A method for rapidly synthesizing ssz-13 zeolite molecular sieves

A technology of SSZ-13 and zeolite molecular sieves, which is applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve problems such as difficulty in widening large-scale industrial applications and expensive equipment, and shorten the synthesis cycle and reduce energy consumption. Consumption, accelerated growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Mix 0.1632g aluminum isopropoxide, 0.0534g ammonium chloride and 2.954g N,N,N-trimethyl-1-adamantyl ammonium hydroxide solution, and stir magnetically at 450rpm until the solid is completely dissolved to become a clear liquid system; Add 2.083 g of tetraethyl orthosilicate to the obtained clear liquid system, and magnetically stir for 20 min to form a uniform gel system.

[0040] The homogeneous gel was transferred to a blast oven, and dried at 90° C. for 24 hours to promote moisture volatilization and transform into a secondary gel. Crush the secondary gel until the powder particles are less than 100 mesh.

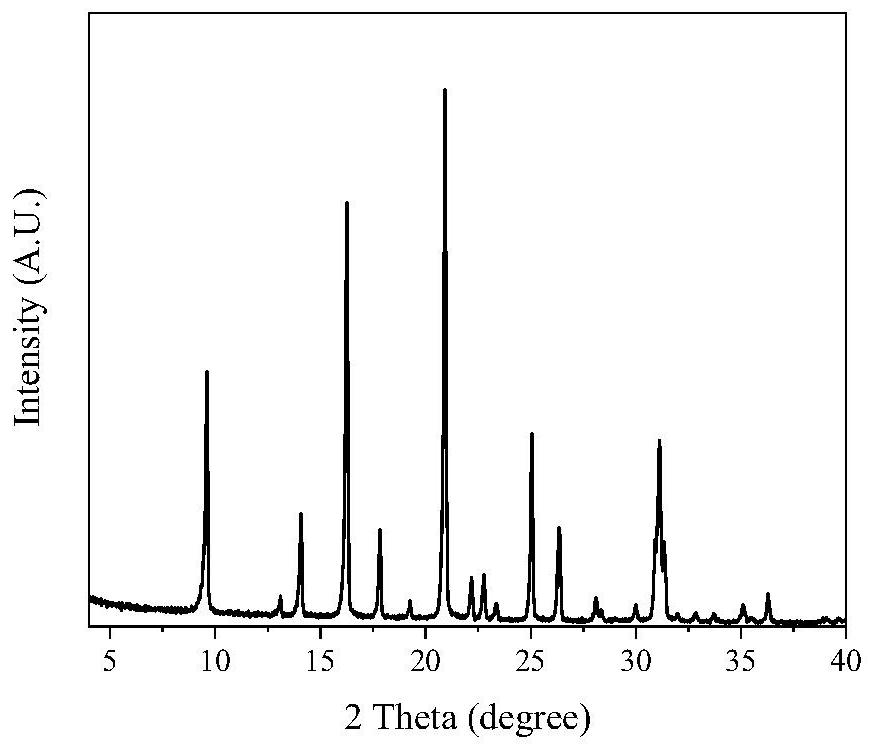

[0041] The obtained powdery secondary gel is placed in a polytetrafluoroethylene-lined hydrothermal reaction kettle together with an open container containing a certain amount of deionized water for steam-assisted crystallization synthesis. direct contact. The reactor was heated to 160°C, and reacted for 7 hours under static conditions to complete the crystalliza...

Embodiment 2

[0044] Mix 0.1632g of aluminum isopropoxide, 0.02g of sodium hydroxide and 2.954g of N,N,N-trimethyl-1-adamantyl ammonium hydroxide solution, and mechanically stir at 400rpm until the solid is completely dissolved to become a clear liquid system; Tetraethyl orthosilicate was added to the clear liquid system, and mechanically stirred for 20 minutes to make a uniform gel system.

[0045] The obtained homogeneous gel is transferred to a blast oven and dried at 90°C for 24 hours to promote the volatilization of water and transform it into a secondary gel. After crushing the homogeneous gel, transfer it to a medium-high temperature environment with forced convection In order to promote the evaporation of water, so that the transformation into a secondary gel. Crush the secondary gel until the powder particles are less than 100 mesh.

[0046] The obtained powdery secondary gel and an open container containing a certain amount of deionized water are placed in a polytetrafluoroethyle...

Embodiment 3

[0050] (1) Mix 0.1632g aluminum isopropoxide, 0.02g sodium hydroxide and 2.954g N,N,N-trimethyl-1-adamantyl ammonium hydroxide solution, and stir magnetically at 400rpm until the solid is completely dissolved and becomes clear Liquid system; the obtained clear liquid system was added with 1.5g of silica sol, and magnetically stirred for 20min to make it called a homogeneous gel system.

[0051] Transfer the obtained homogeneous gel to a blast oven, and dry it at 90°C for 24 hours to promote the volatilization of water and transform it into a secondary gel, and pulverize the secondary gel until the powder particles are less than 100 mesh.

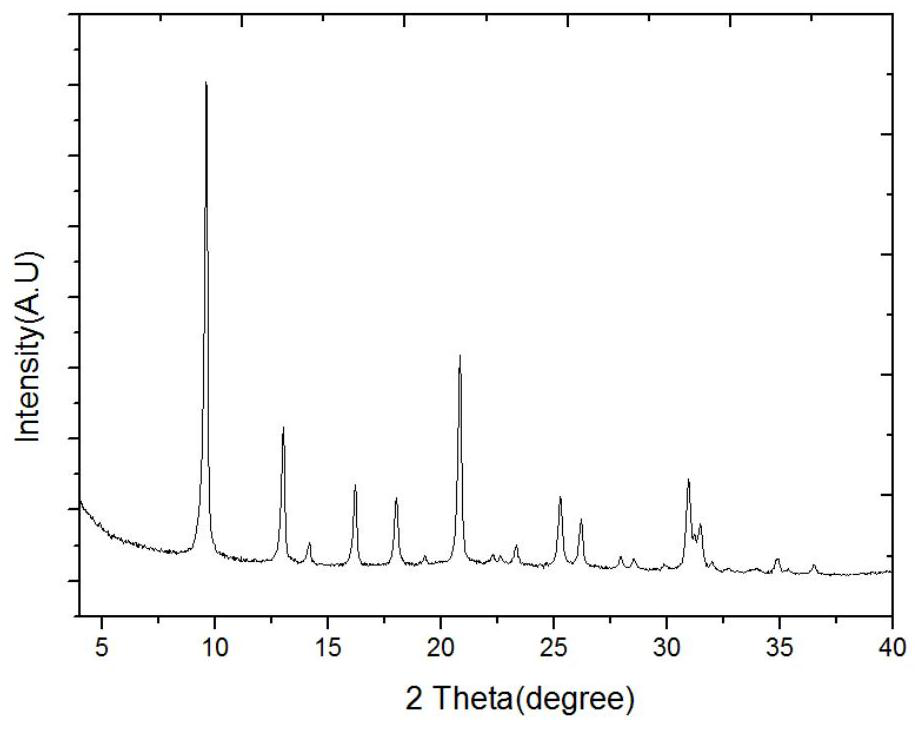

[0052] The obtained powdery secondary gel is placed in a polytetrafluoroethylene-lined hydrothermal reaction kettle together with an open container containing a certain amount of deionized water for steam-assisted crystallization synthesis. direct contact. The reactor was heated to 160°C and reacted for 25 hours under static conditions.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com