Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Eliminate direct contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A magnetic material with high temperature stability and a preparation method thereof

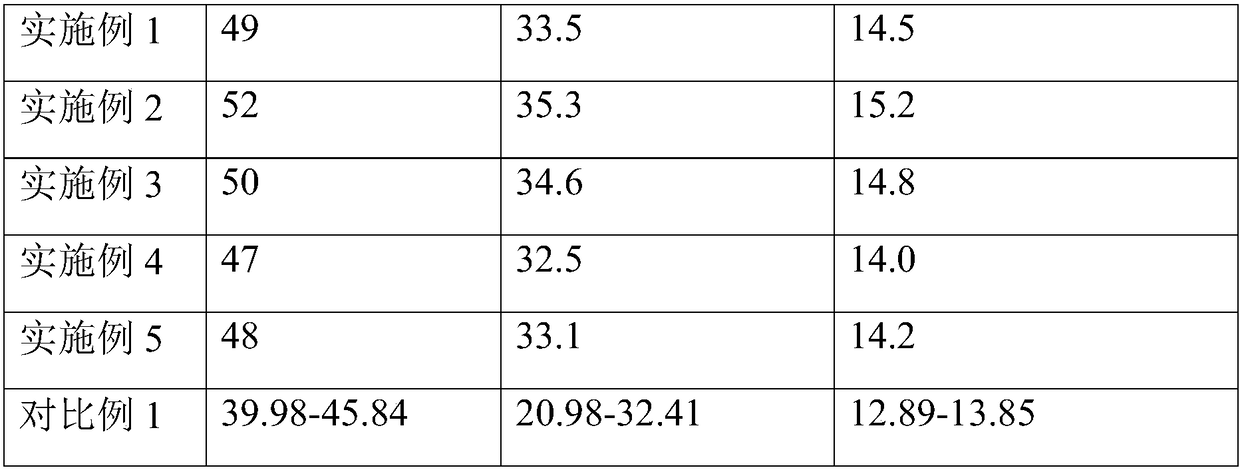

InactiveCN108962528AThree low melting pointsImprove remanenceInorganic material magnetismInductances/transformers/magnets manufactureProper treatmentAlloy

The invention discloses a magnetic material with high temperature stability and a preparation method thereof, which is composed of an alloy material 1, an alloy material 2, an alloy material 3 and aninorganic ceramic material. The weight ratio of the alloy material 1, the alloy material 2, the alloy material 3 and the inorganic ceramic material is 1: 0.03- 0.09:0.003- 0.008:0.011- 0.015. The product obtained by the invention has excellent magnetic properties. In addition, the homogeneity of composition, microstructure and properties of the alloys were ensured by proper treatment, and the quality of the alloys was ensured. The preparation process of the alloy is simple, the cost of raw materials used for preparation is low, the process is simple, and the produced alloy has good properties,which is convenient for industrial production. The permanent magnet material prepared by the invention is suitable for the electric appliance industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

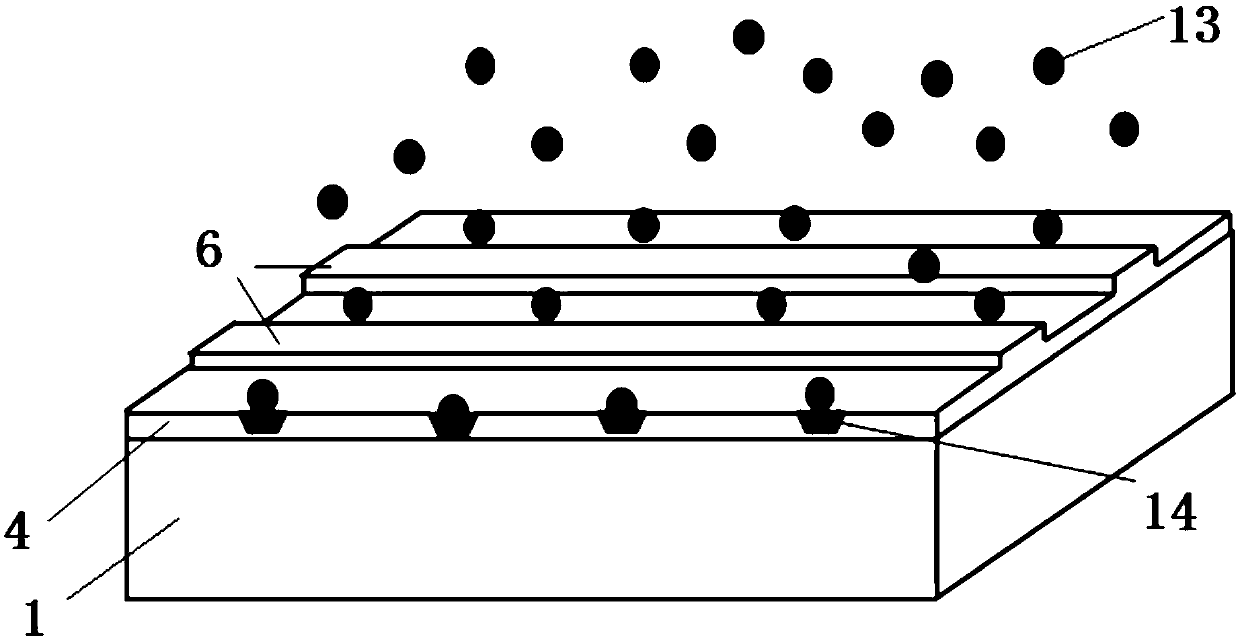

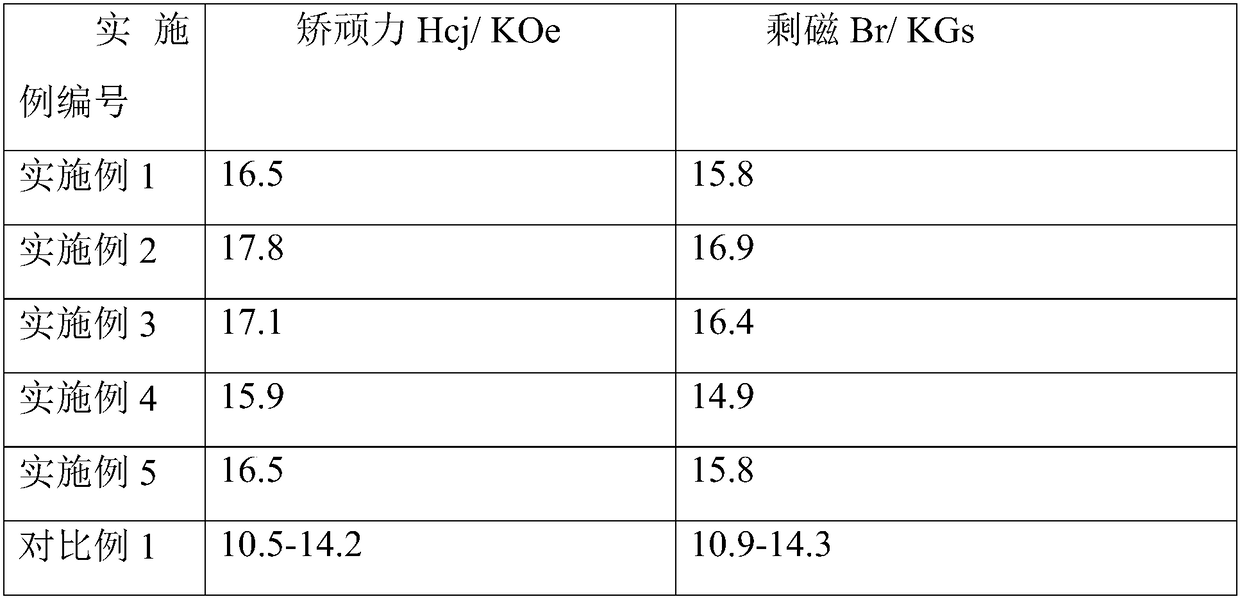

Sintered magnetic composite material and preparation method thereof

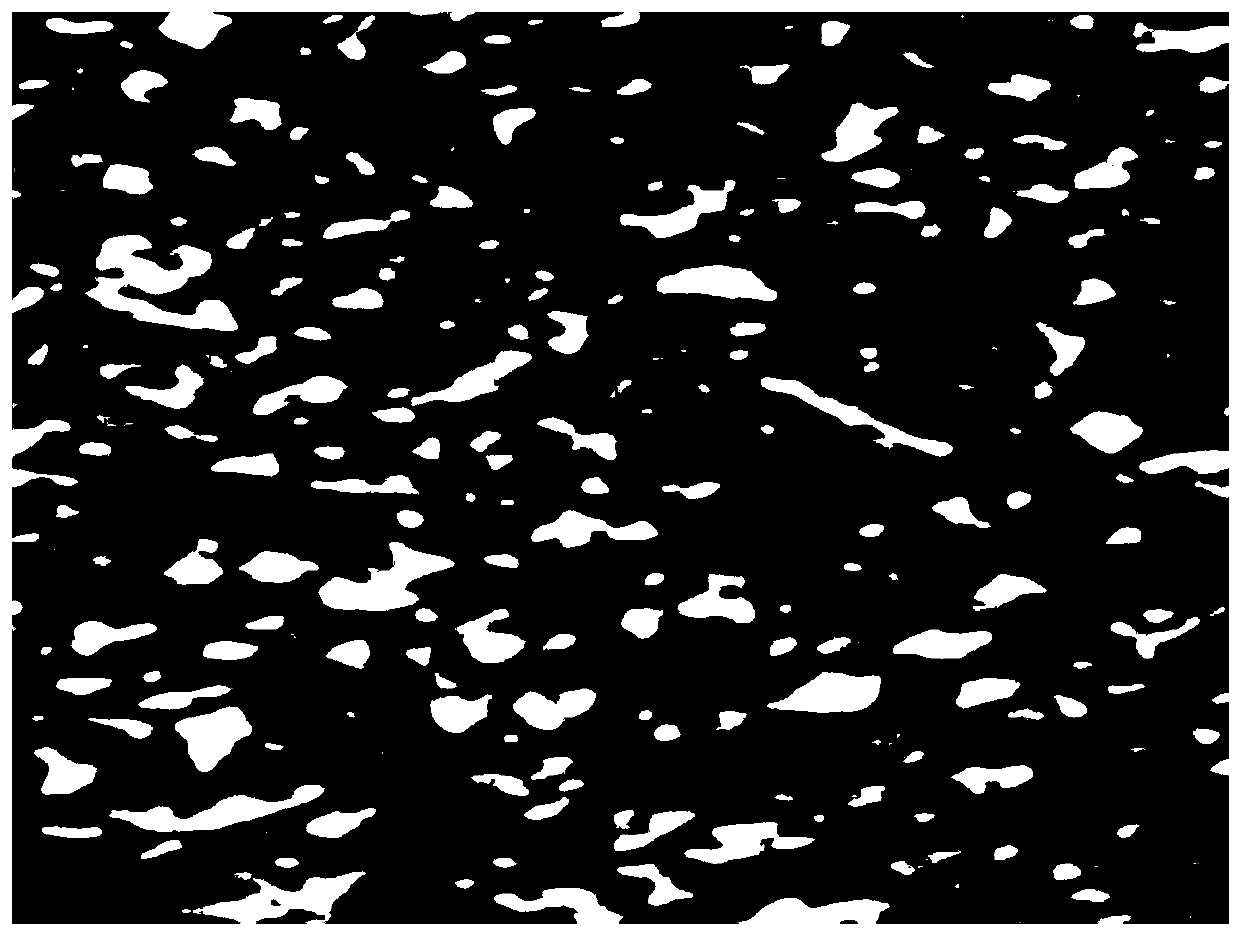

InactiveCN108335819AInhibit growthEliminate direct contactInorganic material magnetismCopper alloyRaw material

The invention discloses a sintered magnetic composite material and a preparation method thereof. The magnetic composite material is prepared by mixing and sintering a material A, a material B, a material C and a copper alloy D, and the weight ratio of the material A, the material B, the material C to the copper alloy D is 0.05:(1-1.3):(0.003-0.008):(0.05-0.09). The sintered magnetic composite material is simple and convenient in preparation technology and simple in process, raw materials for preparation are low in cost, the produced alloy has good performance, industrial production is facilitated, and the prepared permanent magnet material is applicable to electrical equipment industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

