Adhesive tape base material, adhesive tape provided with same and preparation method

A tape and base material technology, which is applied in the direction of adhesives, film/sheet adhesives, N-vinylpyrrolidone copolymer adhesives, etc., can solve the problems of tape non-degradability and poor moisture permeability, etc., to reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

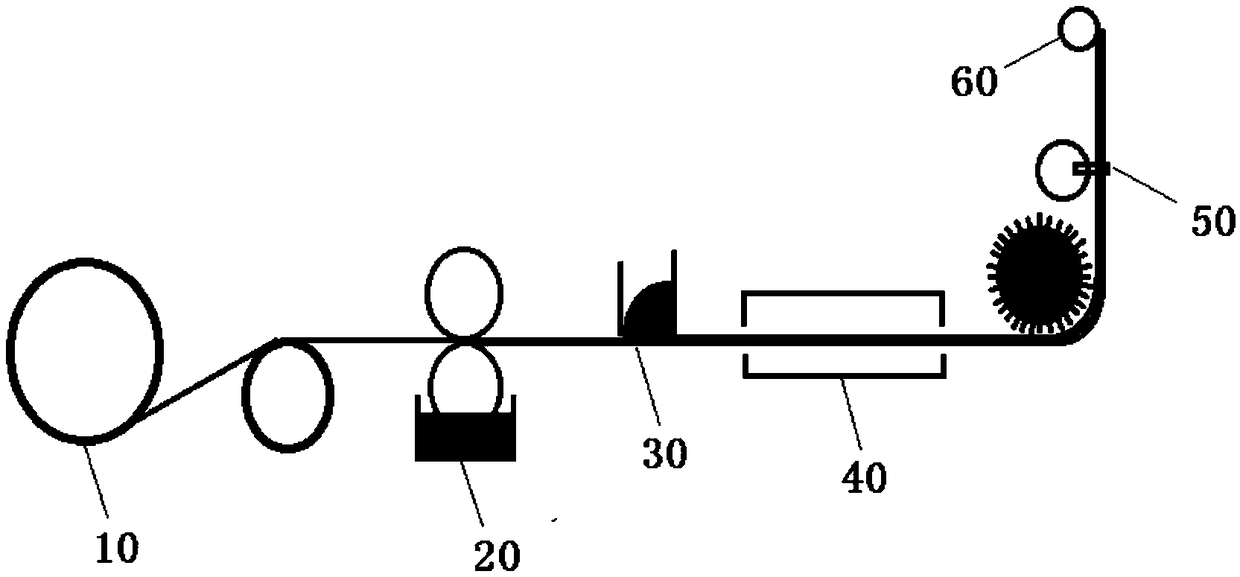

[0041] According to another aspect of the present application, there is also provided a method for preparing the above adhesive tape, which includes the following steps: S1, melt blending and film-forming the first raw material including L-polylactic acid, toughening filler and dispersant, to obtain Adhesive tape substrate; S2, coating the second raw material including peach gum and poly-N-vinylpyrrolidone on the surface of the substrate layer and drying to obtain an adhesive layer covering the surface of the adhesive tape substrate.

[0042] In a preferred embodiment, the above step S1 includes the following steps: S11, using a twin-screw extruder to melt and blend the first raw materials to obtain a modified blend; S12, using a casting process to blend the modified The material is extruded and cast into a film, and then cooled to obtain a tape substrate.

[0043] In the above-mentioned preferred embodiment, more preferably, the length-to-diameter ratio of the screw in the ab...

