Preparation method for sealing adhesive for paper packaging

A sealing adhesive and packaging technology, applied in the field of sealing adhesive, can solve the problems of unfavorable processing, short initial bonding time, low viscosity of sealing adhesive, etc., and achieve the effect of strong adhesion and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

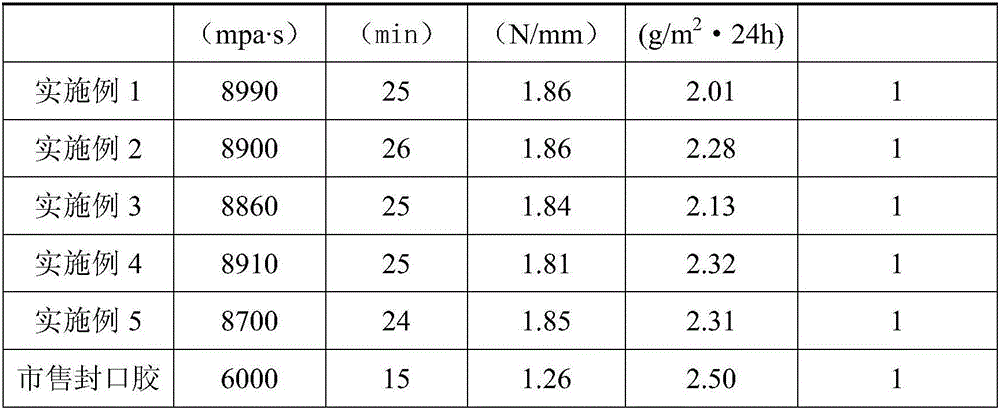

Embodiment 1

[0020] A method for preparing a sealant for paper product packaging, comprising the following steps: in parts by weight, 35 parts of modified epoxy resin, 45 parts of ethylene-vinyl acetate copolymer, 10 parts of polypropylene, polybutadiene 12 parts, 4 parts of ethylene glycol glycidyl ether, 3 parts of curing agent, 4 parts of curing accelerator, 4 parts of organic solvent, 3 parts of antioxidant, after mixing evenly, transfer to the three-roll machine, grind 2 times, and filter through the filter , vacuum degassing for 15 minutes, to obtain;

[0021] The preparation method of the described modified epoxy resin is as follows: by weight, 10 parts of bisphenol A, 4 parts of m-trifluoromethylphenol, 12 parts of epichlorohydrin and 15 parts of hydroxymalonic acid and epichlorohydrin Mix 90 parts of the alkali metal hydroxide aqueous solution evenly, heat to 50°C, and react for 8 hours. After the reaction, wash with water and dry to obtain the modified epoxy resin.

Embodiment 2

[0023] A method for preparing a sealant for paper product packaging, comprising the following steps: by weight, 40 parts of modified epoxy resin, 45 parts of ethylene-vinyl acetate copolymer, 10 parts of polypropylene, polybutadiene 13 parts, 5 parts of ethylene glycol glycidyl ether, 4 parts of curing agent, 4 parts of curing accelerator, 6 parts of organic solvent, and 3 parts of antioxidant, after mixing evenly, transfer to a three-roll machine, grind 2 times, and filter , vacuum degassing for 16 minutes, to obtain;

[0024] The preparation method of the described modified epoxy resin is as follows: by weight, 12 parts of bisphenol A, 4 parts of m-trifluoromethylphenol, 13 parts of epichlorohydrin and 20 parts of hydroxymalonic acid and epichlorohydrin Mix 100 parts of the aqueous solution of alkali metal hydroxide evenly, heat to 60°C, and react for 9 hours. After the reaction, wash with water and dry to obtain the modified epoxy resin.

Embodiment 3

[0026] A method for preparing a sealant for paper product packaging, comprising the following steps: in parts by weight, 40 parts of modified epoxy resin, 50 parts of ethylene-vinyl acetate copolymer, 11 parts of polypropylene, polybutadiene 14 parts, 6 parts of ethylene glycol glycidyl ether, 5 parts of curing agent, 5 parts of curing accelerator, 9 parts of organic solvent, and 3 parts of antioxidant, after mixing evenly, transfer to a three-roll machine, grind 2 times, and filter through a filter , evacuated and degassed for 18 minutes to obtain;

[0027] The preparation method of the described modified epoxy resin is as follows: by weight, 15 parts of bisphenol A, 5 parts of m-trifluoromethylphenol, 14 parts of epichlorohydrin and 25 parts of hydroxymalonic acid and epichlorohydrin Mix 120 parts of alkali metal hydroxide aqueous solution evenly, heat to 70°C, and react for 10 hours. After the reaction, wash with water and dry to obtain the modified epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com