Optical fiber structure and a method of producing thereof

A technology of optical waveguide and optical amplification, which is applied in the direction of manufacturing tools, clad optical fibers, glass manufacturing equipment, etc., can solve the problem of low numerical aperture, achieve consistent quality, eliminate radial and axial changes, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

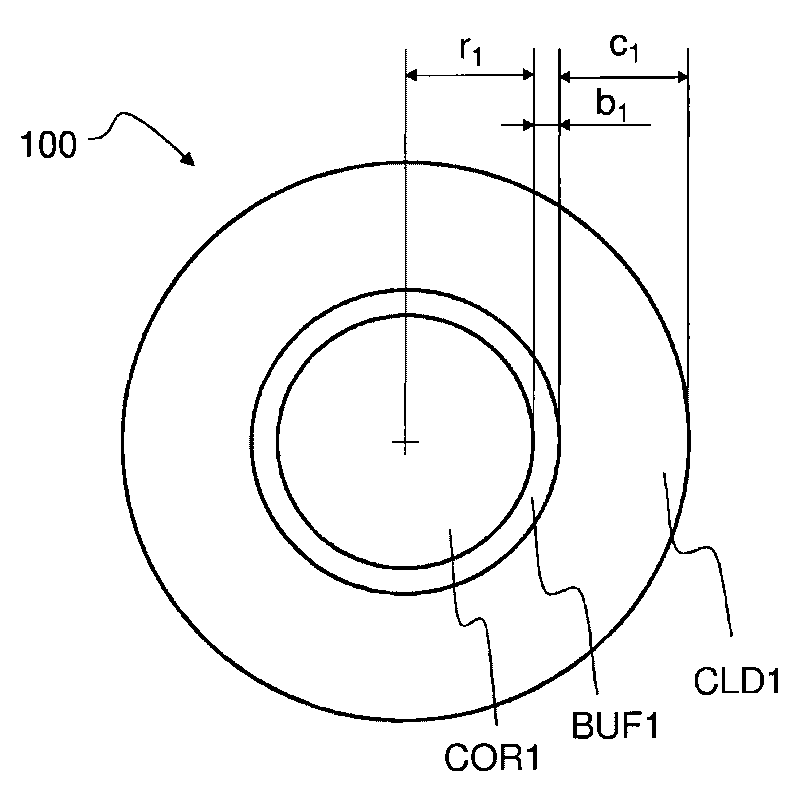

[0071] refer to Figure 1a , the optical amplifying buffered optical fiber 100 includes a core COR1, a buffer BUF1, and a cladding CLD1. The buffer layer BUF1 has a ring shape, and it surrounds the core COR1. The cladding layer CLD1 also has a ring shape and it surrounds the buffer layer BUF1. The core COR1 has a radius r 1 . The buffer layer has a radial dimension b 1 . The cladding has a radial dimension c 1 .

[0072] The buffered fiber 100 may be a large mode area (LMA) fiber such that the effective mode area is greater than or equal to 200 μm 2 . The buffered fiber 100 can be sized as a single mode fiber, or only support 2-4 transverse modes.

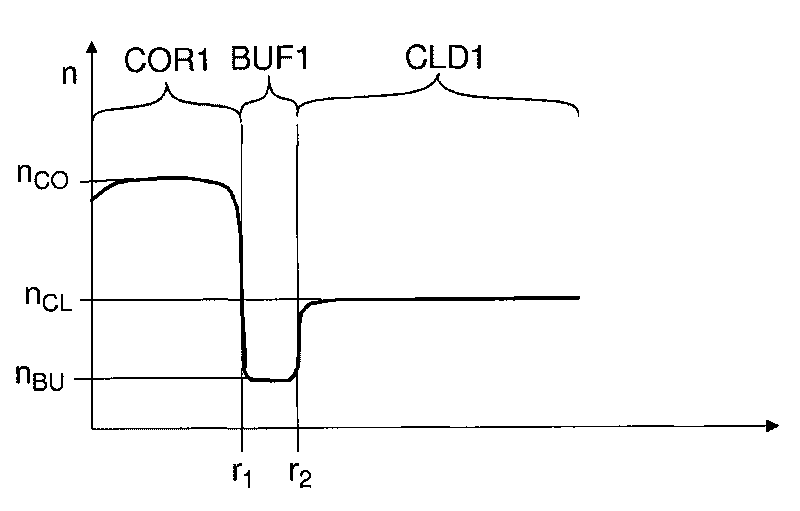

[0073] refer to Figure 1b , the refractive index n of the core COR1 CO than the refractive index n of the cladding layer CLD1 CL large in order to confine the waveguided light in the core COR1.

[0074] The refractive index n of the cladding layer CLD1 can be selected CL to achieve the desired numerical aperture NA of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com