Magnetic composite material and preparation method thereof

A technology for magnetic composite materials and mixed powder materials, which is applied in the fields of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of low comprehensive performance and complex production process, and achieves simple preparation technology, simple process, and high comprehensive magnetic properties. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

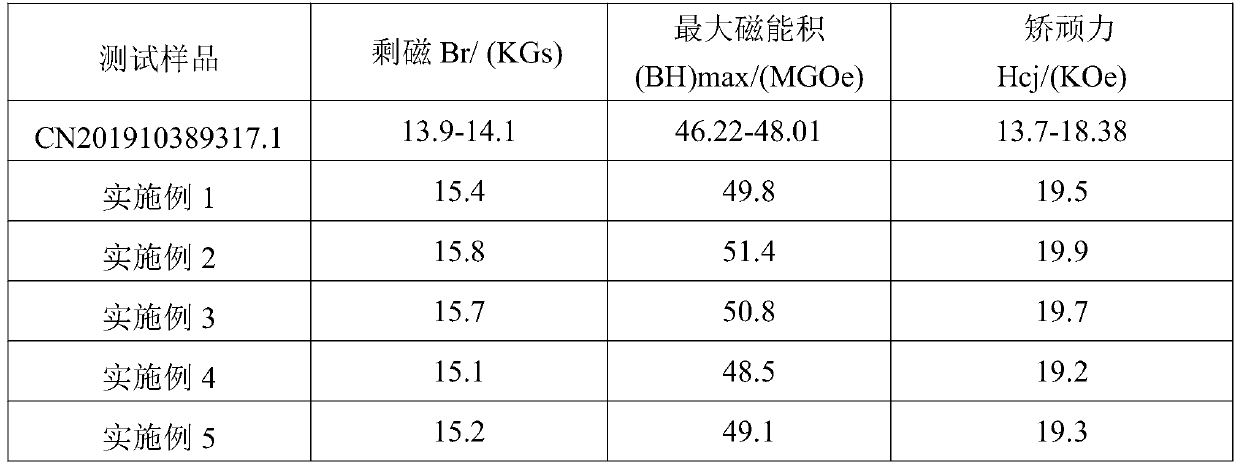

Embodiment 1

[0018] The magnetic composite material is made by mixing and firing material A and material B; the weight ratio of material A to material B is 100:3.

[0019] The weight percentage of each component in material A is: B 1%, Nd 25%, Ni 1.8%, Ag 0.008%, Ta 0.08%, Tm 2%, Be 0.1%, Si 1.5%, and the balance is Fe.

[0020] Material B consists of substances (Na, Ca) 0.33 (Al,Mg) 2 [Si 4 o 10 ](OH) 2 ·nH 2 O, substance Na 2 O·Al 2 o 3 ·6SiO2 2 and ferric oxide, the weight ratio between the three is 1:0.2:5.