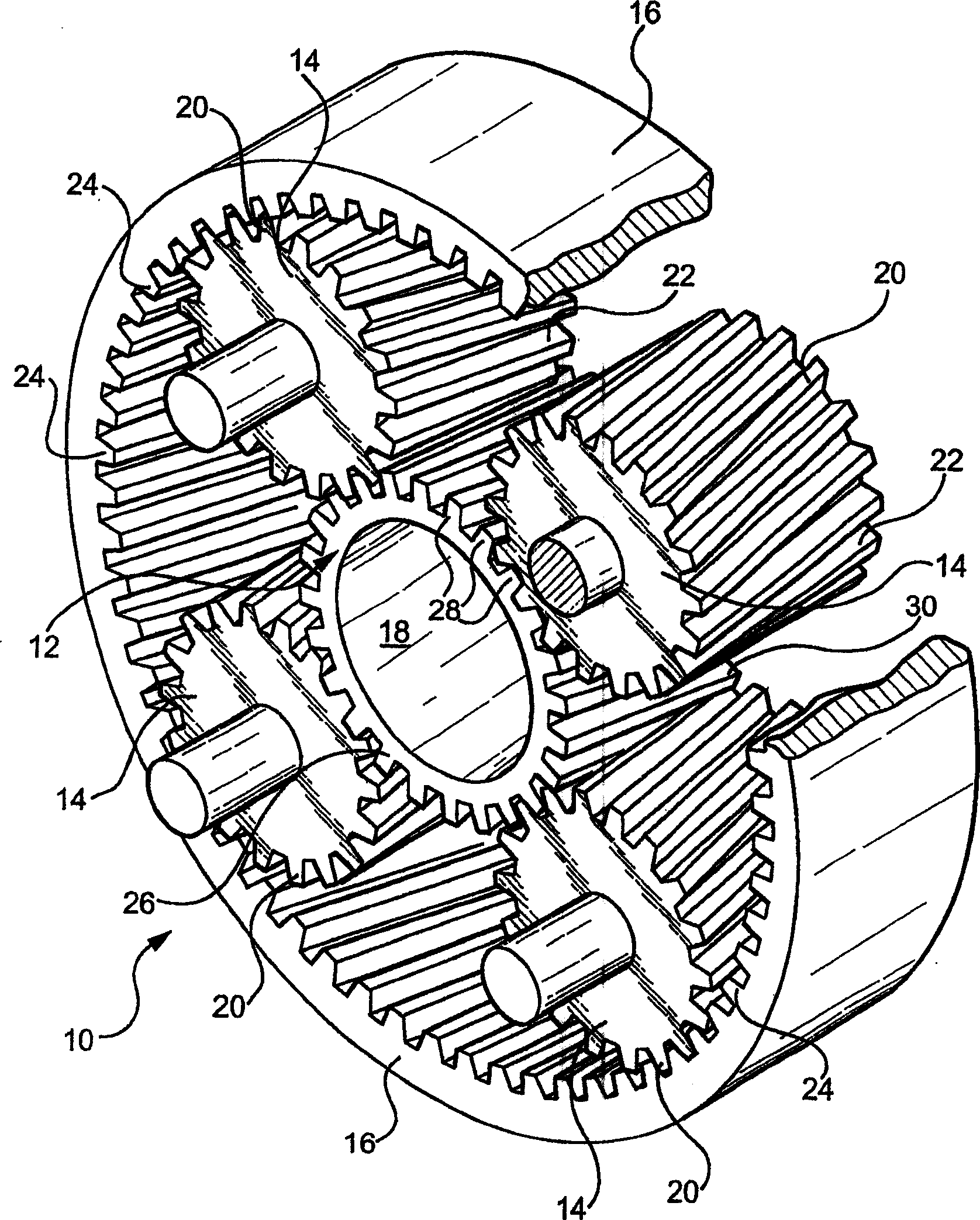

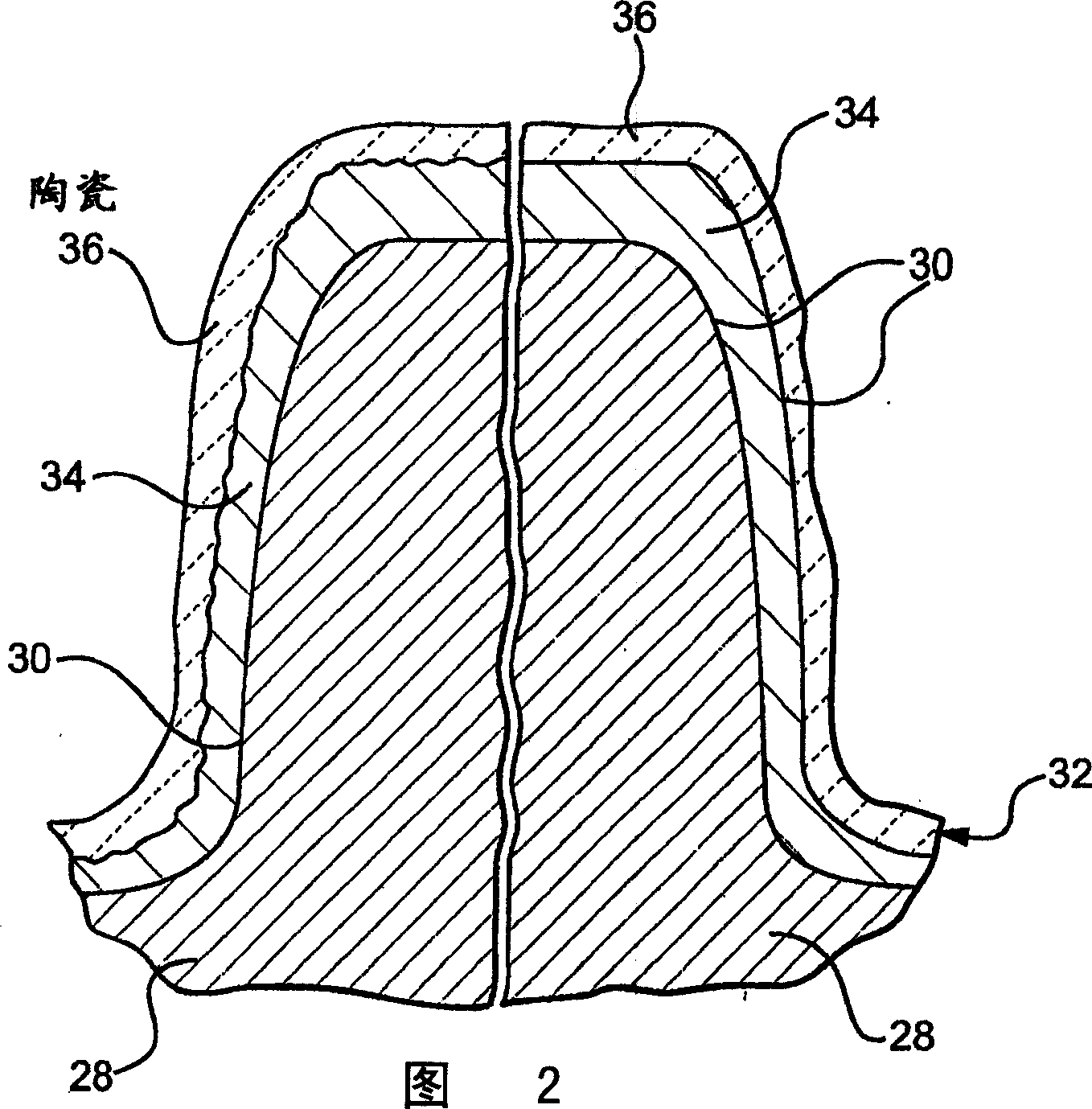

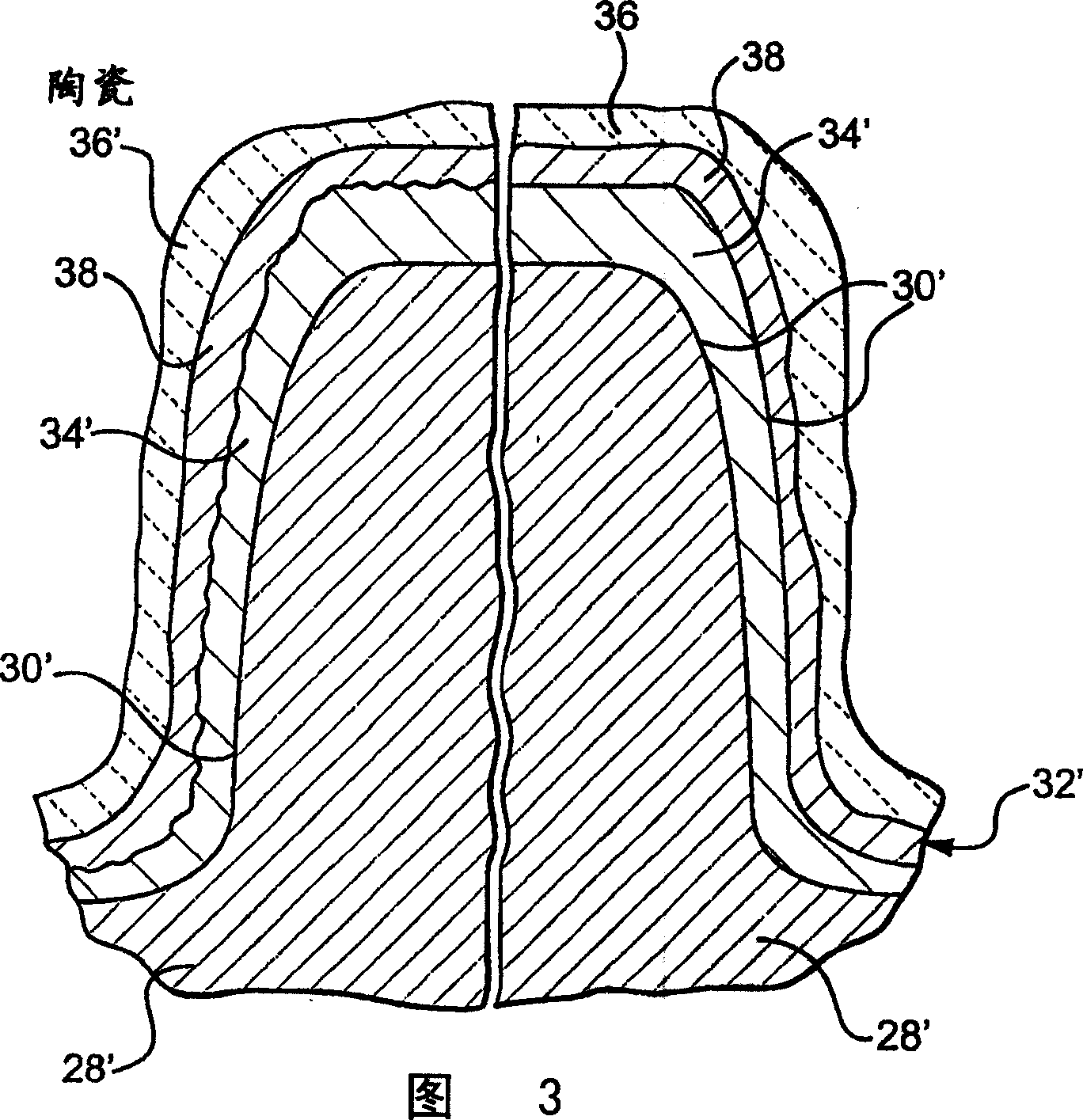

Planetary gearset with multi-layer coated sun gear

InactiveCN1678848AEliminate direct contactExtend your lifePortable liftingGear lubrication/coolingEngineeringGear tooth

A planetary gearset includes a sun gear member having a sun gear body made of a steel material and an outer periphery with a plurality of teeth formed thereon. Each of the sun gear teeth has at least one mating surface for engaging mating surfaces on complementary teeth on at least one planet gear. A fatigue-resistant coating is applied to the mating surfaces of the sun gear teeth. The coating is harder and more abrasive than the mating surfaces of the planet gear teeth.

Owner:GENERAL MOTORS COMPANY

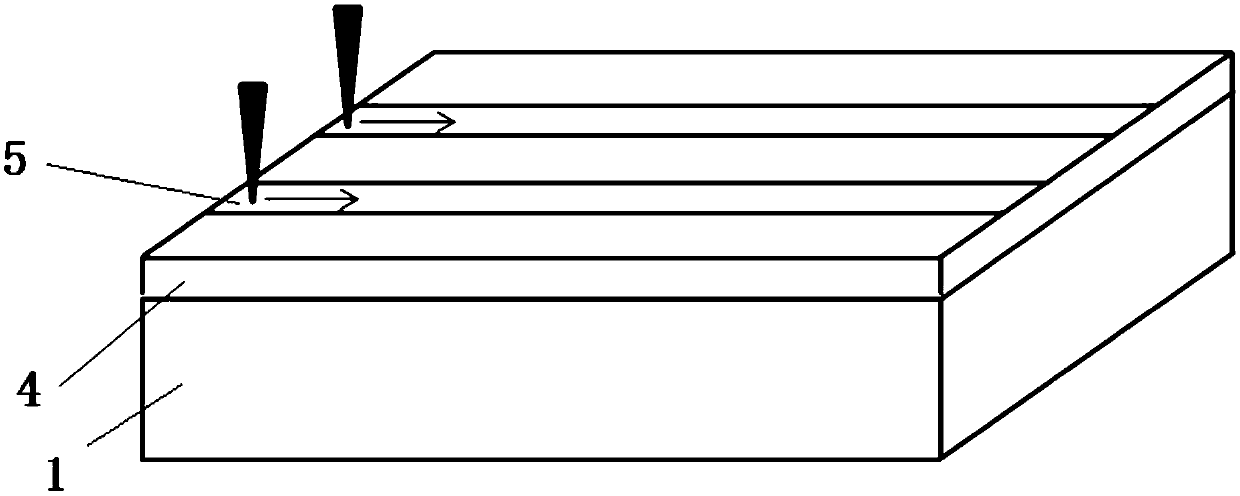

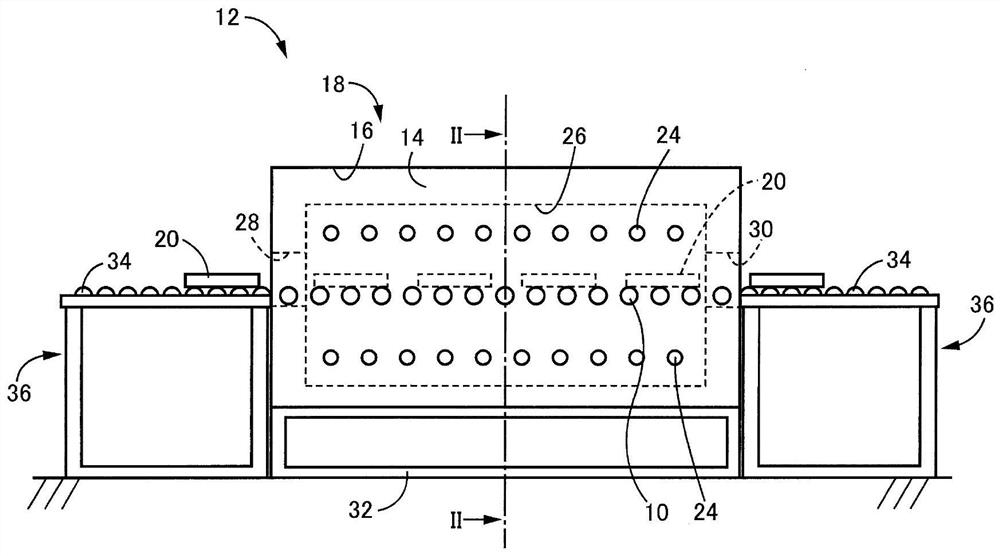

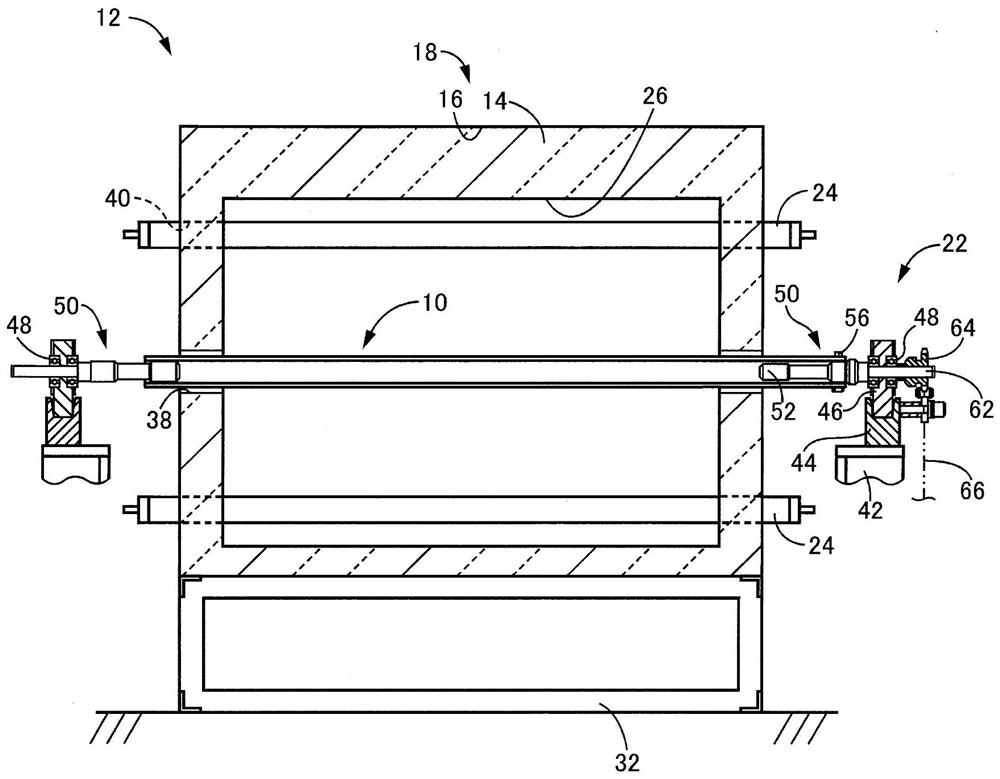

Automatic aluminium material roll-coating production line

InactiveCN102266840AReduce accumulationEliminate direct contactPretreated surfacesCoatingsProduction lineHigh energy

The invention relates to an automatic aluminium material roll-coating production line, and the production process comprises the following steps of: a. roll charging; b. cleaning; c. chromization; d. coating; e. baking; f. cooling; g. film covering; h. roll discharging. With the method, the automatic aluminium material roll-coating production line of the invention can reduce dust accumulation in a furnace, and has high energy efficiency, and no burner or igniting source which can combust directly is in the furnace area, which completely eliminates the phenomenon of direct contact of burning particles with band materials, increases the quality of the surface coatings of the band materials, and is energy-saving and environment-friendly.

Owner:CHANGZHOU LIDAO METALLIC MATERIAL MFG

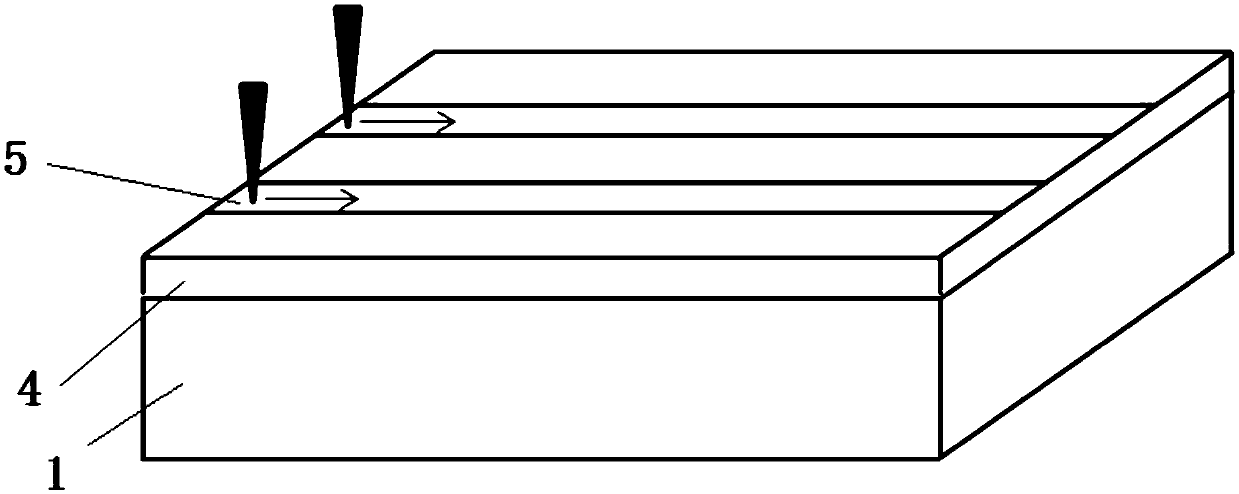

Preparation process of solar cell

InactiveCN111063759ASimple processEliminate direct contactFinal product manufacturePhotovoltaic energy generationSolar cellBattery cell

The invention discloses a preparation process of a solar cell. The preparation process comprises the steps of S1 arranging a doped silicon layer on at least one surface of a silicon substrate; S2 setting a coating on a preset region of the doped silicon layer; and S3 removing the doped silicon layer which is not provided with the coating area, and forming a local doped silicon layer on at least one surface of the silicon substrate. According to the process, the silicon layer is locally doped by the coating, and the process is simple and feasible.