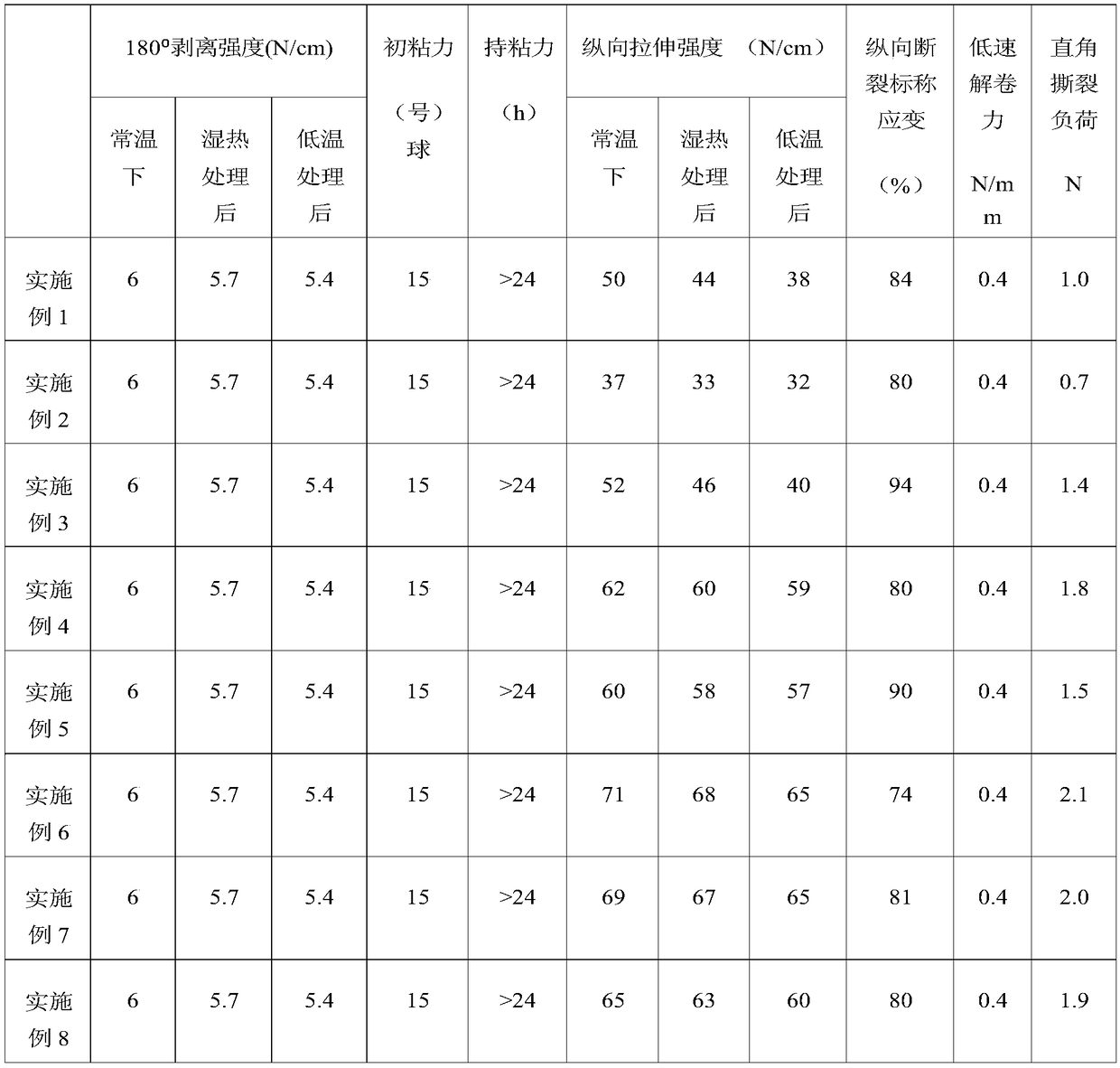

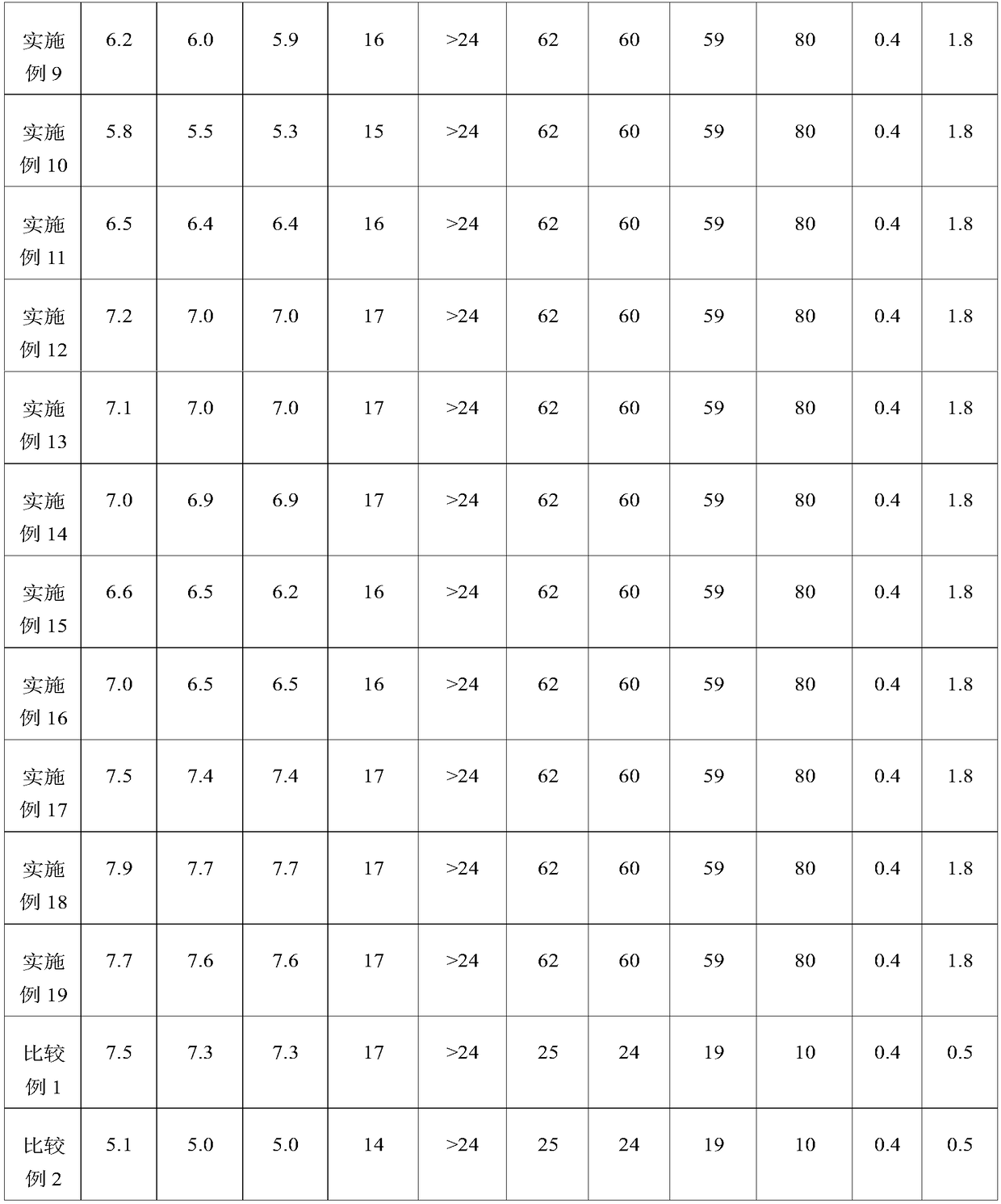

Embodiment 1

[0052] The preparation method of the adhesive tape provided in the present embodiment comprises the following steps:

[0053] (1) Preparation of nano-silica / polyoxyethylene composition: 100 parts by weight concentration of 5% polyethylene oxide and 24.6 parts by weight concentration of 30% sodium silicate aqueous solution are mixed in a three-necked flask, heated to 40 -45°C, add 10% sulfuric acid solution dropwise to PH = 6-6.5, then raise the temperature to 80-90°C and keep it warm for 30 minutes, after cooling, centrifuge, pour off the supernatant, and continue to wash the lower suspension with distilled water until no Sulfate ion, the lower layer after centrifugation was vacuum-dried at 80°C for 2h.

[0054] (2) After mechanically blending 60 parts of poly-L-lactic acid and 4 parts of nano-silica / polyethylene oxide composition (containing 2 parts of nano-silica and 2 parts of polyethylene oxide), a twin-screw extruder is used to The three raw materials are melt blended, t...

Embodiment 2

[0059] The difference between the preparation method of the adhesive tape provided in this embodiment and embodiment 1 is:

[0060] In step (3), the raw materials for melt blending include 55 parts of poly-L-lactic acid, 0.25 parts of nano silicon dioxide, and 0.25 parts of polyethylene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stay sticky | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com