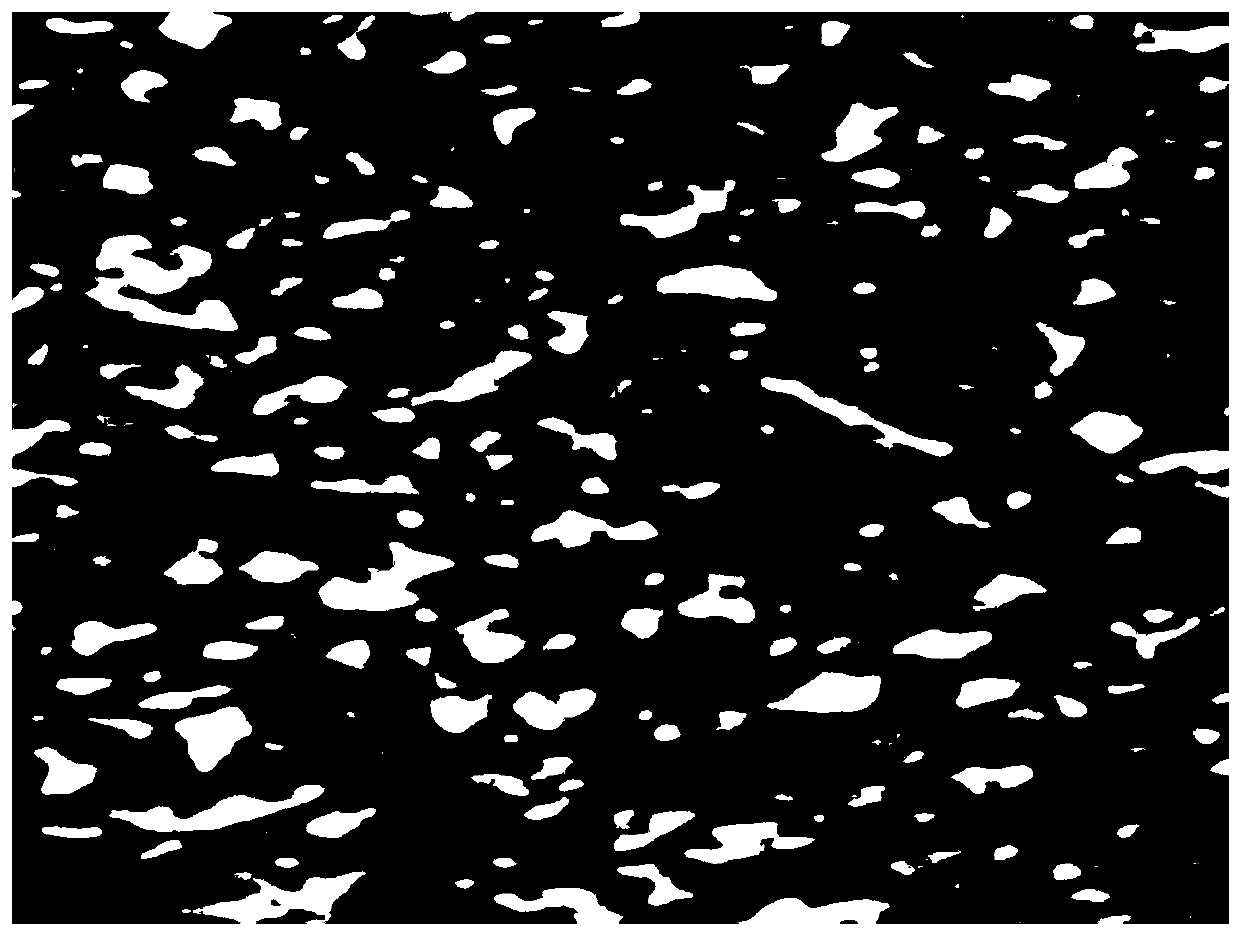

[0021] The structure diagram of the magnetic composite material is shown in figure 1 shown.

Embodiment 2

[0023] The magnetic composite material is mixed and fired from material A and material B; the weight ratio of material A to material B is 100:5.

[0024] The weight percentage of each component in material A is: B 2%, Nd 27%, Ni 2%, Ag 0.011%, Ta 0.11%, Tm 4%, Be 0.3%, Si 1.7%, and the balance is Fe.

[0025] Material B consists of substances (Na, Ca) 0.33 (Al,Mg) 2 [Si 4 o 10 ](OH) 2 ·nH 2 O, substance Na 2 O·Al 2 o 3 ·6SiO2 2 and ferric oxide, the weight ratio between the three is 1:0.4:5.

Embodiment 3

[0027] The magnetic composite material is mixed and fired from material A and material B; the weight ratio of material A to material B is 100:6.

[0028] The weight percentage of each component in material A is: B 3%, Nd 28%, Ni 2.2%, Ag 0.013%, Ta 0.12%, Tm 5%, Be 0.5%, Si 1.9%, and the balance is Fe.

[0029] Material B consists of substances (Na, Ca) 0.33 (Al,Mg) 2 [Si 4 o 10 ](OH) 2 ·nH 2 O, substance Na 2 O·Al 2 o 3 ·6SiO2 2 and ferric oxide, the weight ratio between the three is 1:0.6:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com