Owner:JA SOLAR +1

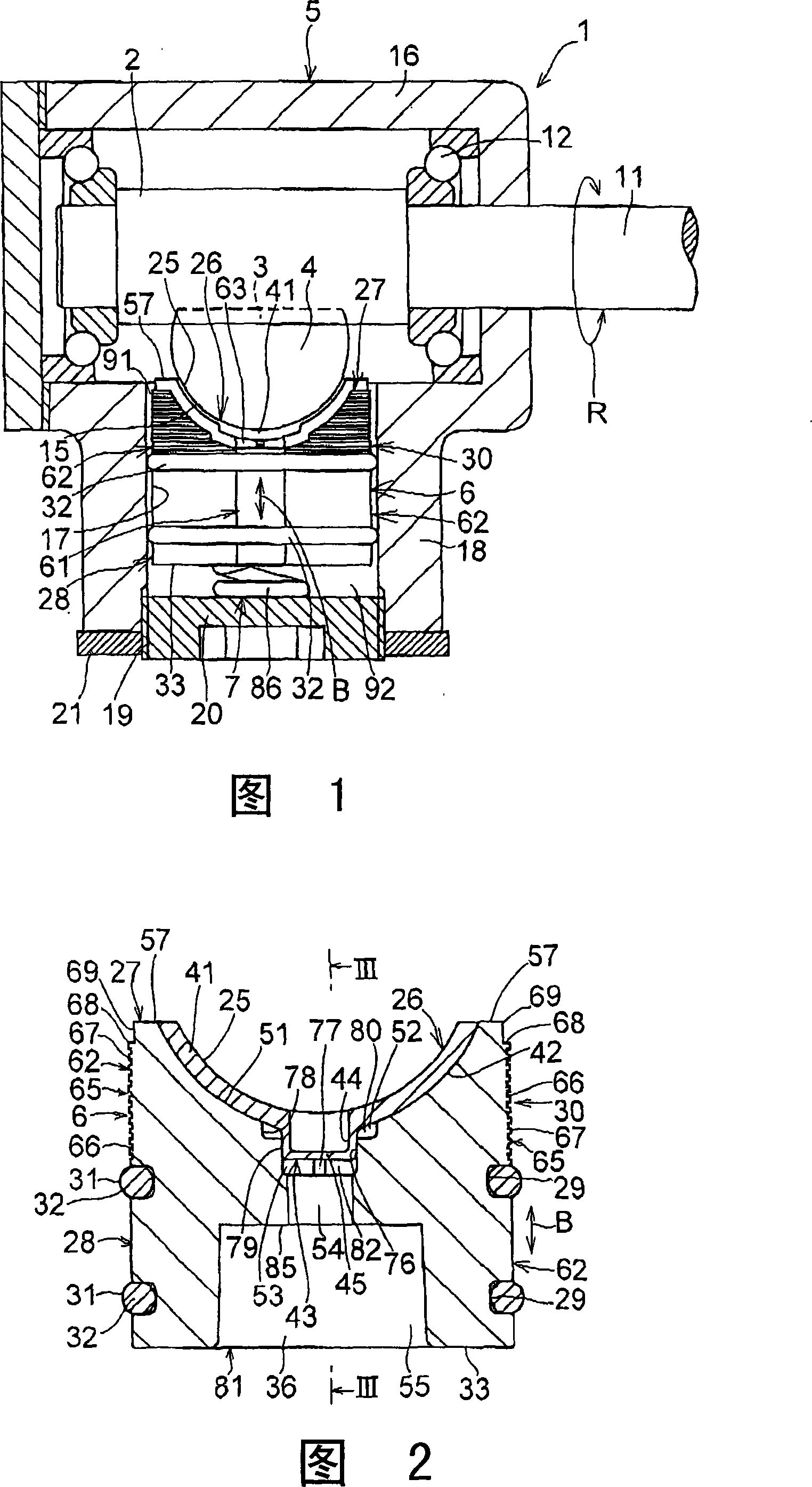

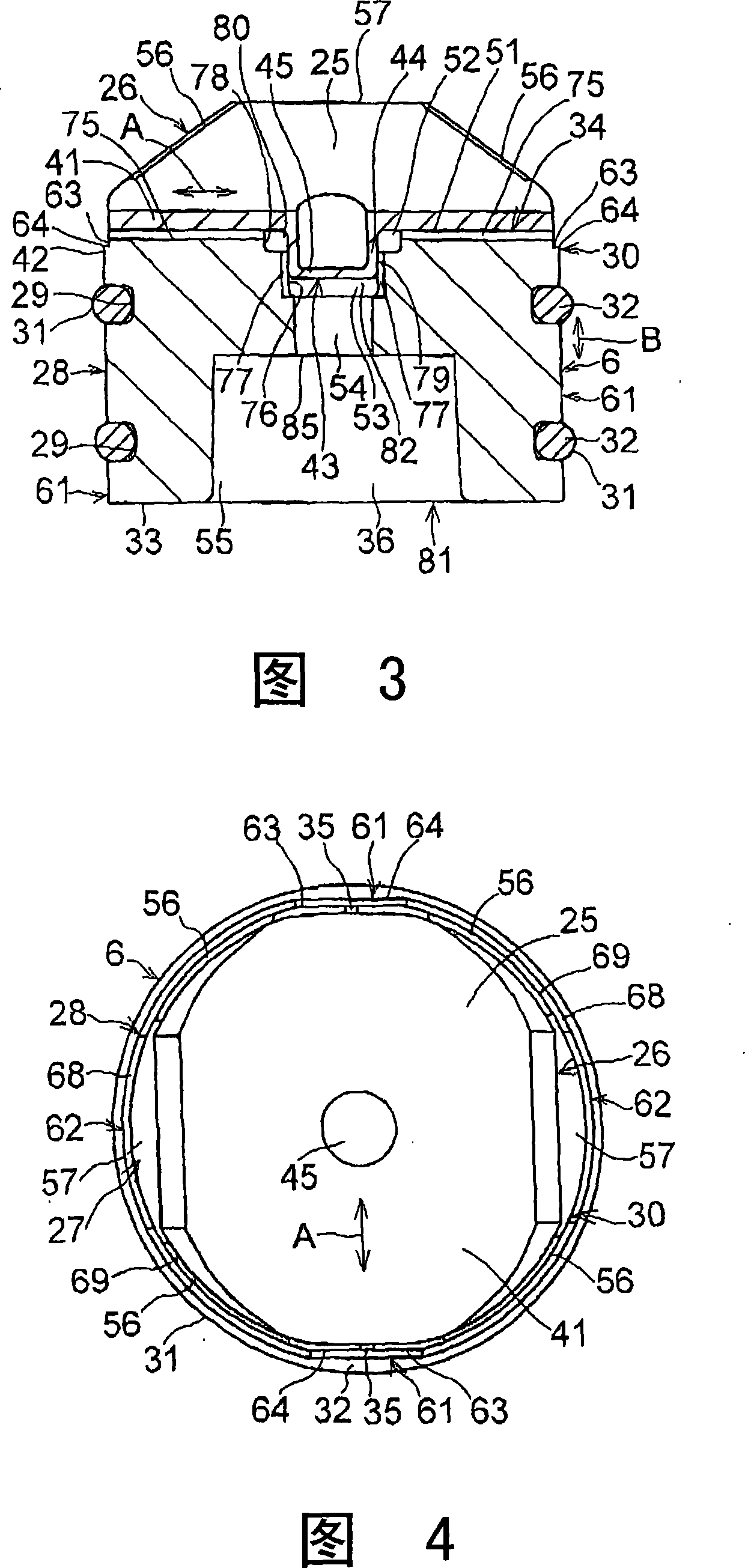

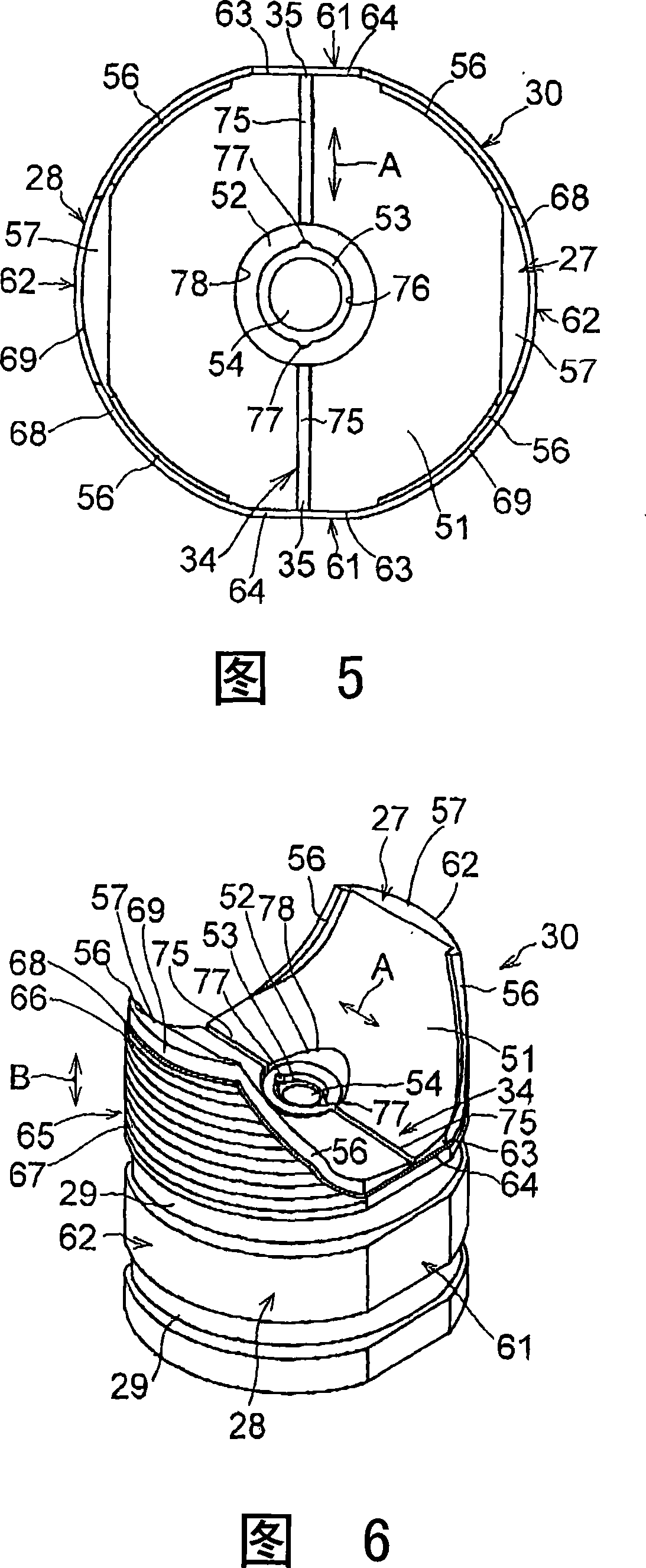

Rack guide, and rack and pinion steering device with the rack guide

ActiveCN101180199AEliminate direct contactMechanical steering gearsGearing elementsMechanical engineeringRack and pinion

A rack-and-pinion type steering apparatus (1) includes a pinion (2) which is rotatable in an R direction, a rack bar (4) which has rack teeth (3) meshing with the pinion (2) and is linearly movable in an A direction, a housing (5) for rotatably supporting the pinion (2), a rack guide (6) for slidably supporting the rack bar (4), and a resilient means (7) for pressing the rack guide (6) toward the pinion (2).

Owner:JTEKT CORP +1

Preparation process of solar cell

InactiveCN111063761ASimple processEliminate direct contactFinal product manufacturePhotovoltaic energy generationEngineeringSilicon oxide

The invention discloses a preparation process of a solar cell. The preparation process comprises the steps of S1 arranging a doped silicon layer on at least one surface of a silicon substrate; S2 irradiating a preset region of the doped silicon layer by adopting laser, and forming a doped source-containing silicon oxide protection layer in the preset region of the doped silicon layer; and S3 removing the doped silicon layer which does not form the region of the doped source-containing silicon oxide protection layer, and forming a local doped silicon layer on at least one surface of the siliconsubstrate. The process utilizes laser local scanning to complete local silicon layer doping, and the process is simple and feasible.

Owner:JA SOLAR +1

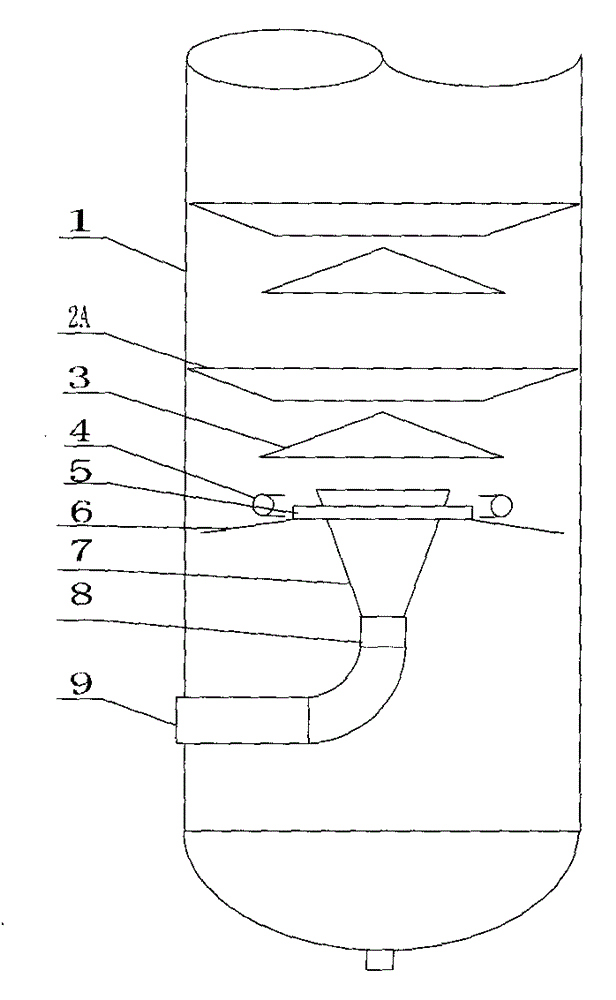

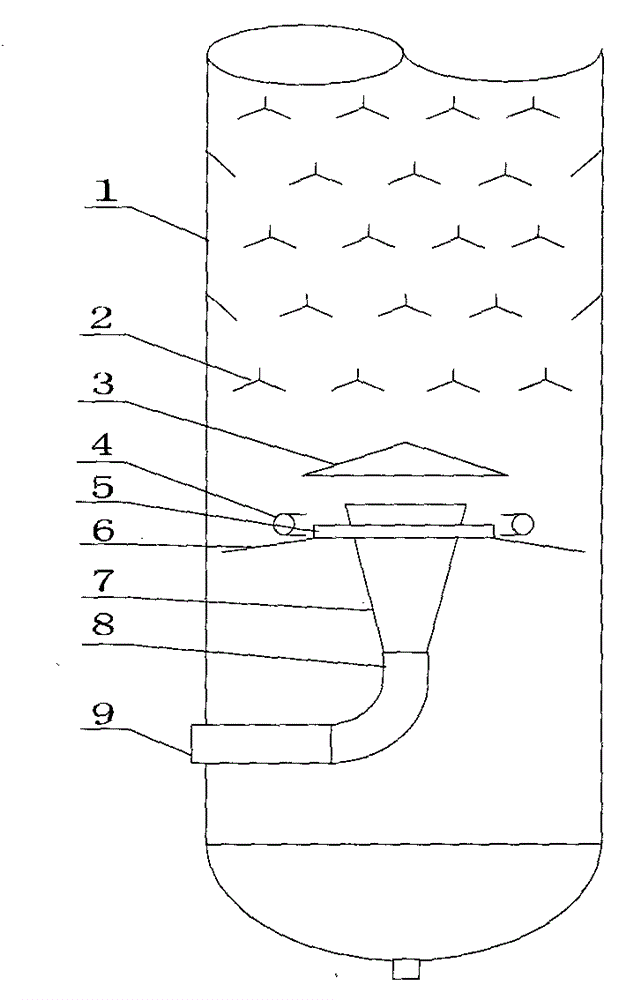

Heavy oil processing coking prevention method and fractionating tower

A heavy oil processing coking prevention method belongs to the technical field of petroleum chemical engineering and process apparatuses, and is used to solve the coking problem of heavy processing fractionating towers. The method comprises the steps of fractionating tower washing desuperheating, high temperature oil gas entrance, low temperature cycle slurry oil entrance, low temperature oil gas discharge and high temperature cycle slurry oil discharge. The method is characterized in that a high temperature oil gas guiding device is arranged to guide high temperature oil gas entering the tower to a fractionating tower washing desuperheating segment, so the retention time of the high temperature oil gas in the fractioning tower is shortened, direct contact of high temperature cycle slurry oil with the high temperature oil gas is avoided, and local superheating of the high temperature cycle slurry oil is avoided; and the lower end of the washing desuperheating segment is provided with a high temperature cycle slurry oil collecting liquid guiding and cooling device in order to timely and rapidly reduce the temperature of the cycle slurry oil, so the retention time of the high temperature cycle slurry oil is shortened. The invention also provides an oil gas guiding tube, a liquid collecting and guiding skirt board and a rapid cooling medium distribution tube fractioning tower for realizing the method. The method maximally shortens the retention time of the high temperature oil gas and the high temperature cycle slurry oil and avoids local superheating of the cycle slurry oil in order to avoid system coking of the fractioning tower, and is applied in heavy oil catalytic cracking and coking fractionate towers.

