Planetary gearset with multi-layer coated sun gear

A technology for planetary gear sets and sun gears, applied to elements with teeth, gear lubrication/cooling, belts/chains/gears, etc., can solve damage to driving or driven devices, planetary gear set fatigue wear, gear failure, etc. problem, achieve the effect of improving lubrication conditions and uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

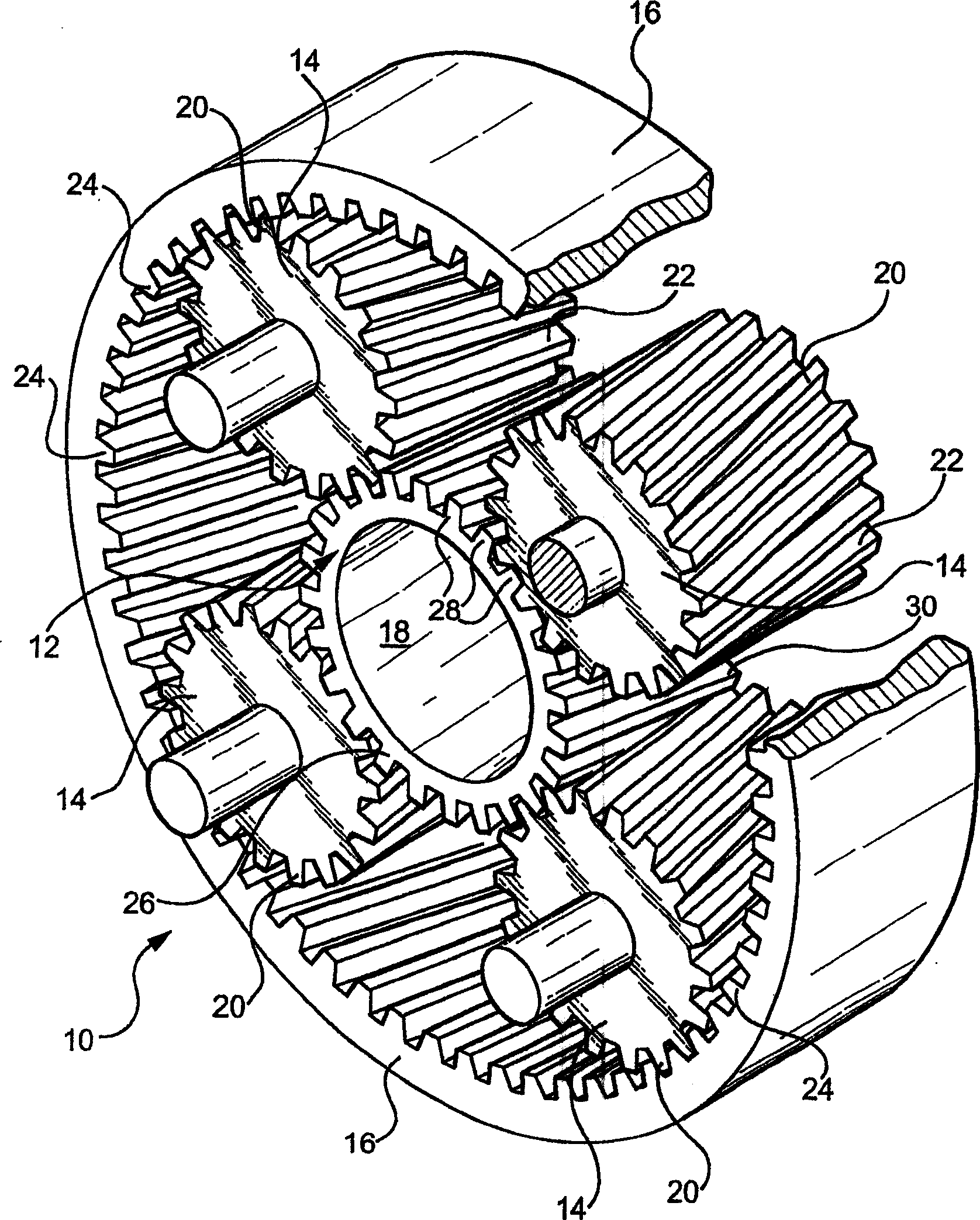

[0023] now refer to figure 1 , the planetary gear set is generally represented by 10. Gearset 10 includes a sun gear member 12 , a number of planetary gear members 14 and a ring gear member 16 . The sun gear member 12, the planet gear members 14 and the ring gear member 16 are preferably made of a steel material. The sun gear member 12 has a central opening 18 for connection to a drive shaft (not shown), such as the drive shaft (not shown) of an automotive automatic transmission. Each planet gear 14 is connected to an associated shaft 19 by a bearing (not shown) extending from its axis of rotation, and a number of teeth 20 are formed on the outer circumference of the planet gear. Each tooth 20 of the planetary gear 14 includes a mating surface 22 that engages a corresponding mating surface (not shown) of a number of teeth 24 on the inner surface of the ring gear 16 .

