried out at the first temperature (T1), the second temperature (T2), the third temperature (T3) and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com