Owner:刘英聚

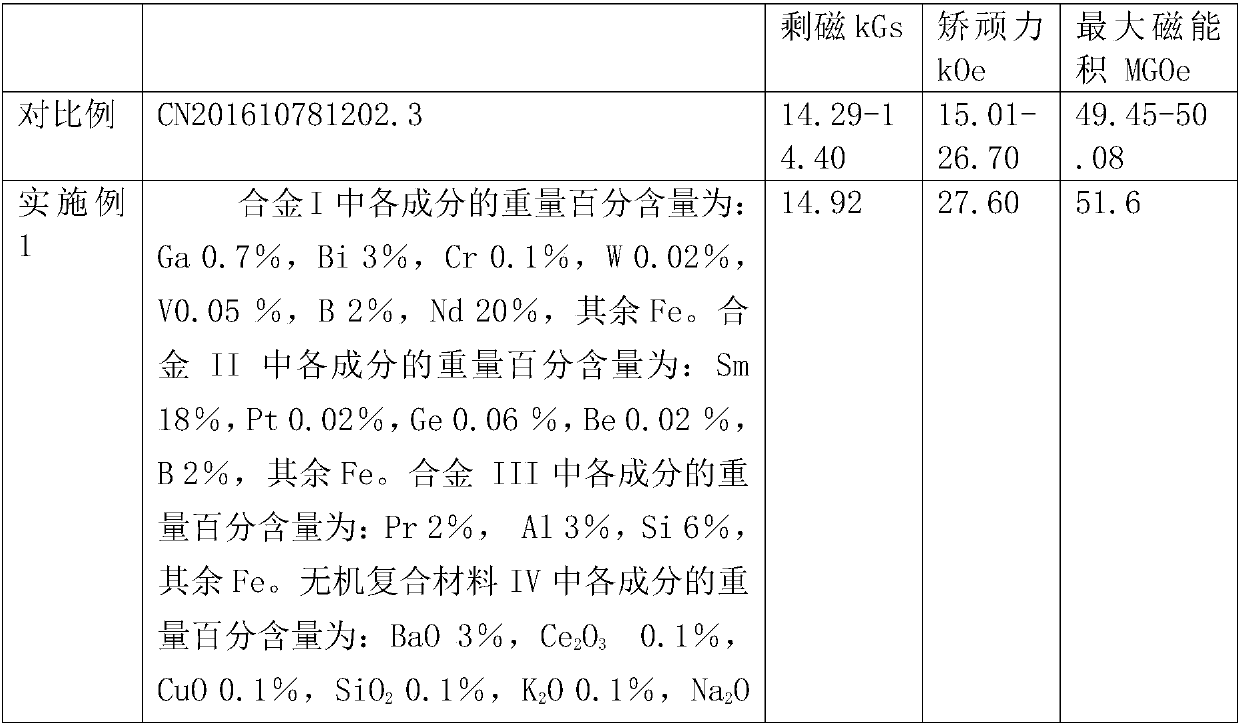

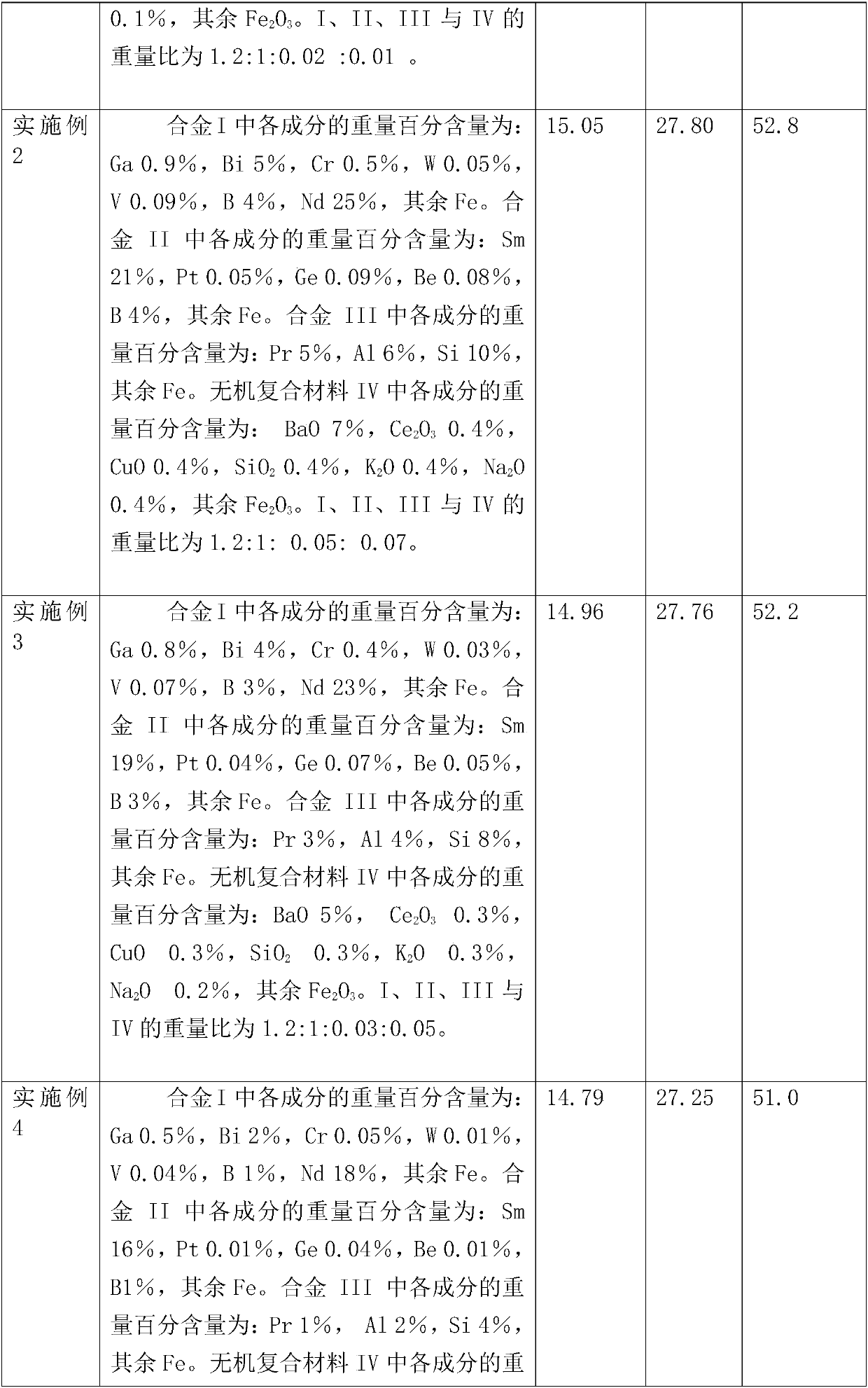

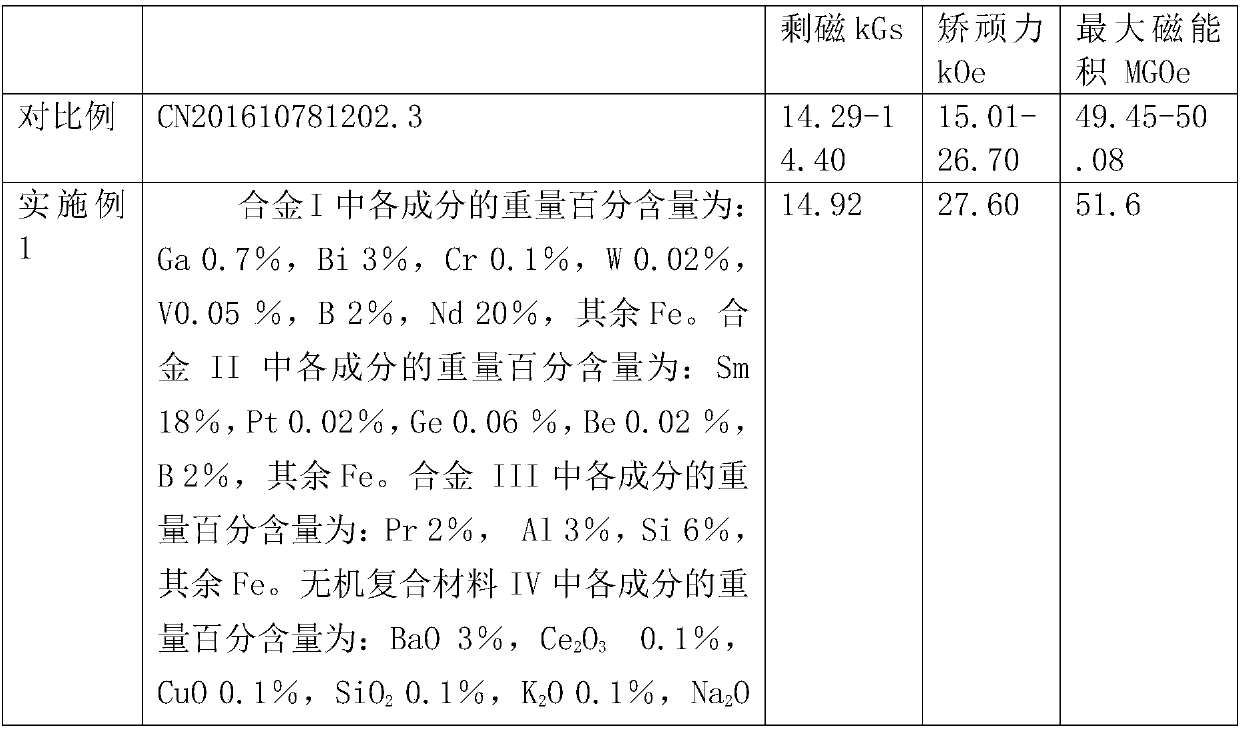

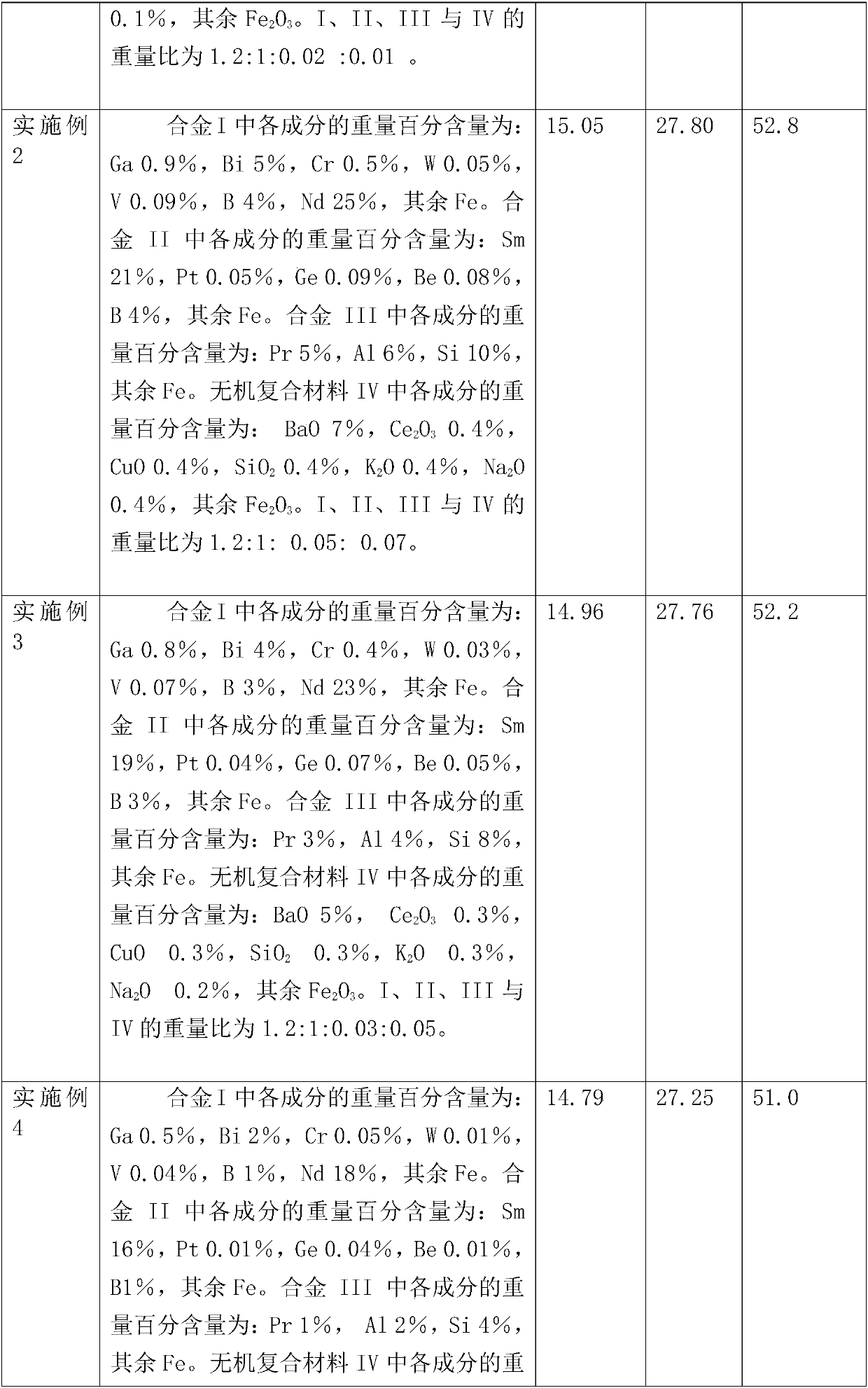

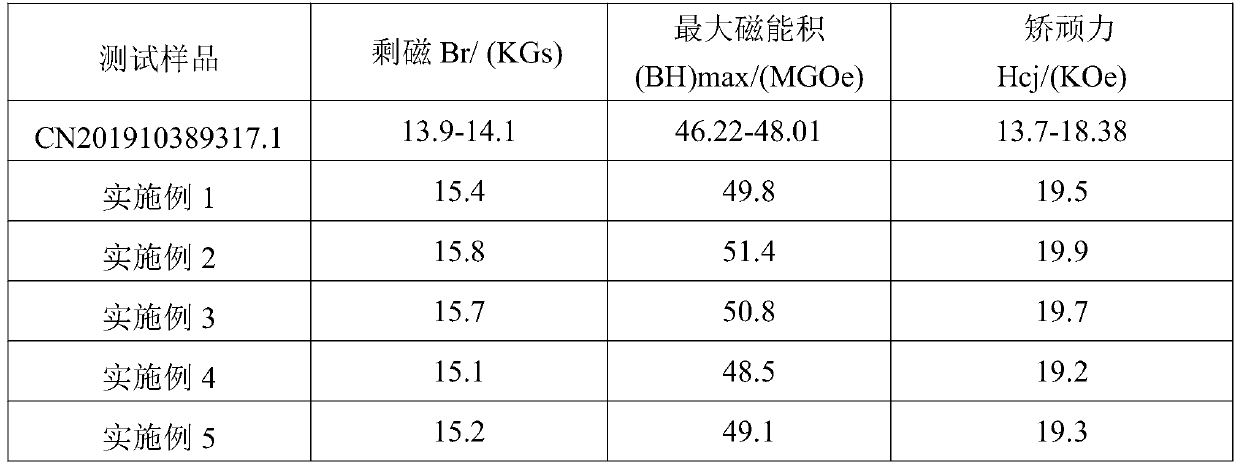

High-residual-magnetism material and preparation method therefor

ActiveCN107564651AImprove coercive forceImprove remanenceInorganic material magnetismAlloyMagnetic field

The invention relates to a high-residual-magnetism material and a preparation method therefor. The high-residual-magnetism material consists of a combination of three kinds of alloy materials I, II and III, and an oxide complex IV; the materials are prepared separately, and the alloy materials I, II and III, and the oxide complex IV are prepared based on the weight ratio and added to a three-dimensional mixer to be mixed uniformly to obtain mixed powder; next, the mixed powder is subjected to orientation in a magnetic field press and shaped by adopting an isostatic pressing mode; and the formed blank is put into a sintering furnace under argon protection to be subjected to sintering treatment to obtain a high-residual-magnetism product. The alloy preparation process is simple and convenient, the process is simple, and the produced alloys have high performance, so that industrial production can be realized very conveniently.

Owner:太原市迪辉磁材科技有限公司

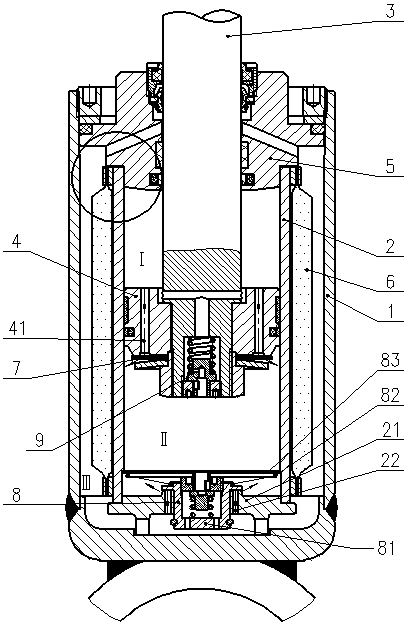

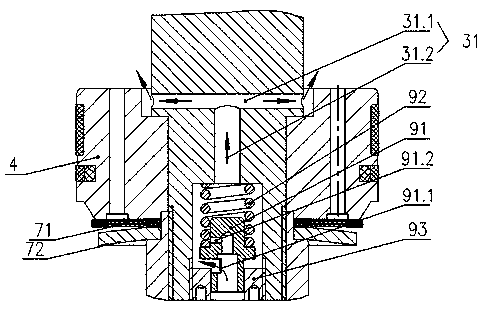

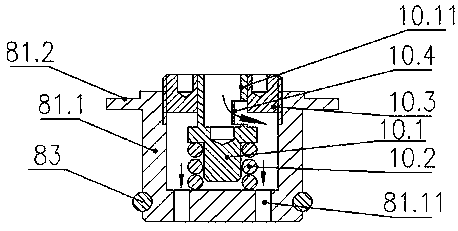

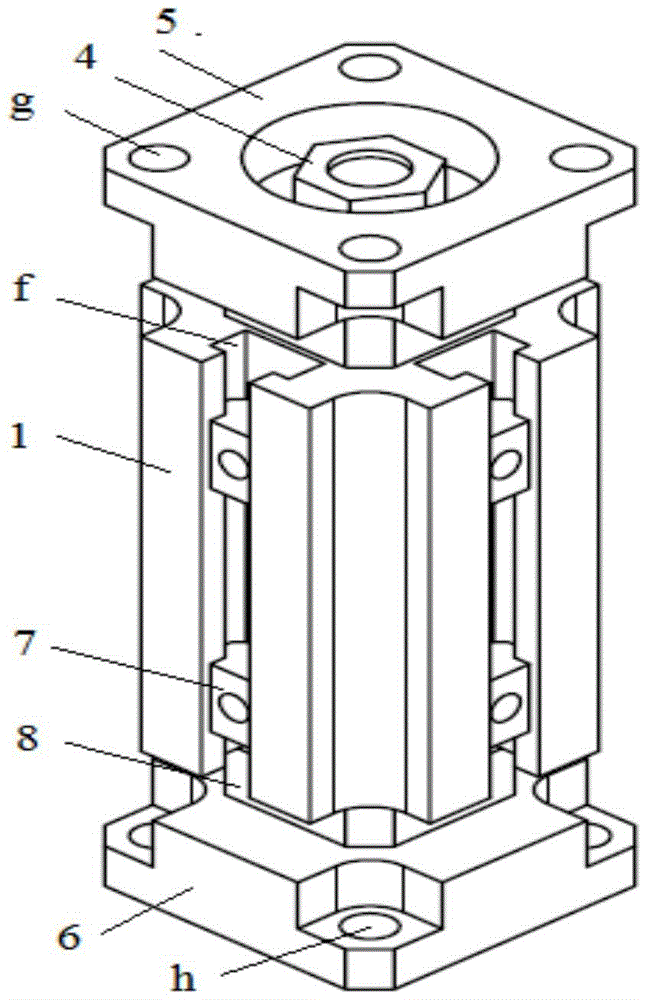

Oil damper and design method thereof

PendingCN110439952ARegulating pressureSimple structureSpringsLiquid based dampersPiston rodDesign methods

An oil damper comprises an oil storage cylinder, a pressure cylinder, a piston rod, a piston and a guide seat. The pressure cylinder is divided into a piston upper cavity and a piston lower cavity through the piston. An oil storage cavity is formed between the oil storage cylinder and the pressure cylinder. An inflation bag is arranged in the oil storage cavity, and a stretching throttling elasticvalve bank communicating with the oil storage cavity and the piston lower cavity when the piston rod stretches out is mounted at the bottom of the pressure cylinder. A compression damping adjusting elastic valve bank communicating with the piston lower cavity and the piston upper cavity when the piston rod is pressed in is mounted at the inner end of the piston rod. A compression unloading adjusting elastic valve bank communicating with the piston lower cavity and the oil storage cavity when the piston rod is pressed in is mounted at the bottom of the pressure cylinder. The rigidity of the compression damping adjusting elastic valve bank is smaller than that of the compression unloading adjusting elastic valve bank. According to the oil damper, different damping adjusting needs can be provided, and the oil damper is effective, reliable and stable in performance. The invention further provides a design method of the oil damper.

Owner:株洲联诚集团减振器有限责任公司 +1

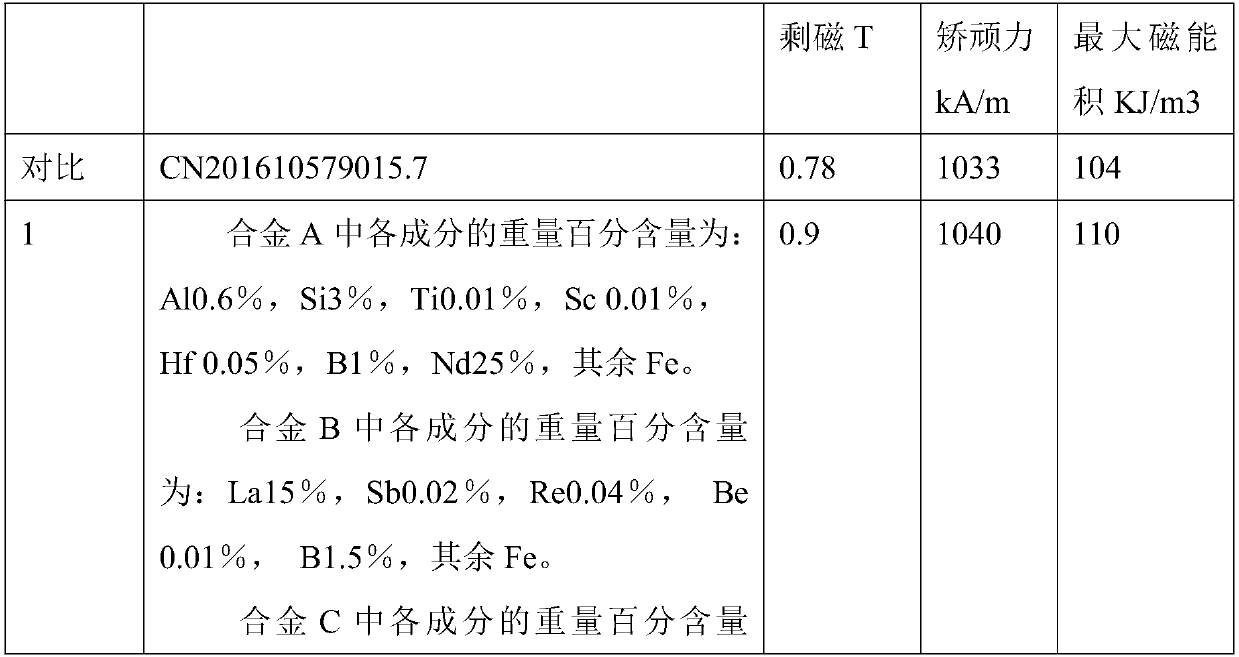

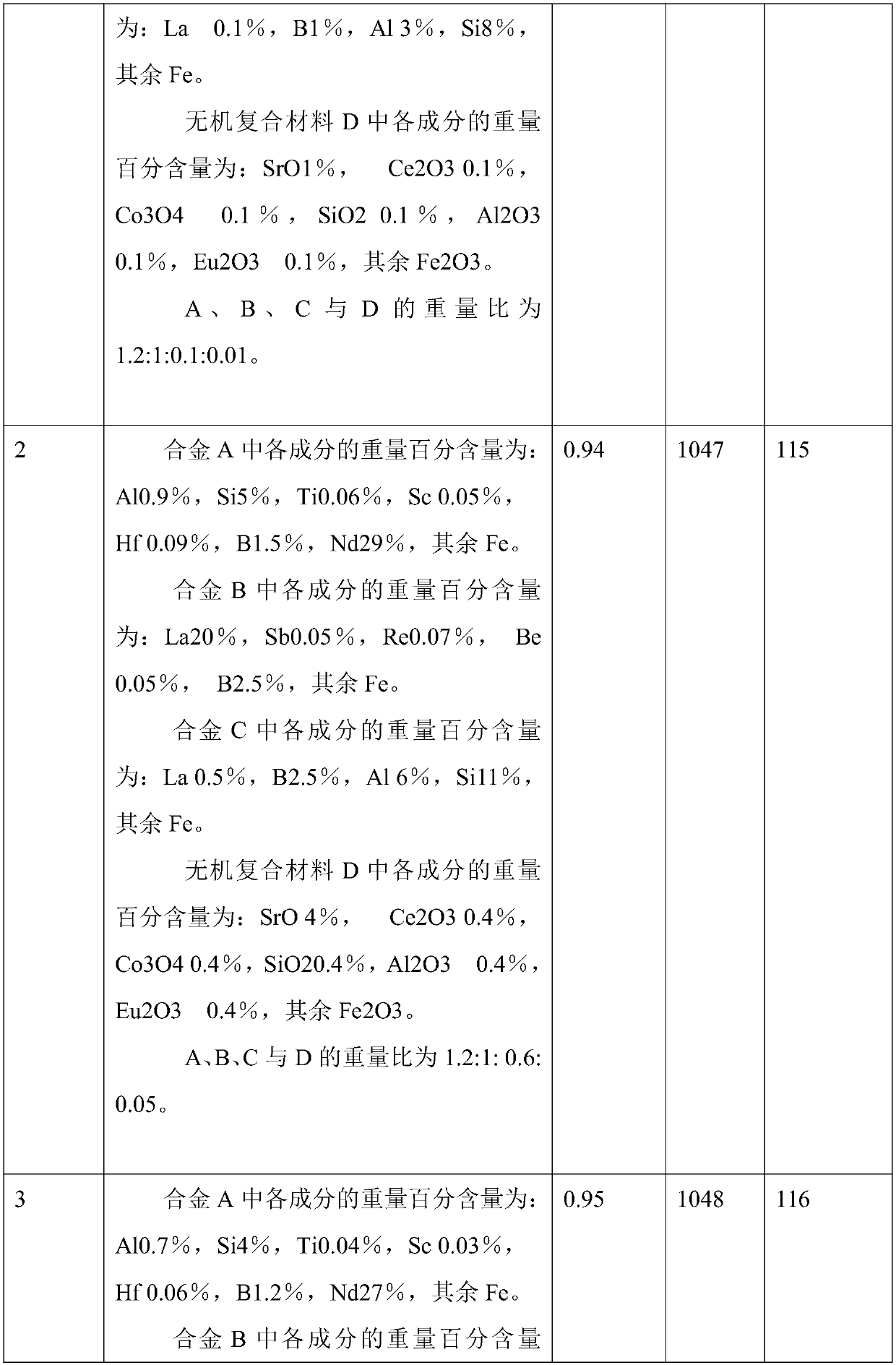

Permanent magnet composite and preparing method

The invention discloses a permanent magnet composite which is composed of three alloy materials A, B and C and an inorganic composite D according to the weight ratio of A to B to C to D being 1.2 to 1to (0.1-0.6) to (0.01-0.05). Through material mixing and press forming, a blank is placed in a sintering furnace to be sintered under the protection of argon, the temperature is first raised to 500-750 DEG C and then kept for 3-4 hours, then the temperature is raised to 1050-1090 DEG C for sintering for 3-4 hours, cooling is conducted to the room temperature, two times of tempering treatment including thermal treatment tempering at 880-900 DEG C and thermal treatment tempering at 530-560 DEG C for 1-2 hours are conducted, and finally aging treatment at 180-220 DEG C is conducted to obtain thepermanent magnet composite.