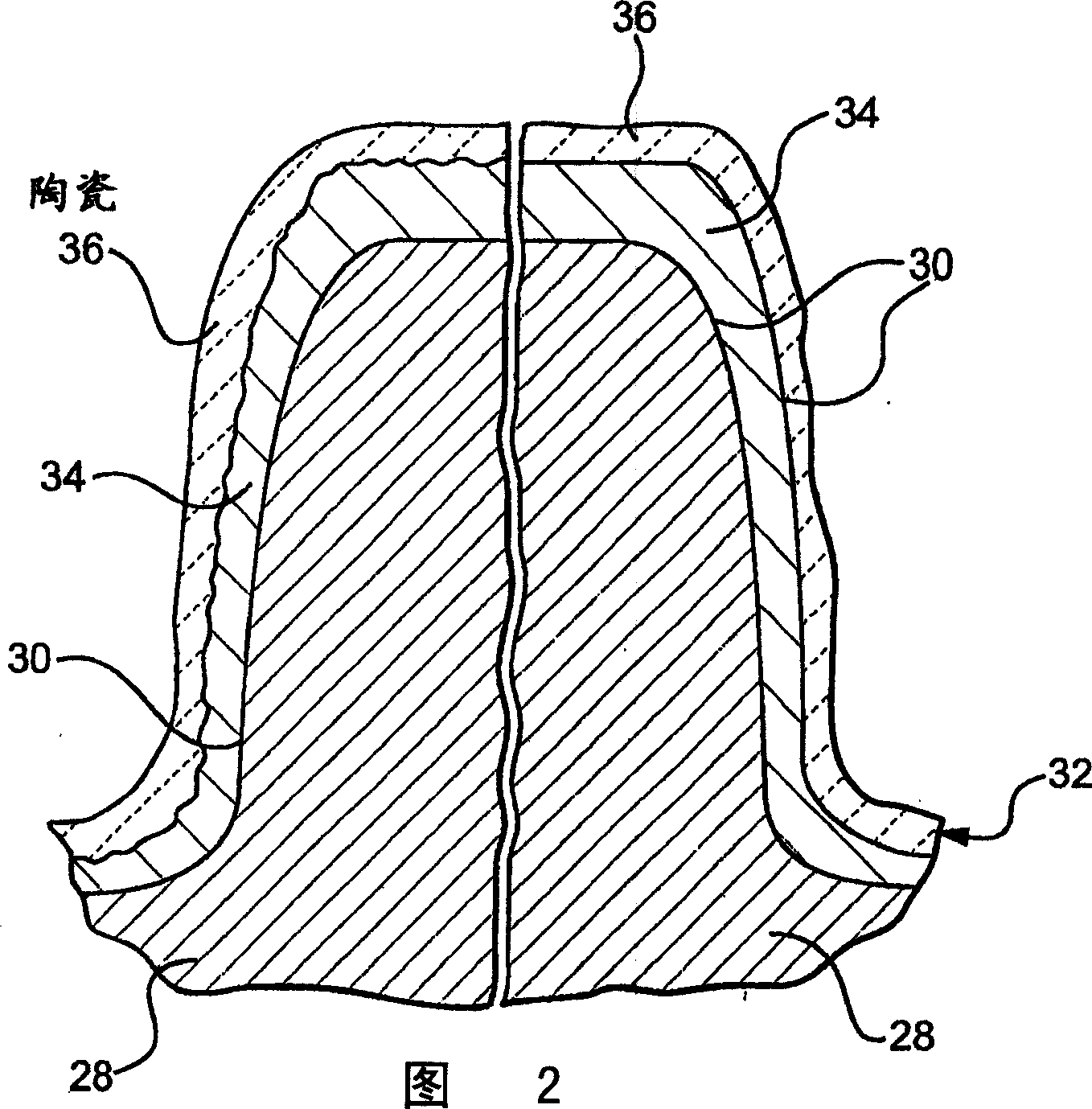

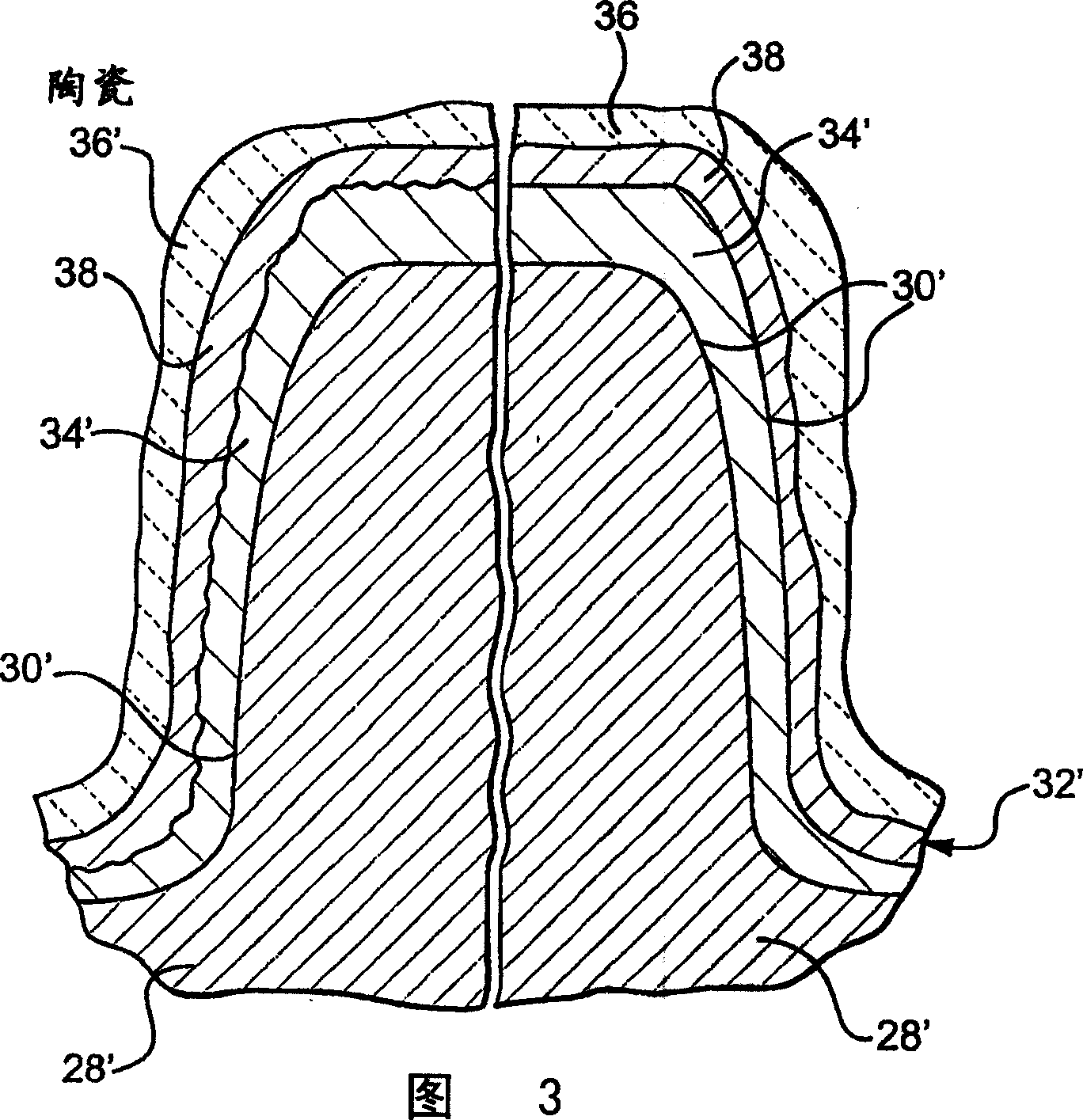

[0024] The sun gear member 12 includes a sun gear body 26 having a number of teeth 28 formed on its outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com