Owner:BAOTOU INST MAGNETIC NEW MATERIALS CO LTD

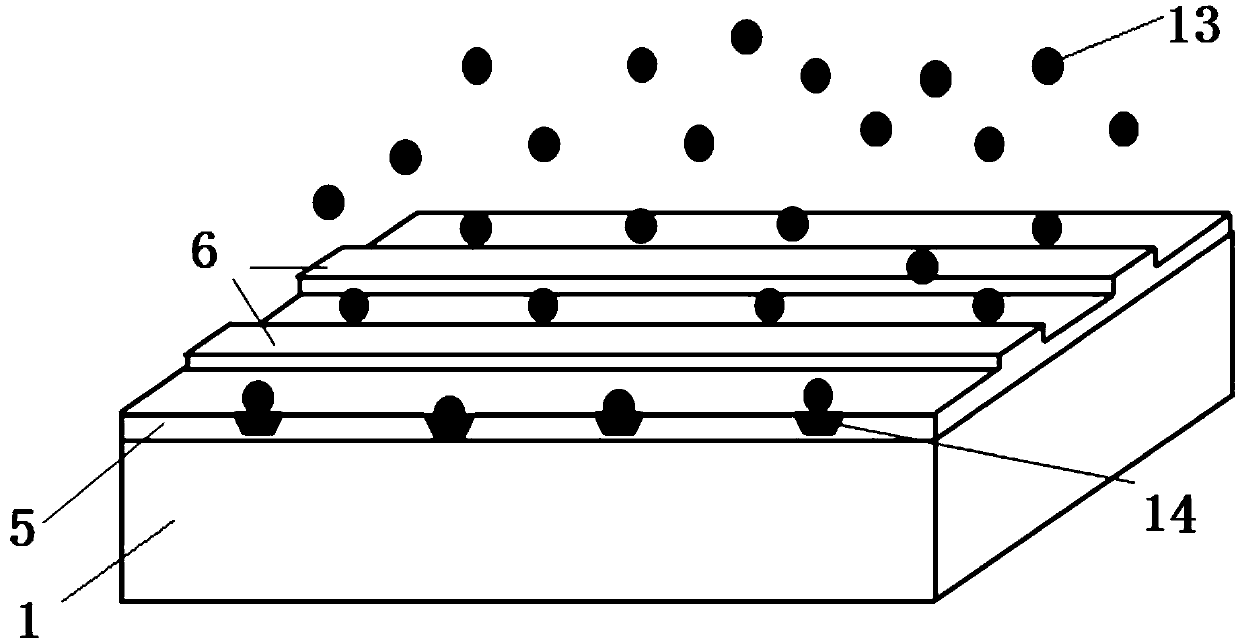

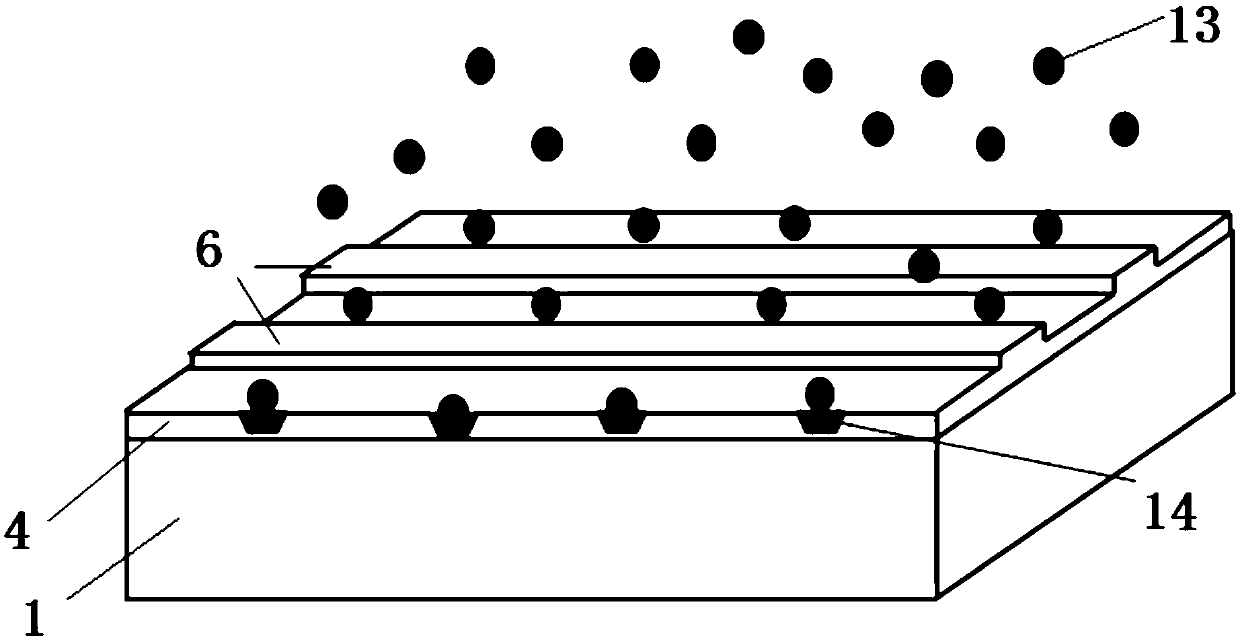

Preparation process of solar cell

ActiveCN111063760ASimple processEliminate direct contactFinal product manufactureSemiconductor devicesAmorphous siliconEngineering

The invention discloses a preparation process of a solar cell. The preparation process comprises the steps of S1 arranging an intrinsic silicon layer on at least one surface of a silicon substrate; S2arranging a doping source layer on the intrinsic silicon layer; S3 enabling a doping source of the doping source layer at a position corresponding to the preset region of the intrinsic silicon layerto decompose doping ions, and enabling the doping ions to enter the preset region of the intrinsic silicon layer, forming a doped region in the preset region of the intrinsic silicon layer, and forming a silicon oxide protective layer containing the doping source in the doped region; and S4 removing the non-doped region, provided with the doping source layer, on the intrinsic silicon layer, and forming a locally doped silicon layer on at least one surface of the silicon substrate. According to the process, the polycrystalline silicon layer or the amorphous silicon layer is locally doped by laser, and the process is simple and feasible.

Owner:JA SOLAR +1

Permanent magnet alloy and preparing method thereof

ActiveCN107424705AImprove coercive forceSmall residual magnetismInorganic material magnetismMass ratioAlloy

The invention relates to permanent magnet alloy and a preparing method thereof. The permanent magnet alloy is compounded by alloy I, alloy II, alloy III and an inorganic composite material IV, and the mass ratio of alloyIto alloyIIto alloyIII and to the inorganic composite material IV is 1: (1-1.5) : (0.2-0.6) : 0.01. The preparing method comprises the steps of material preparing, pressing and forming, sintering and heat treatment. According to the permanent magnet alloy and the preparing method thereof, the permanent magnet alloy has good thermal stability and good magnetic performance; the preparing method of the permanent magnet alloy is simple in technology, the production cost is low, and the permanent magnet alloy is suitable for industrialized production.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

A piezoelectric sensor pretensioning device

ActiveCN104280163BSimple structureEasy to adjustForce measurement using piezo-electric devicesPiezoelectric quartzEngineering

The invention provides a piezoelectric sensor pre-tightening device, belongs to the field of sensors and measuring and control devices of the sensors and particularly relates to application of a piezoelectric quartz sensor in the field of three-dimensional force measurement. The piezoelectric sensor pre-tightening device consists of a stress block, an upper three-dimensional piezoelectric sensor, a lower three-dimensional piezoelectric sensor, a stud, a nut, an upper press block, a lower press block and a plurality of T-shaped groove nuts. The piezoelectric sensor pre-tightening device eliminates interference brought by pre-tightening force change by using the two sensors, avoids direct contact between an elastic pre-tightening part and the stress block, accordingly eliminates the influence on outputting, of the pre-tightening force change, when the pre-tightening part is stressed to deform, and improves consistency and accuracy of area measurement. The piezoelectric sensor pre-tightening device can perform three-dimensional force measurement, and a reliable measurement area can be further expanded through combined usage. The piezoelectric sensor pre-tightening device is simple in structure, easy to adjust, flexible and convenient to use and wide in application.

Owner:DALIAN UNIV OF TECH

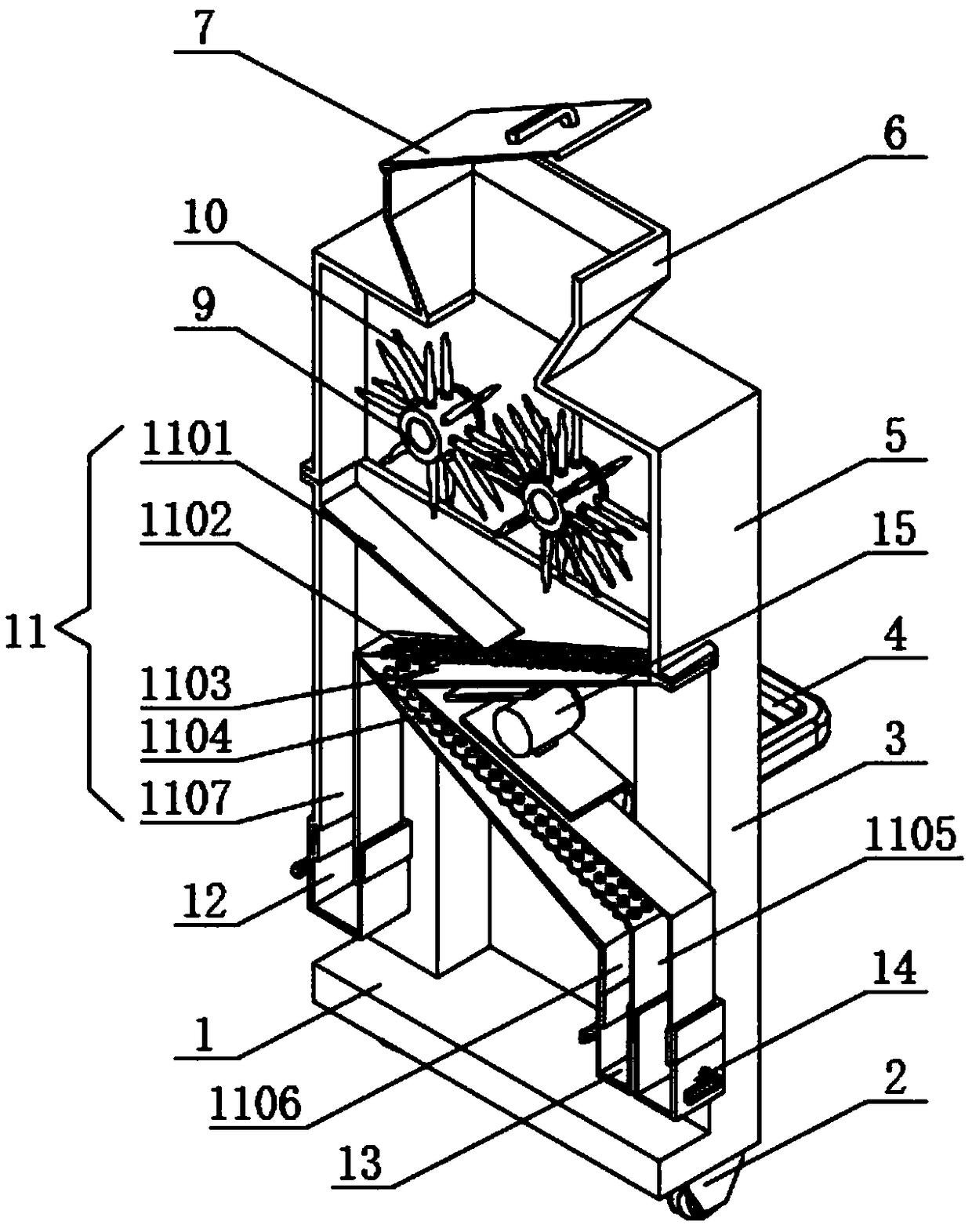

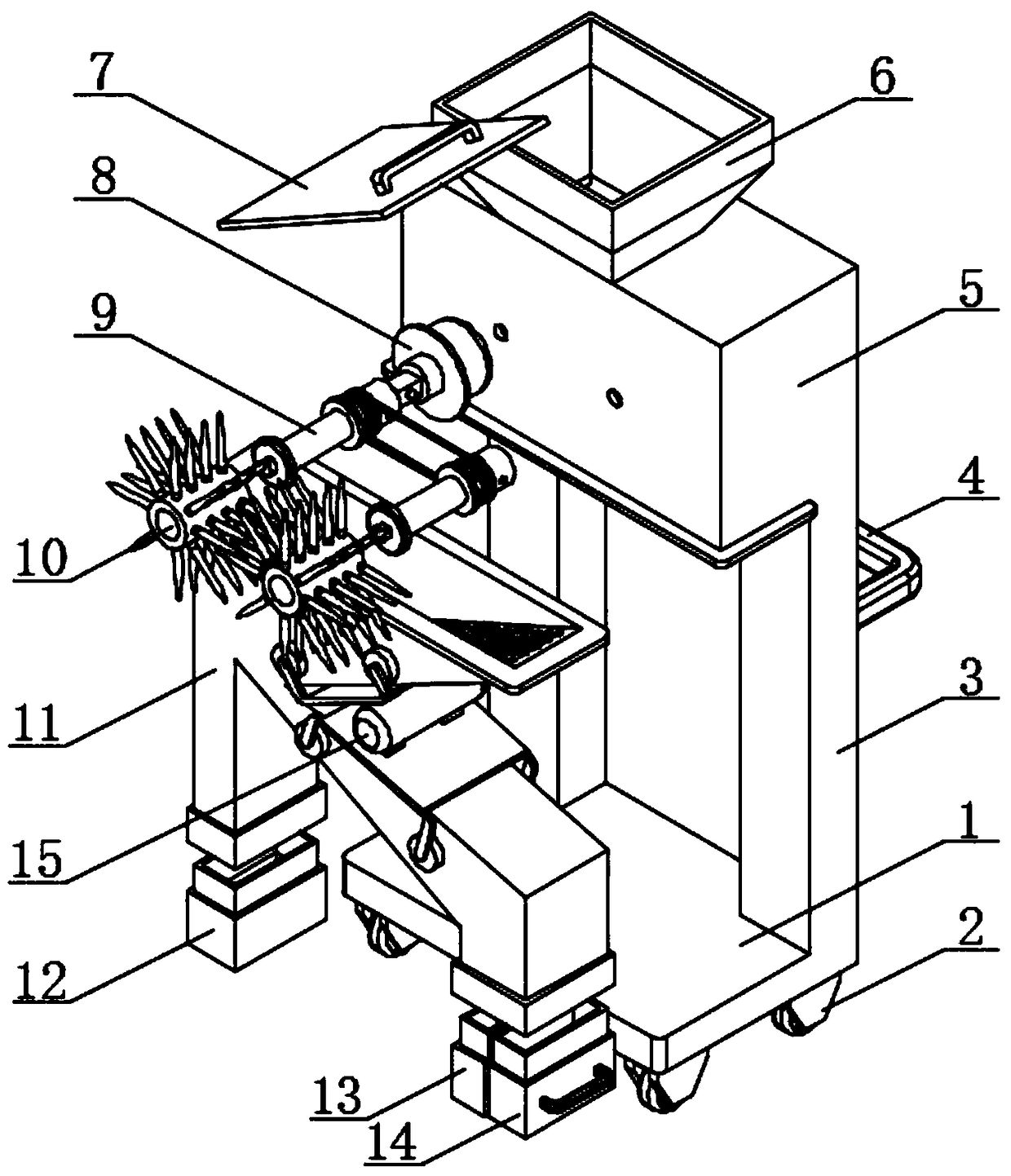

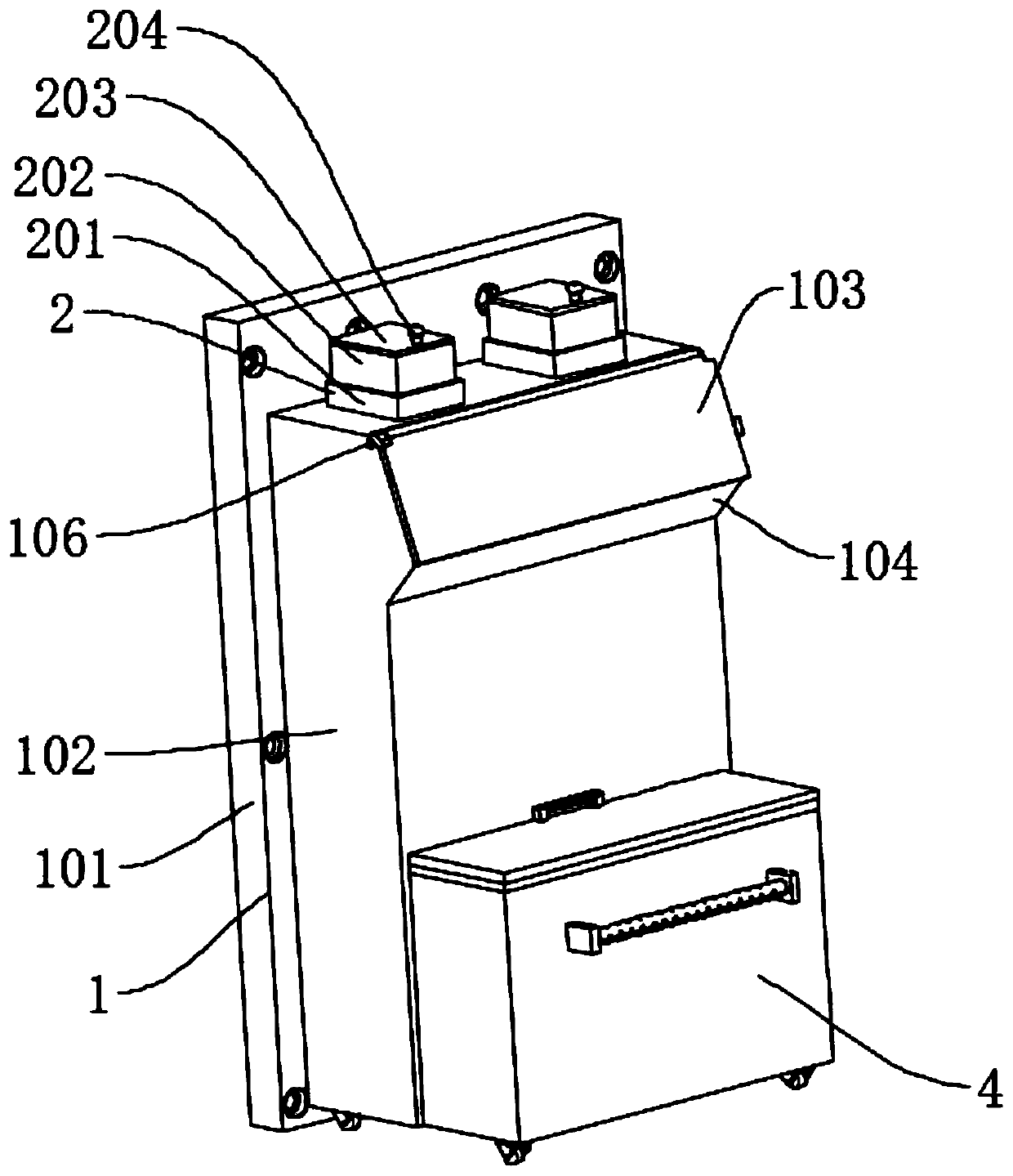

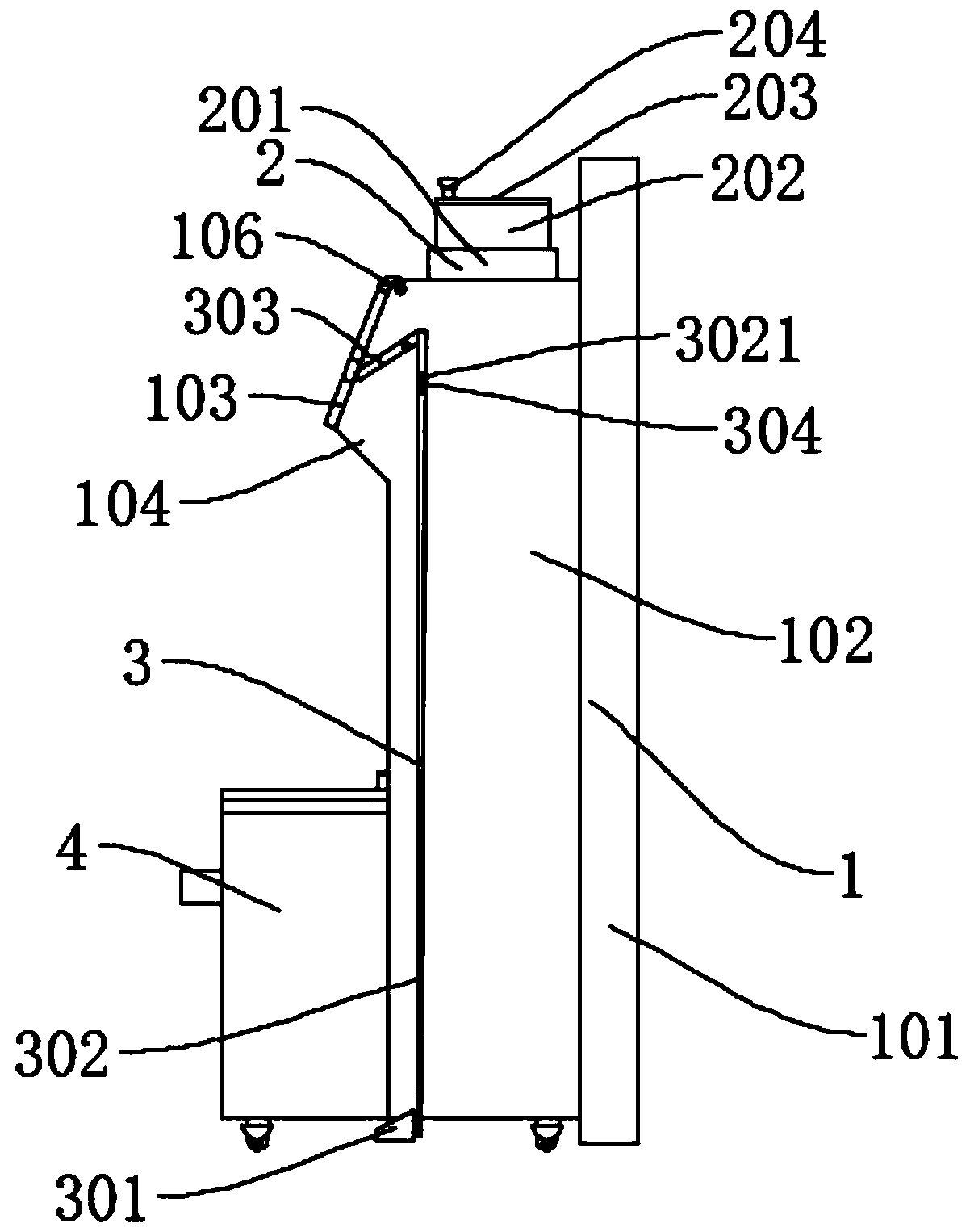

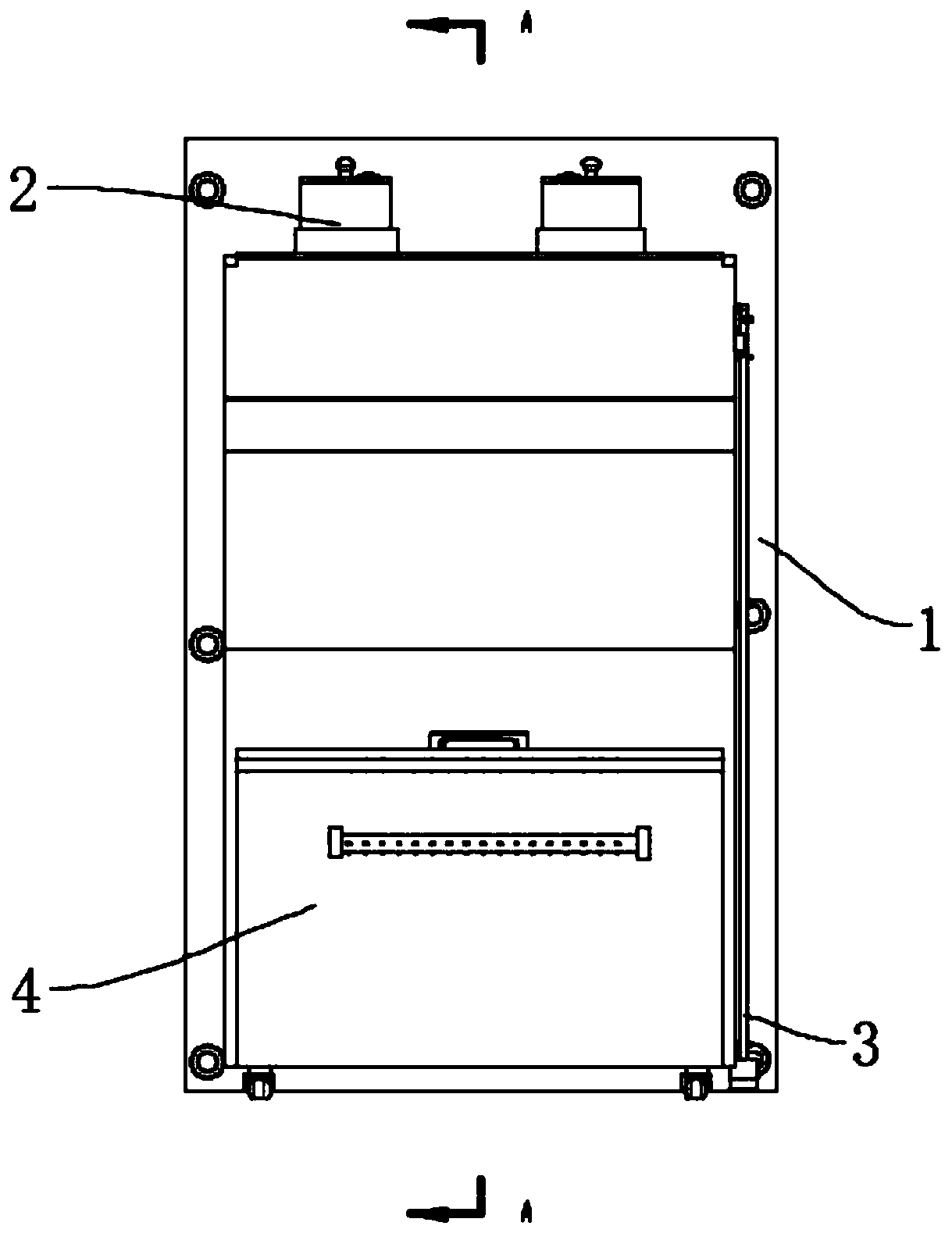

Device for separating and filtering pollen of fruits and vegetables

The invention discloses a device for separating and filtering pollens of fruits and vegetables, comprising a supporting mechanism, a smashing mechanism arranged at the upper end of the supporting mechanism, and a filtering mechanism arranged at the lower end of the smashing mechanism. A supporting plate of a square-plate structure is arranged at the lower end of the supporting mechanism. Four trundles are symmetrically arranged at the four corners of the lower ends of the supporting plate. Two supporting columns of square column structures are symmetrically arranged on the left and right sidesof the upper end surface of the supporting plate. According to the device for separating and filtering pollens of fruits and vegetables, the smashing mechanism is driven by the driving motor, so thatflowers can be smashed and decomposed in a smashing bucket, the direct contact between the human body and the pollens is avoided, the corrosive damage to the pollens is avoided, and the separating efficiency is high. The decomposed flowers sequentially pass through a filtering plate I and a filter plate II through the vibration action of a vibration motor in a vibration filter box, and residues larger than the size of the anthers and residues smaller than the size of the anthers are removed sequentially during this process, so that pure anthers can be obtained, and the purity of the pollens can be greatly improved.

Owner:潍坊华高信息科技有限公司

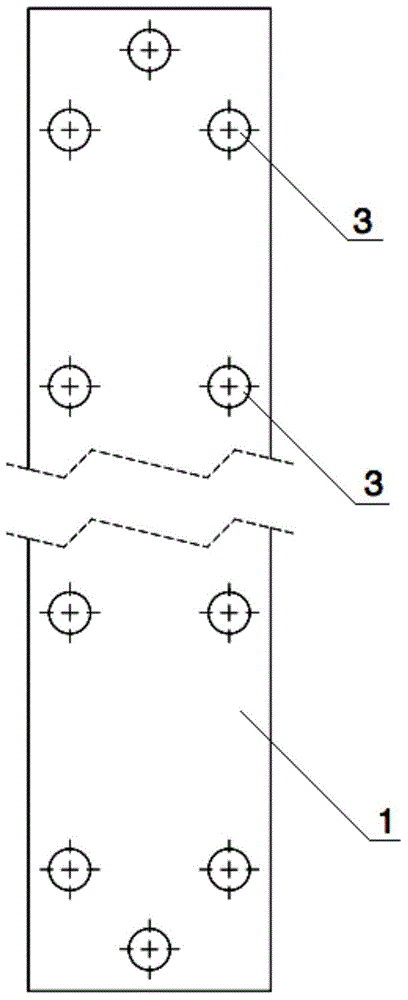

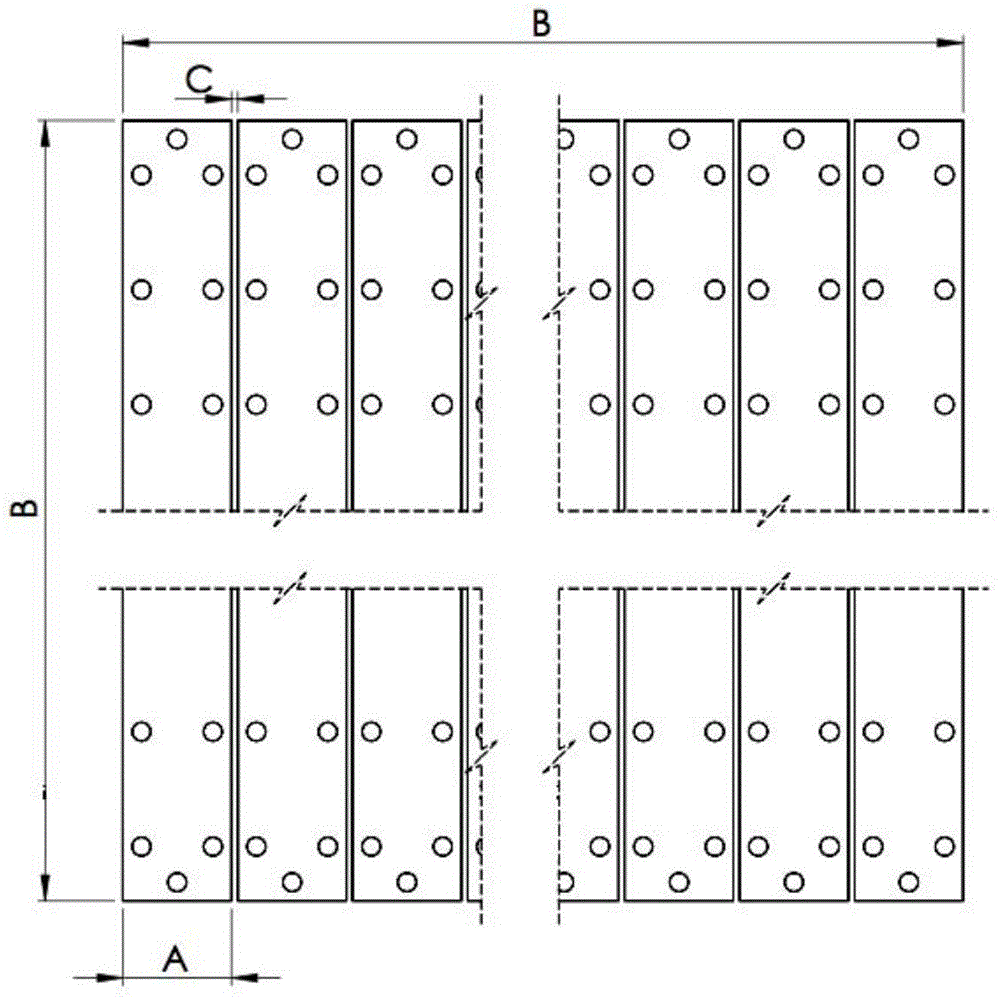

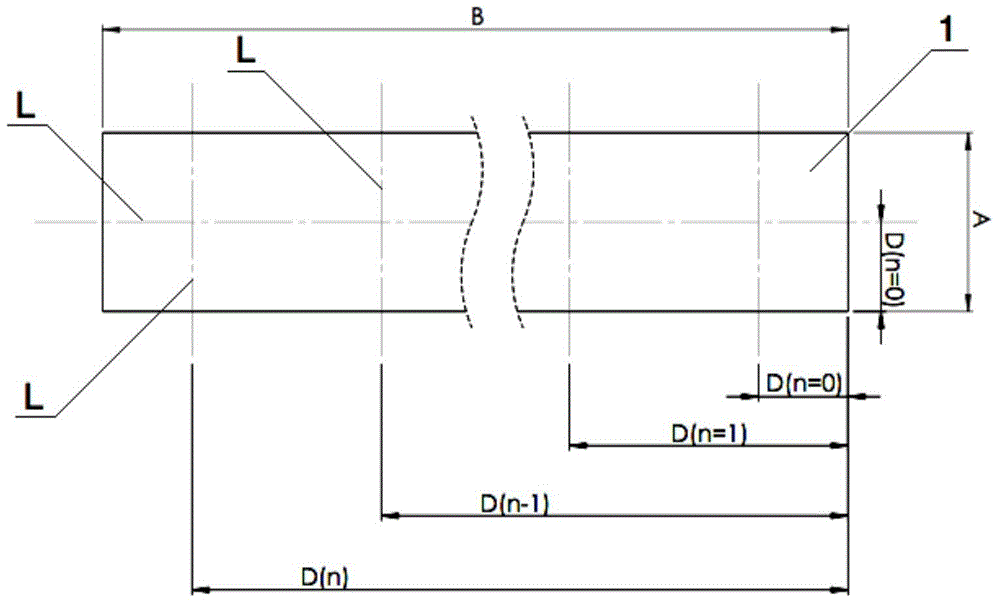

Construction set for covering substrate, in particular floor substrate

ActiveCN103850419ASimple designImprove aestheticsSingle unit pavingsSheet joiningMechanical engineeringStructural element

The invention refers to a construction set for covering a substrate, in particular a floor substrate, comprising plate structural elements for covering the substrate, and connecting elements for joining together the neighbouring plate elements, optionally while preserving a fixed distance between them to form a dilatation gap, characterized in that the connecting elements (4) comprise at least two, located on a base (5), assembly protrusions (6) seated in the neighbouring, connected plate elements (1) equipped on their substrate side with identical assembly sections (2) comprising at least one drilled assembly hole (3), and in the holes (3) there are seated, by means of the assembly protrusions (6), the connecting elements (4) joining the neighbouring plate elements (1).

Owner:IDEATEK SP ZOO SPOLKA KOMANDYTOWA

Rare-earth modification material and preparation method thereof

InactiveCN108922711AImprove coercive forceLow melting pointInductances/transformers/magnets manufactureMagnetic materialsRare earthMaterials science

The invention discloses a rare-earth modification material and a preparation method thereof. The preparation method comprises the preparation of a material A, the preparation of a material B, the preparation of a material C and the preparation of a material D; the material A, the material B, the material C and the material D are mixed and compacted to form a blank N, and sintering treatment and secondary tempering treatment are carried out on the blank N respectively to obtain the rare-earth modification material. The problems that a traditional preparation method is complex and an obtained rare-earth modification material is not high in overall performance are solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

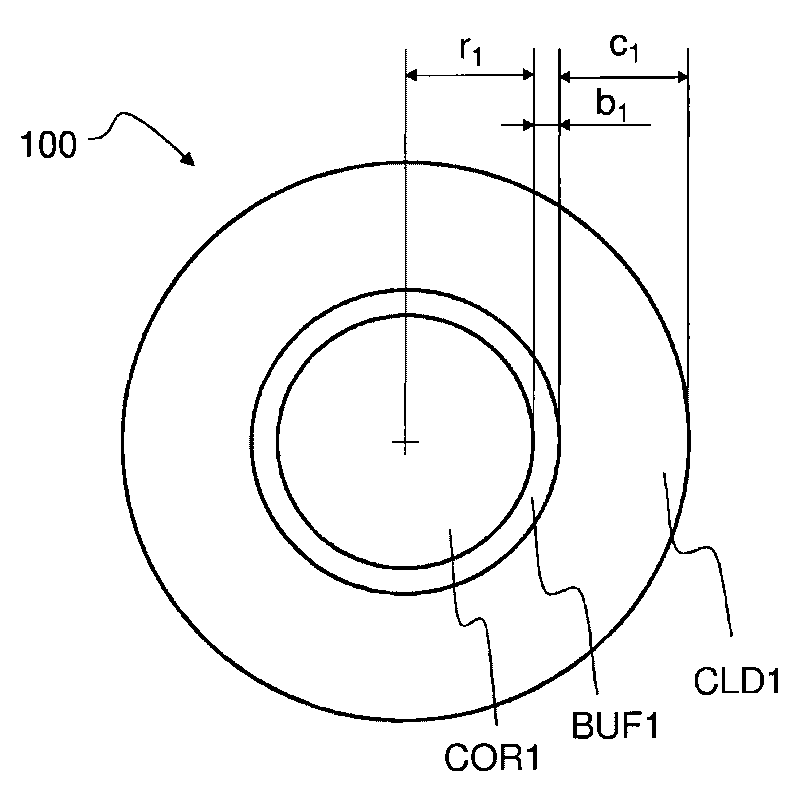

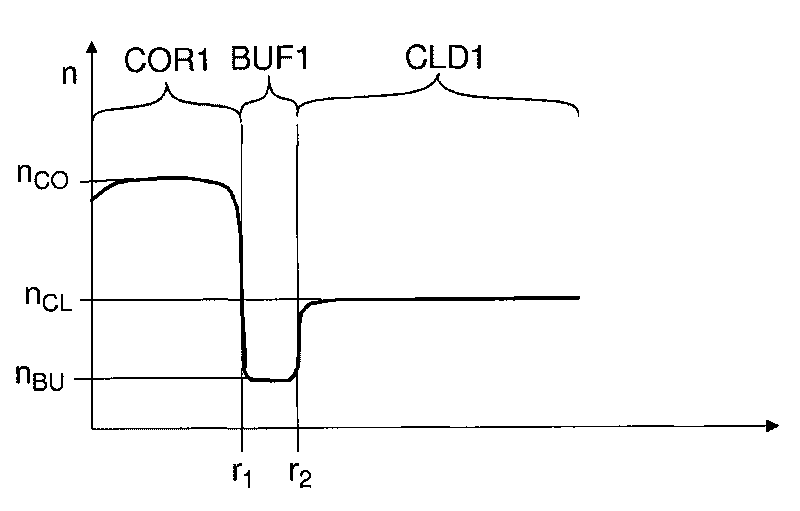

Optical fiber structure and a method of producing thereof

InactiveCN101755228AReduce in quantityConsistent qualityOptical fibre with multilayer core/claddingGlass deposition burnersRefractive indexWaveguide

An optical waveguide (100) comprises a core (COR1), a buffer (BUF1) surrounding said core (COR1), and a cladding (CLD1) surrounding said buffer (BUF1), said core (COR1), said buffer (BUF1) and said cladding (CLD1) comprising silica glass, and the refractive index (nBU) of said buffer (BUF1) being substantially equal to the refractive index of pure amorphous silica glass. The buffer (BUF1) may reduce bubble formation during manufacturing and may facilitate splicing of the waveguide (100). The numerical aperture of the waveguide (100) may be fine-tuned by adjusting the radial dimension (b1) of the buffer (BUF1) in order to compensate variations in the refractive index (nCO) of the core (COR1).

Owner:XUNLIGHT CORPORATION

A kind of high remanence material and preparation method thereof

ActiveCN107564651BImprove coercive forceImprove remanenceInorganic material magnetismMaterials scienceHot isostatic pressing

The invention relates to a high-residual-magnetism material and a preparation method therefor. The high-residual-magnetism material consists of a combination of three kinds of alloy materials I, II and III, and an oxide complex IV; the materials are prepared separately, and the alloy materials I, II and III, and the oxide complex IV are prepared based on the weight ratio and added to a three-dimensional mixer to be mixed uniformly to obtain mixed powder; next, the mixed powder is subjected to orientation in a magnetic field press and shaped by adopting an isostatic pressing mode; and the formed blank is put into a sintering furnace under argon protection to be subjected to sintering treatment to obtain a high-residual-magnetism product. The alloy preparation process is simple and convenient, the process is simple, and the produced alloys have high performance, so that industrial production can be realized very conveniently.

Owner:太原市迪辉磁材科技有限公司

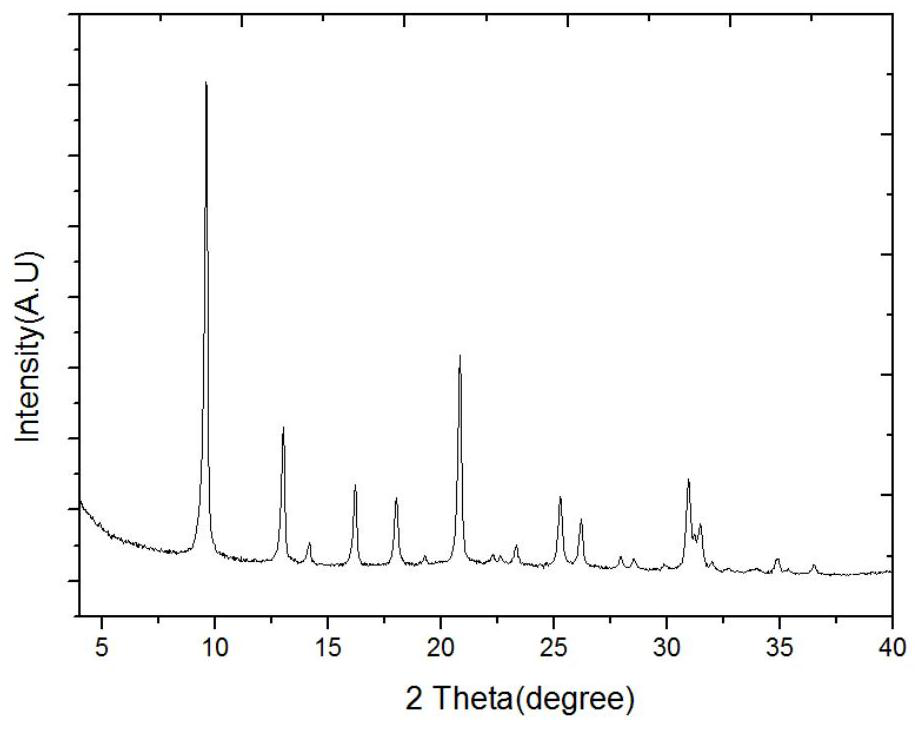

A method for rapidly synthesizing ssz-13 zeolite molecular sieves

ActiveCN110342537BPromote generationShorten the path needed for diffusionMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveCatalytic transformation

The invention provides a method for rapidly synthesizing SSZ-13 zeolite molecular sieves, using tetravalent silicon sources, trivalent aluminum sources, hydroxide ions, and inorganic cation sources as raw materials, and N,N,N-trimethyl- 1-adamantyl ammonium hydroxide solution is used as template agent, and SSZ-13 molecular sieve is synthesized by hydrothermal synthesis method. The method aims to provide a method for rapidly synthesizing SSZ‑13 type zeolite molecular sieves under conventional synthesis conditions without using crystal seeds. The fully crystallized SSZ-13 zeolite molecular sieve can be obtained in the shortest 7 hours through a special gel preparation route. The synthesized SSZ‑13 zeolite can be used for the catalytic conversion of methanol to light olefins and the removal of nitrogen oxides in exhaust gas of fuel machinery. Compared with the existing traditional hydrothermal synthesis method, the required time is greatly shortened, no waste water is generated in the process, and the yield of zeolite is higher.

Owner:NORTHEASTERN UNIV LIAONING

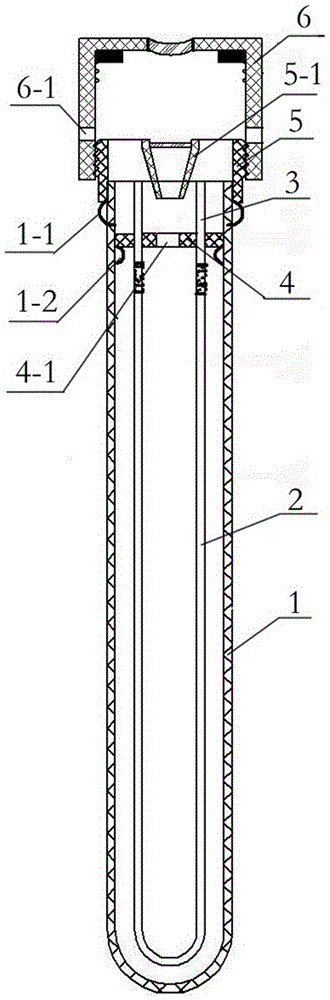

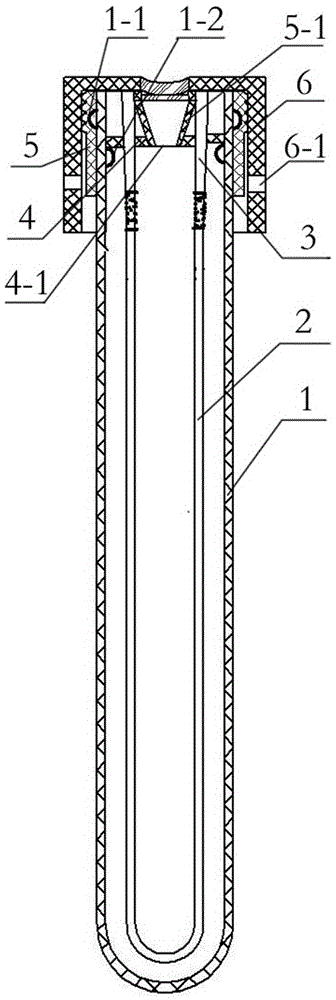

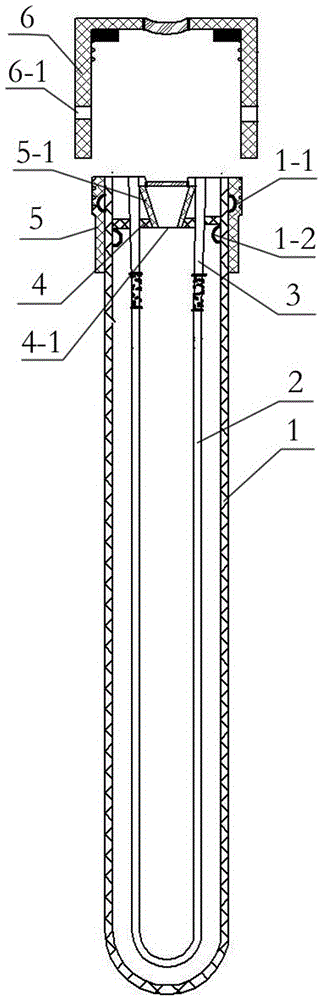

Safe biological sample pretreatment device and method integrating collection and processing

ActiveCN104614204BEliminate direct contactEliminates the chance of direct contact with pathogenic pathogenic microorganismsWithdrawing sample devicesPreparing sample for investigationPathogenic microorganismUltrafiltration

The invention provides a safe biological sample pretreatment device and method integrating collection and processing. The safe biological sample pretreatment device integrating collection and processing provided by the present invention includes a main pipe, a hollow fiber membrane, a catheter, a fixed plug (or a movable plug), an inner protective cap and an outer protective cap. The device is a fully enclosed device that integrates sampling, removal and separation of macromolecular substances. For the case where the sampled sample is whole blood, the use of this device can avoid the need for separation of plasma and removal of macromolecular substances such as protein. Operation, that is, the device uses the principle of ultrafiltration to directly obtain the filtrate containing only small molecular substances to be tested, while the dangerous pathogenic microorganisms contained in the whole blood sample are always in a fully enclosed negative pressure during the entire analysis process In the environment, there is no chance of exposure and transmission, which can ensure the health and safety of the operator; it can also reduce the operation steps and improve the accuracy and reliability of the test results.

Owner:HEBEI MEDICAL UNIVERSITY

Magnetic composite material and preparation method thereof

InactiveCN108922712AEnhanced grain boundary modificationPrevention of Diffusion TransferInductances/transformers/magnets manufactureMagnetic materialsRare earthNanotechnology

The invention discloses a magnetic composite material and a preparation method thereof. The preparation method comprises the steps of preparation of a material A and preparation of a material B, preparation of a material C and preparation of a material D; and mixing the material A, the material B, the material C and the material D, and compacting to form a blank N; and carrying out sintering treatment and secondary tempering treatment on the blank N to obtain a rare-earth modified material. The problems that the traditional preparation method is complex and the comprehensive performance of theprepared magnetic composite material is not high are solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

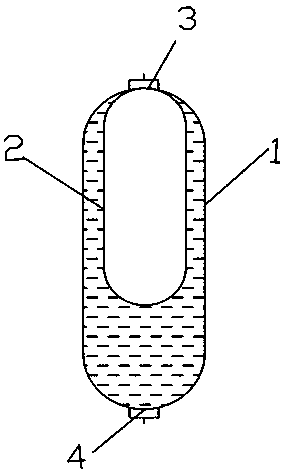

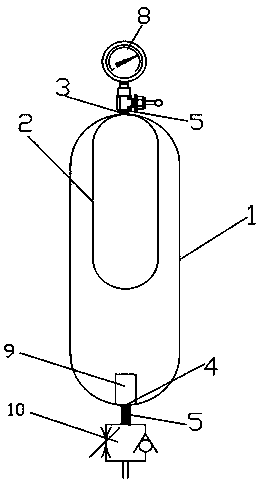

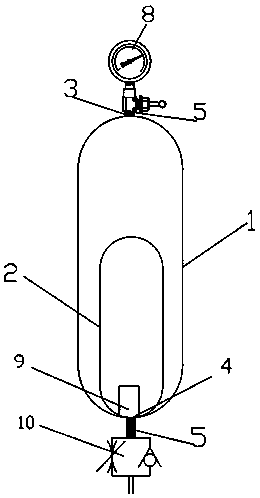

Gas-liquid isolating tank based on flexible transmission, and application thereof in gas-liquid linkage actuator

PendingCN108533538ANo fuel injectionNo oil and gas emulsificationFluid-pressure actuator testingOperating means/releasing devices for valvesTransmission mediumEngineering

The invention discloses a gas-liquid isolating tank based on flexible transmission (hereinafter referred to as the gas-liquid isolation tank), and application of the gas-liquid isolating tank in a gas-liquid linkage actuator. The gas-liquid isolation tank comprises a tank body, an isolating skin bag, a gas in-out opening and a liquid in-out opening. An opening of the isolating skin bag is formed in the gas in-out opening or the liquid in-out opening in a sealed mode, and the isolating skin bag isolates an inner cavity of the tank body into a gas cavity and a liquid cavity. The gas-liquid isolating and flexible transmission gas-liquid isolation tank is used for replacing a traditional gas-liquid non-isolating tank (hereinafter referred to as the gas-liquid tank) of the gas-liquid linkage actuator, direct contact and mutual blending between high-pressure gas and hydraulic oil serving as a transmission medium in a system are thoroughly eliminated, thus the oil injection phenomenon of thegas-liquid linkage actuator in the using process is prevented, and the problems that in the processes such as design, layout, mounting, using, packaging and transporting of gas-liquid linkage actuatorproducts, the gas-liquid tank cannot be completely horizontally placed or levelly placed, and can only be vertically placed or obliquely upwards placed are solved.

Owner:CHENGDU MAIKESEN FLUID CONTROL EQUIP

Magnetic composite material and preparation method thereof

InactiveCN110571008AImprove magnetismSimple preparation processInorganic material magnetismInductances/transformers/magnets manufactureMaterials preparationAlloy

The invention discloses a magnetic composite material and a preparation method thereof. The composite material is prepared by mixing and firing a material A and a material B. The weight ratio of the material A to the material B is 100: 3 to 6. The material A comprises, by weight, 1 to 3% of B, 25 to 28% of Nd, 1.8 to 2.2% of Ni, 0.008 to 0.013% of Ag, 0.08 to 0.12% of Ta, 2 to 5% of Tm, 0.1 to 0.5% of Be, 1.5 to 1.9% of Si and the balance of Fe. The material B consists of a substance (Na, Ca) 0.33 (Al, Mg) 2 [Si4O10] (OH) 2.nH2O, a substance Na2O.Al2O3.6SiO2 and ferric tetroxide, wherein the weight ratio between the three is 1: 0.2 to 0.6: 5. The magnetic composite material provided by the invention has high comprehensive magnetic properties. In addition, the materials are properly treatedduring preparation to ensure the uniformity of material composition, structure and properties, and to ensure the alloy quality. The material preparation process is simple. The cost of raw materials used for preparation is low. The process is simple. The produced material has good properties, is convenient for industrial production, and has a good application prospect in electric appliance industry.

Owner:XUZHOU NANFANG YONGCI MATERIAL

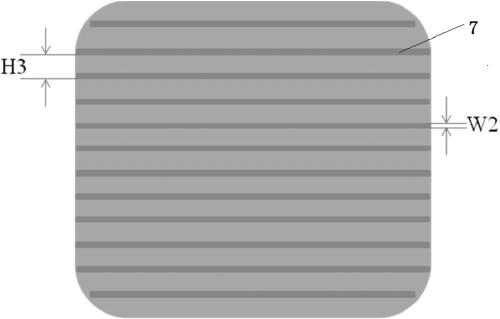

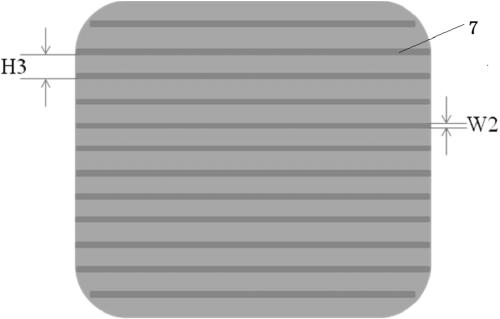

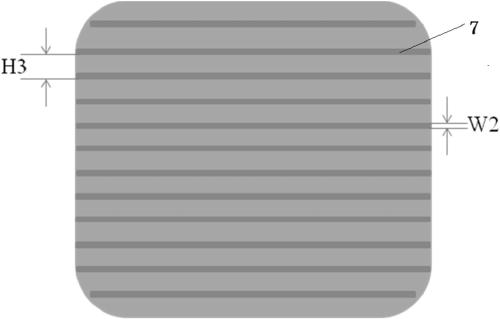

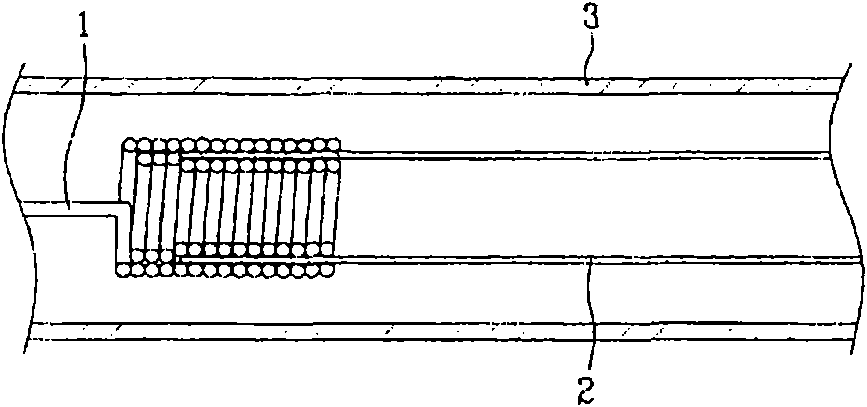

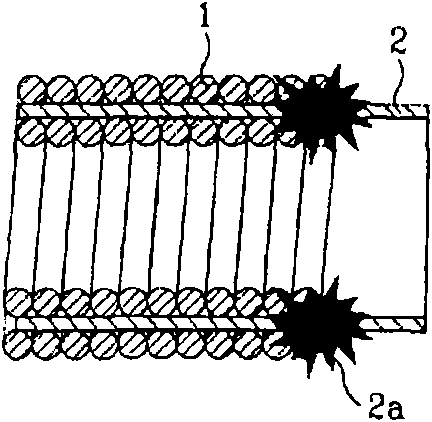

Conveyance roller for heating furnace

InactiveCN111971401AEliminate obstacles to deliveryInhibit direct contactConveyorsCharge manipulationEngineeringAlloy

Provided is a conveyance roller for a heating furnace, the roller being resistant to local deformation. A steel sheet is conveyed in a state held entirely by holding projections (70), which are made of a heat-resistant alloy and protrude higher than a shielding member (72), at multiple positions on the outer circumferential surface of a roller body (68) at a specified interval in the longitudinaldirection of the roller body (68). The holding projections (70) made of a heat-resistant alloy contact the inward-conveyed, cold steel sheet over little contact area, so the transmission of heat fromthe roller body (68) to the steel sheet is minimal, rapid cooling of the roller body (68) is suppressed due to radiative cooling from the hot roller body (68) being shielded by the shielding member (72) provided between the holding projections (70), and local deformation of the outer circumferential surface of the roller body (68) is suppressed. As a result, the holding projections (70) do not deform, and the occurrence of hindrances to the conveyance of the steel sheet is resolved.

Owner:NORITAKE CO LTD

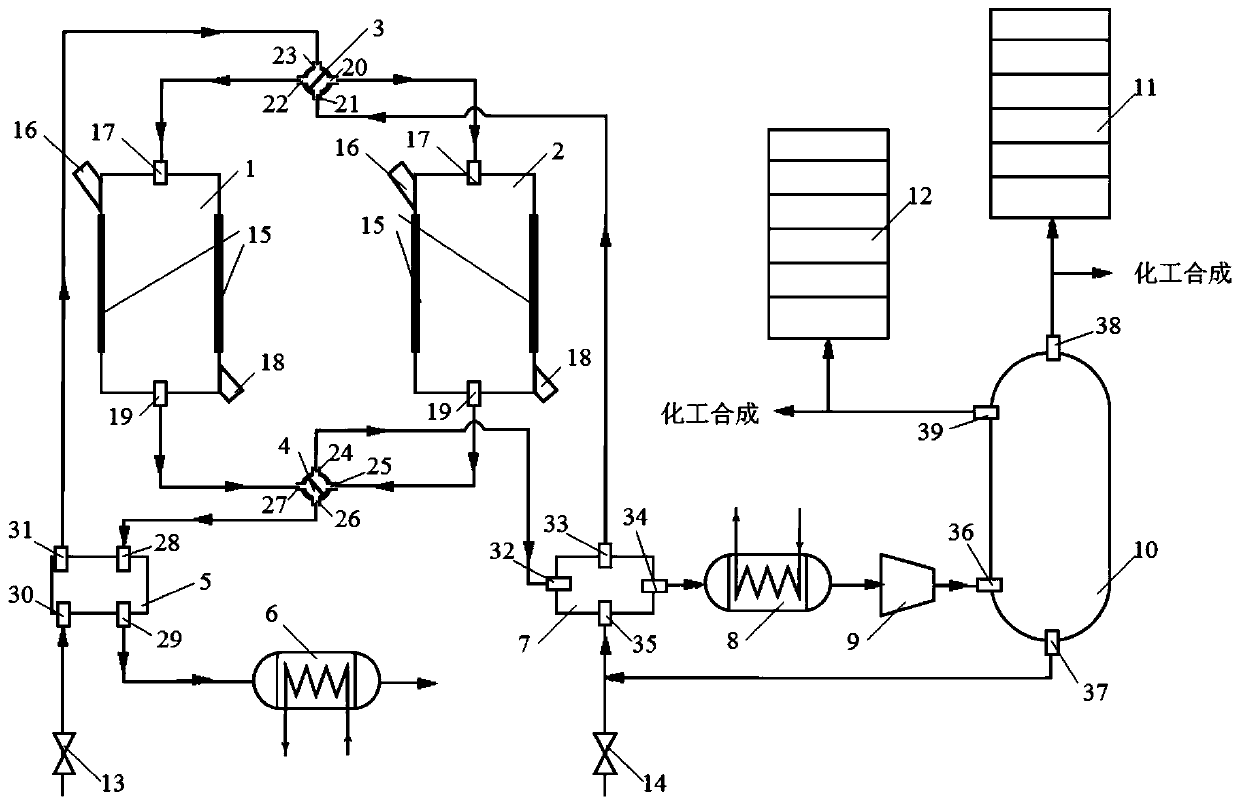

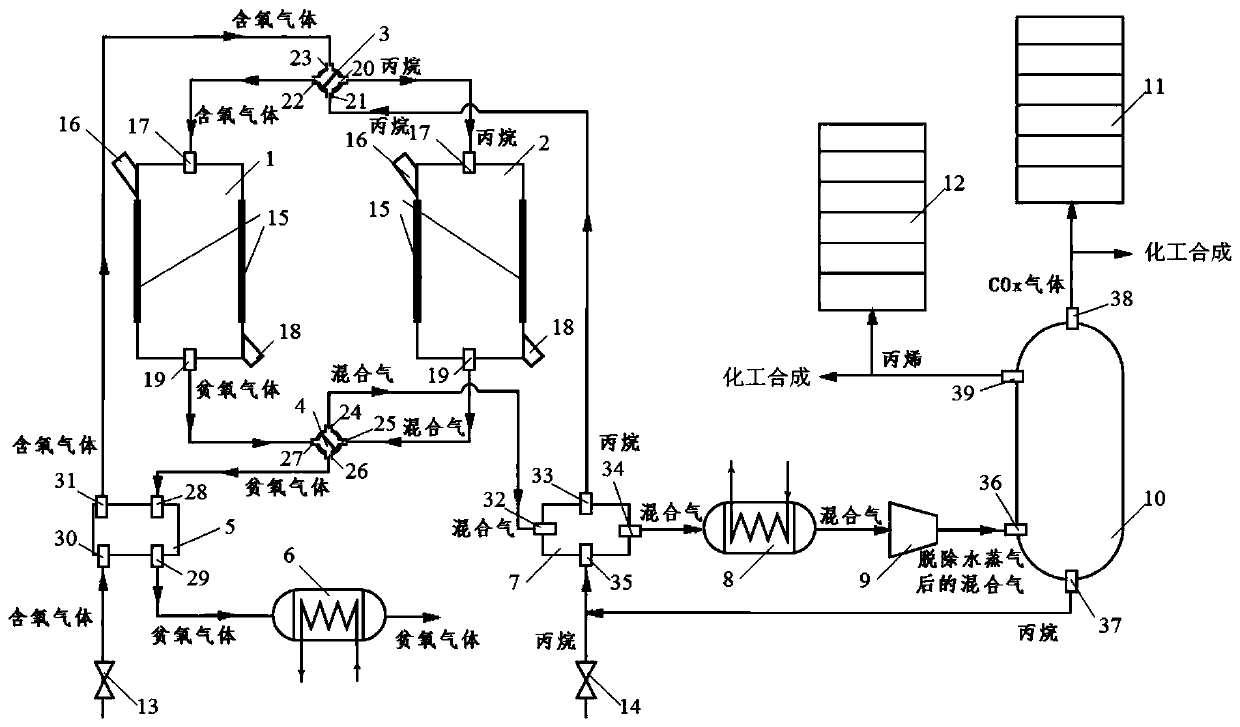

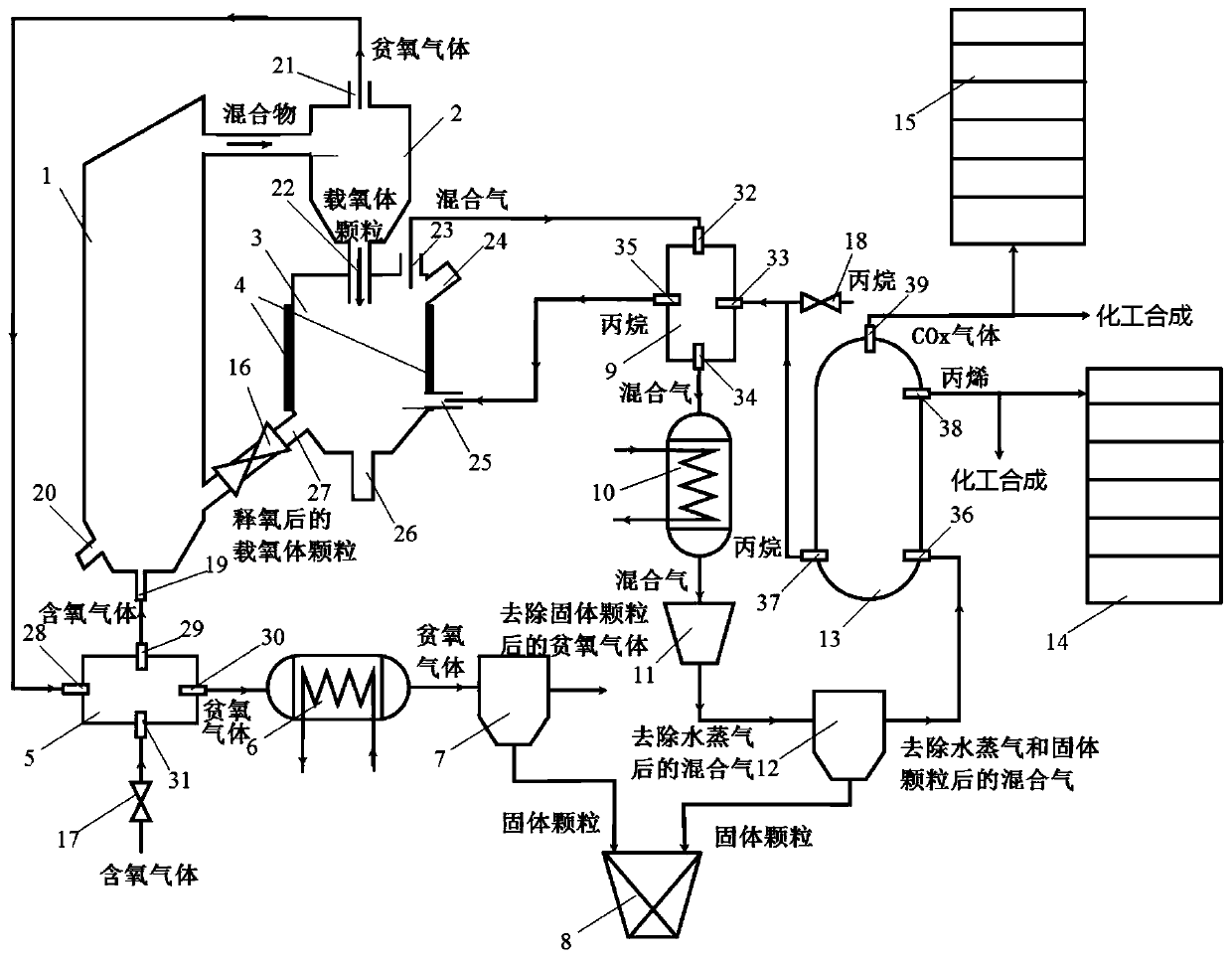

System and method for producing propylene by oxidative dehydrogenation of propane with chemical chain

ActiveCN107721801BWide variety of sourcesHigh yieldHydrocarbonsHydrocarbon preparationWater vaporFixed bed

The present invention relates to a system and method for preparing propylene by oxidative dehydrogenation of chemical chain propane. The above system includes two fixed beds, two reversing valves, mixed gas dehydration equipment, and mixed gas separation equipment. The two fixed beds are connected to two reversing valves. In the above method, two reversing valves are linked to make the two fixed beds serve as dehydrogenation reactors and oxidation reactors in turns. When the fixed bed is used as a dehydrogenation reactor, oxygen carrier particles and propane react at high temperature to generate a mixed gas containing propylene, water vapor and COx gas and oxygen carrier particles after oxygen loss. When the fixed bed is used as an oxidation reactor The deoxygenated oxygen carrier particles undergo an oxidation reaction with the oxygen-containing gas at high temperature to generate regenerated oxygen carrier particles. The mixed gas dehydration equipment dries the mixed gas, and the mixed gas separation equipment separates propylene from the mixed gas. The system and method of the present invention for preparing propylene by oxidative dehydrogenation of chemical chain propane have the advantages of high efficiency, energy saving, environmental protection, economy, safety and other advantages.

Owner:NORTHEASTERN UNIV LIAONING

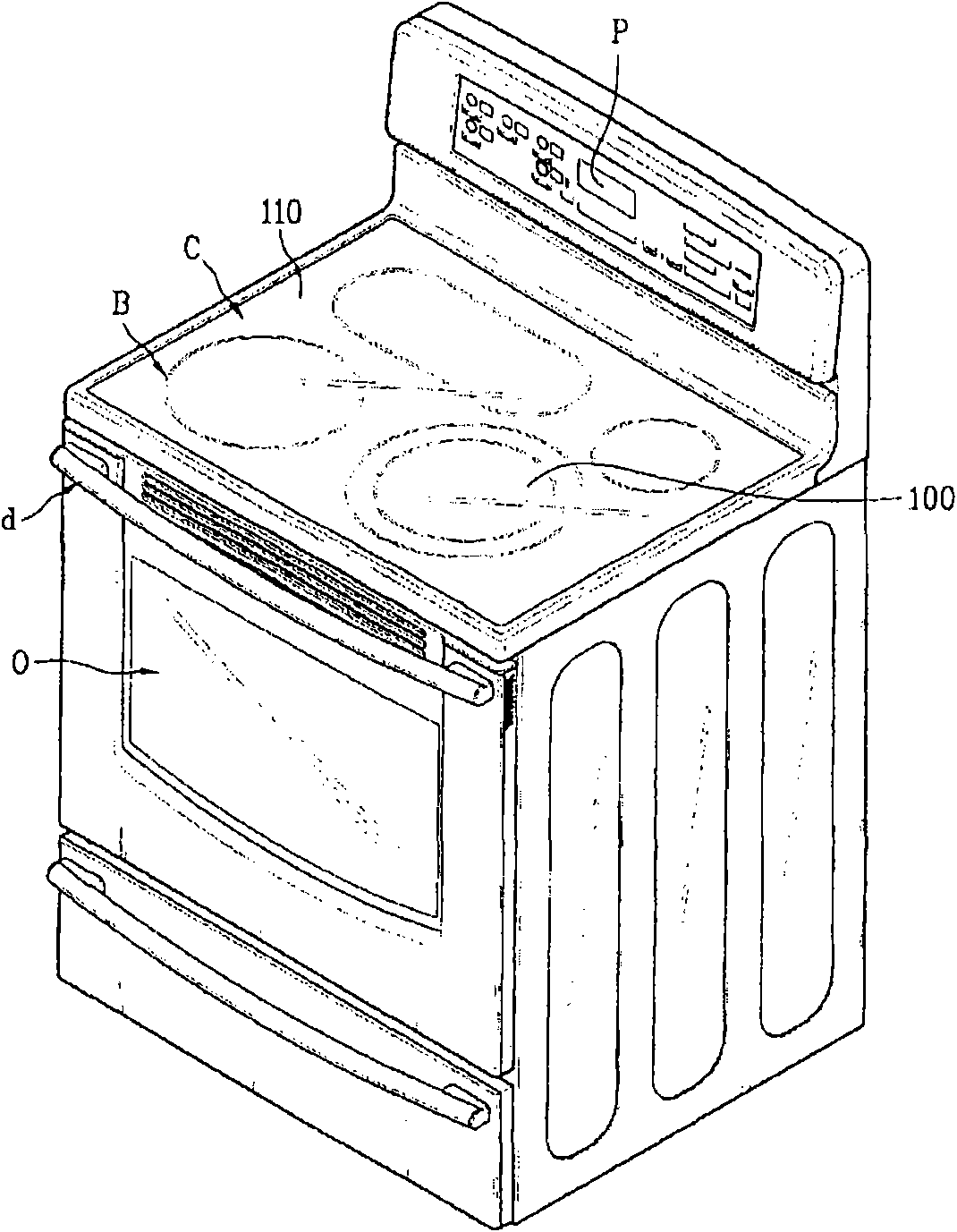

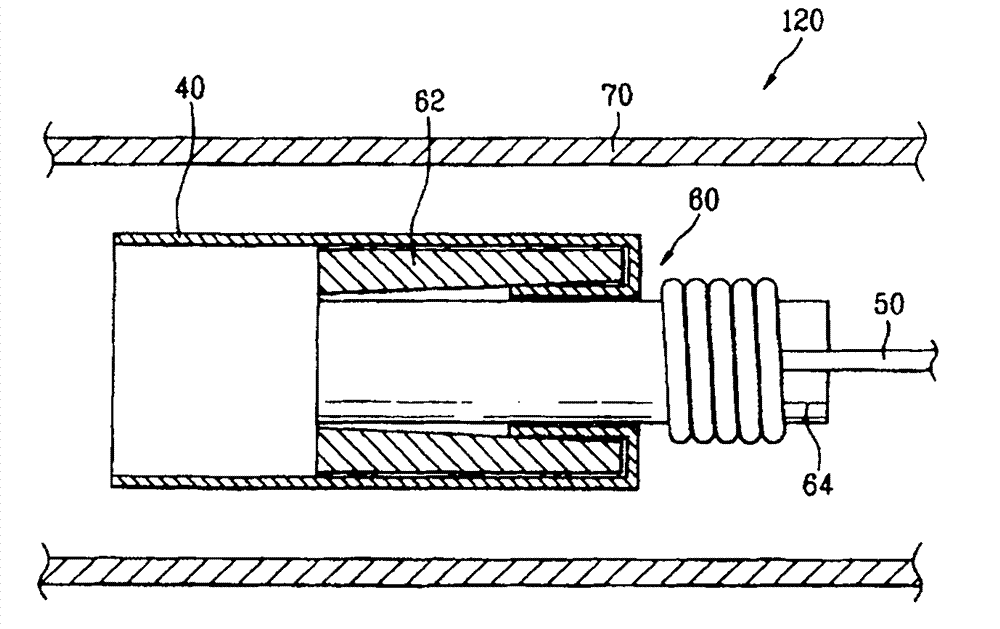

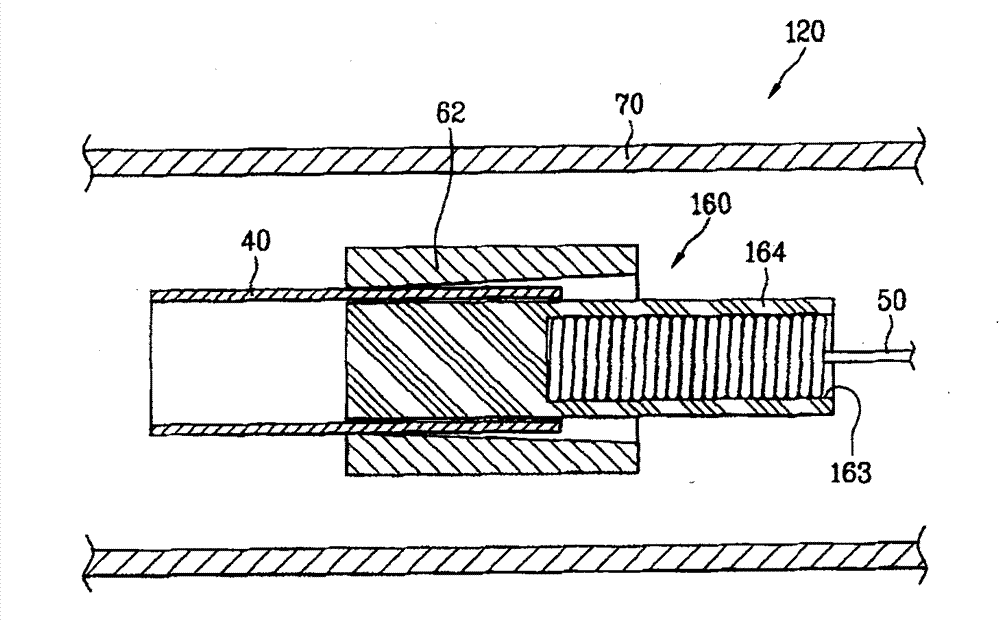

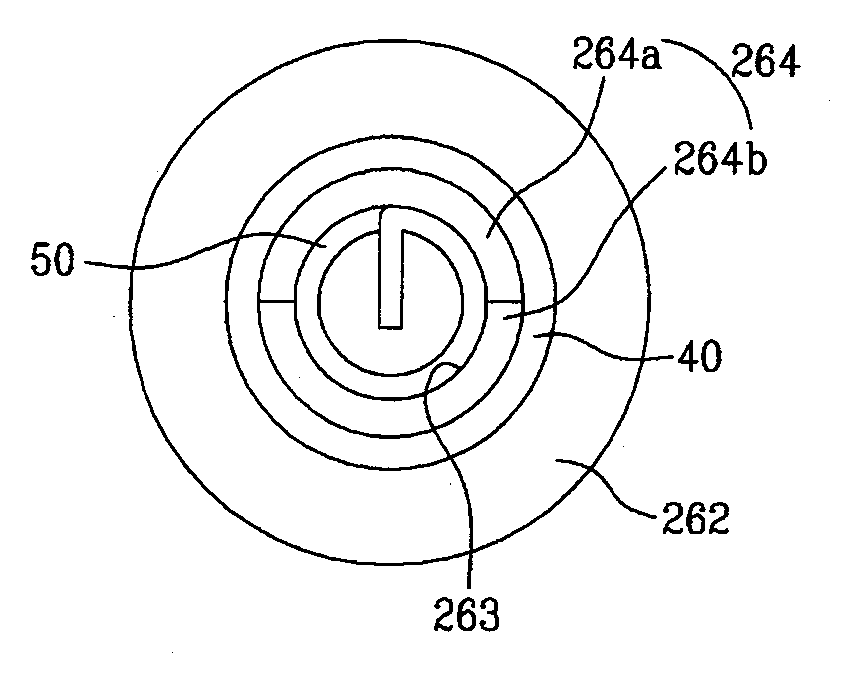

Heating device

InactiveCN101632325ASimplify the assembly processImprove productivityHeater elementsHot plates heating arrangementsElectricityHeat resistance

A heating device having an improved heat resistance structure is provided. The heating device may include a heating element that generates heat, and an elastic conductive part that applies electricity to the heating element. A connector may be provided between the elastic conductive part and the heating element to preclude direct contact between the heating element and the elastic conductive part. The heating element may be fixed to one side of the connector, and the elastic conductive part may be fixed to the other side of the connector to allow current applied from the elastic conductive part to flow to the heating element.

Owner:LG ELECTRONICS INC

Assembly type nuclear medical waste collecting device

The invention discloses an assembly type nuclear medical waste collecting device. The device comprises a small storage mechanism and a power mechanism, and also comprises a fixed mechanism and a movable mechanism. The small storage mechanism which is detachable is arranged above the fixed mechanism, the power mechanism is arranged on one side of the fixed mechanism, and the movable mechanism whichcan be moved is arranged below the fixed mechanism. Due to the arrangement of the fixed mechanism, the whole device can be fixed conveniently, and the situation that the device is not tidy and accordingly 5S management of a hospital is affected is prevented. The position arrangement of a camera and an ultraviolet sterilization lamp eliminates direct contact between the surface of the camera, thesurface of the ultraviolet sterilization lamp and medical waste, and reduces contamination of the surface of the camera and the surface of the ultraviolet sterilization lamp, so that the camera and the ultraviolet sterilization lamp can work better. The movable mechanism is arranged, so that treatment of the medical waste is facilitated. Besides, the medical waste is in a closed state in the transportation process, and leakage of rays is prevented.

Owner:中国人民解放军联勤保障部队第九六0医院

Method and system for preparing propylene by oxidative dehydrogenation of chemical chain propane

ActiveCN107698419BWide variety of sourcesHigh yieldChemical industryHydrocarbonsWater vaporDehydrogenation

The invention relates to a method and system for preparing propylene through oxidative dehydrogenation of chemical chain propane. The method includes the following steps: propane reacts with oxygen carrier particles in a dehydrogenation reactor to generate propylene, water vapor and COx gas, and the oxygen carrier particles lose oxygen; separate propylene from the mixed gas; carry oxygen after oxygen loss The bulk particles undergo an oxidation reaction with the oxygen-containing gas to generate oxygen-poor gas and regenerated oxygen carrier particles. The regenerated oxygen carrier particles are circulated to participate in dehydrogenation. The system includes a dehydrogenation reactor, mixed gas purification equipment, mixed gas separation equipment, and an oxidation reactor. The dehydrogenation reactor can receive oxygen carrier particles generated in the oxidation reactor. The method and system for preparing propylene through oxidative dehydrogenation of chemical chain propane are highly efficient, energy-saving, environmentally friendly, economical and safe.

Owner:NORTHEASTERN UNIV LIAONING

Heating device

InactiveCN101632325BEliminate direct contactReduced risk of failureHeater elementsHot plates heating arrangementsThermodynamicsHeat resistance

A heating device having an improved heat resistance structure is provided. The heating device may include a heating element that generates heat, and an elastic conductive part that applies electricity to the heating element. A connector may be provided between the elastic conductive part and the heating element to preclude direct contact between the heating element and the elastic conductive part. The heating element may be fixed to one side of the connector, and the elastic conductive part may be fixed to the other side of the connector to allow current applied from the elastic conductive part to flow to the heating element.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com